Anchor bolt-slurry-surrounding rock bond strength test method

一种粘结强度、测试方法的技术,应用在安装锚杆、强度特性、使用施加稳定的剪切力测试材料强度等方向,达到克服剪应力分布不均匀、力学参数准确的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for testing the bond strength of a bolt-slurry-surrounding rock, comprising the following steps:

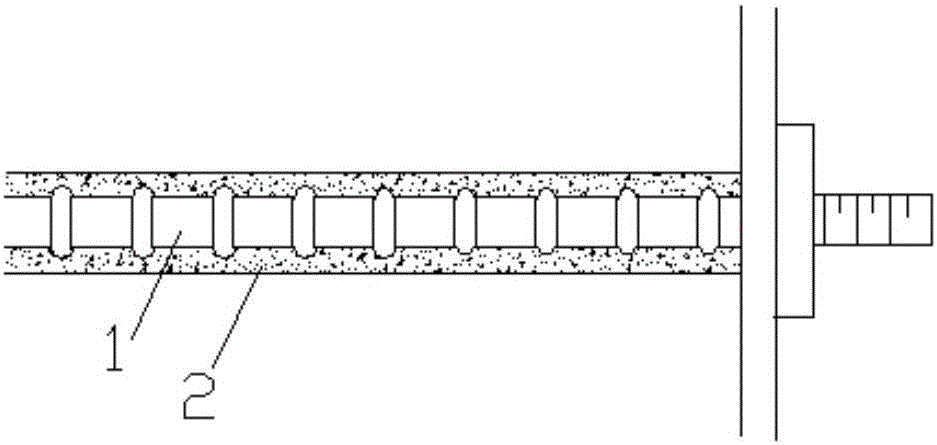

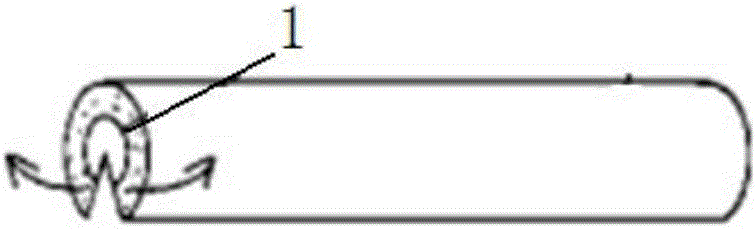

[0041] ①Take the bolt used in the project site, scan the surface of the bolt with a laser scanner, and obtain the topography data of the bolt surface;

[0042] ②Transmit the surface topography data of the anchor rod to the 3D printer, and print out the mold 5 with the surface topography of the anchor rod for making the anchor rod shear test piece 3 through the 3D printer, such as Figure 5shown;

[0043] ③Using the mold 5 as a template to make the anchor shear specimen 3, the anchor shear specimen 3 is in the shape of a cuboid as a whole, its upper surface has the same shape as the anchor surface, and the side and lower surfaces are smooth surfaces. The material is consistent with the material type of the anchor bolt on the project site;

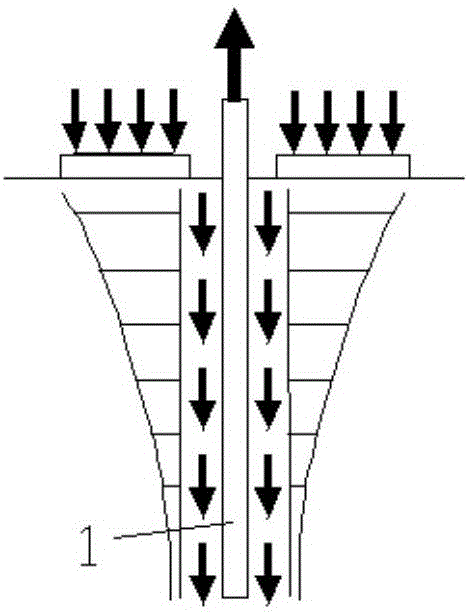

[0044] ④Using the anchor shear test piece 3 as a template, pour the anchor bonding material on the anchor shear test piece 3...

Embodiment 2

[0048] ①Cut a section of the anchor rod at the project site as the anchor rod test piece, roll the anchor rod test piece through the plastic material under the set pressure condition, and leave the surface morphology of the anchor rod on the surface of the plastic material;

[0049] ② Use the plastic material surface as a template to make the anchor shear test piece 3. The anchor shear test piece 3 is in the shape of a cuboid as a whole, its upper surface has the same shape as the anchor surface, and the side and lower surfaces are smooth. Surface, the material used is consistent with the material type of the anchor bolt on the project site;

[0050] ③Using the anchor shear test piece 3 as a template, pour the anchor bonding material on the anchor shear test piece 3 to form a slurry layer 6, the thickness of the slurry layer 6 is the same as the thickness of the slurry in the project site Consistent, after the slurry layer 6 is solidified, the rock-like material is poured to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com