A method and device for arranging segmental insulation of buried pipelines

A technology of buried pipelines and segmental insulation, which is applied in the fields of instruments, calculations, electrical digital data processing, etc., can solve the problems of lack of standardized operating procedures and low accuracy, avoid subjective factors, and reduce follow-up engineering quantities and materials Loss, the effect of accurate optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

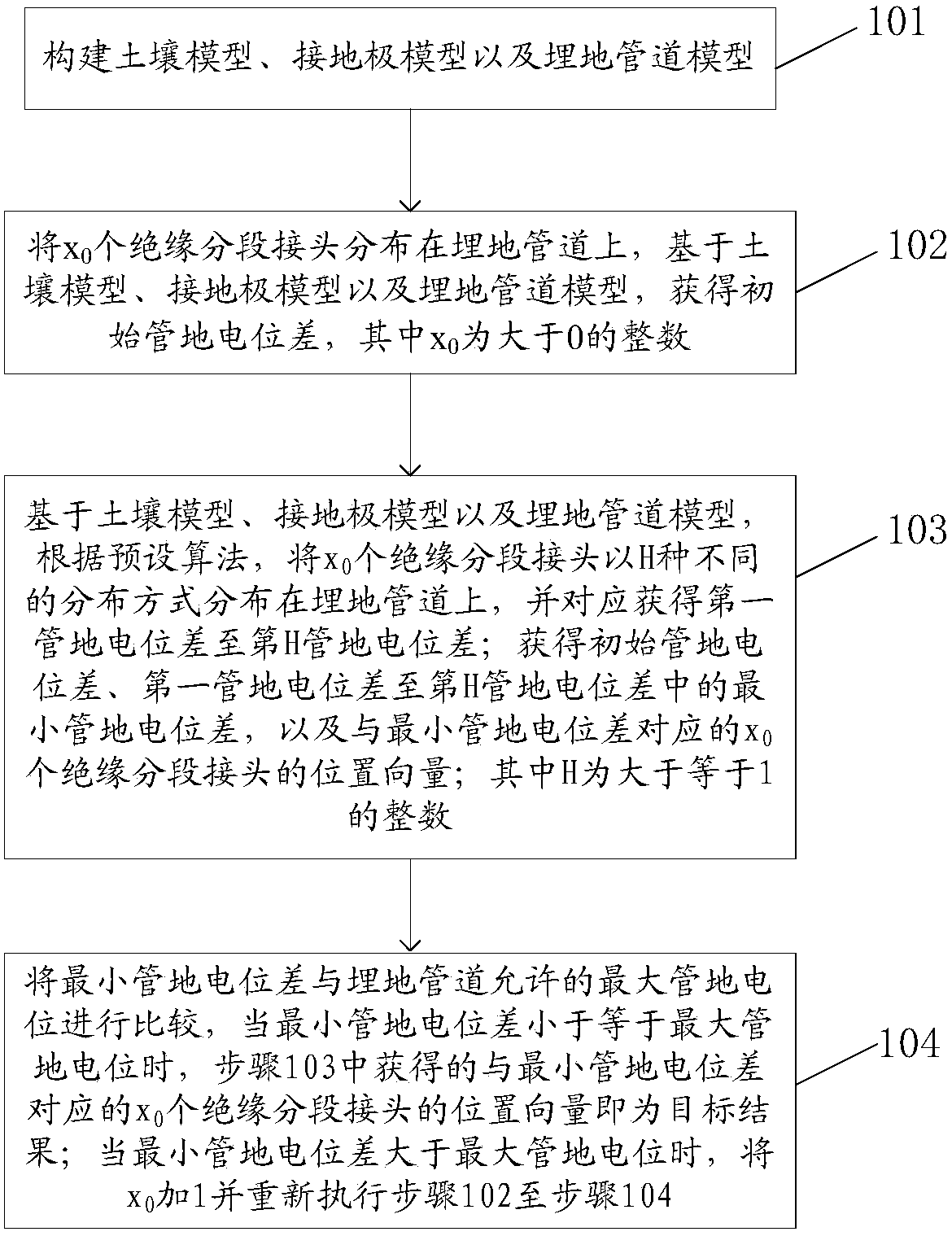

Method used

Image

Examples

Embodiment 1

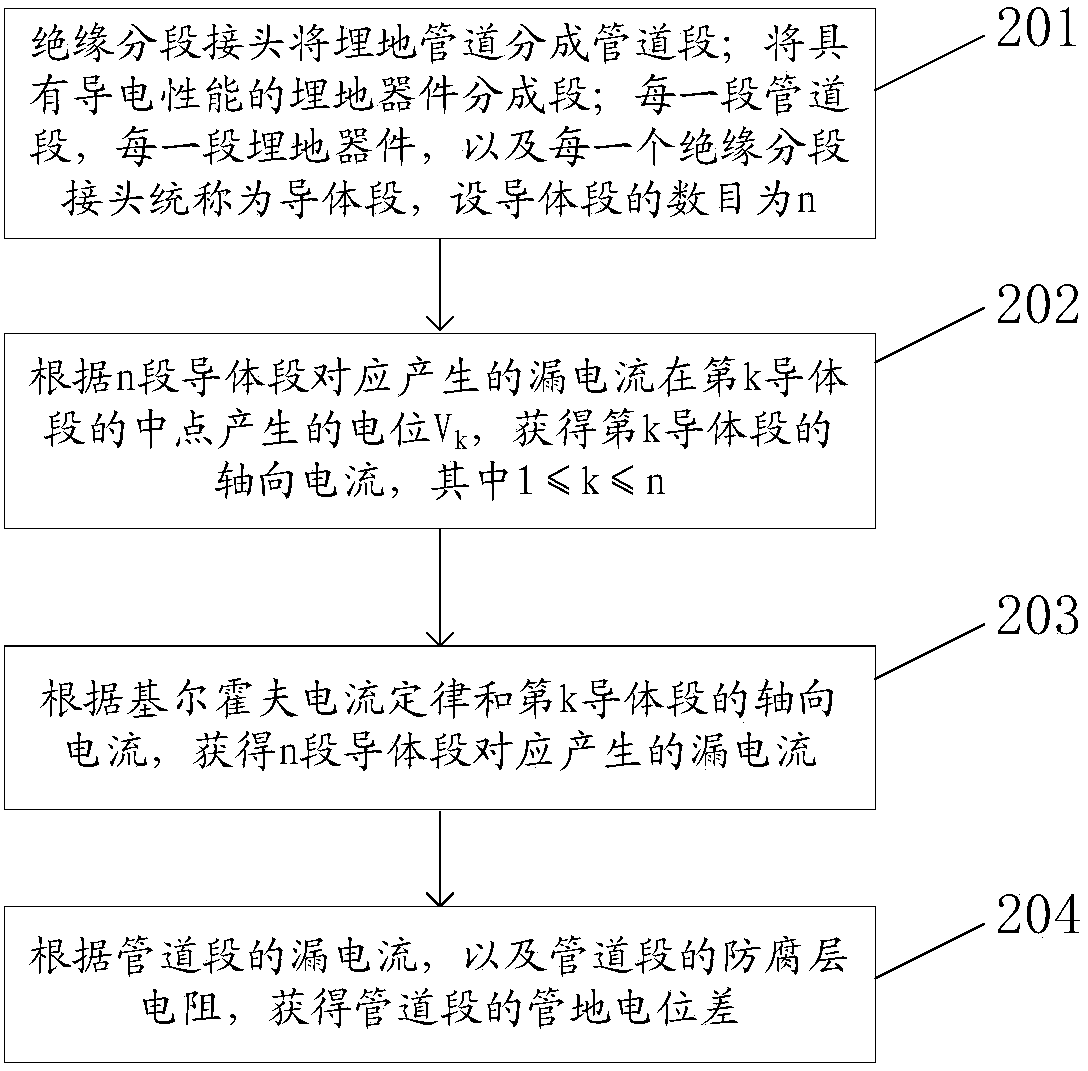

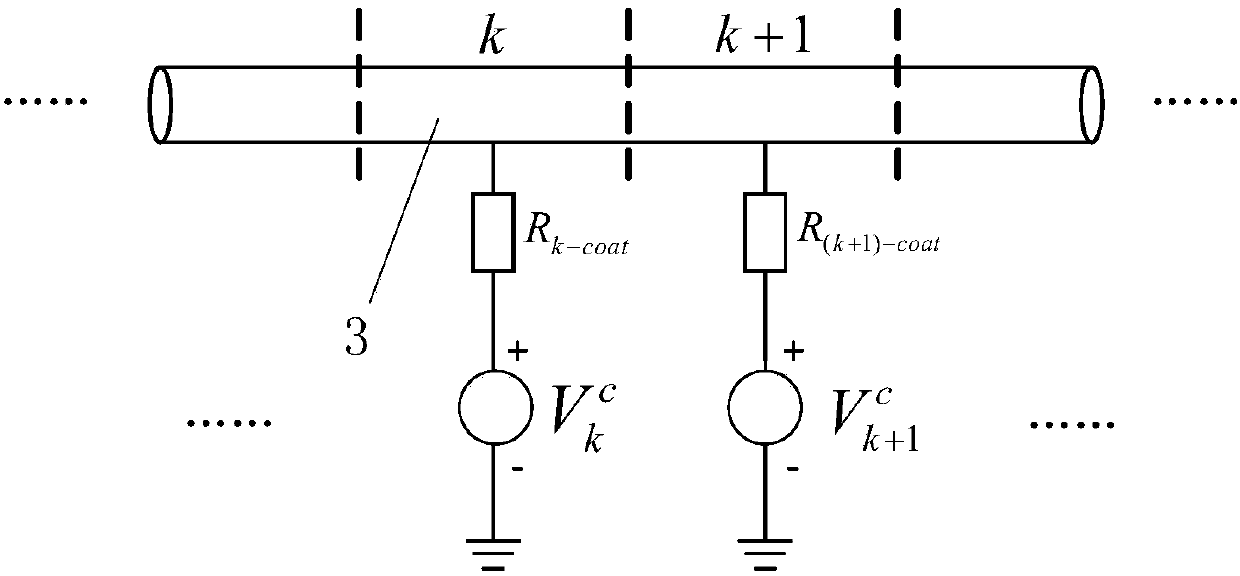

[0060] The buried pipeline 7 is a hollow buried cylindrical conductor covered with an insulating anti-corrosion layer 5. After the buried pipeline 7 is divided into several small sections by using insulating segment joints, the entire buried pipeline 7 is equivalent to being divided into several sections. A small section of hollow buried cylindrical conductor; the ground electrode 6 is a conductor or a combination of several conductors that are buried in the earth so as to be connected to the earth, and can also be regarded as a buried cylindrical conductor; The potential at one point is jointly produced by the leakage currents of all buried conductors; therefore, when calculating the pipe-to-ground potential of the buried pipeline 7, it is necessary to obtain the leakage current of each buried conductor at the corresponding position on the buried pipeline 7. current distribution.

[0061] see image 3 , the buried pipeline 7 is divided into several sections, and each buried ...

specific Embodiment

[0118] see Figure 9 The length of the buried pipeline 7 is 100km, the diameter of the buried pipeline 7 is 1219mm, the wall thickness of the buried pipeline 7 is 18.4mm, the material of the buried pipeline 7 is X80 steel pipe, and the resistivity of the three-layer PE anti-corrosion layer 5 is 10 5 Ω·m 2 . Soil characteristic parameters near grounding electrode 6: single layer soil, resistivity 1000Ω·m; grounding electrode 6 injected current 3000A, vertical distance between grounding electrode 6 and buried pipeline 7 is 5km. When no insulated section joint is added, the maximum pipe-to-ground potential of the buried pipeline 7 is 47.5V, and now the following optimization calculation is performed:

[0119] The maximum allowable pipe-to-ground potential of the buried pipeline 7 is set to 30V, and the number of insulation section joints expected to be added is set to two. The calculation result is obtained: the minimum pipe-to-ground potential difference is 28.2V, which is le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com