Method and device for controlling residual thread length of bobbin of sewing machine

A control device and sewing machine technology, which is applied in the direction of bobbin winding, sewing machine components, sewing equipment, etc. in the sewing machine, can solve the problems affecting the quality of clothing, etc., and achieve the effect of high degree of automation and high judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

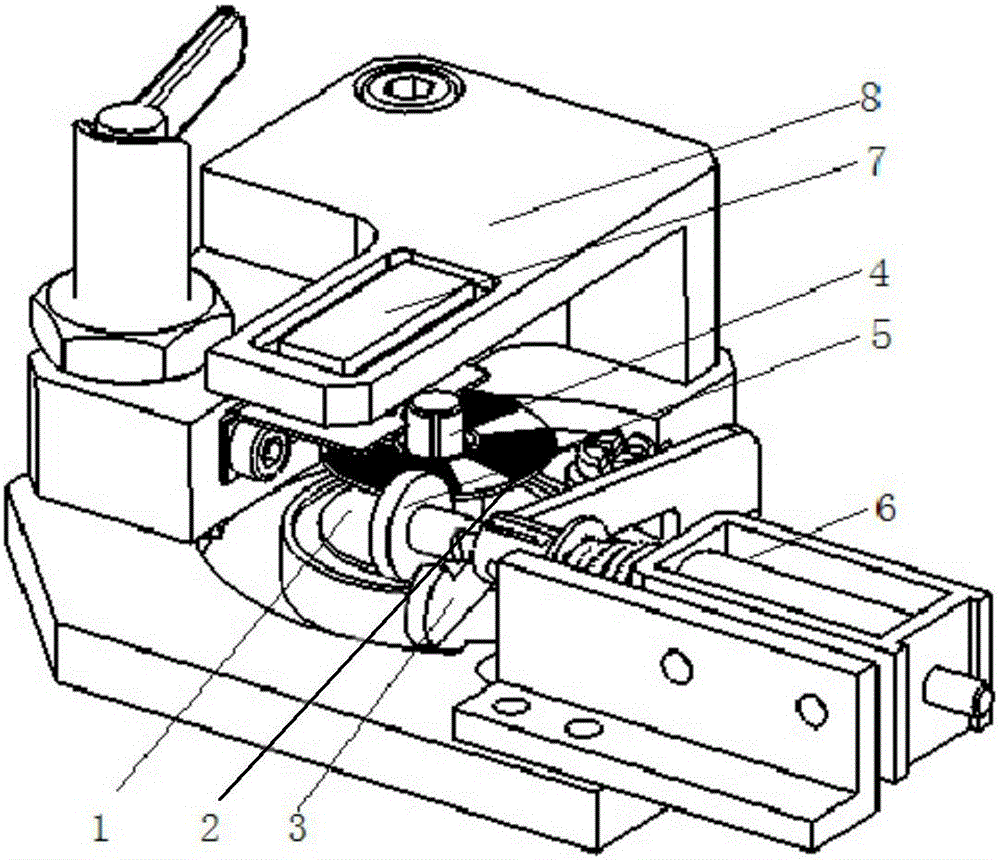

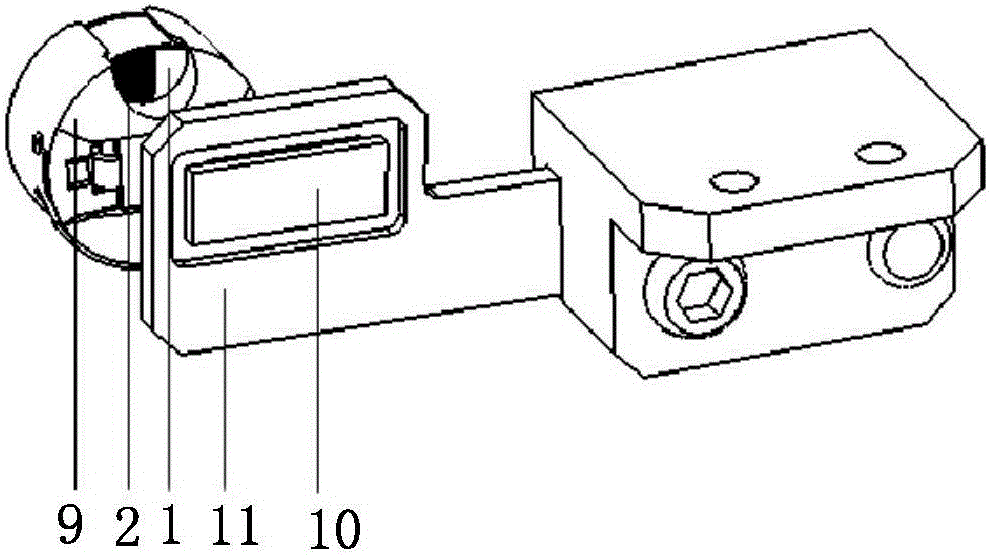

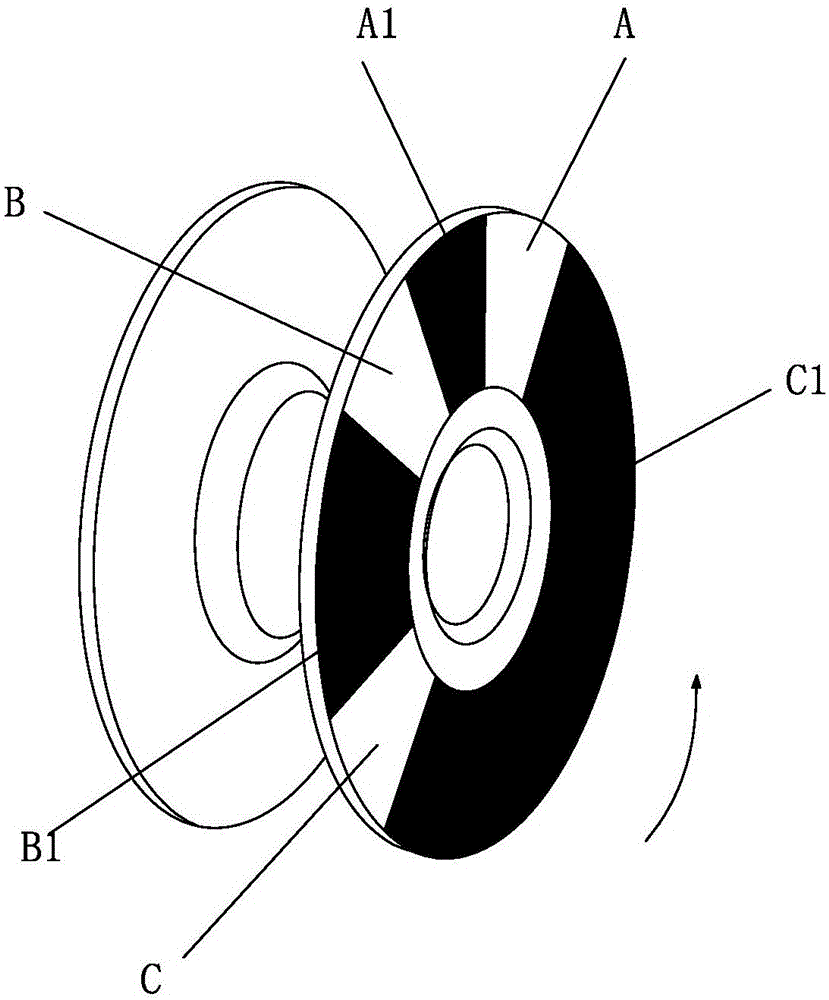

[0024] The present invention will be further described below with specific embodiment, see figure 1 —4:

[0025] A device for controlling the amount of remaining thread in a sewing machine bobbin, comprising a bobbin 1, an automatic winding amount control device and a detection device for the number of unwinding stitches, a code 2 is arranged on one side or both sides of the bobbin 1, and the automatic winding amount The control device obtains the winding number of the bobbin 1 according to the signal returned by the code 2 on the measuring bobbin 1. 1, and the controller judges whether the length of the line segment required by the next sewing process is satisfied according to the difference between the number of coils unwound and the number of unwound coils of bobbin 1 during the sewing process; if it is satisfied, the sewing machine continues to work; if If it is not satisfied, the controller will send out an alarm to remind the sewing machine operator to change the bobbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com