a cotton cleaning machine

A cotton cleaning machine and cotton cleaning technology, which is applied in the field of cotton cleaning machines, can solve the problems of wasting manpower and material resources, entangled in acupuncture, and reducing the working efficiency of the cotton cleaning machine, and achieves the effect of improving quality and increasing or decreasing the sufficient degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

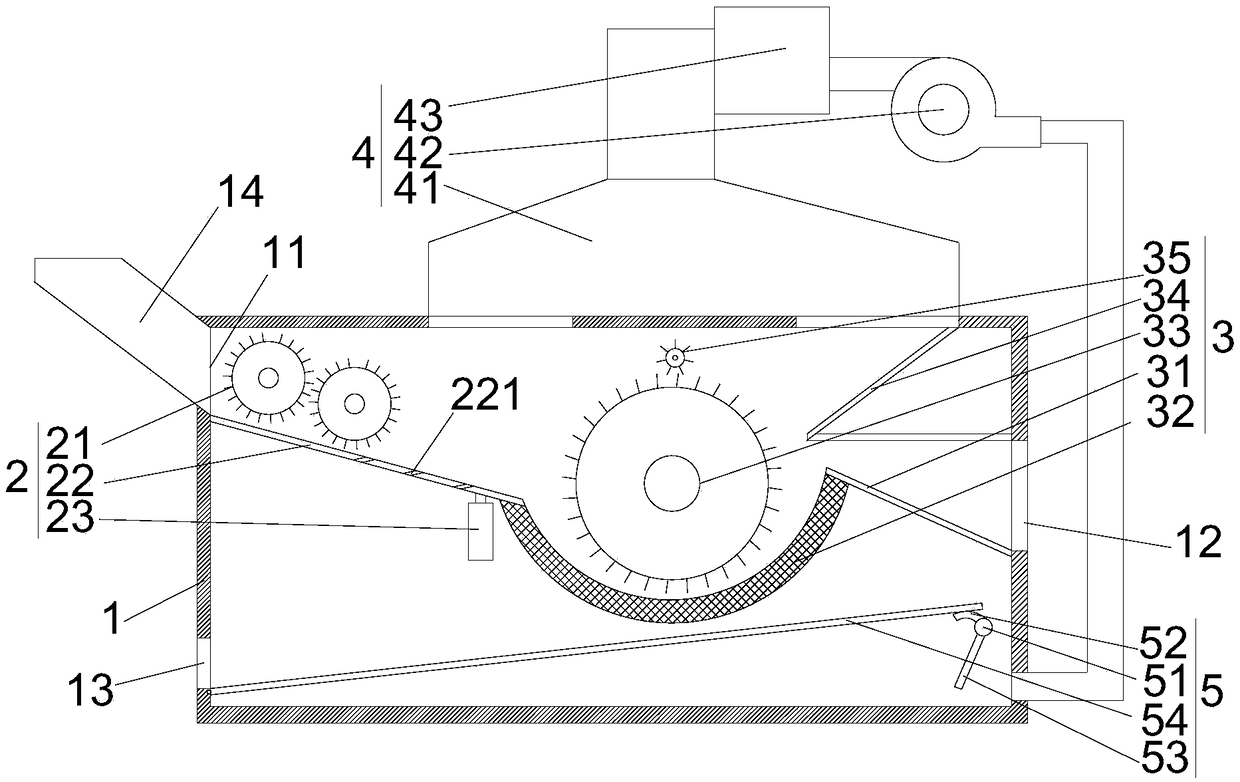

[0017] refer to figure 1 As shown, a kind of cleaning machine proposed by the present invention includes a cleaning box 1, an initial cleaning mechanism 2, a fine cleaning mechanism 3, a dust removal mechanism 4 and a miscellaneous guiding mechanism 5;

[0018] One side of the cleaning box 1 is provided with a feed port 11, and the side of the cleaning box 1 away from the feed port 11 is provided with a discharge port 12, and the cleaning box 1 is provided with a miscellaneous port 13, which is connected to the feed port 13 The port 11 is located on the same side of the cleaning box 1 and the miscellaneous outlet 13 is located below the feeding port 11, and the cleaning box 1 is provided with a feeding pipe 14 corresponding to the feeding port 11.

[0019] The initial cleaning mechanism 2 includes at least two small beater rollers 21, a cotton guide plate 22 and a vibrating motor 23; the small beater roller 21 is provided with acupuncture, and the cotton guide plate 22 is obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com