Patents

Literature

66results about How to "The optimization result is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

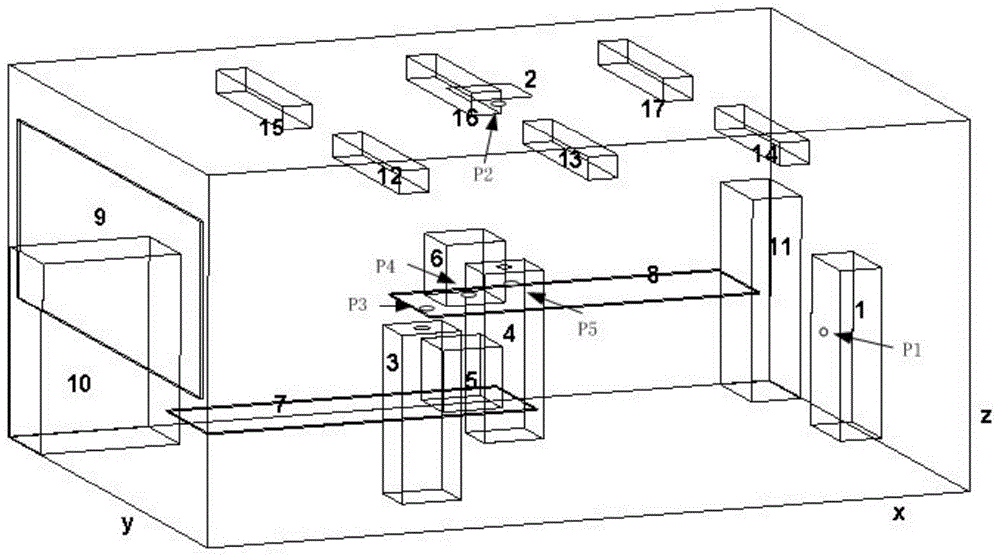

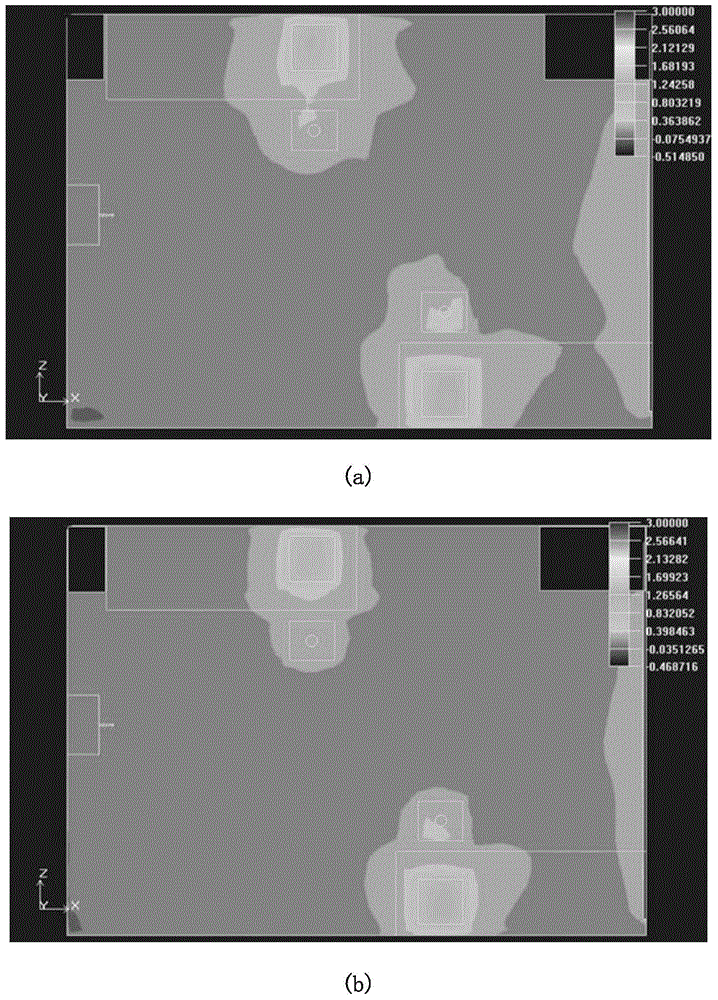

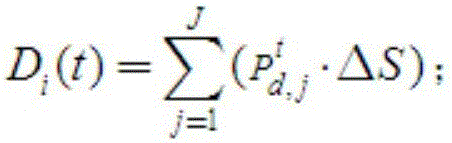

Building indoor environment optimization method based on model order reduction technology

InactiveCN103049612AQuick solveHigh precisionSpecial data processing applicationsGenetic algorithmComputer science

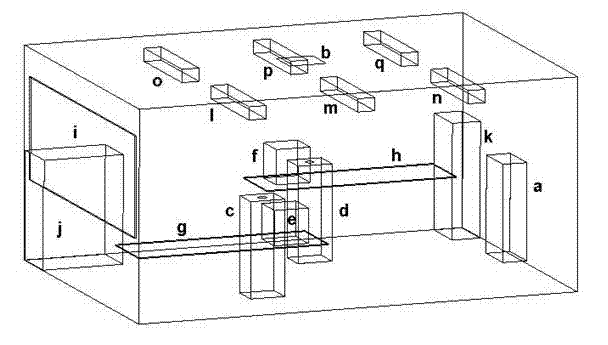

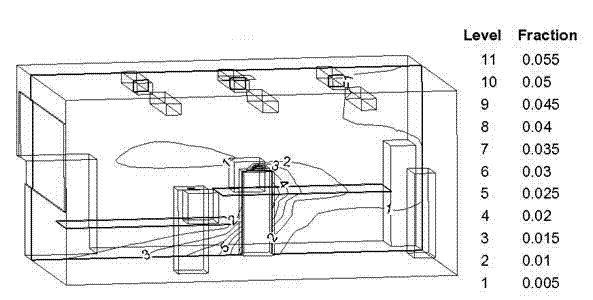

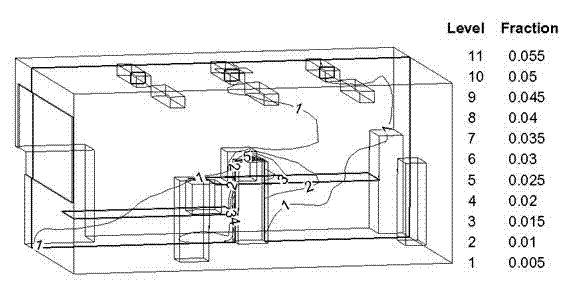

The invention discloses a building indoor environment optimization method based on the model order reduction technology. The method mainly includes the three steps: (1) using CFD (computational fluid dynamics) software for steady-state simulation of the indoor environment, and constructing variation spaces of various environmental parameters; 2) reconstructing low-order parameter variation subspaces by the aid of the POD (proper orthogonal decomposition) technology; and 3) searching the optimal air conditioner air supply temperature and the optimal air conditioner air supply speed by operating the genetic algorithm. The variation subspaces of the indoor environmental parameters are constructed by the aid of the POD technology, so that influences of spatial distribution on the environmental parameters are considered fully in an optimizing strategy, and optimization accuracy is improved. The POD model order reduction method maps a control equation in an original space into one orthogonal subspace, and accordingly mapping error can be guaranteed to minimum in the energy sense. Besides, compared with a present environment optimization strategy, the building indoor environment optimization method based on the model order reduction technology has the advantages of high optimization precision, high speed and the like.

Owner:JIANGSU UNIV

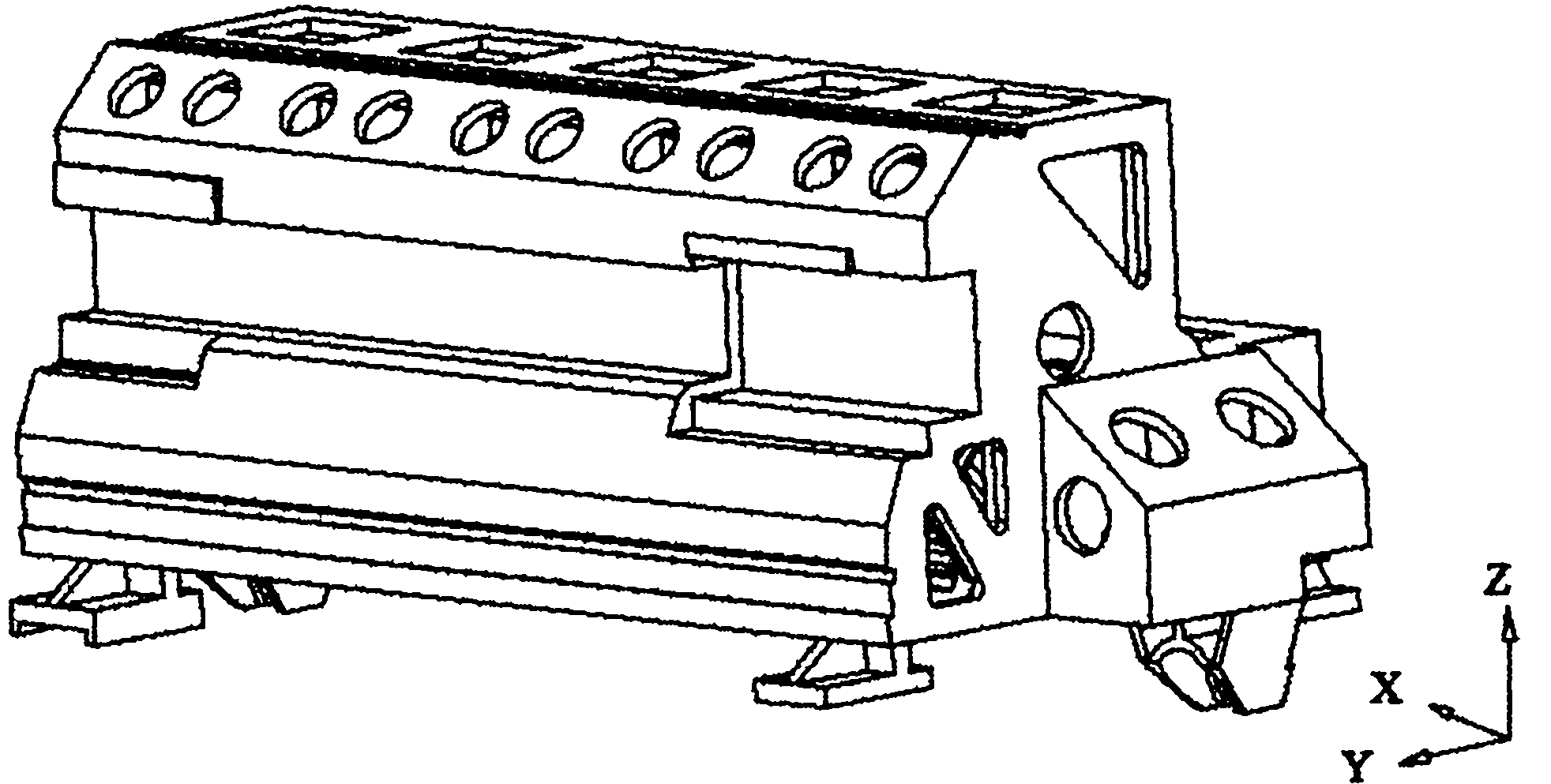

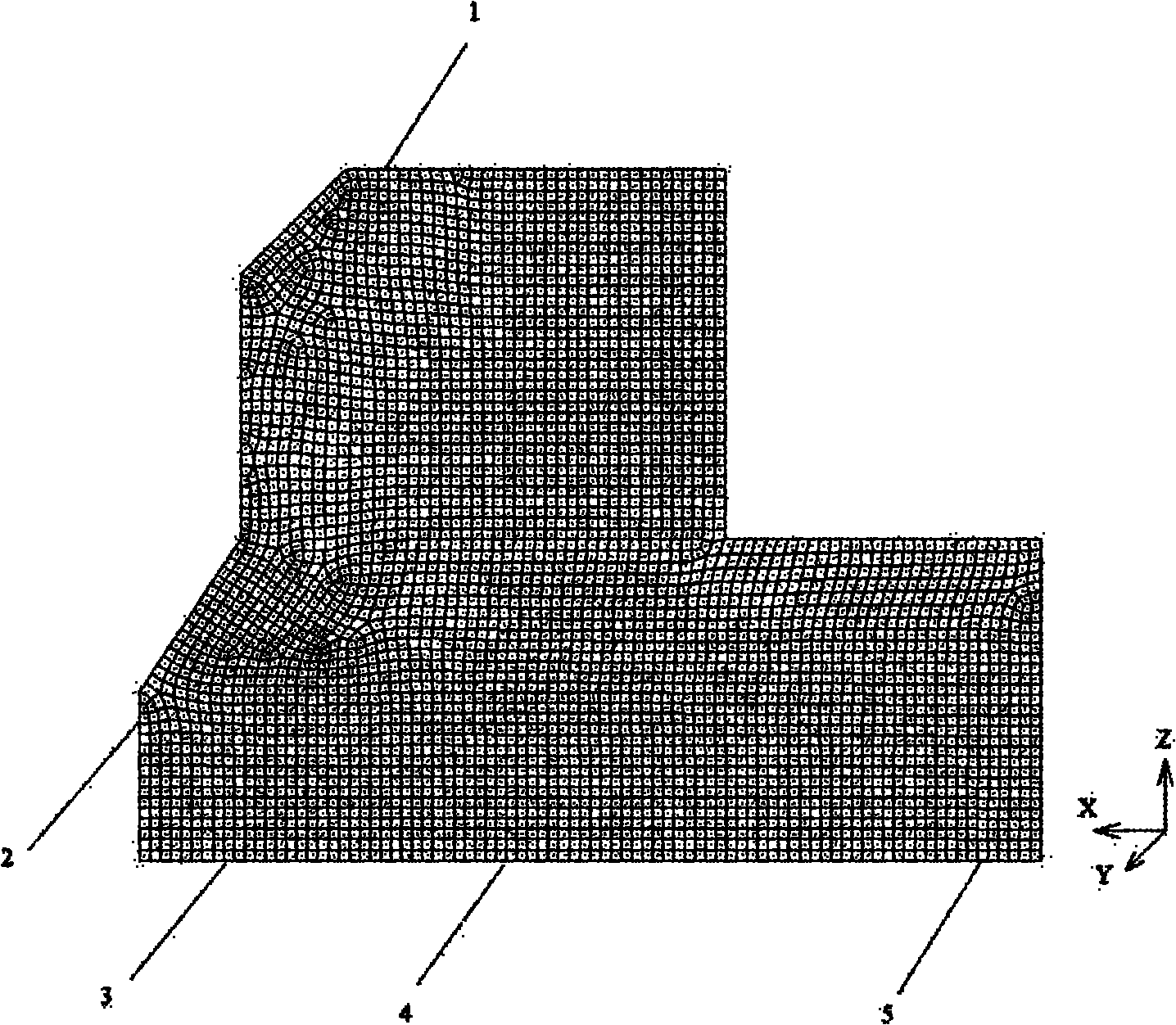

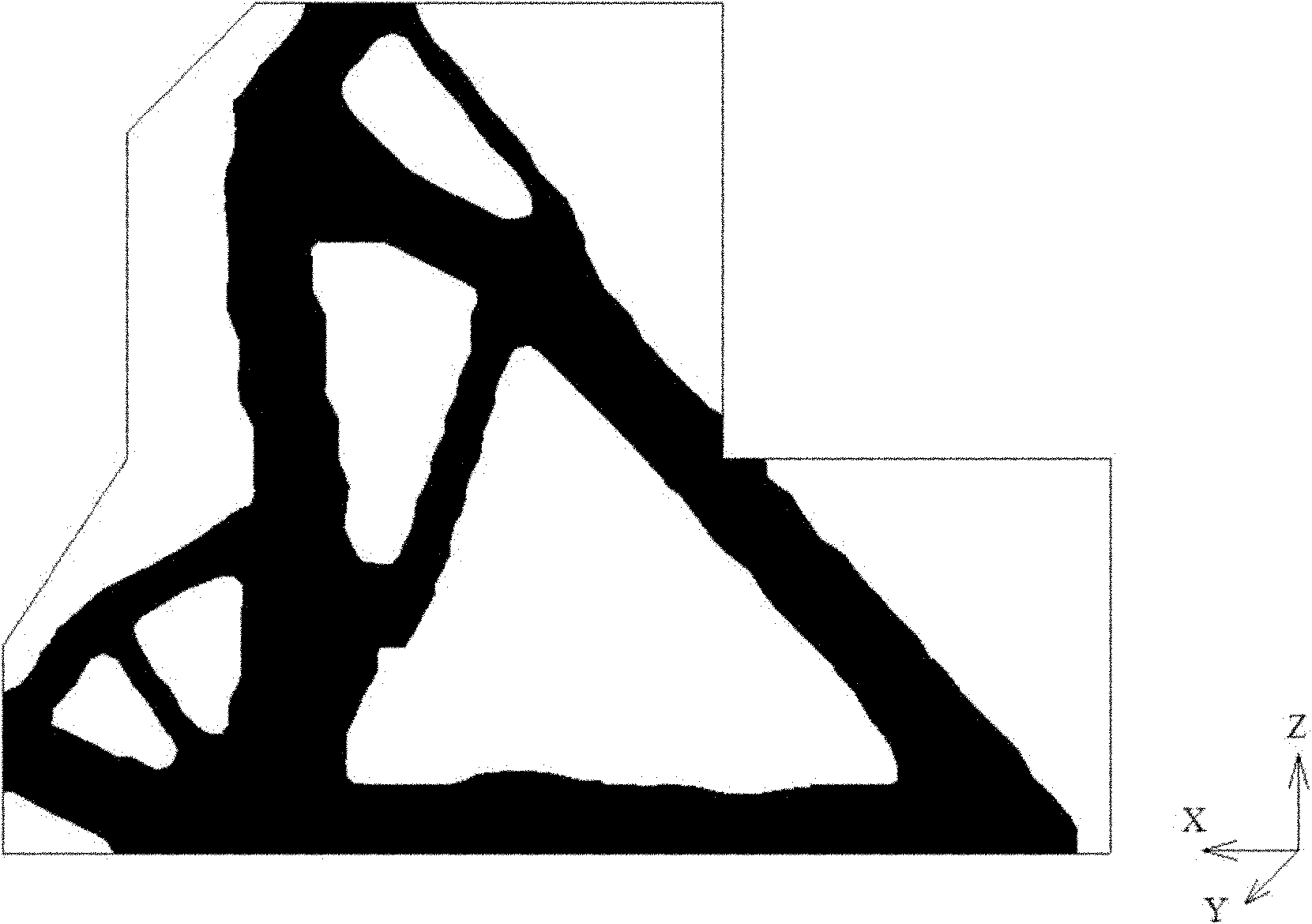

Topological optimization design method for high-speed vertical machining centre long-span beam

InactiveCN101950319AImprove optimization efficiencyGuaranteed availabilitySpecial data processing applicationsSolid structureStrain energy

The invention belongs to the technical field of mechanical design and relates to a topological optimization design method for a high-speed vertical machining centre long-span beam. The method is mainly for the topological optimization of the three-dimensional solid structure of the long-span beam. The method consists two parts of early basis analysis and topological optimization design; the early basis analysis is to grasp the static and dynamic properties of the original beam, find out the parts of relatively weak static and dynamic properties and perform structural topological optimization on the beam correspondingly; and in the later topological optimization design, based on the result of the basic analysis, the later structural topological optimization including two-dimensional topological optimization and three-dimensional topological optimization of the beam is performed according to the characteristics of the beam. In the topological optimization method, a density method is adopted, the volume fraction response is used as a constraint function, and the static strain energy response is used as a target function; and finally an innovative model is established again according to the results of the two-dimensional and three-dimensional topological optimization analysis. The structural topological optimization method has the advantages of improving the optimization efficiency, along with accurate and reliable optimized results.

Owner:DALIAN UNIV OF TECH

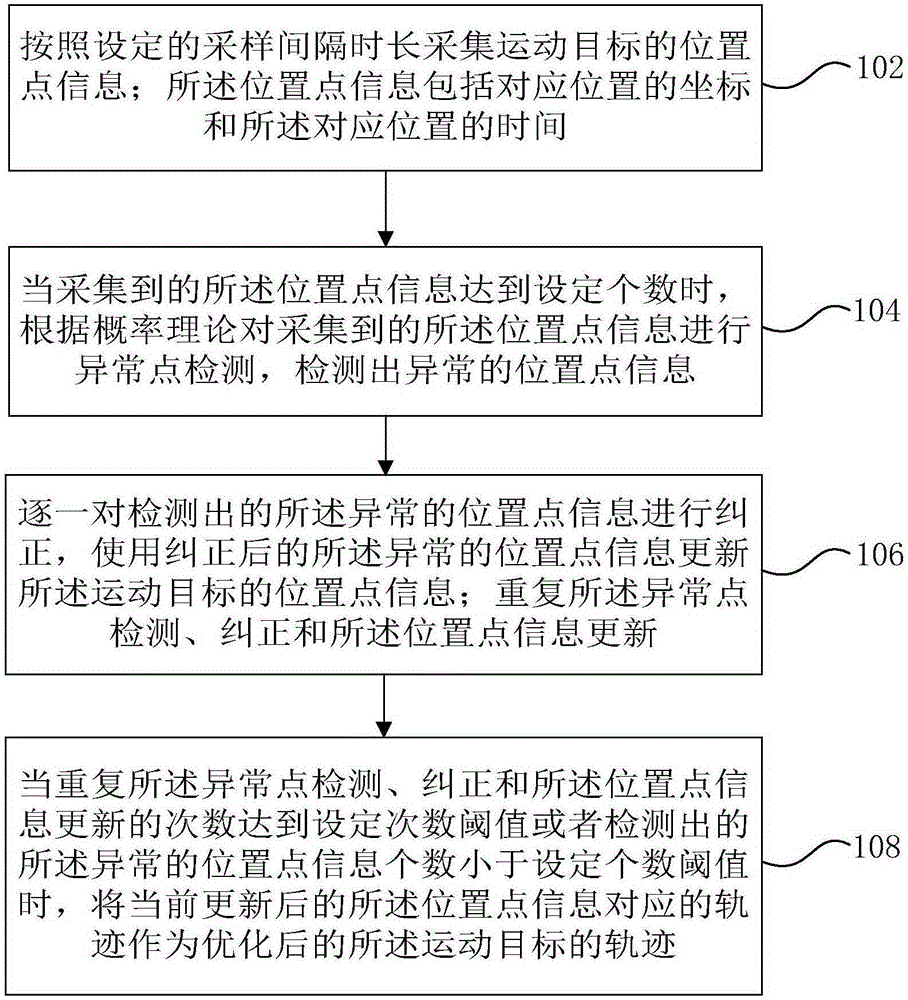

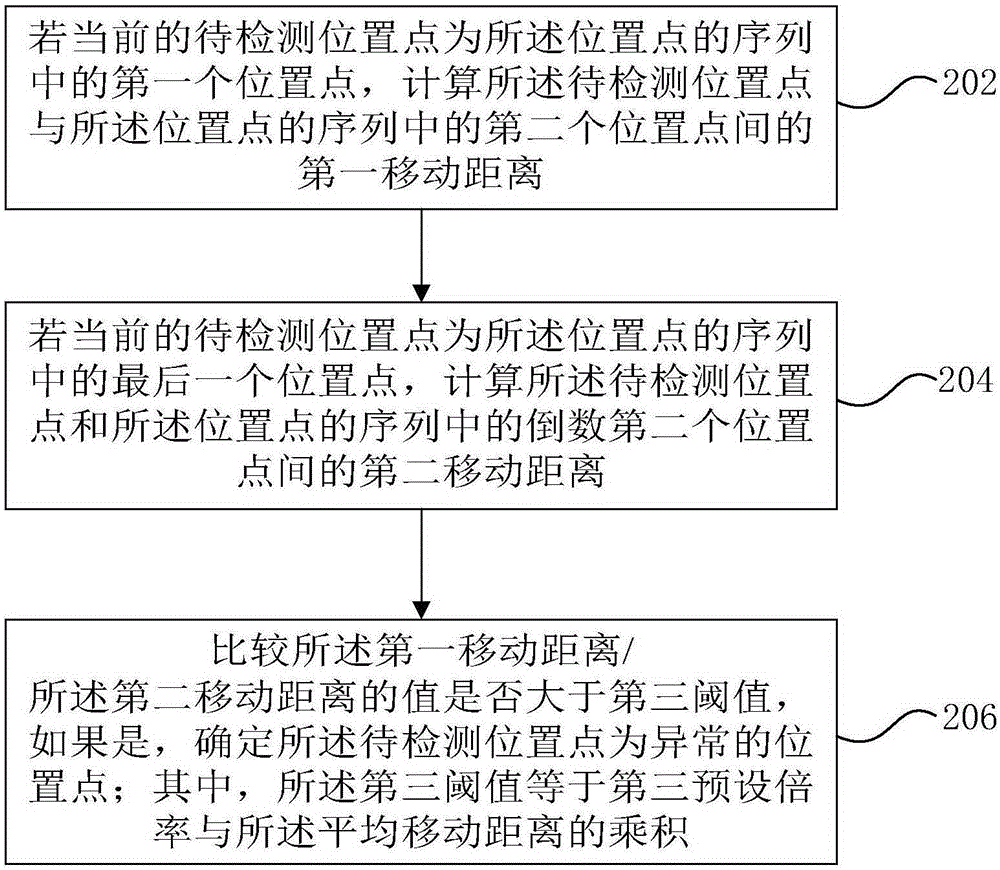

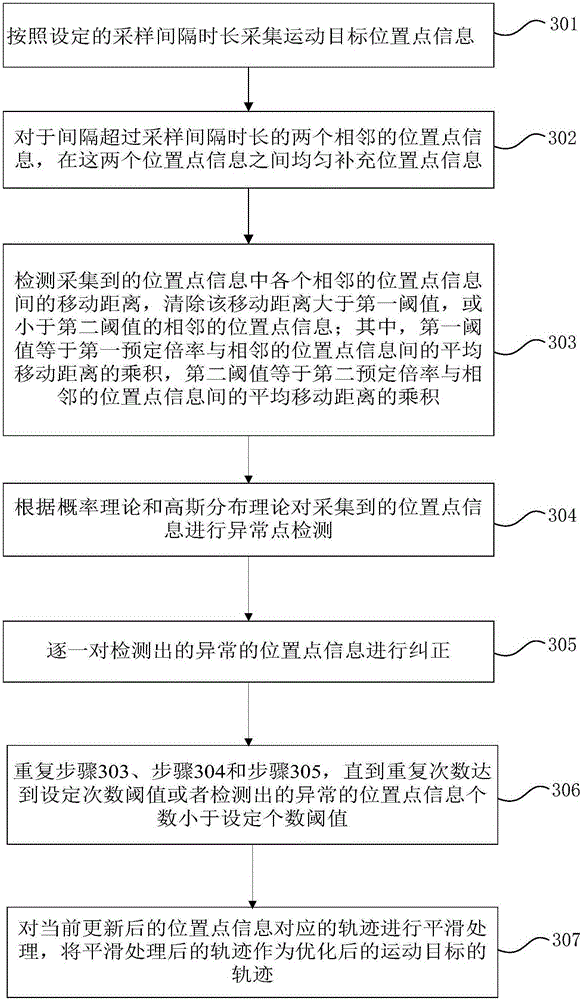

Optimization method of trajectory and device

ActiveCN105184382AThe optimization result is accurateMotion trajectory is realForecastingAbnormal positionsComputer vision

Owner:CHENGDU LEDONG INFORMATION TECH CO LTD

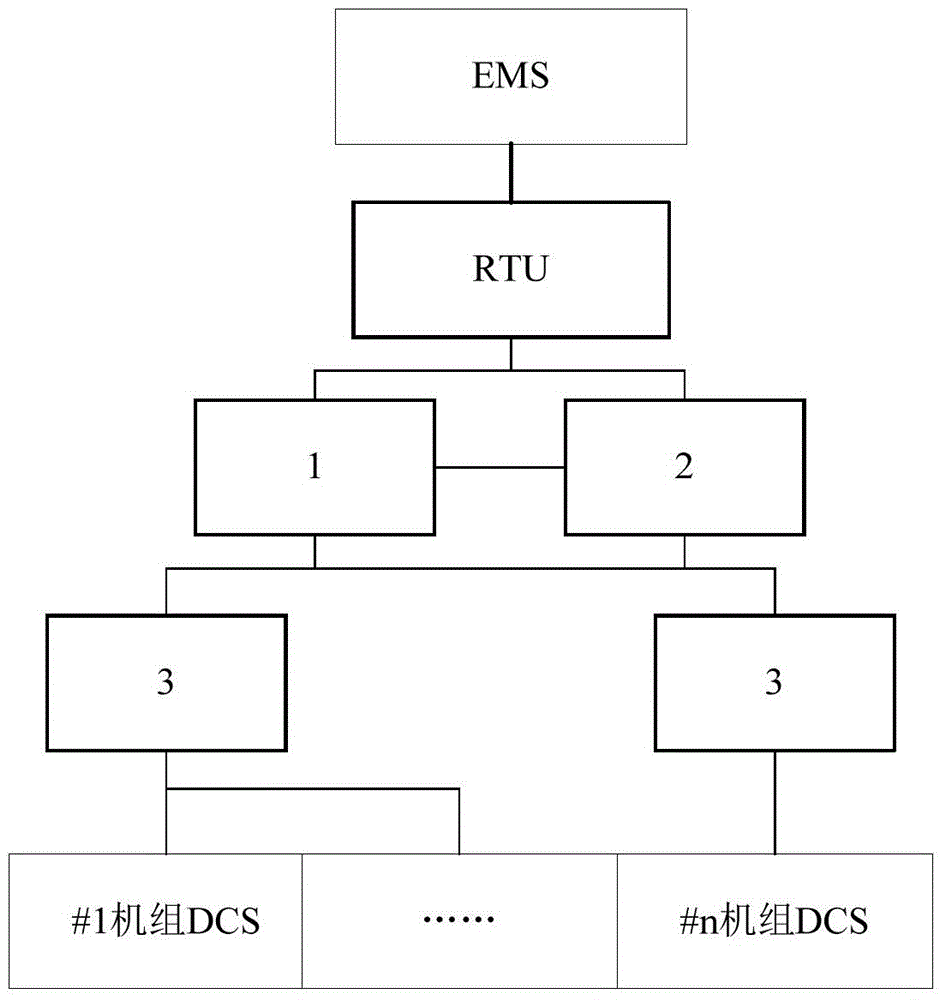

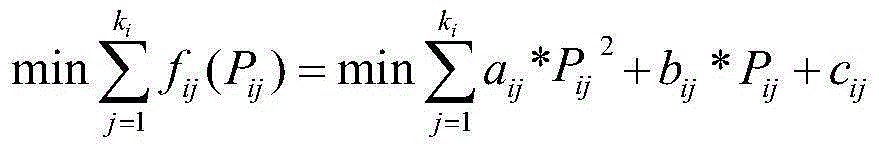

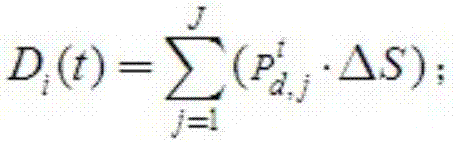

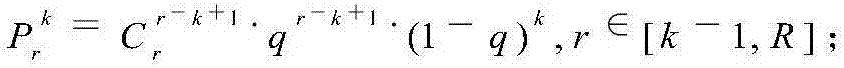

Power plant level automatic power generation control system applied load optimizing and distributing method and system

ActiveCN105098843AReduce the number of variablesMeet the requirements of FMSingle network parallel feeding arrangementsForecastingAutomatic controlSafety control

The invention discloses a power plant level automatic power generation control system applied load optimizing and distributing method. The method is carried out through the following steps: pre-classifying a plurality of sub-clusters of generator sets according the properties of the generator sets of the power plant; optimizing and distributing load to the plurality of sub-clusters of generator sets according to the principle of using the least amount of coals; attaining the best load state space of each generator set in each sub-cluster of the generator sets within an allowed load and storing best load state space in a database of a system; performing load distribution according to a speed regulation priority method or a coal consumption optimizing method so as to check the best load state space of the sub-clusters of generator sets and attaining the best load of all generator sets in the power plant with the attained best load of all machines transmitted to an automatic control system through a monitoring apparatus of a plant level AGC system. The invention further provides a system corresponding the method. According to the invention, the method is capable of effectively shortening the calculation and distribution time for load when a power plant comprises a great number of generator sets with vast type difference so as to fulfill the requirement of safety control to a power grid and to improve the authenticity and the accuracy of an optimization result.

Owner:NR ELECTRIC CO LTD +1

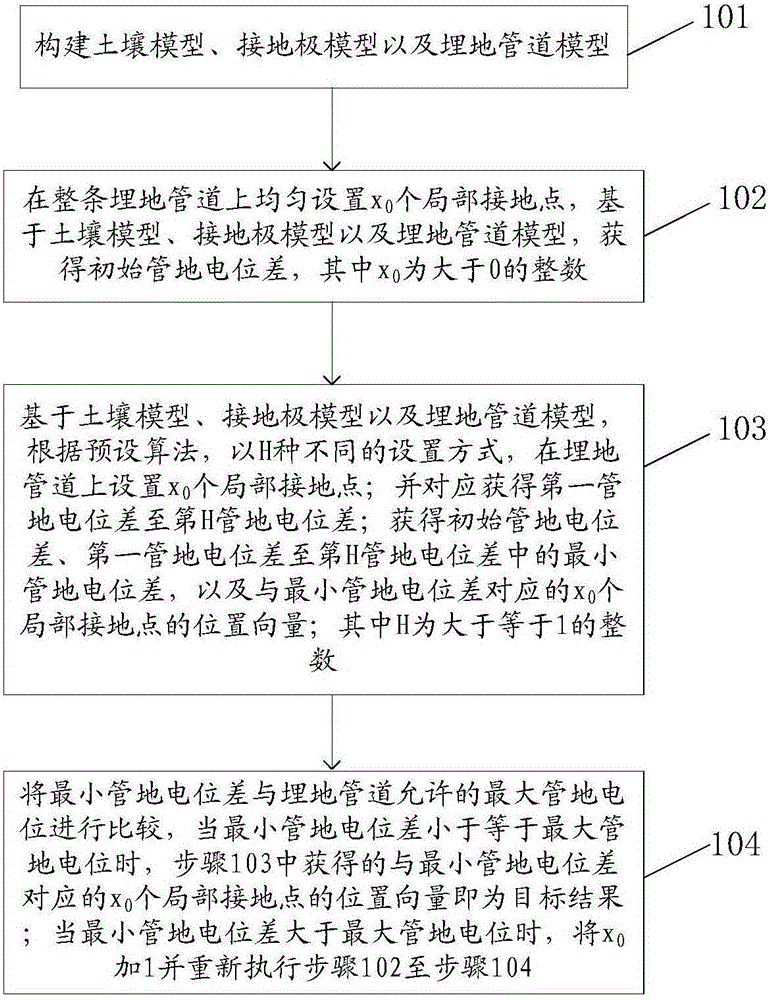

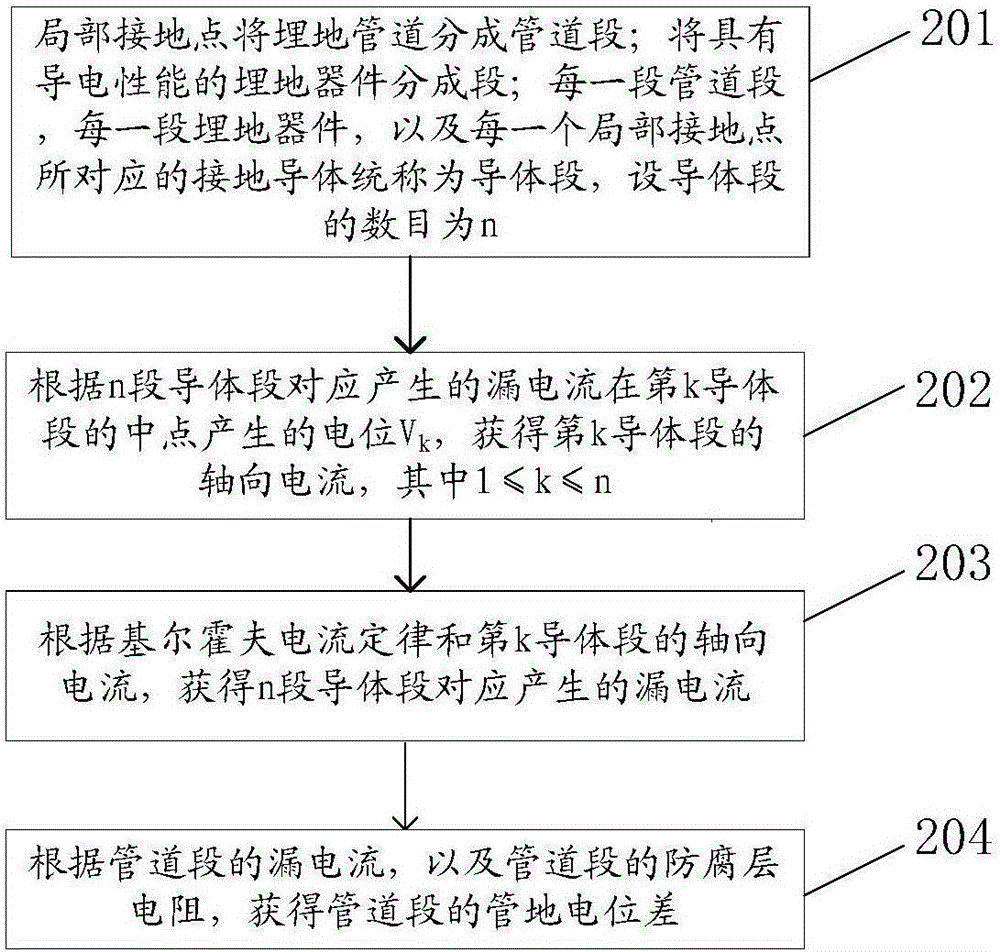

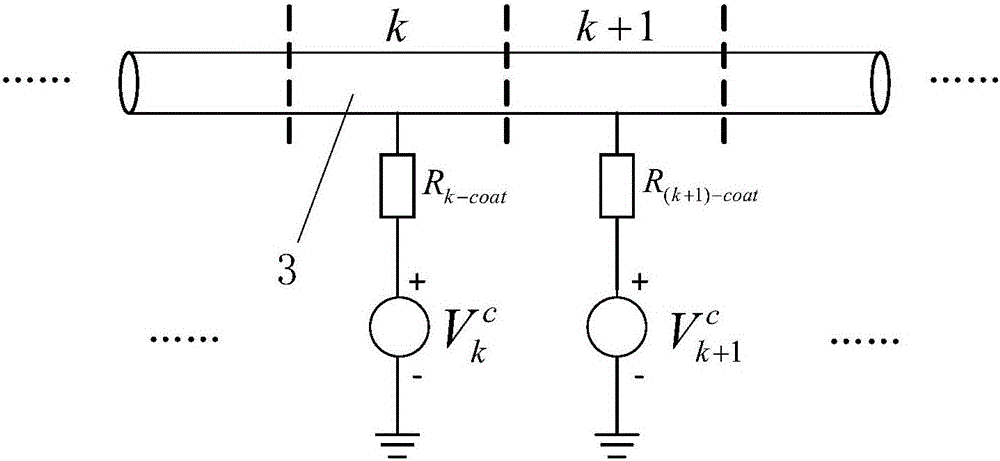

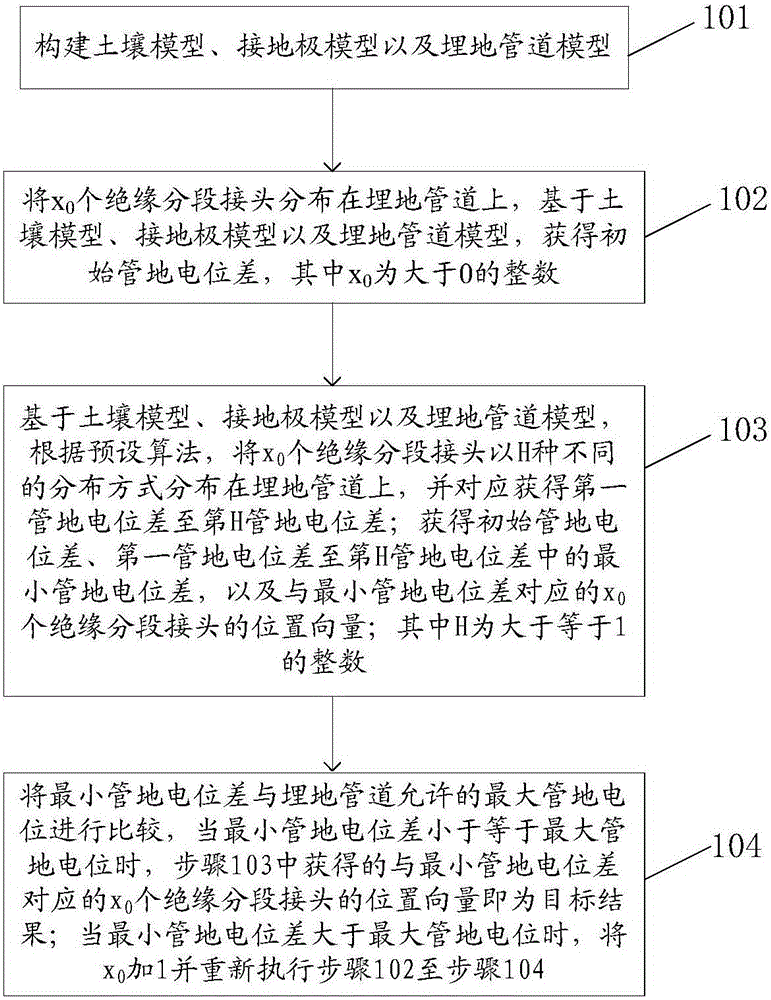

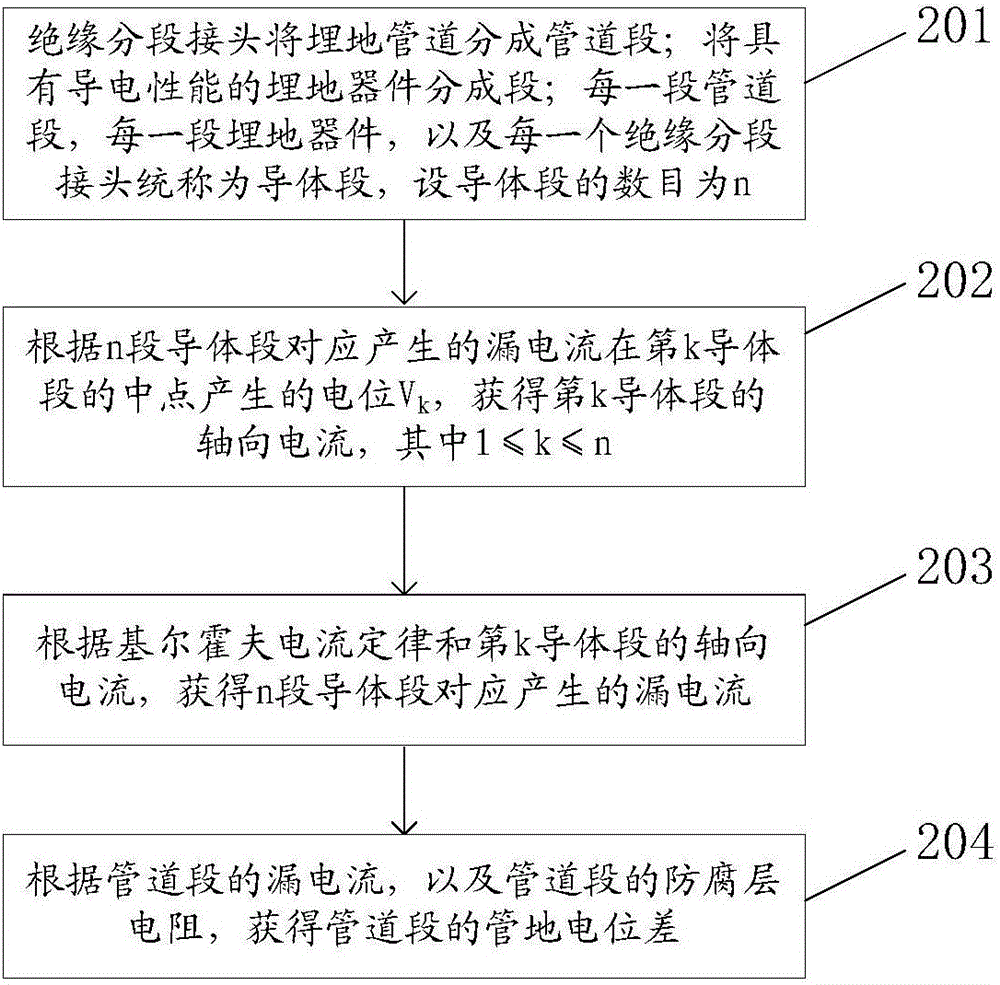

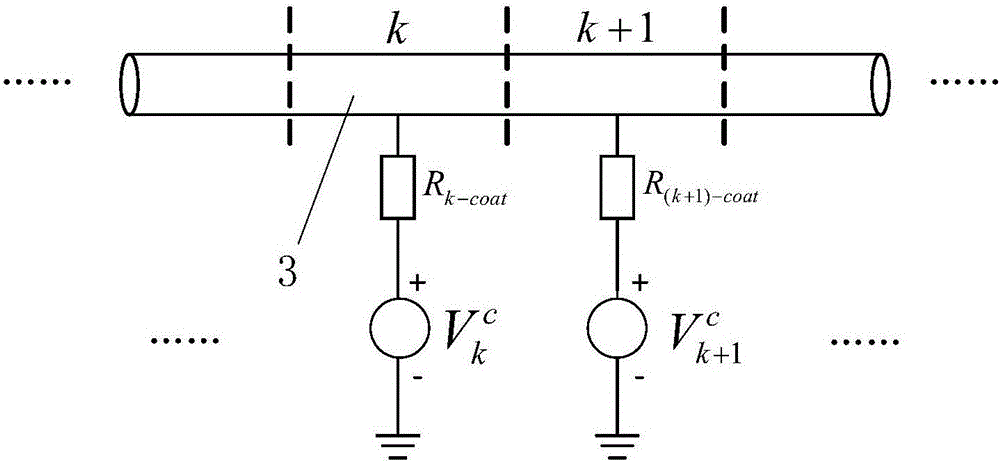

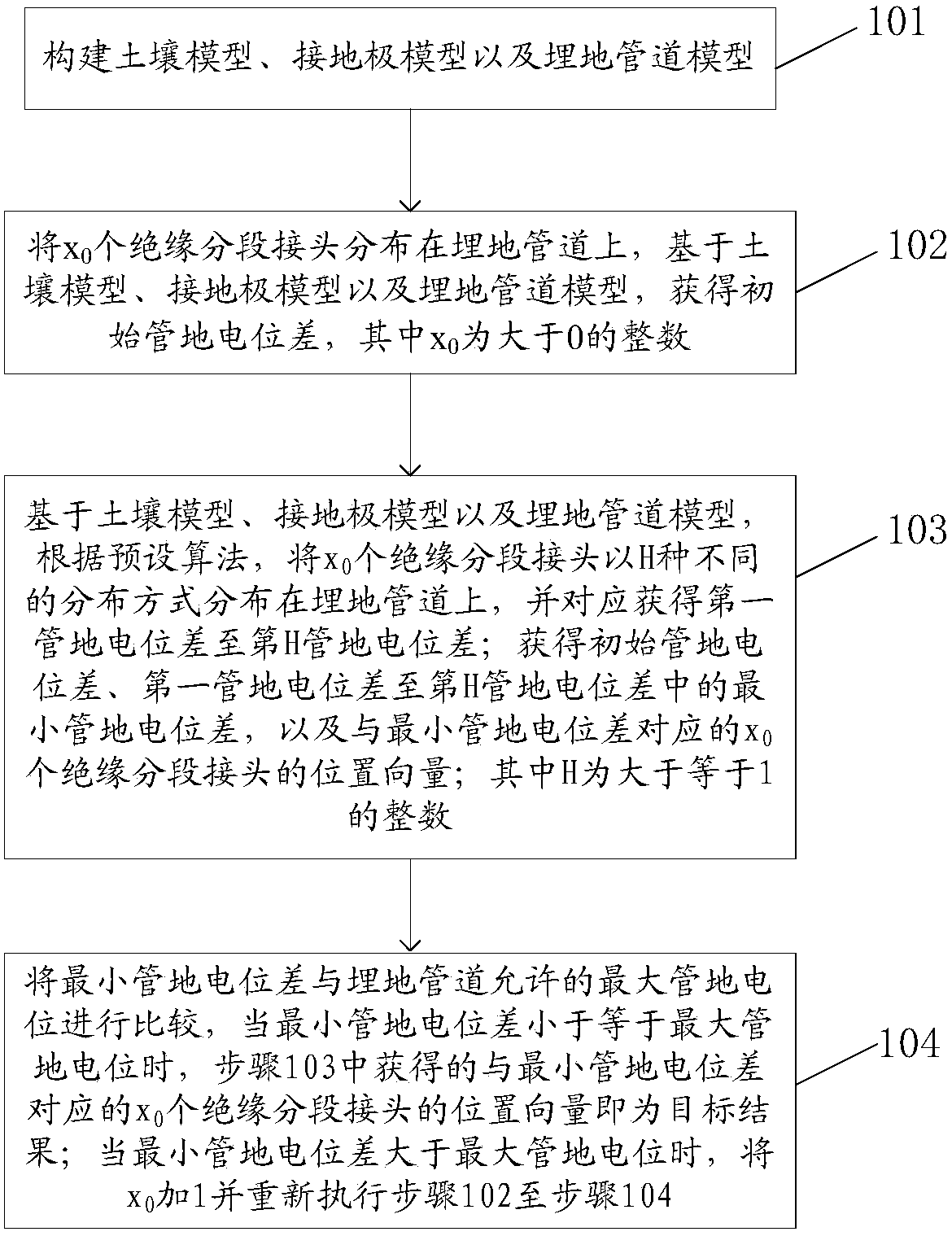

Method and device for arranging buried pipeline local grounding points

ActiveCN105974175AOptimizing Process ScienceThe optimization result is accurateCurrent/voltage measurementEngineeringPotential difference

The invention discloses a method and a device for arranging buried pipeline local grounding points, which relate to the technical field of buried pipeline protection and aim at solving the problems of low accuracy and lacked standard operation process when local grounding point arrangement is carried out on the buried pipeline according to experience. The method of arranging buried pipeline local grounding points comprises steps: an initial pipe-ground potential difference and pipe-ground potential differences from a first to an Hth are acquired; the minimal pipe-ground potential difference and the corresponding position vector are then acquired; the minimal pipe-ground potential difference is then compared with the maximal pipe-ground potential allowed by the buried pipeline, and when conditions are met, the acquired position vector corresponding to the minimal pipe-ground potential difference is the target result; or otherwise, one is added to the number of local grounding points and the minimal pipe-ground potential difference is then acquired again until the conditions are met. The method of arranging buried pipeline local grounding points provided by the invention is used for optimally arranging the buried pipeline local grounding points.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

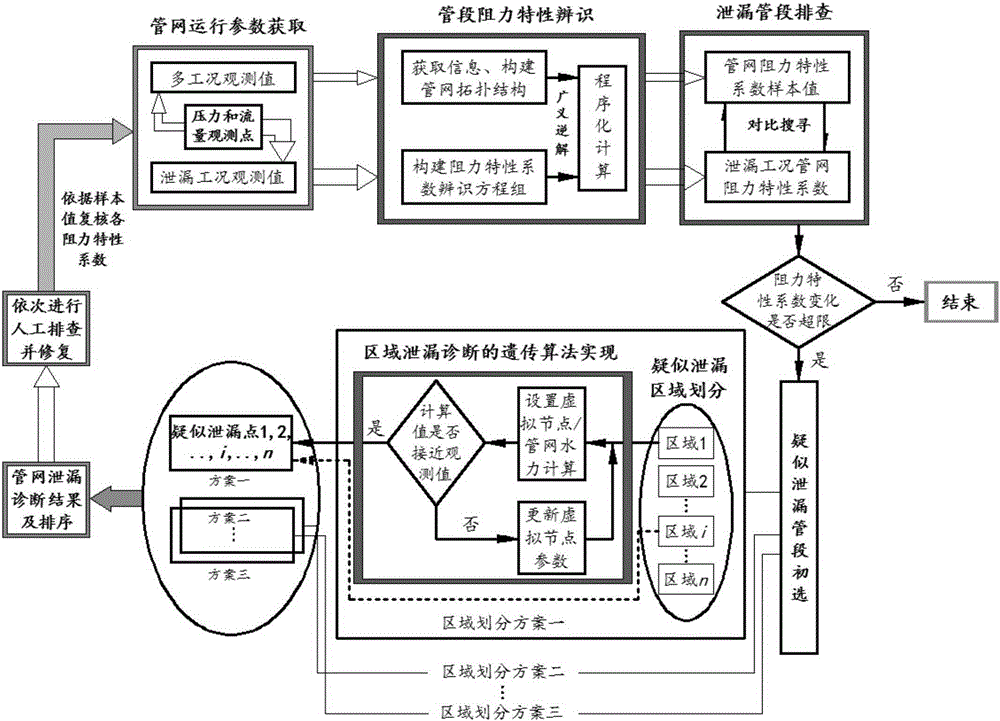

Pipe network leak detecting method in combination with resistance identification

InactiveCN105221933ALow data requirementsReduce computing timePipeline systemsControl systemGeneralized inverse

The invention discloses a pipe network leak detecting method in combination with resistance identification, relates to pipe network leak detecting methods and aims to solve the problems that passive leakage control methods mainly need a large number of instruments, equipment and manpower and are hardly combined with automatic monitored control systems, and large deviation of optimization results due to a small number of samples and long consuming time exist in artificial neural network methods. The pipe network leak detecting method in combination with resistance identification includes that firstly, pressure observed values of flow nodes of part of pipe sections are used as known conditions; an equation set containing pipe section resistance information is established; resistance results are expressed through generalized inverse solution of the equation set. Then, a pipeline where leakage possibly occurs is divided into a plurality of different areas; in each area, observed values of operation parameters of an edge pipe network are used as known conditions, virtual nodes are introduced to represent leakage points, and specific positions and leakage flow of the virtual nodes are determined by the aid of genetic algorithm optimization; accordingly, leakage is positioned and quantified. Then sequential manual troubleshooting and re-checking is performed. The pipe network leak detecting method in combination with resistance identification is applicable to the field of pipe network leak detection.

Owner:HARBIN INST OF TECH

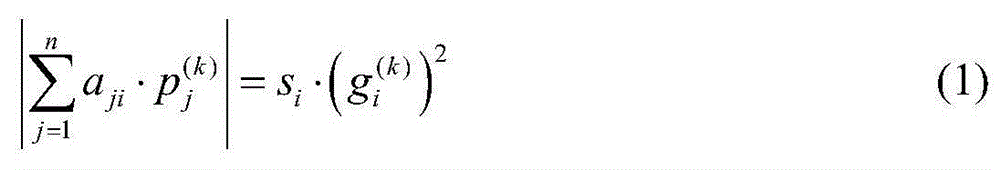

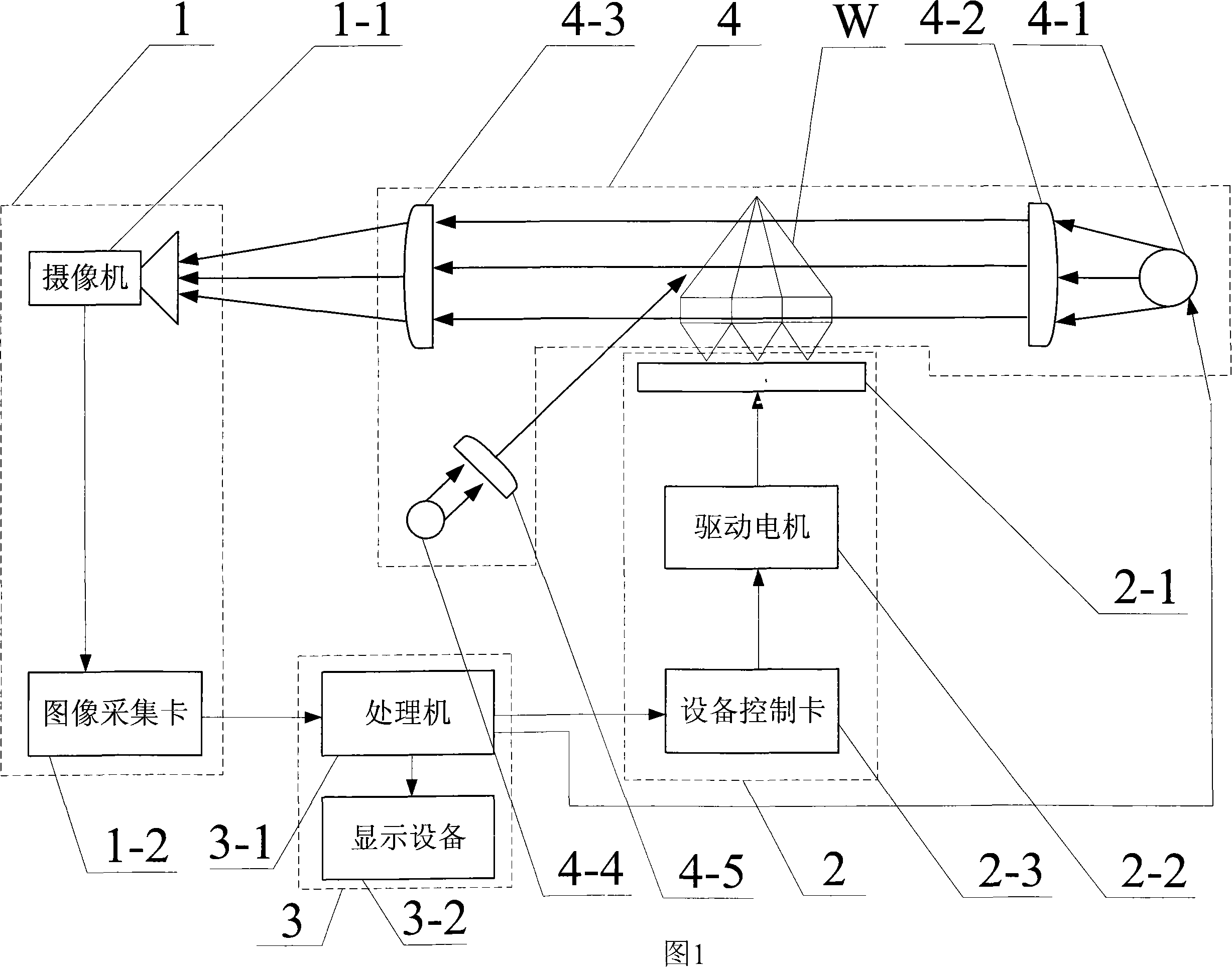

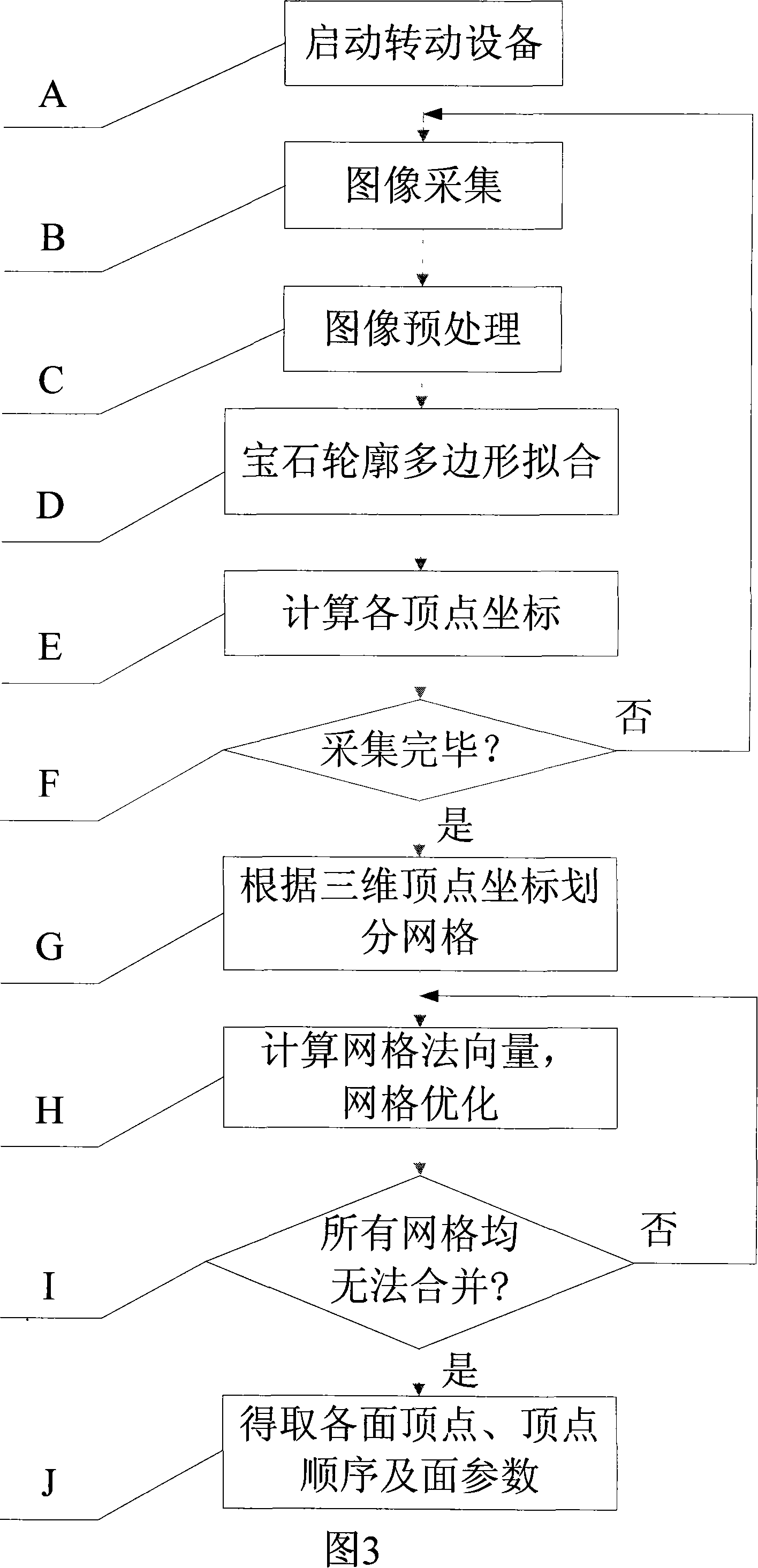

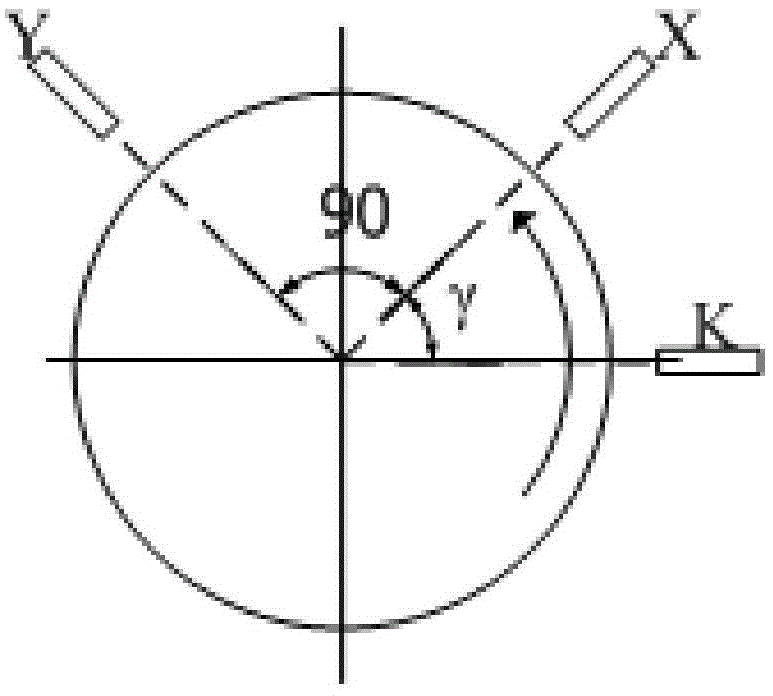

Device and method for gem three-dimensional blank reconstruction design based on machine vision

InactiveCN101118570AShort detection timeEasy to measureUsing optical meansImage data processing detailsLight equipmentMachine vision

A device and a method for reconstruction designing of the precious stone three-dimensional blank based on mechanical vision relates to a device and a method for reconstruction cutting work designing of the precious stone three-dimensional blank based on mechanical vision method, so as to solve the problems that the blank reconstruction device of the existing precious stone is complicated in structure and expensive in cost; as well as the designing method exists the problems that the designing method cannot support automatic designing, the manual design parameter process is fussy and wastes a long time, the experience of the designer is depended on very much, and the best design is very difficult to achieve. The signal output terminal of the picture collection equipment of the present invention is connected with the signal input terminal of the processing system, the control input terminal of the rotate platform equipment and the illumination equipment are connected with the control output terminal of the processing system, the output light of the illumination equipment supplies the input terminal of the picture collection equipment. The method and the step of the present invention is as follows: step one, start; step two, blank reconstruction; step three, cutting work designing; step four, three-dimensional modeling. The present invention has the advantages that the testing time is short, the cutting work designing is flexible and the cost performance is high, and is convenient for users to purchase and apply.

Owner:许焱 +3

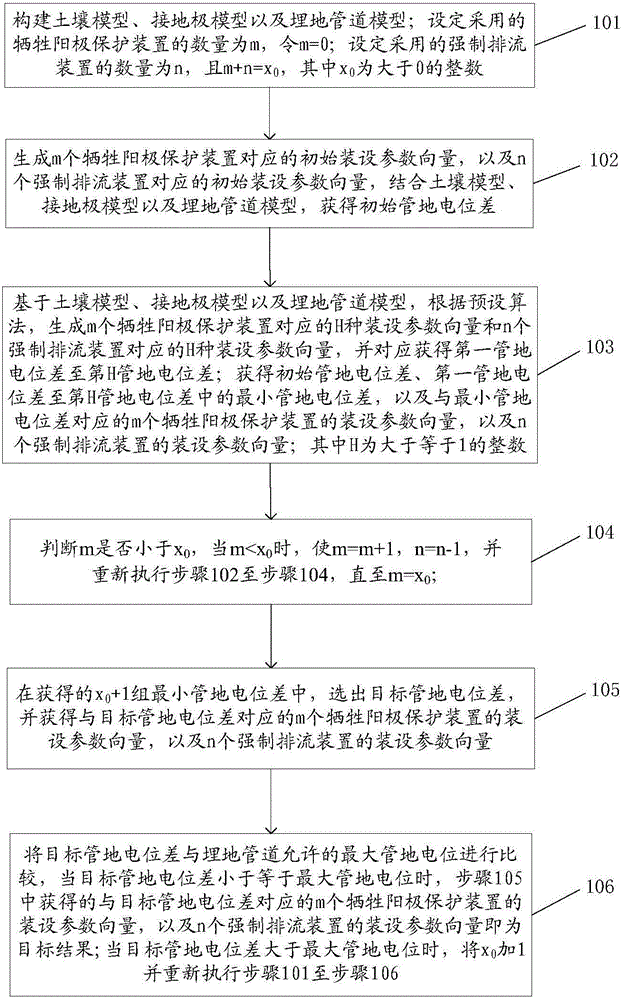

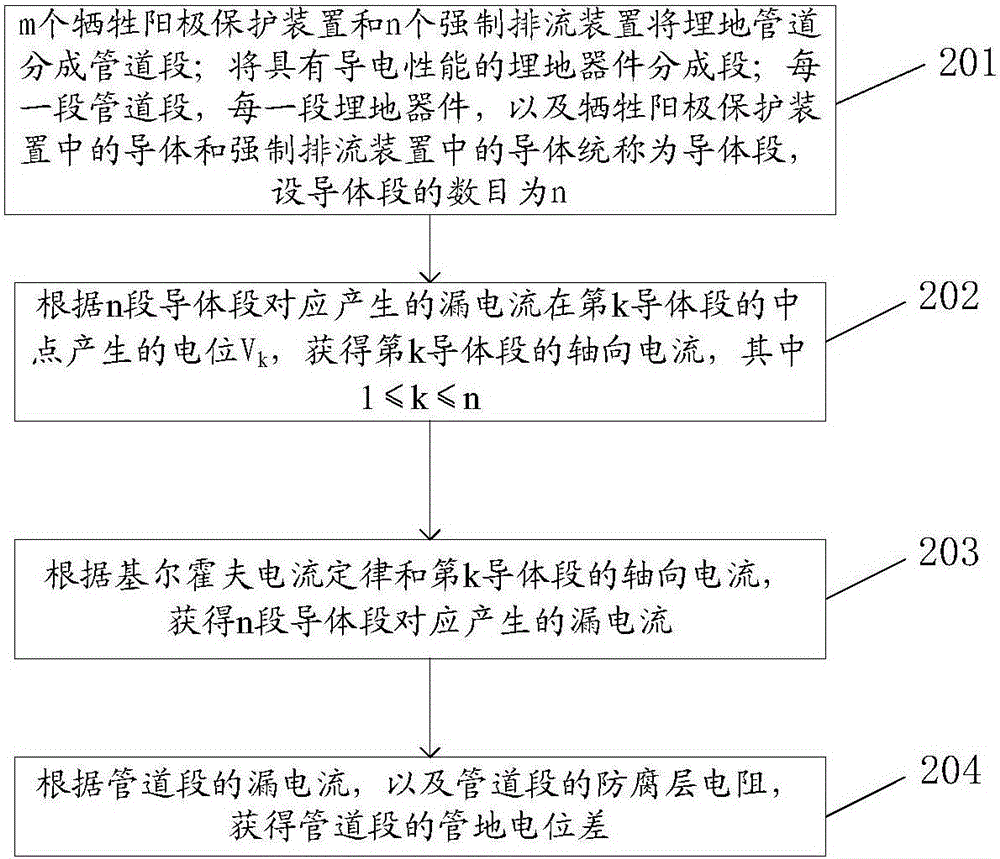

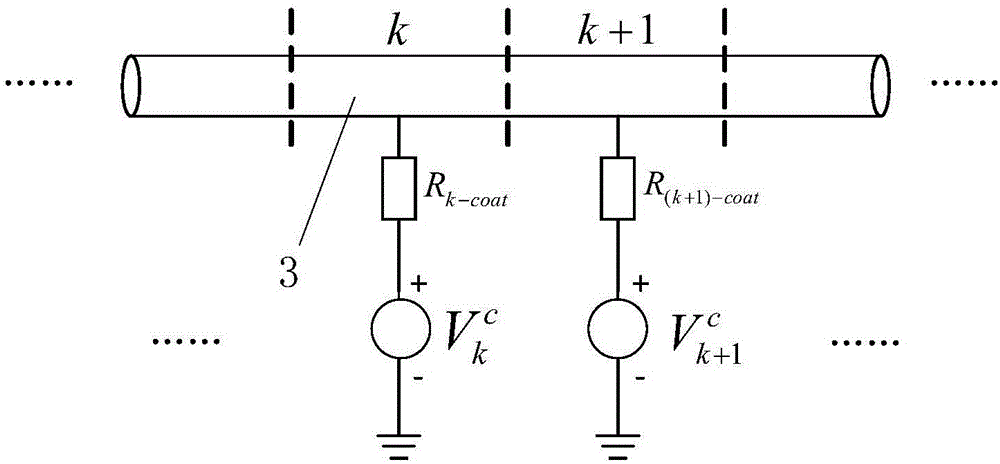

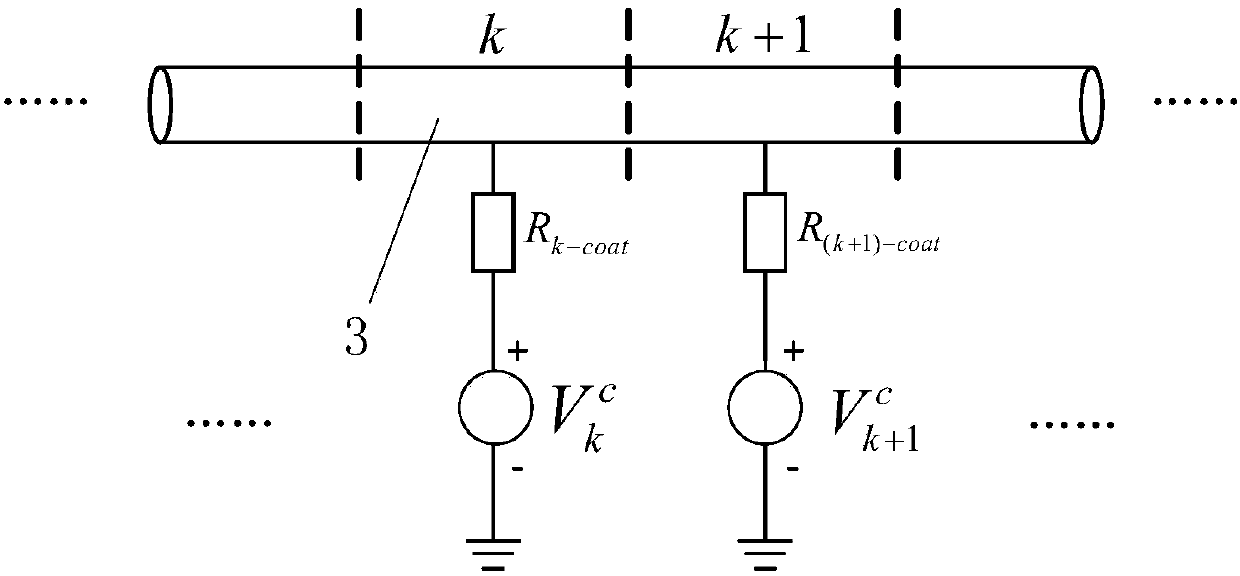

Buried pipeline cathode protection method and system

The invention discloses a buried pipeline cathode protection method and system, relates to the technical field of buried pipeline protection, and aims at solving the problems that a method for conducting cathode protection on a buried pipeline according to the experience is low in accuracy, and standard operation procedures are lacked. The buried pipeline cathode protection method comprises the steps that the ground potential difference of an initial pipe and the ground potential differences from a first pipe to an nth pipe are obtained; the ground potential difference of a target pipe and a corresponding installation parameter vector are obtained; then, the ground potential difference of the target pipe and the allowed maximum pipe ground potential of the buried pipeline are compared, and when conditions are met, the obtained installation parameter vector corresponding to the ground potential difference of the target pipe is a target result; or otherwise, the number of anodic sacrifice protection devices and the number of forced drainage devices are adjusted till the conditions are met. The buried pipeline cathode protection method is used for optimal arrangement of buried pipeline cathode protection devices.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

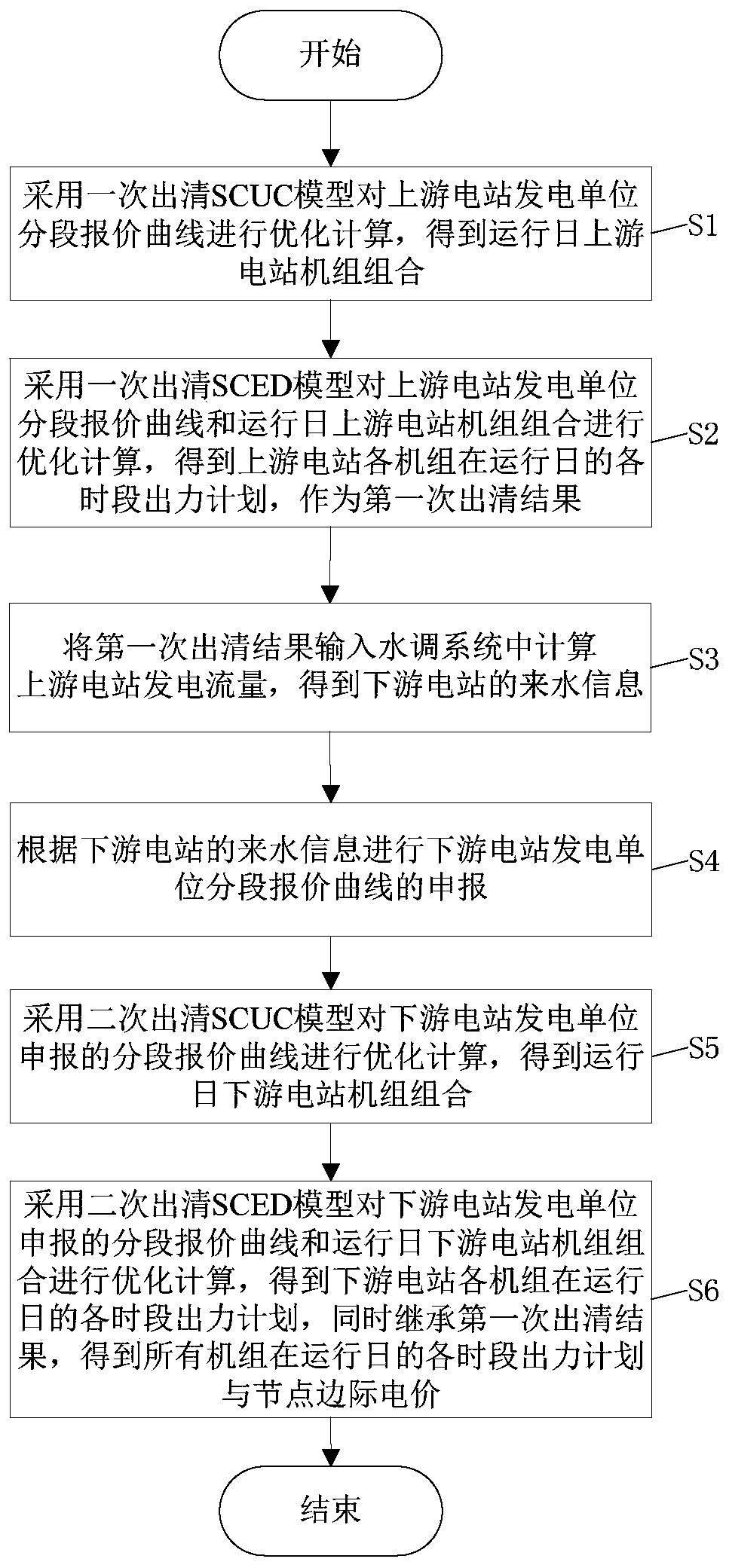

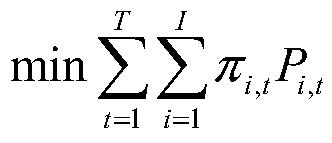

Basin cascade upstream and downstream power station participation electric power spot market secondary clearing method

ActiveCN110555590AFull participationEnsure market transaction balanceMarket predictionsResourcesElectricityPower station

The invention discloses a basin cascade upstream and downstream power station participation electric power spot market secondary clearing method. Compared with the prior art, the agent mechanism and the water and electricity benefit compensation mechanism are provided; the secondary clearing mode can ensure that the cascade hydropower upstream and downstream power stations have sufficient participation degree in the spot market as power generators, the bid winning amount and the actual distribution amount of the downstream power stations are kept consistent without joint bidding, and market transaction balance is ensured.

Owner:YUNNAN POWER GRID

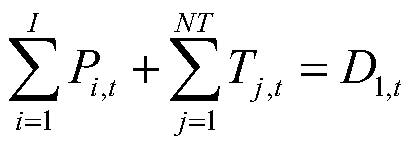

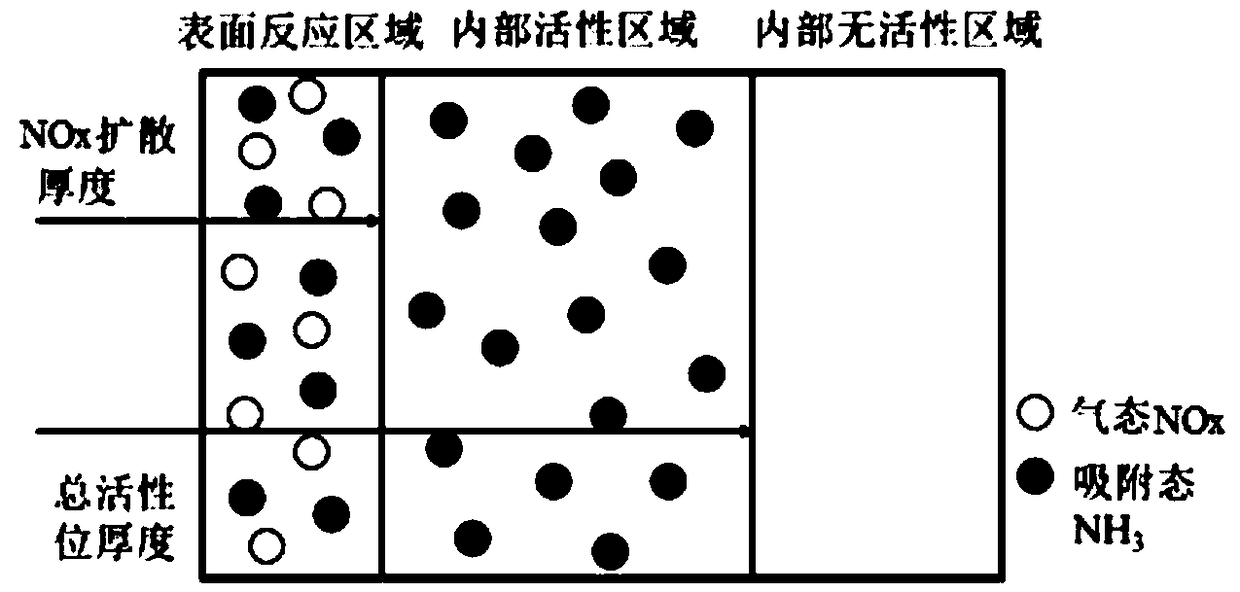

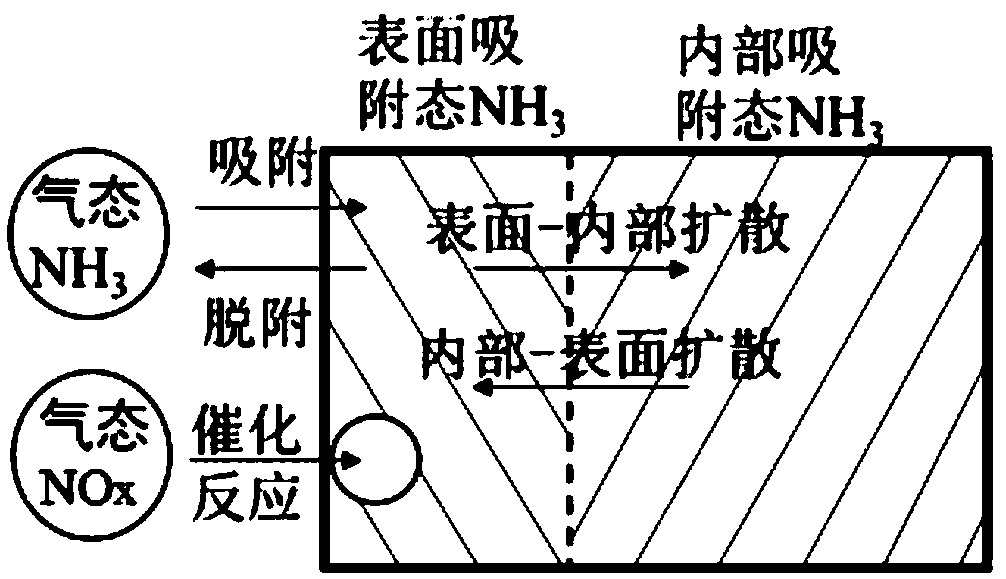

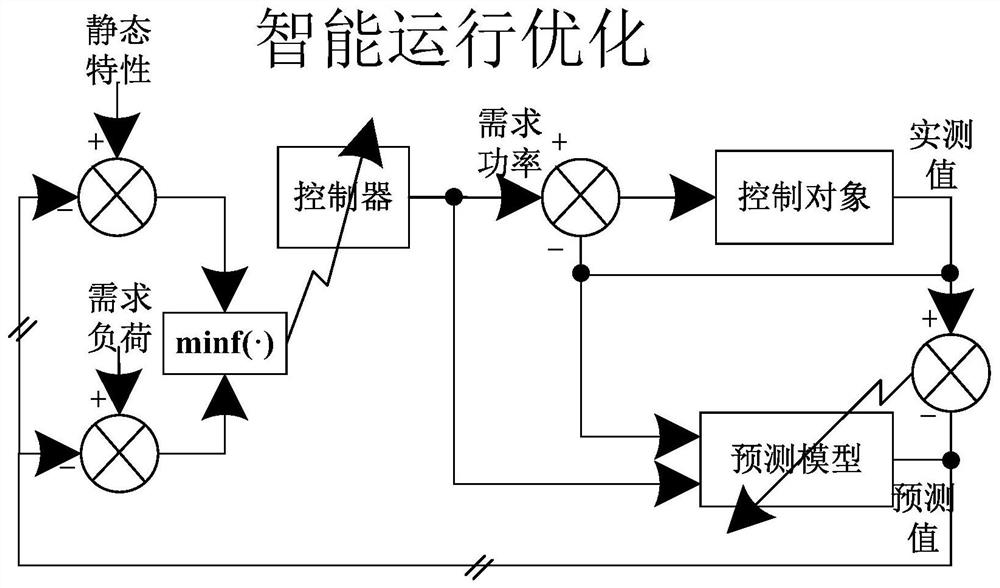

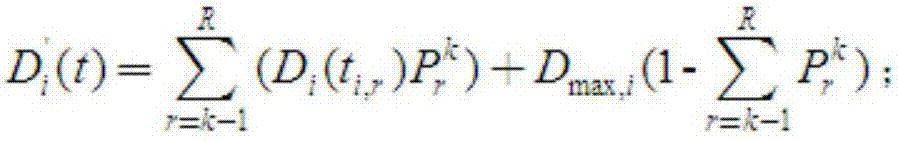

Power station SCR (selective catalytic reduction) ammonia spraying control method based on denitration reaction kinetic equation

ActiveCN109304087APredicted concentrationInhibition of concentration fluctuationsDispersed particle separationAdaptive controlAutomatic controlPower station

The invention belongs to the field of thermotechnical automatic control, and particularly discloses a power station SCR (selective catalytic reduction) ammonia spraying control method based on a denitration reaction kinetic equation. The method specifically comprises the following steps: equally dividing an SCR system to n reaction areas and building a model, determining an unknown parameter of the model, so as to obtain a practical reaction model, forecasting for p moments in future according to a working condition parameter at a current moment, and through optimizing a performance index, acquiring an optimal ammonia spraying quantity change rate, after executing an ammonia spraying quantity in the next moment, repeatedly performing the above steps, so as to realize rolling optimization.According to the method, through building the reaction model and optimizing the performance index, the on-line rolling optimization to an ammonia spraying flow is realized, thereby the problems of great inertia and uncertainty of the SCR system are solved, the precision, speed and stable capacity of SCR ammonia spraying control are improved, and the problems that NOx discharge exceeds a standard or ammonia escapes are effectively avoided, and the method is particularly suitable for a set with frequently fluctuant load.

Owner:HUAZHONG UNIV OF SCI & TECH

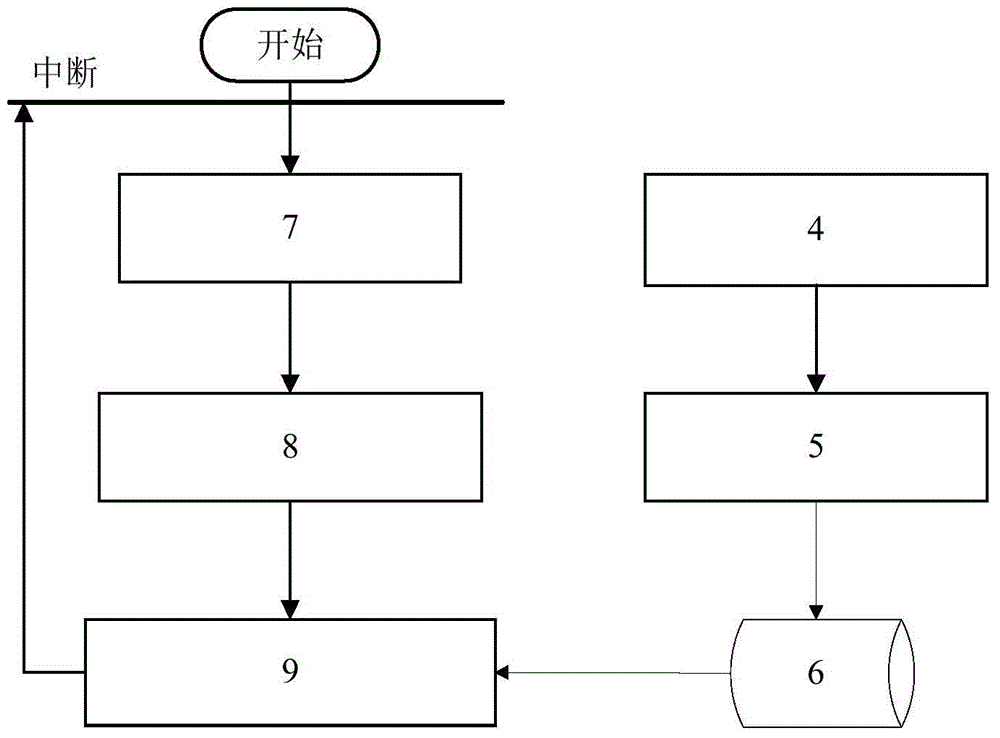

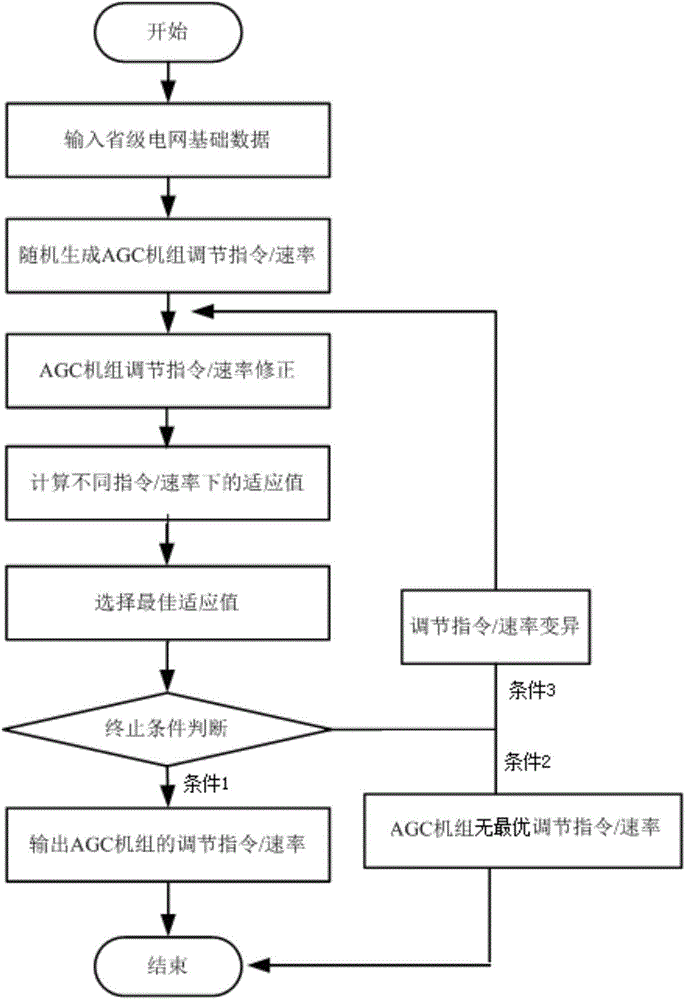

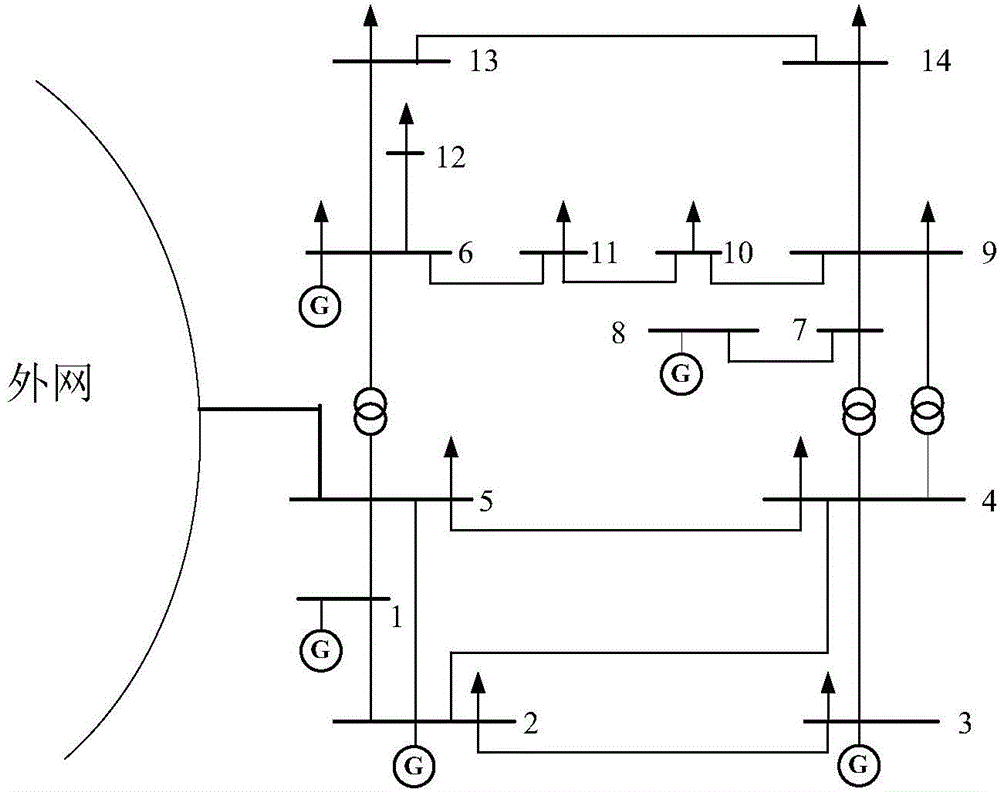

Circuit security constraint-considering provincial grid AGC (automatic generation control) unit dynamic optimization scheduling method

InactiveCN104682392AReduce control errorIncrease FM power onceAc networks with different sources same frequencyControl variableAutomatic gain control

The invention discloses a circuit security constraint-considering provincial grid AGC (automatic generation control) unit dynamic optimization scheduling method. The method comprises the following steps of firstly, inputting provincial grid basic data, i.e., acquiring a network structure and related data of a provincial grid, acquiring AGC related data, and setting an evolutionary programming parameter; secondly, randomly generating an initial population of control variables (a regulating instruction and a regulating rate), and performing adaptive mutation operation on antibodies in the population; thirdly, correcting the antibodies according to a regulating instruction constraint, a regulating rate constraint and the minimum continuous climbing time constraint, and comprehensively considering target functions of a CPS1 (control performance standard) index and AGC regulation ancillary service charge, and inequality constraints of tie-line power deviation, system frequency deviation, CPS indexes, unit output and circuit safety, and calculating the adaptive value of each antibody in the population; finally, on the basis of adaptability, evaluating and selecting the antibodies, and performing termination judgment to realize decision on the regulating instruction and the regulating rate of an AGC unit.

Owner:CHONGQING UNIV

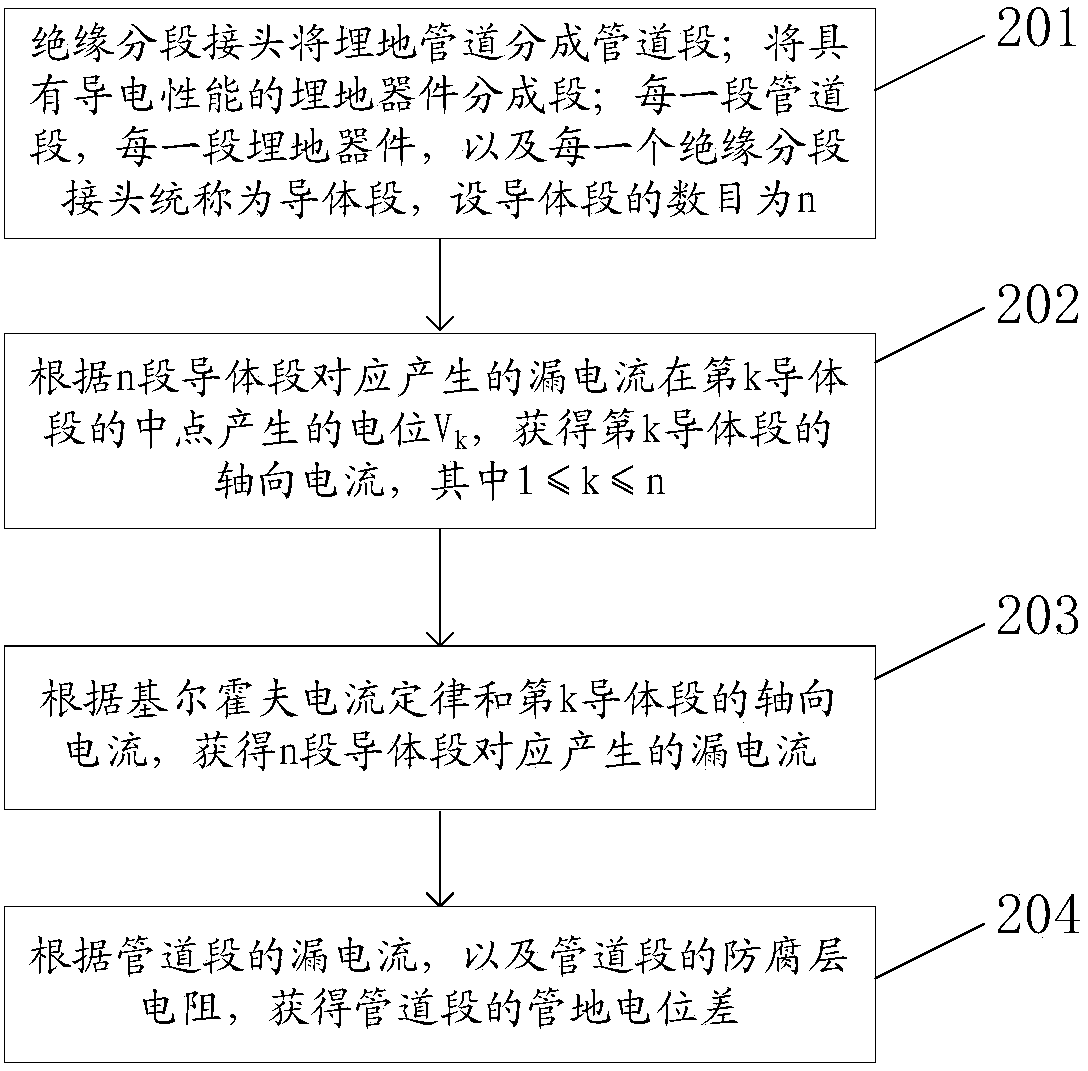

Method and apparatus for arranging buried pipeline in sectional insulation manner

ActiveCN105975768AOptimizing Process ScienceThe optimization result is accurateSpecial data processing applicationsInformaticsEngineeringPotential difference

The invention discloses a method and an apparatus for arranging a buried pipeline in a sectional insulation manner, relates to the technical field of buried pipeline protection, and aims to solve the problems of low accuracy and lack of a standardized operation process for a method for performing sectional insulation design on the buried pipeline according to experience. The method for arranging the buried pipeline in the sectional insulation manner comprises the steps of obtaining an initial pipeline-soil potential difference and first to Hth pipeline-soil potential differences; obtaining a minimum pipeline-soil potential difference and a corresponding position vector; comparing the minimum pipeline-soil potential difference with a maximum pipeline-soil potential allowed by the buried pipeline, and when a condition is met, taking the obtained position vector corresponding to the minimum pipeline-soil potential difference as a target result; or otherwise, adding 1 to the number of insulated sectional connectors and obtaining the minimum pipeline-soil potential difference again until the condition is met. The method for arranging the buried pipeline in the sectional insulation manner, provided by the invention, is used for optimizing the arrangement of the buried pipeline in the sectional insulation manner.

Owner:CHINA SOUTH POWER GRID ELECTRIC POWER RES INST +1

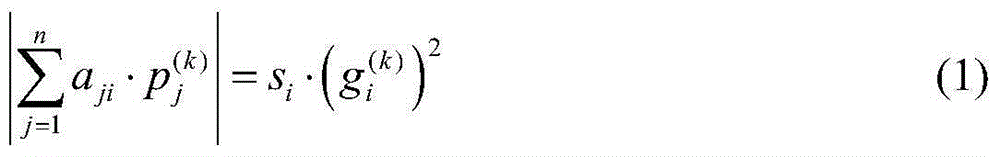

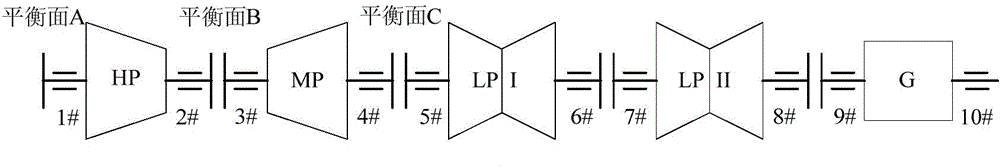

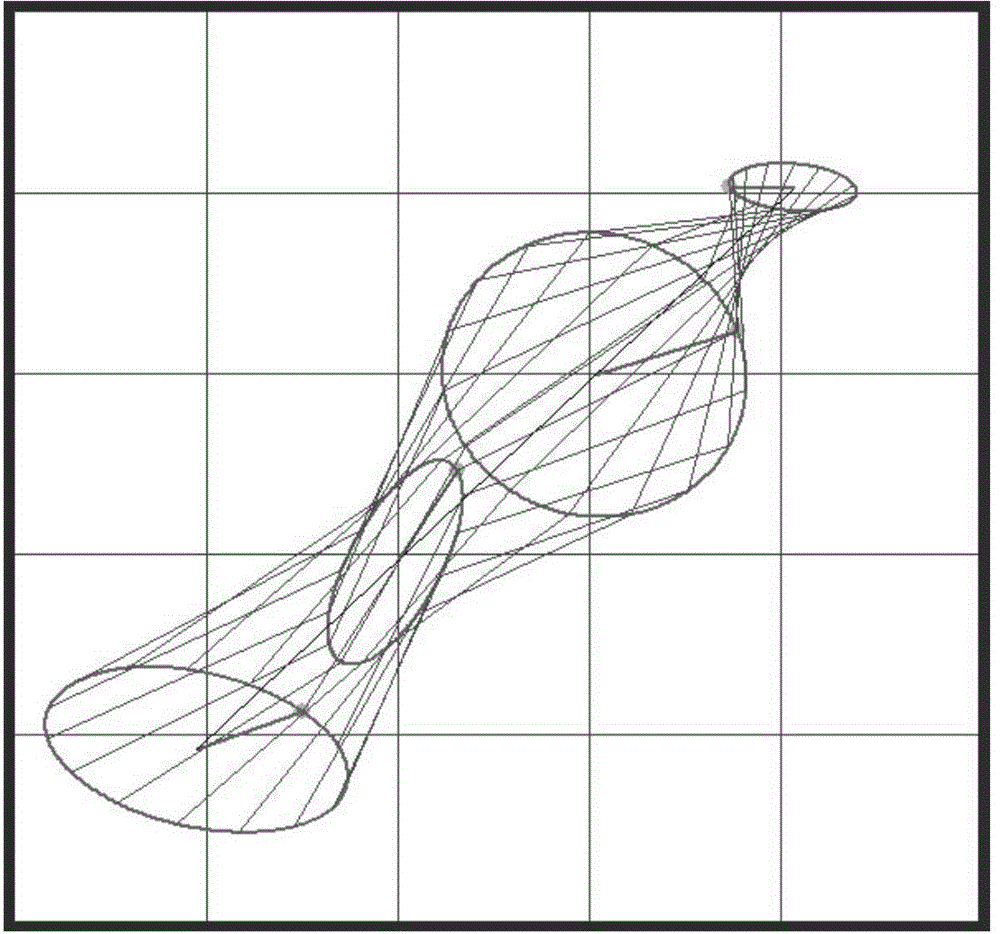

Shafting dynamic balance multi-target optimization method based on differential search algorithm

ActiveCN104062072AImprove balanceNot easy to fall into local optimumStatic/dynamic balance measurementDynamic balanceDifferential search algorithm

The invention discloses a shafting dynamic balance multi-target optimization method based on a differential search algorithm. The method is characterized by utilizing the accuracy, stability and rapidness features of the DS (differential search) algorithm to the multi-target optimization of rotation mechanical shafting balance. The method utilizes three targets of the residual oscillation quadratic sum, the residual oscillation maximum value and the difference of the residual oscillation maximum value and residual oscillation minimum value to weigh the machine residual oscillation state; the multi-target optimization is carried out through the DS algorithm; and the quality of the balance effect is comprehensively evaluated, and the defect that with the influence factor method in the past, only the residual oscillation quadratic sum minimum is served as a single balance target in the dynamic balance is solved.

Owner:XI AN JIAOTONG UNIV

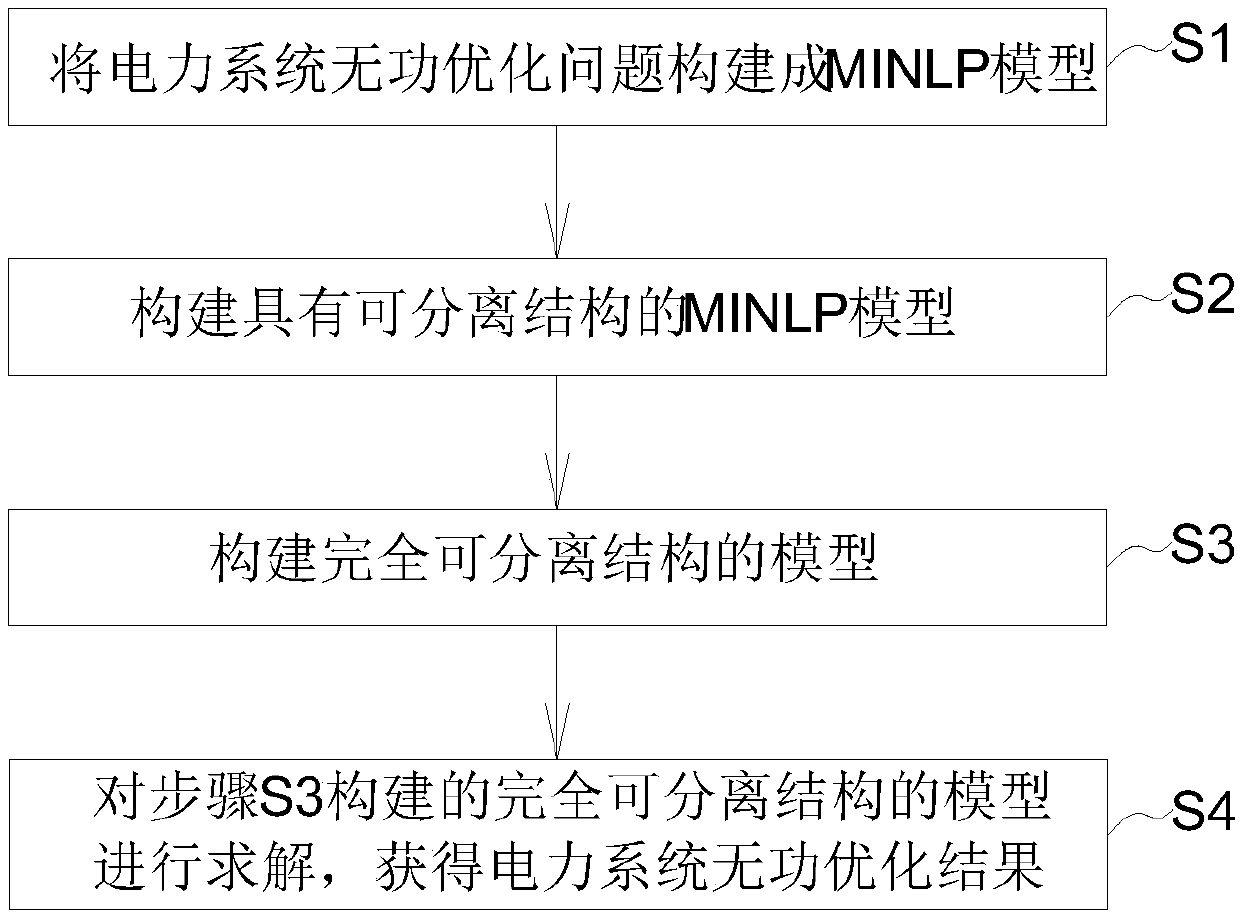

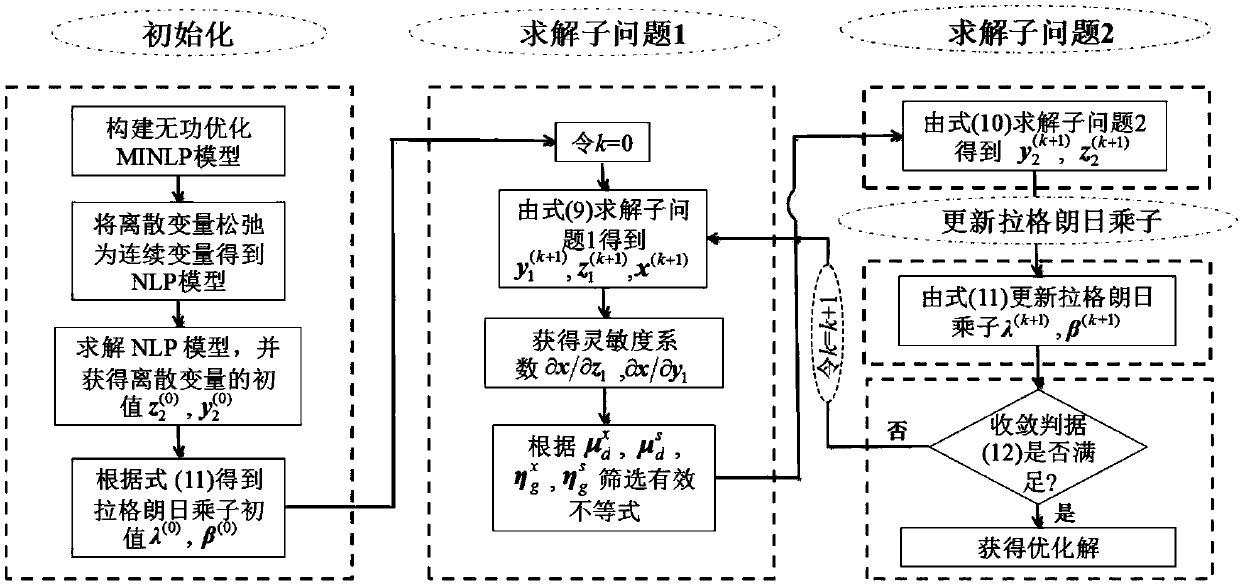

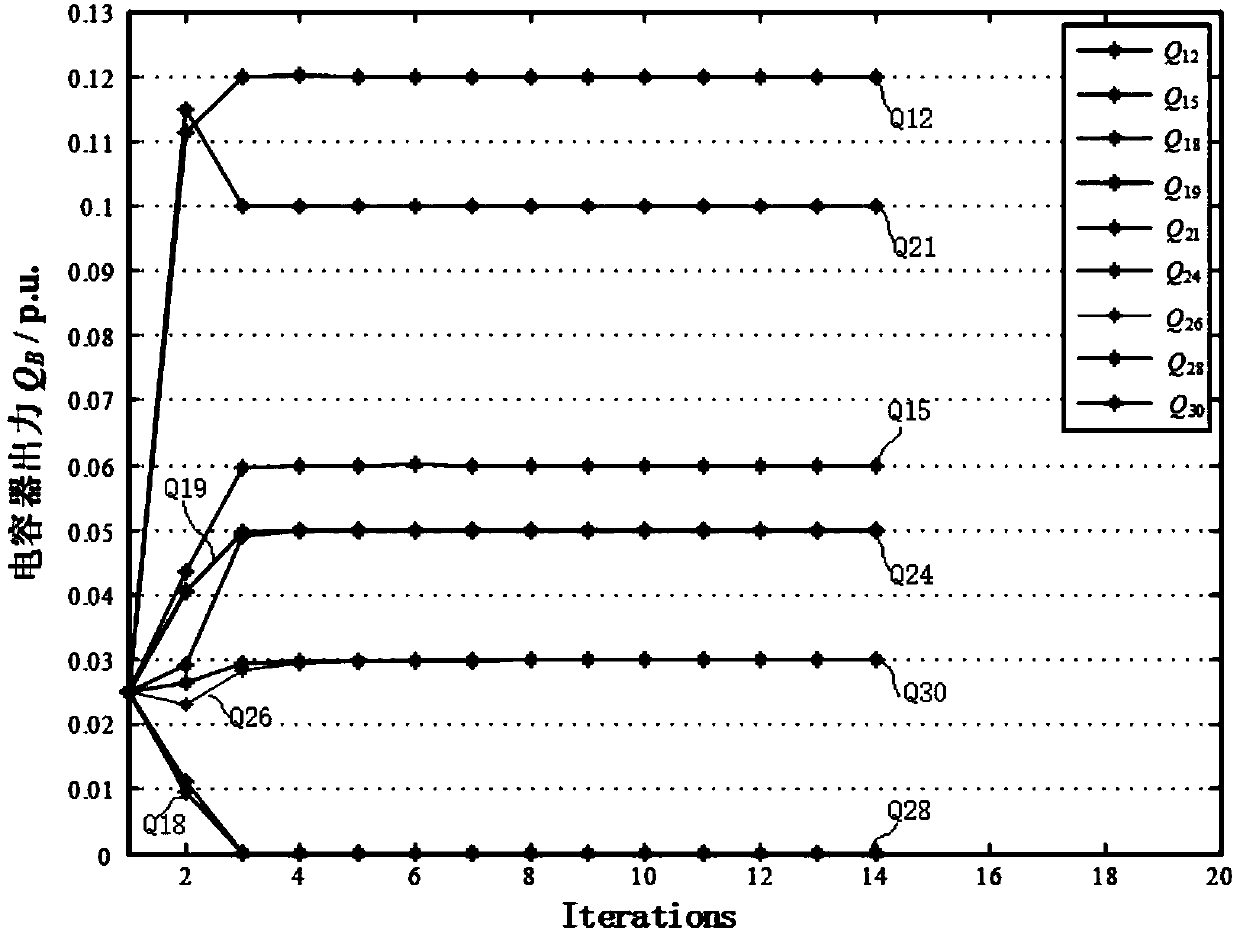

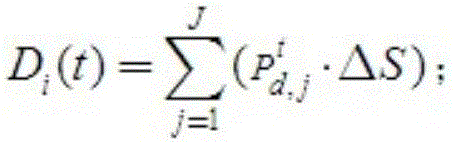

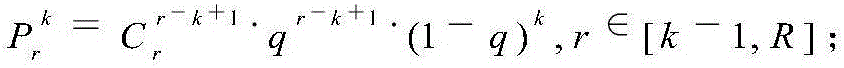

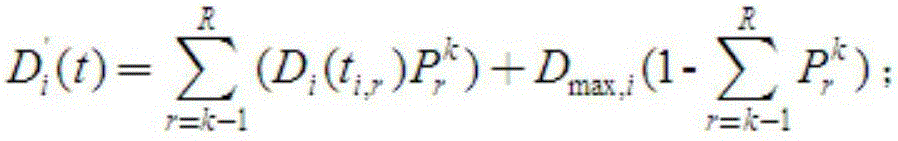

Decomposition method of solving discrete control-containing electric power system reactive optimization

ActiveCN107591815AAdd Consistency ConstraintsWide applicabilityAc network voltage adjustmentReactive power compensationLow voltageElectric power system

The present invention discloses a decomposition method of solving discrete control-containing electric power system reactive optimization. The method comprises the following steps of S1 constructing an electric power system reactive optimization problem into a mixed-integer nonlinear programming (MINLP) model; S2 constructing the MINLP model having a separable structure; S3 constructing a model ofa totally separable structure; S4 solving the model of the totally separable structure to obtain an electric power system reactive optimization result. According to the method of the present invention, firstly the electric power system reactive optimization problem is constructed into the MINLP model, the model does not have the special requirements for a grid structure, is suitable for a mediumand low voltage power distribution network having the radiativity, is also suitable for a complex high voltage large grid and is wide in applicability; then by copying the discrete control variables,allowing one discrete control variable in the model to change continuously, at the same time, increasing the consistency constraint between the discrete control variables and the discrete control variable changing continuously, the original problem has the separable structure besides the consistency constraint, and the optimization result can be obtained more rapidly and accurately.

Owner:SOUTH CHINA UNIV OF TECH

Method for optimizing site selection of gas detecting alarm instrument of oil refining device by considering conditional risk value

ActiveCN106055803AImprove detection efficiencyAvoid blindnessDesign optimisation/simulationSpecial data processing applicationsDependabilityObject function

The invention discloses a method for optimizing site selection of a gas detecting alarm instrument of an oil refining device by considering a conditional risk value. Quantitative presentation of a real-time risk of the oil refining device is realized based on a risk triple theory and a leakage site set, so that it is used as a quantitative index of an arrangement decision risk; then, minimization of the arrangement decision risk is used as an optimization object; an optimal conditional value risk and the number of detecting alarm instruments are used as constraint conditions; whether arranged alternative points of the alarm instruments are selected or not is used as a binary decision variable; a target function and a constraint function of an optimization model are defined; and a P-media model having the minimum decision risk and by considering the reliability, the voting logic and the conditional risk value is established. The method disclosed by the invention has the benefits that: when scheme optimization is carried out, the unavailable property and the failure condition of the detecting alarm instrument are sufficiently considered; the successful detection probability of the detecting alarm instrument is in a considered range; and thus, the optimization result is more accurate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

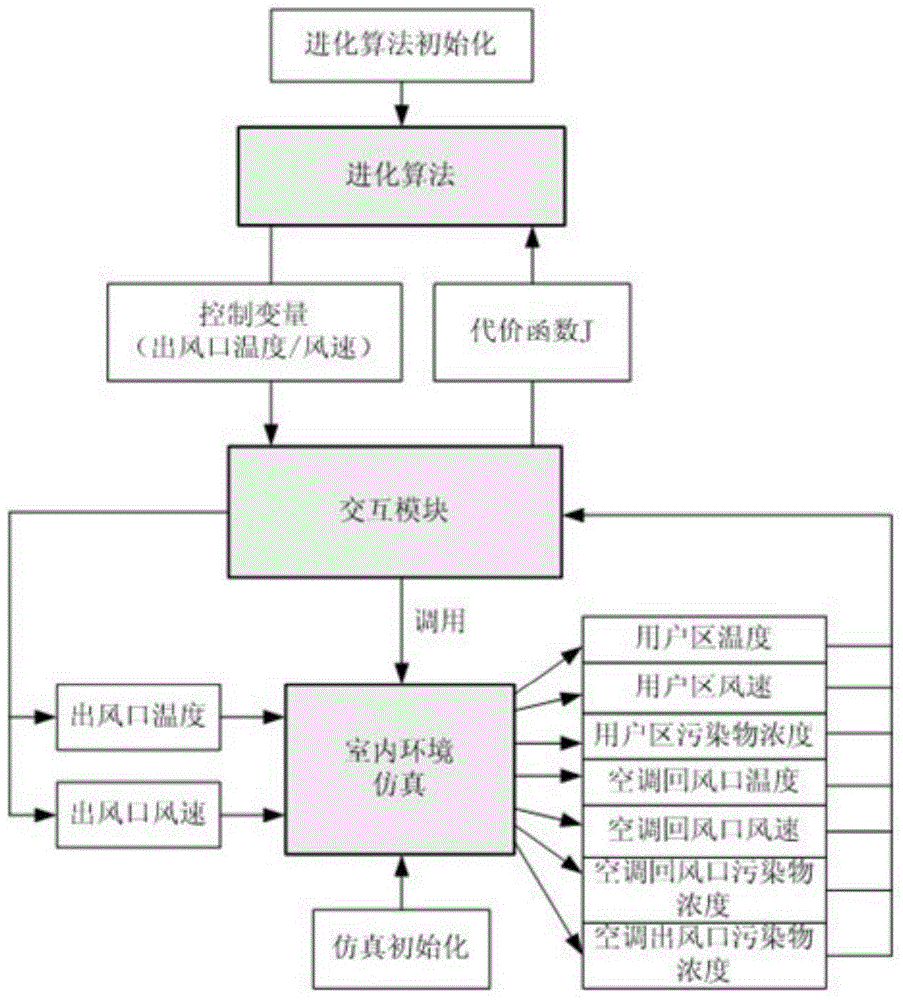

Interactive optimization method for improving internal environment of building

InactiveCN104572246AHigh precisionImprove optimization resultsSoftware simulation/interpretation/emulationData interfaceComputer science

The invention discloses an interactive optimization method for improving an internal environment of a building. The method comprises the steps of building an indoor environment simulation module based on software for calculating fluid mechanics, and configuring relevant data interfaces; building a data interaction module to realize data interaction between a simulation procedure and an optimization algorithm; building an optimization module based on an evolutionary algorithm, and searching for the optimal values of the air supply temperature and the speed of an HVAC (Heating Ventilation Air Conditioning) by applying the evolutionary algorithm so as to enable the internal environment of the building to be optimal and the energy consumption of the building to be minimal. According to the method provided by the invention, different modules are formed by integrating a plurality of software by using an environment simulation interface and scientific calculating software, therefore, the influence on environment parameters caused by space distribution can be fully considered by the optimization method; furthermore, compared with an existing optimization method for the environment of the building, the interactive optimization method provided by the invention has the characteristics of good universality, high precision, etc.

Owner:JIANGSU UNIV

Oil refining device gas detection alarm apparatus site selection arrangement method capable of considering multiple factors

ActiveCN106096104AImprove detection efficiencyAvoid blindnessSpecial data processing applicationsEngineeringSite selection

The invention discloses an oil refining device gas detection alarm apparatus site selection arrangement method capable of considering multiple factors. The real-time risk quantitative characterization of an oil refining device is realized on the basis of a risk triple theory and a leakage scene set and is used as an arrangement decision risk quantitative index. Then, arrangement decision risk minimum is taken as an optimization objective, the amount of detection alarm apparatuses is taken as a constraint condition, whether an alarm apparatus arrangement alternative point is selected or not is taken as a binary decision variable to define a target function and a constraint function of an optimization model, and a MRPMP-UV (Minimal Risk P-median Problems Including Unavailability and Voting Affects) is esablished. The method has the following beneficial effects that the unavailability and invalidation situations of the alarm apparatus are fully considered when scheme optimization is carried out, the successful detection probability of the detection alarm apparatus is brought into a consideration range, and therefore, an optimization result is accurate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

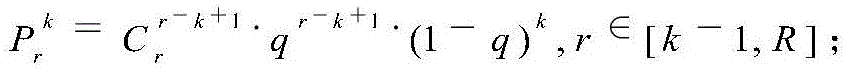

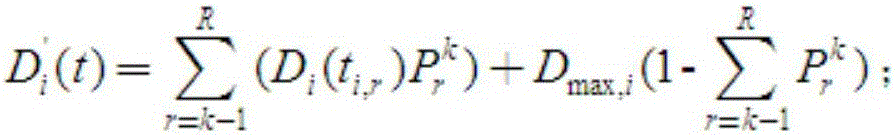

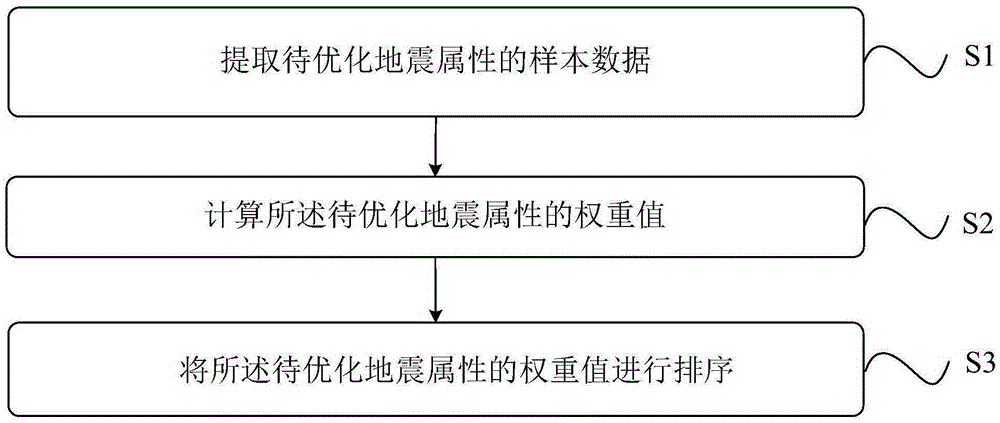

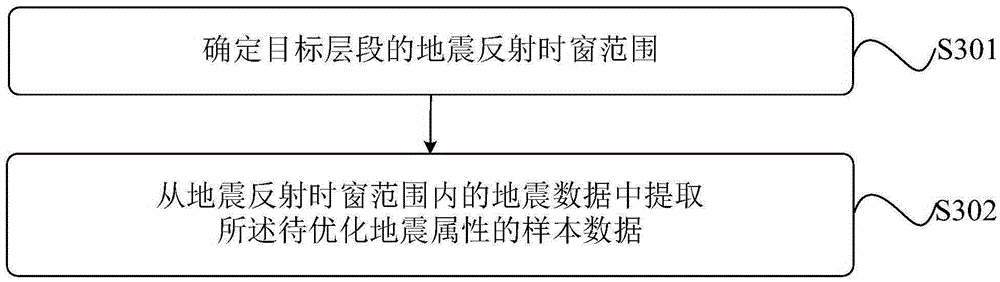

Seismic attribute optimization method and device

ActiveCN105277979AOptimizing Seismic PropertiesSeismic Attributes PreservedSeismic signal processingSeismic attributeWeight value

The invention provides a seismic attribute optimization method and device. The method comprises the steps that the sample data of seismic attributes to be optimized in seismic data are extracted; according to the sample data, the weight values of the seismic attributes to be optimized are calculated; and the weight values of the seismic attributes to be optimized are sorted. Quantitative analysis is carried out on the extracted weight data of the seismic attributes to be optimized. A mathematical method is used to calculate the weight values of the seismic attributes to be optimized. According to the size of the weight values, the seismic attributes with small weight values are removed. The seismic attributes with large weight values are kept as optimized seismic attributes. Compared with an expertise optimization method, a mathematical optimization method has more adequate theoretical proof, a more rigorous derivation process and a more accurate optimization result.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

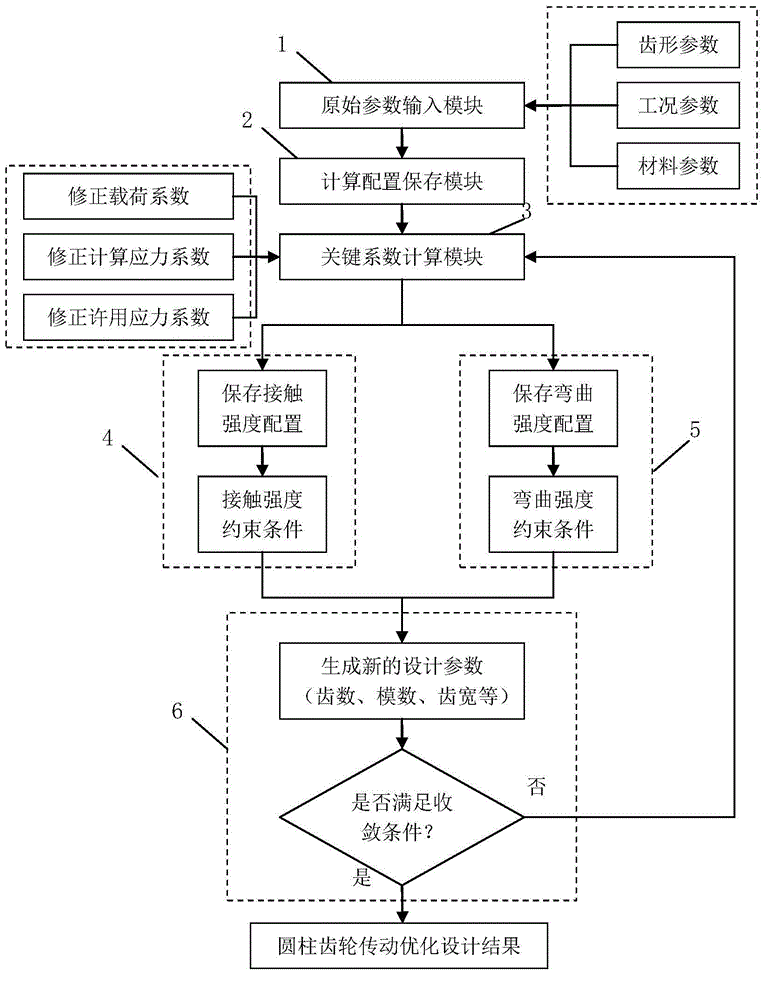

Accurate constraint condition-based cylindrical gearing optimization design method and accurate constraint condition-based cylindrical gearing CAD (computer-aided design) optimization design system

ActiveCN104408239AThe optimization result is accurateImprove design efficiencyPortable liftingSpecial data processing applicationsDesign systemsEngineering

The invention provides an accurate constraint condition-based cylindrical gearing optimization design method and an accurate constraint condition-based cylindrical gearing CAD (computer-aided design) optimization design system, and belongs to the field of the optimization design method and the CAD optimization design system; the invention aims at overcoming the abuse that all key coefficients are processed as constants in the existing gear optimization method, and therefore the accuracy of an optimization result is effectively improved. The accurate constraint condition-based cylindrical gearing optimization design method comprises the following steps: inputting original parameters, saving computing configuration, computing key coefficients, reconstructing a tooth surface contact strength constraint condition, reconstructing a teeth bending strength constraint condition and optimizing iteration; the accurate constraint condition-based cylindrical gearing CAD (computer-aided design) optimization design system comprises the following modules: an original parameter input module, a computing configuration saving module, a key coefficient computing module, a tooth surface contact strength constraint condition reconstruction module, a teeth bending strength constraint condition reconstruction module and an iteration optimization module.

Owner:SHANDONG UNIV OF SCI & TECH

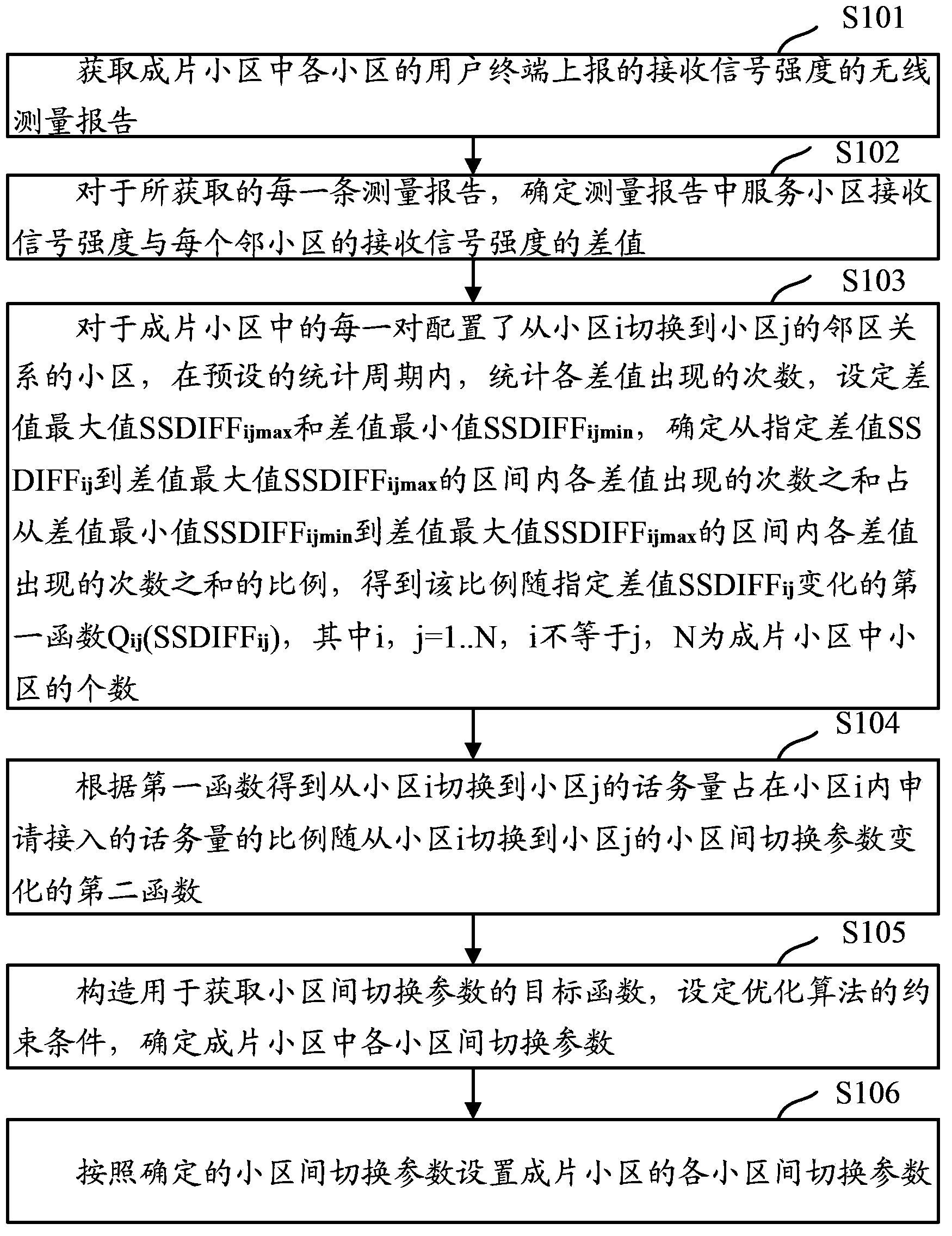

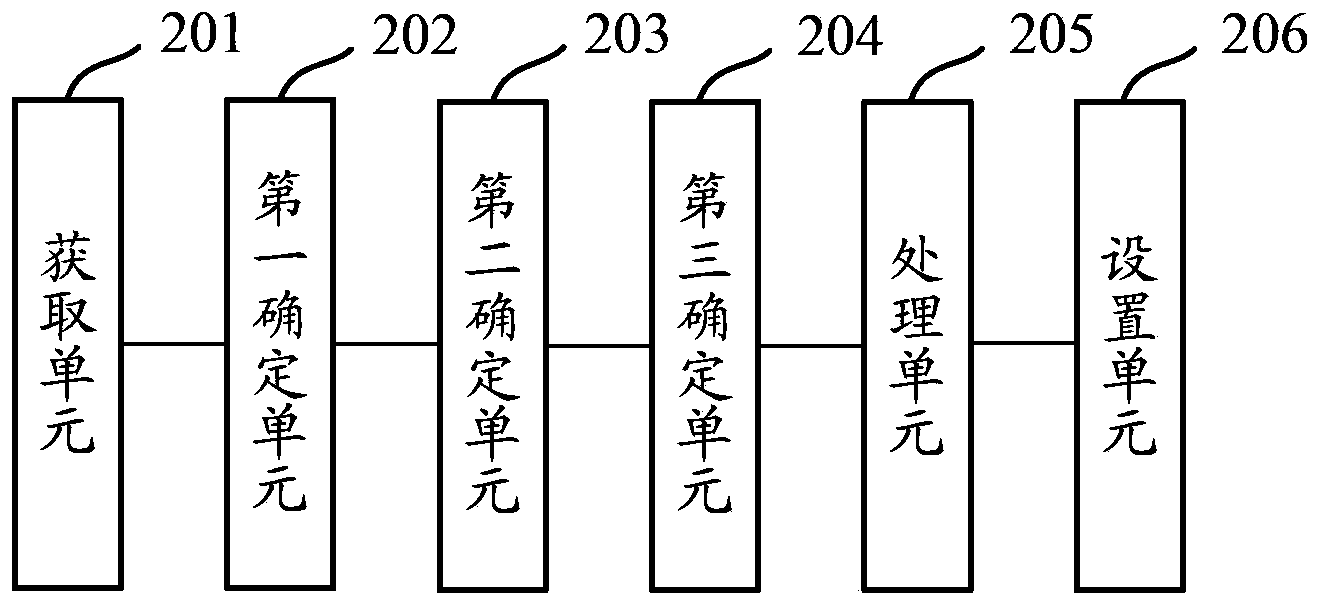

Method, device and system for obtaining switching parameters among cells

ActiveCN104219707AScience of Optimization MethodsThe optimization result is accurateWireless communicationWireless measurementTelecommunications

The invention discloses a method, device and system for obtaining switching parameters among cells, and the problem that the overall network capacity of a cell cluster cannot be optimized within short time by using a manual method in the prior art is solved. The method comprises the following steps: obtaining a wireless measurement report about received signal strength reported by a user terminal of a cell in the cell cluster ; determining a difference value between the received signal strength of a service cell in the measurement report and the received signal strength of each adjacent cell; further obtaining a function of telephone traffic changing along with an inter-cell switching parameter when the service cell is switched to the adjacent cell; determining the inter-cell switching parameter for maximizing the telephone traffic summation accessed by the cells in the cell cluster through a target optimization algorithm; and setting the inter-cell switching parameter of the cell cluster according to the determined inter-cell switching parameter.

Owner:CHINA MOBILE GROUP DESIGN INST +1

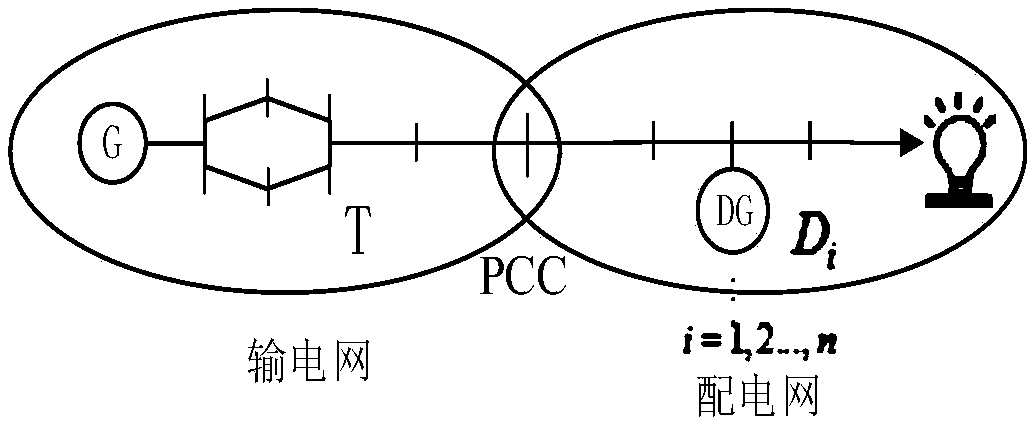

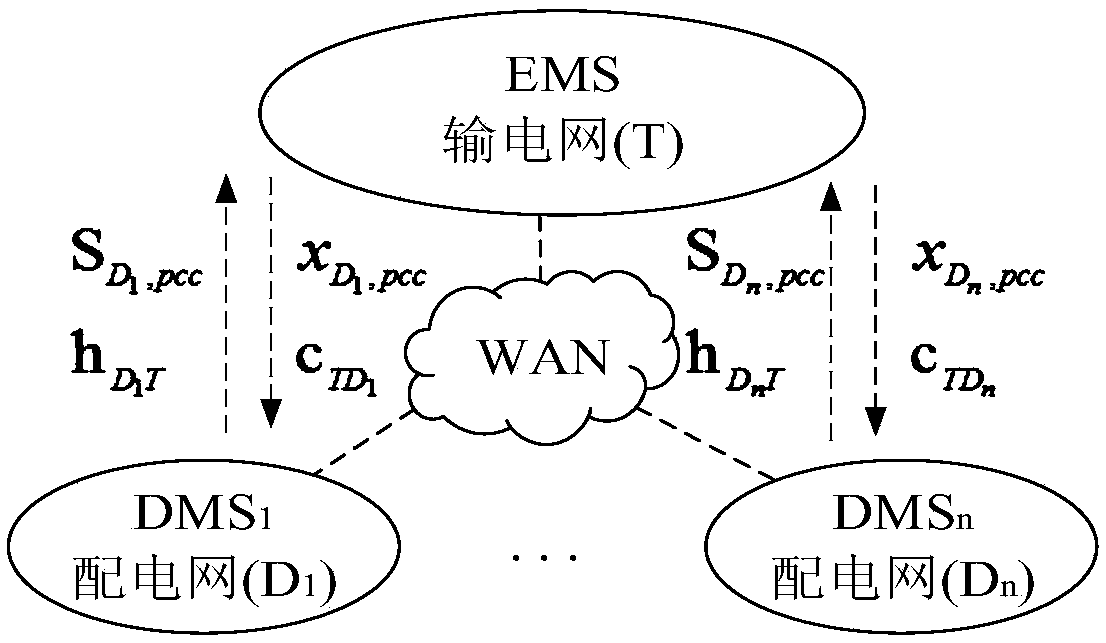

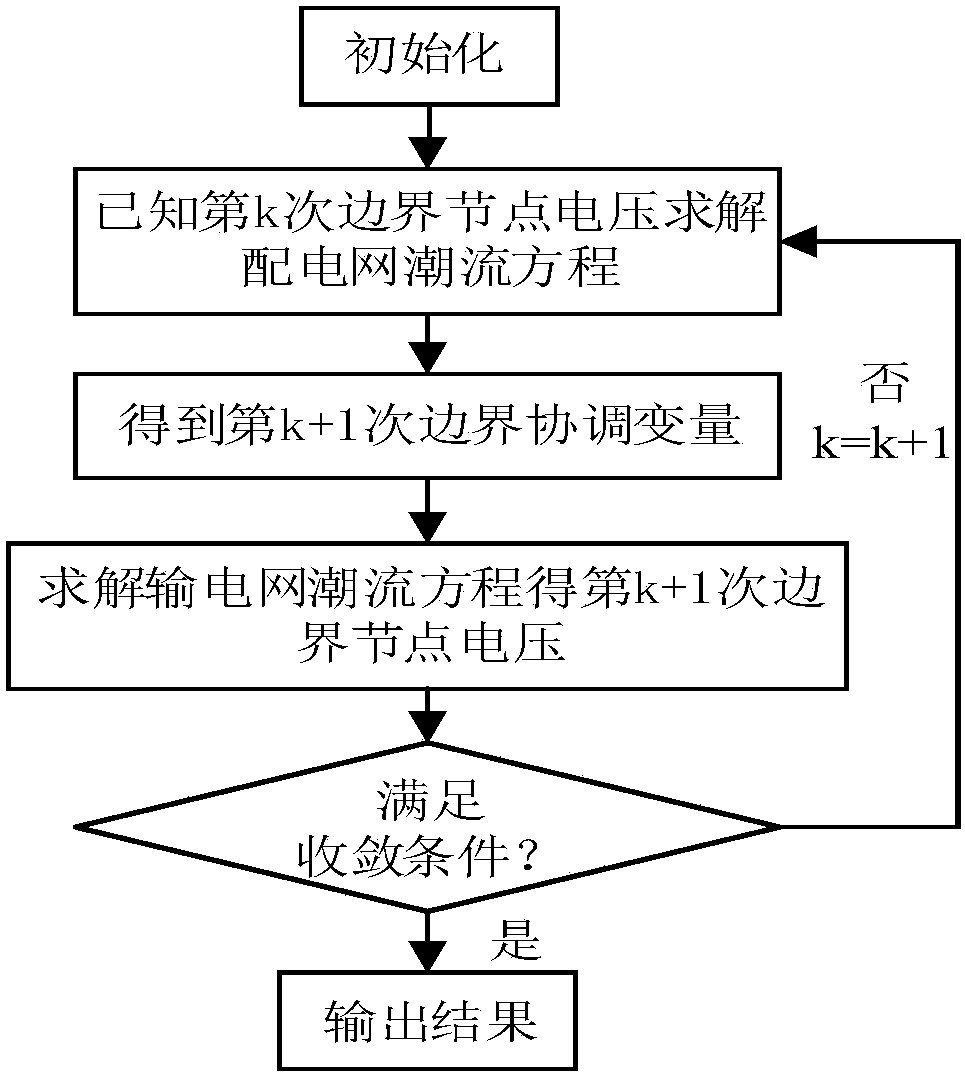

Distribution calculation method for stable control on global voltage of power transmission/distribution grid

InactiveCN108536917AStability controlFlexible controlForecastingSingle network parallel feeding arrangementsElectric power transmissionStabilization control

The invention discloses a distribution calculation method for stable control on a global voltage of a power transmission / distribution grid. Aiming at a power transmission / distribution grid of a multi-stage scheduling center layered management structure, the method has a target of minimum total control cost of the power transmission / distribution grid, and boundary influence factors are introduced to decompose global optimization problems into sub-problems of stable control on voltages of a power transmission grid and different power distribution grids; by continuously switching voltages, equivalent value power and the boundary influence factors at boundary connecting points of the power transmission / distribution grid, distribution calculation of global control can be achieved; since the boundary influence factors need to be constructed by antithesis multipliers in different sub-problem optimization solutions, the sub-problems of stable control of the power transmission / distribution gridneed to be solved by using antithesis multiplier type optimization control algorithms. Equivalent value models of power transmission grids or power distribution grids do not need to be established, and stable voltage control distribution calculation of power transmission / distribution grids can be achieved by only exchanging a small amount of boundary node information.

Owner:HOHAI UNIV

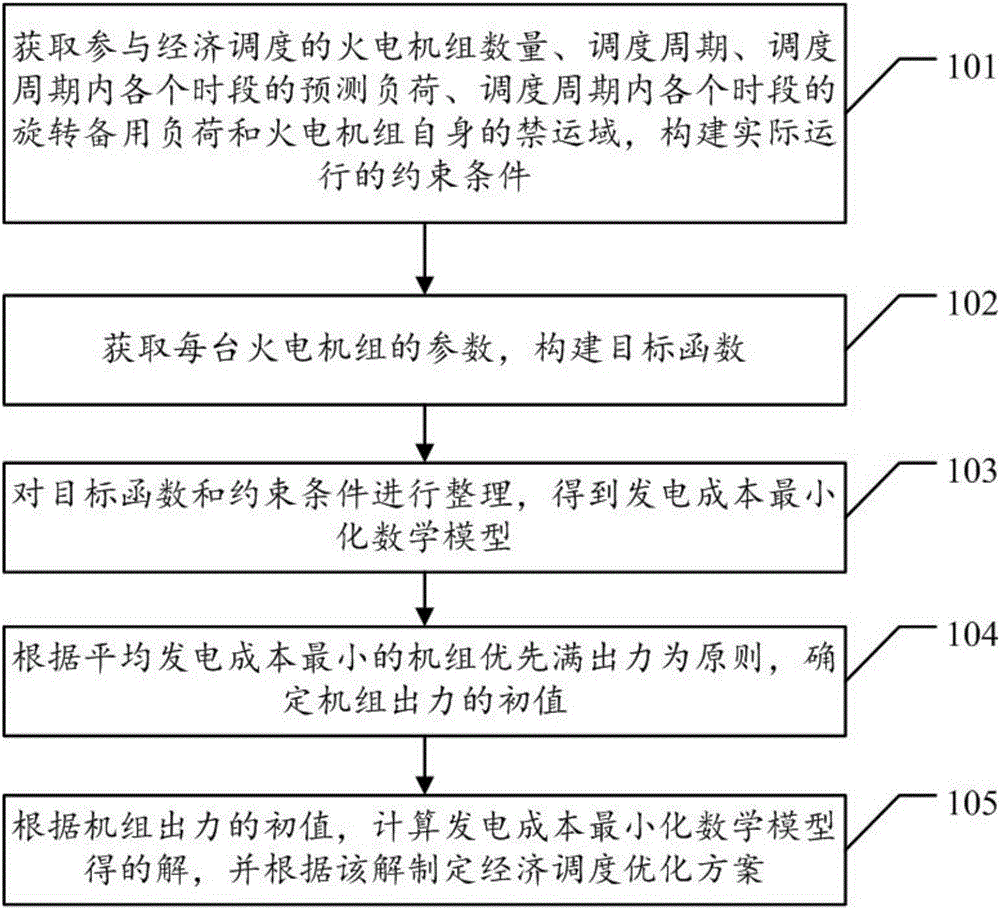

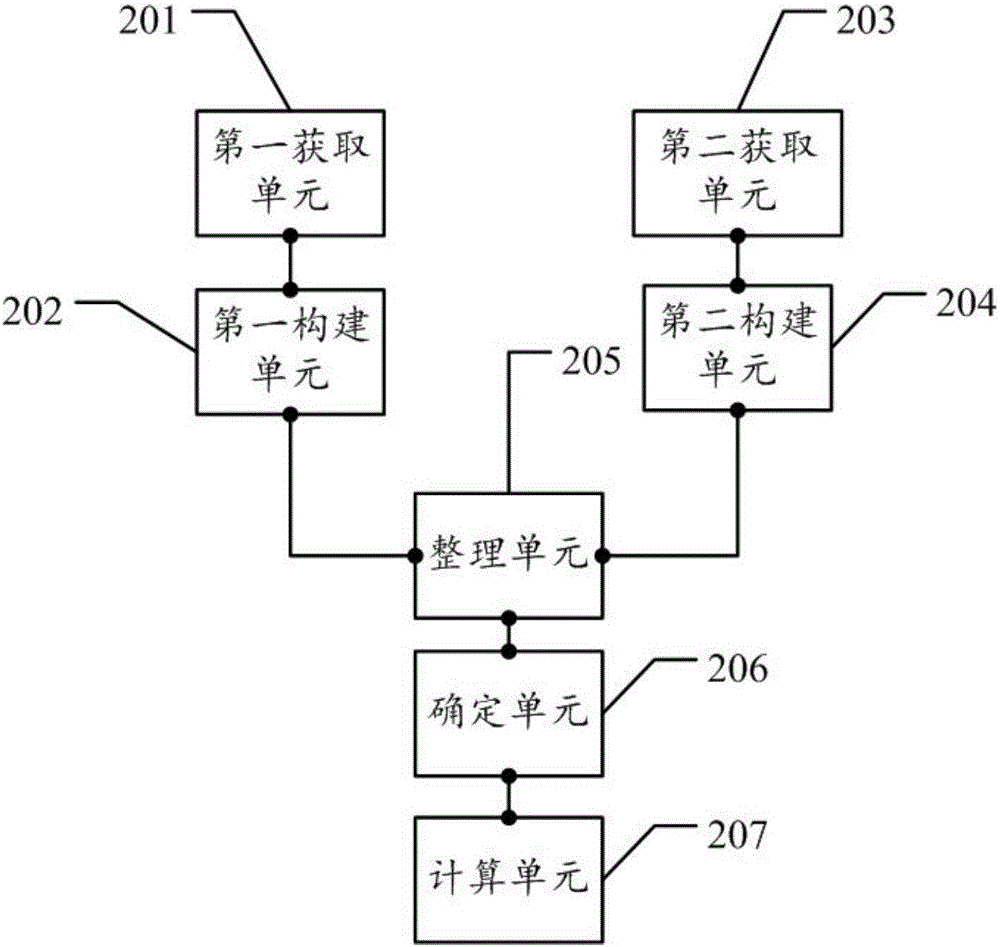

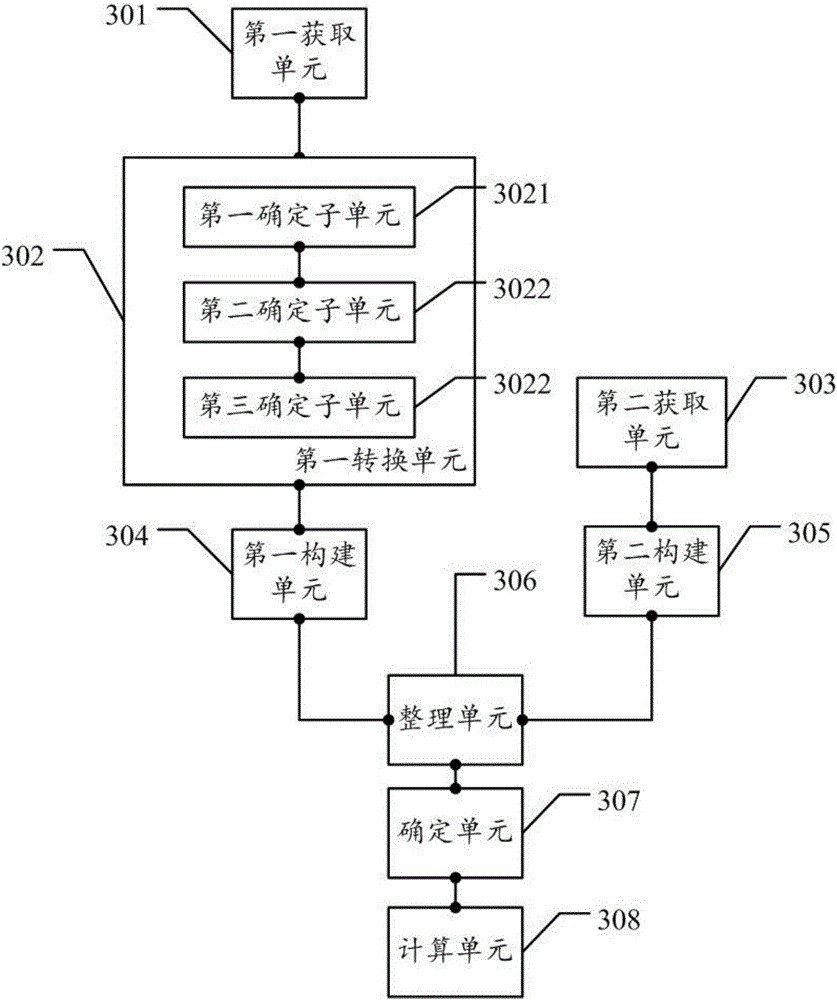

Data processing method and device for economic dispatch of wind power plant

InactiveCN106257502AQuickly optimize resultsThe optimization result is accurateForecastingResourcesPeaking power plantObject function

The invention discloses a data processing method and device for economic dispatch of a wind power plant. Mechanical constraint of thermal power generating units can be considered reasonably, and an optimization result can be obtained quickly and accurately by arranging an embargo area. The method comprises the steps of acquiring the number of thermal power generating units participating in economic dispatch, dispatch cycle, forecasting load of each time frame in the dispatch cycle, spinning reserve load of each time frame in the dispatch cycle, and the embargo area of the thermal power generating units, and establishing the constraint condition of actual operation; acquiring the parameters of each thermal power generating unit, and establishing an objective function; systemizing the objective function and the constraint condition to obtain a generating cost minimization mathematical model; determining the initial value of unit output based on the principle that the unit with minimum average generating cost conducts outputting completely as priority; solving the generating cost minimization mathematical model according to the initial value of unit output, and making an economic dispatch optimizing scheme according to the solution.

Owner:GUANGDONG UNIV OF TECH

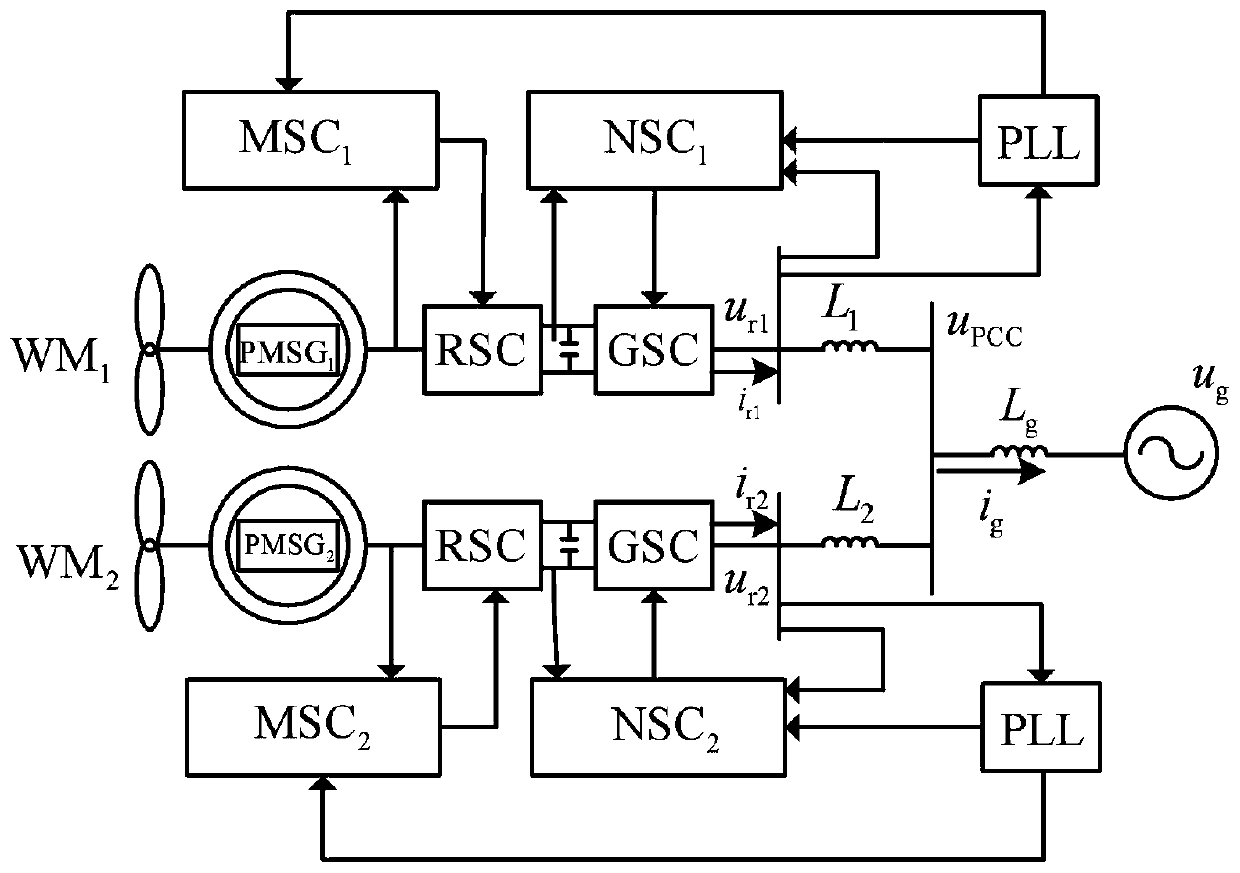

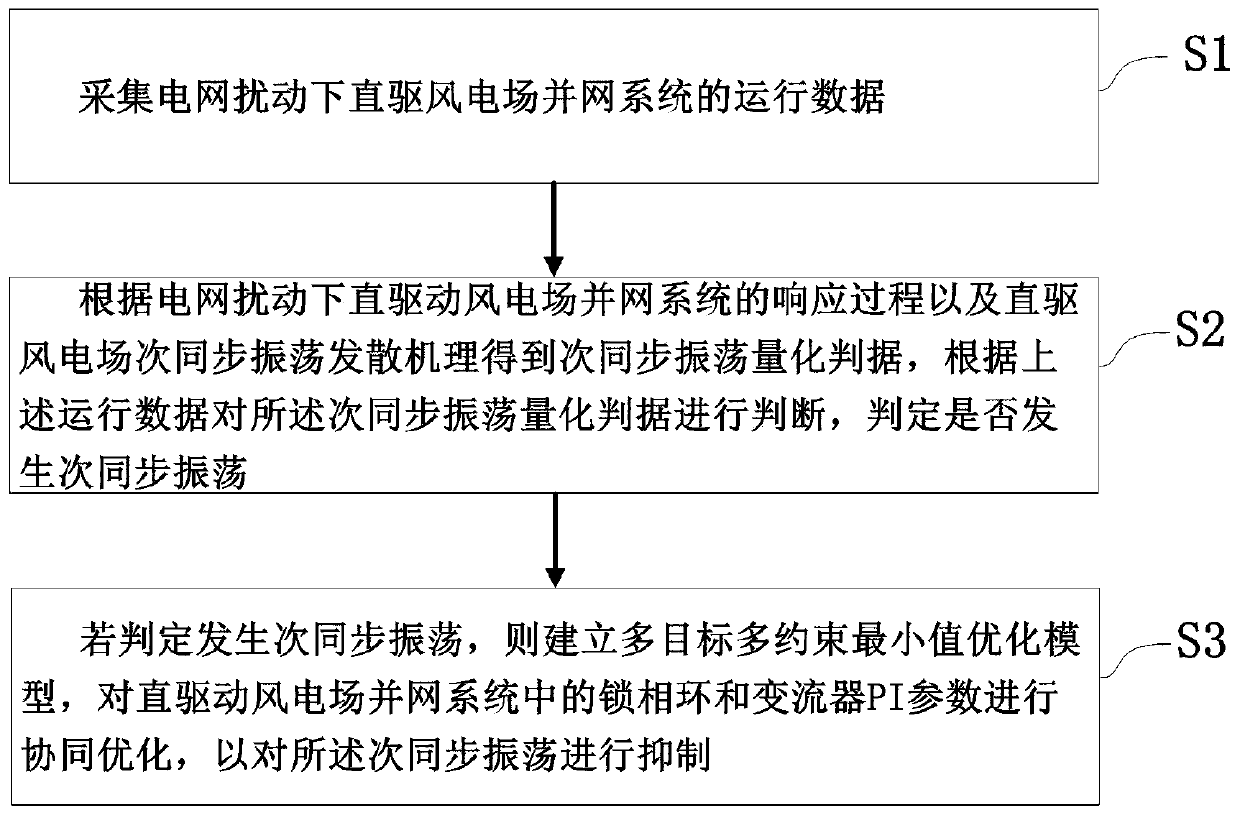

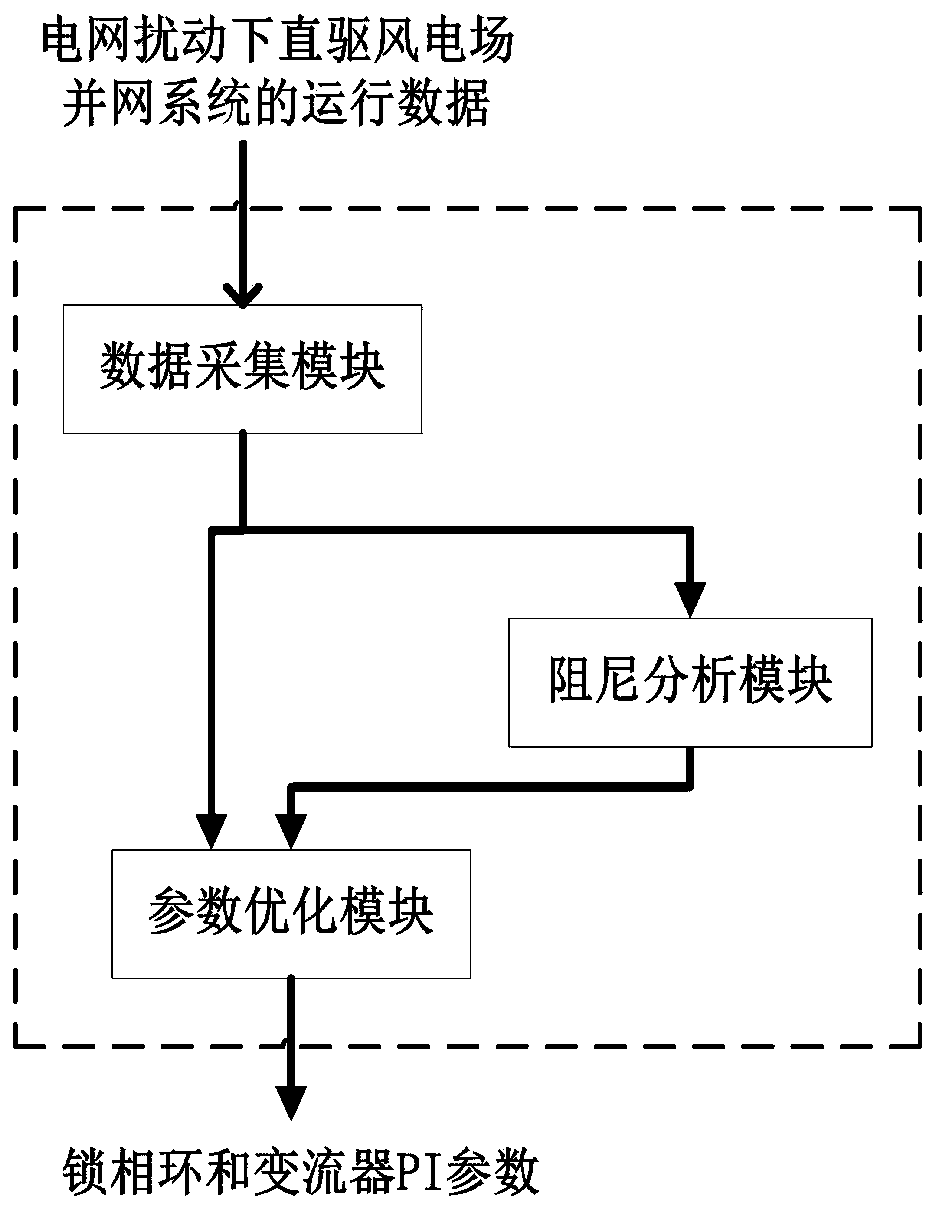

Subsynchronous oscillation suppression method and system for direct drive wind farm

ActiveCN110380432AAccurate amplitudeCriterion is simpleSingle network parallel feeding arrangementsPower oscillations reduction/preventionResponse processElectricity

The invention relates to a subsynchronous oscillation suppression method and system for a direct drive wind farm, belongs to the technical field of a wind power grid connected and solves a problem ofunstable performance due to cooperation optimization of all the fan parameters of a wind farm in the prior art. The method comprises steps that operating data of a grid-connected system of the direct-drive wind farm under grid disturbance are collected; subsynchronous oscillation quantification criterion is obtained according to the response process of the grid-connected system of the direct-drivewind farm under grid disturbance and the subsynchronous oscillation divergence mechanism of the direct drive wind farm, the subsynchronous oscillation quantization criterion is determined based on the above operating data, whether or not sub-synchronous oscillation occurs is determined, if yes, a multi-target multi-constraint minimum optimization model is established, a phase-locked loop and converter PI parameters in the grid-connected system of the direct drive wind farm are collaboratively optimized, and subsynchronous oscillation suppression is performed. The method is advantaged in thatcooperation optimization of all the fans in the wind farm is achieved, and subsynchronous oscillation is effectively suppressed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

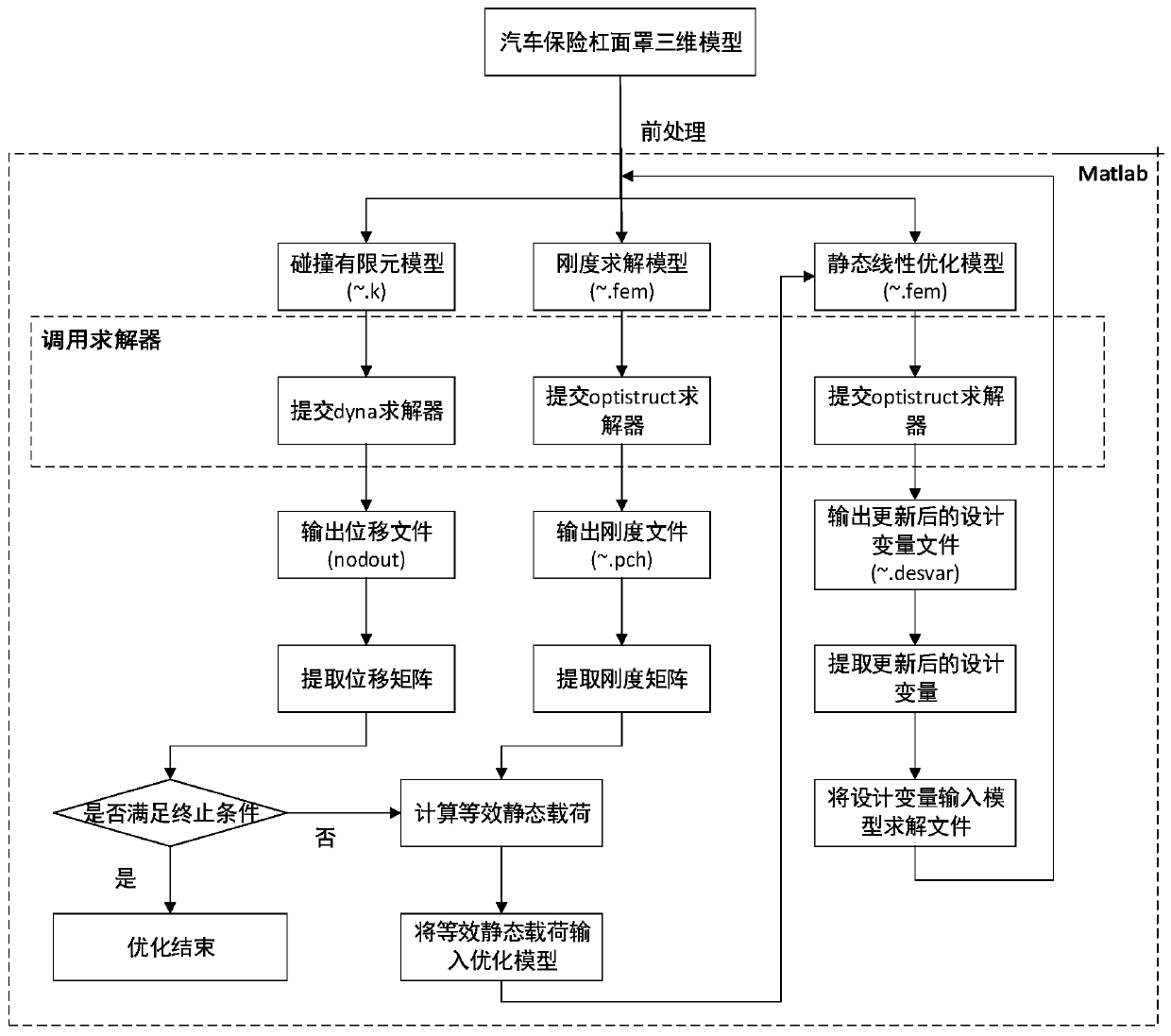

An automobile bumper mask size optimization method based on an equivalent static load method

ActiveCN109726506AImprove general performanceStrong computational efficiencySustainable transportationSpecial data processing applicationsEngineeringFinite element software

The invention belongs to the technical field of automobiles, and particularly relates to an automobile bumper mask size optimization method based on an equivalent static load method. According to themethod, the total mass of the automobile bumper mask is taken as an objective function, displacement is taken as a constraint, and the thickness of the mask is taken as a design variable to carry outsize optimization design on the bumper mask. According to the method, a final optimization result is required to meet a convergence condition and a displacement constraint condition, and the optimization result is more accurate. In addition, only the equivalent static load of the time step with the maximum displacement is calculated, the equivalent static load of all the time steps does not need to be calculated, and the calculation efficiency is high. All the functions are integrated through matlab, automatic solving is achieved, besides basic model preprocessing, finite element software doesnot need to be opened any more to solve the model, a running program directly calls a related solver to solve the model, and operation is convenient.

Owner:JILIN UNIV

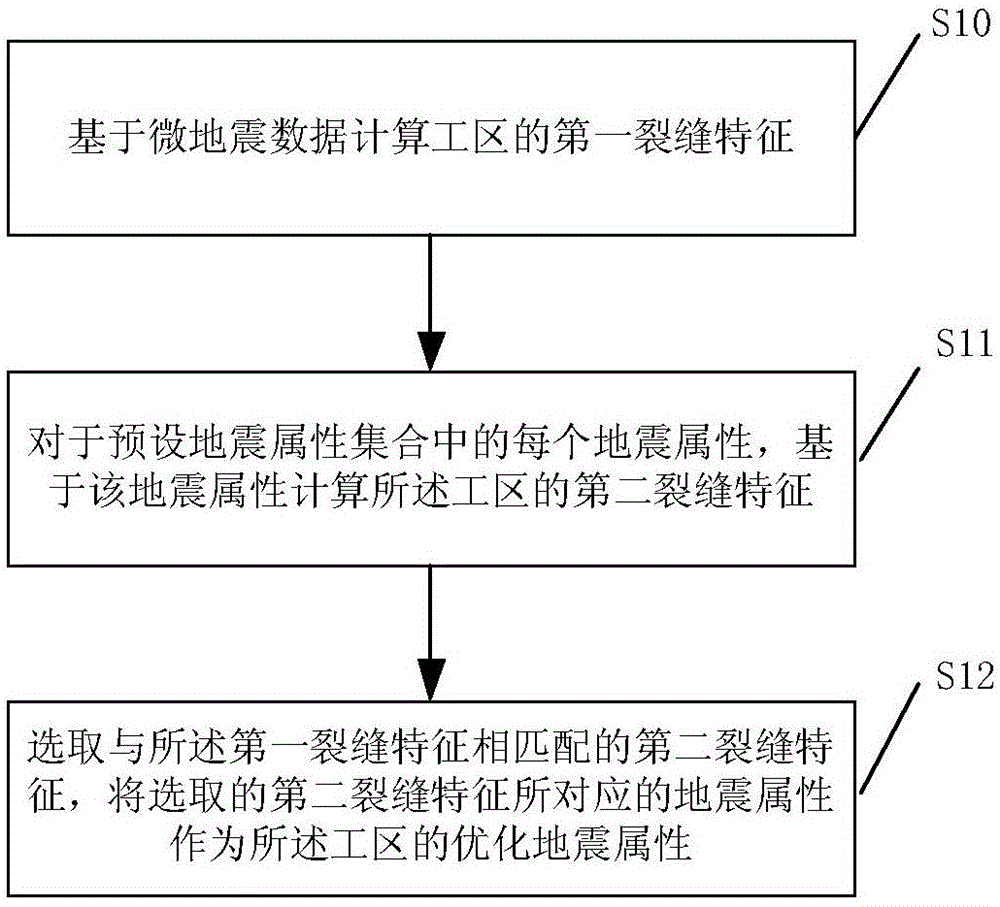

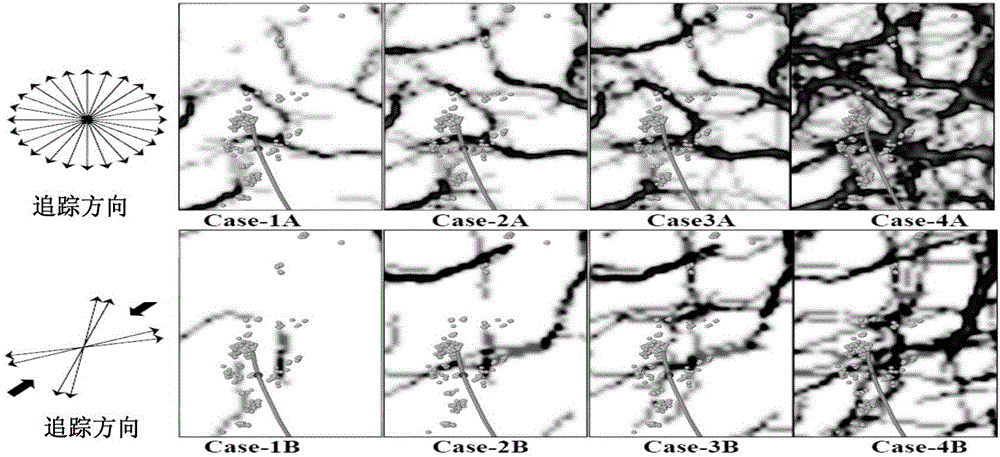

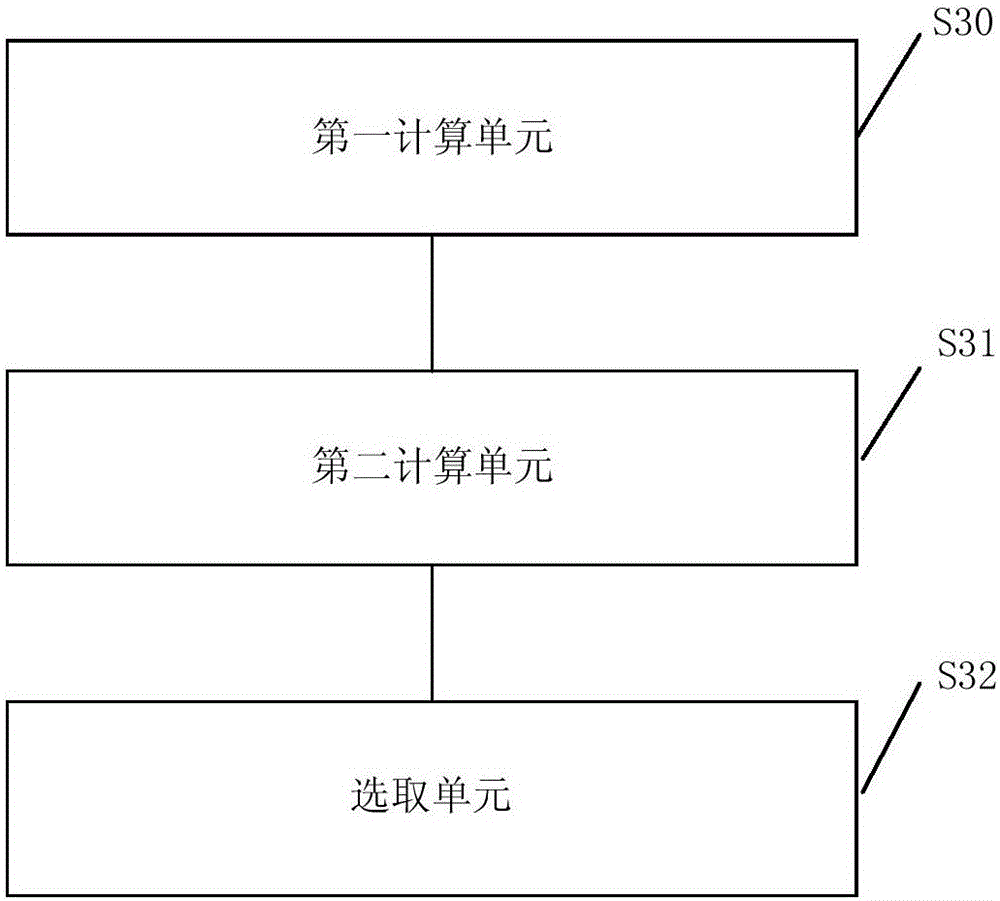

Seismic attribute optimization method and device

ActiveCN106501851ASufficient theoretical proofThe optimization result is accurateSeismic signal processingGeomorphologySeismic attribute

The embodiment of the invention discloses a seismic attribute optimization method and device. The seismic attribute optimization method comprises the steps of calculating a first fracture characteristic of a work area based on micro-seismic data; as for each seismic attribute in a preset seismic attribute set, calculating a second fracture characteristic of the work area based on the seismic attribute; selecting a second fracture characteristic matched with the first fracture characteristic, and regarding a seismic attribute corresponding to the selected second fracture characteristic as an optimized seismic attribute of the work area. The method and the device disclosed by the embodiment of the invention can improve the accuracy of an optimization result.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

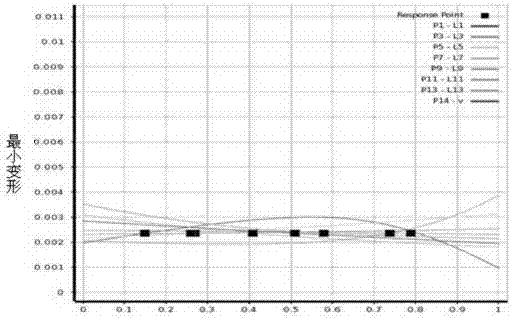

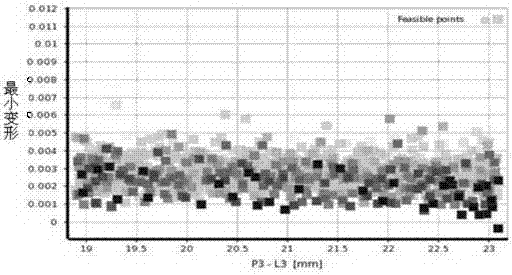

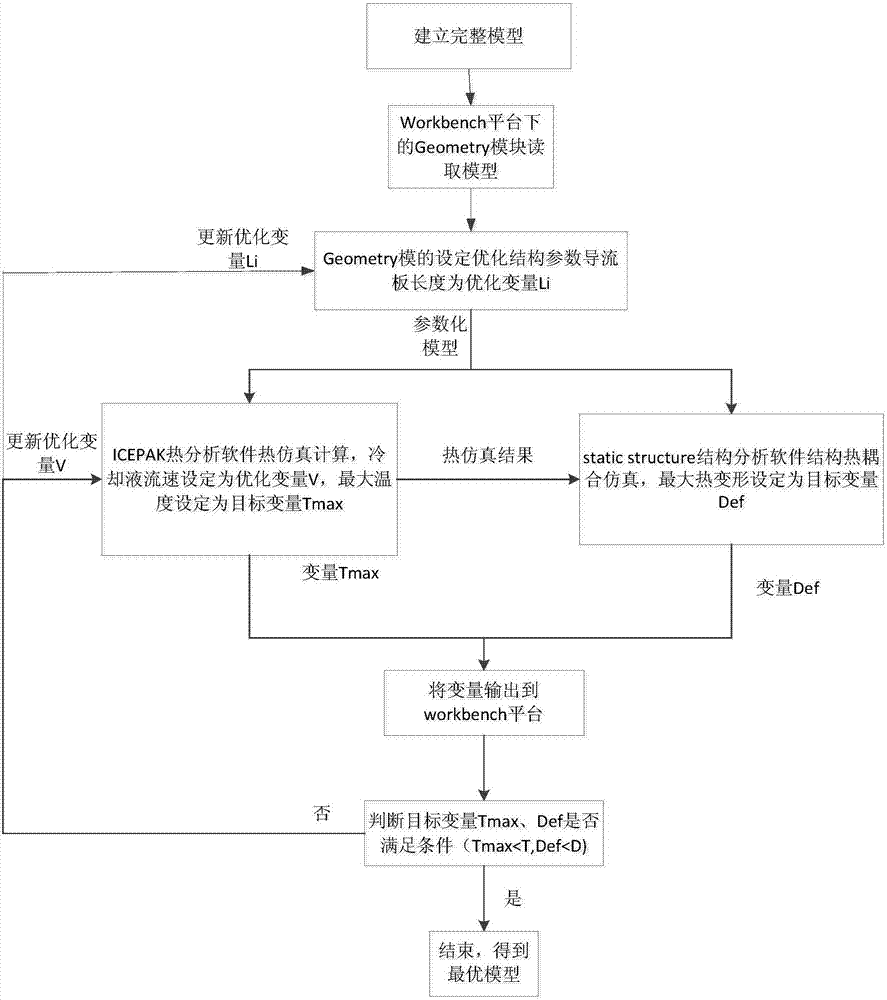

Optimum structural design method for electronic equipment

ActiveCN106874566AGuaranteed performance and stabilityThe optimization result is accurateGeometric CADDesign optimisation/simulationThermal deformationSimulation

The invention discloses an optimum structural design method for electronic equipment. The method comprises the following steps: using three-dimensional model software pro / e for establishing an electronic equipment model; using Workbench analysis software for remodeling a structure parameter of the electronic equipment model, thereby acquiring an optimized structure parameter; performing thermal simulation analysis on an optimizing model in Icepak thermal simulation software, thereby acquiring a working temperature of the electronic equipment; applying the working temperature to an optimizing model structure for performing thermal-structure coupling simulation analysis in static structure simulation software, thereby acquiring structure thermal deformation of the electronic equipment; establishing a mathematical optimization model of the electronic equipment and judging the working temperature and the structure thermal deformation f of the electronic equipment, thereby confirming the design reasonability of the electronic equipment with such a structure. The method provided by the invention can be used for guiding the design for chassis under mutual influence of structure-thermal two fields and prolonging the service life of the chassis; the optimizing result is more accurate; the performance stability of the chassis under a severe service environment can be guaranteed.

Owner:XIDIAN UNIV

A method and device for arranging segmental insulation of buried pipelines

ActiveCN105975768BReduce usageAvoid subjective factorsSpecial data processing applicationsInformaticsPotential differenceEngineering

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

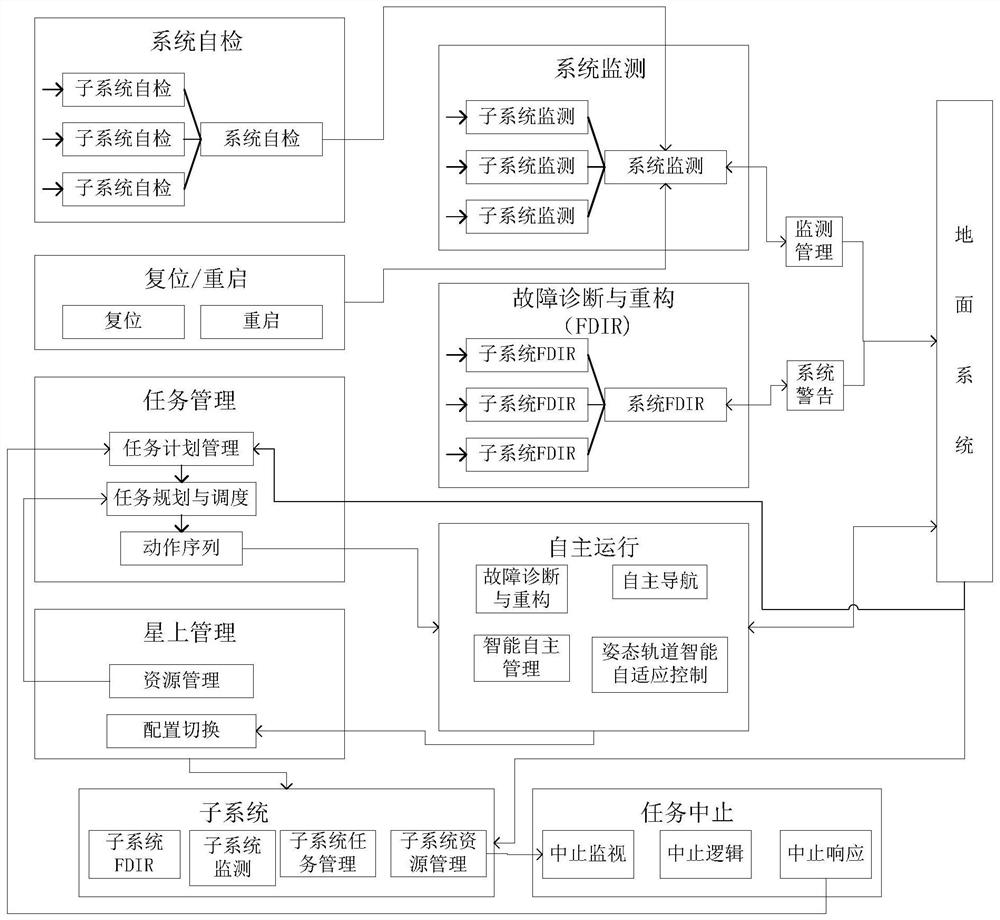

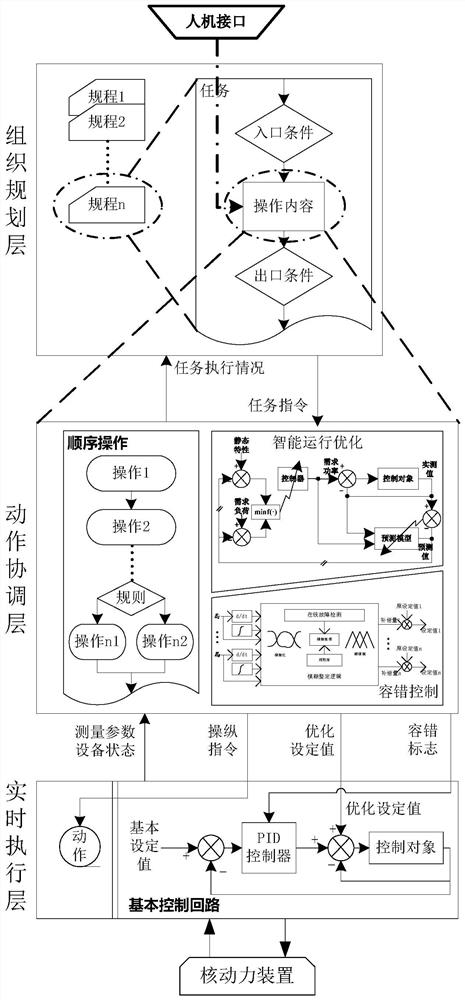

Autonomous control system of nuclear power plant

The invention discloses an autonomous control system of a nuclear power plant. The autonomous control system comprises an organization planning layer used for transmitting a task instruction to an action coordination layer; the organization planning layer is also used for receiving the task state fed back by the action coordination layer and transmitting the task instruction to the action coordination layer according to the task state; the action coordination layer receives the task instruction and transmits an action instruction to a real-time execution layer according to the task instruction; the action coordination layer is also used for receiving the measurement parameters and the equipment state fed back by a real-time execution layer and transmitting the action instruction to the real-time execution layer according to the measurement parameters and the equipment state; when all the instructions of the task instruction are executed, the action coordination layer is further used for feeding back the task state to the organization planning layer; and the real-time execution layer drives the equipment to act according to the action instruction and feeds back the measurement parameters and the equipment state to the action coordination layer. The invention aims to provide the autonomous control system of the nuclear power plant, so that the control system of the nuclear powerplant has higher automation and intelligence levels.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

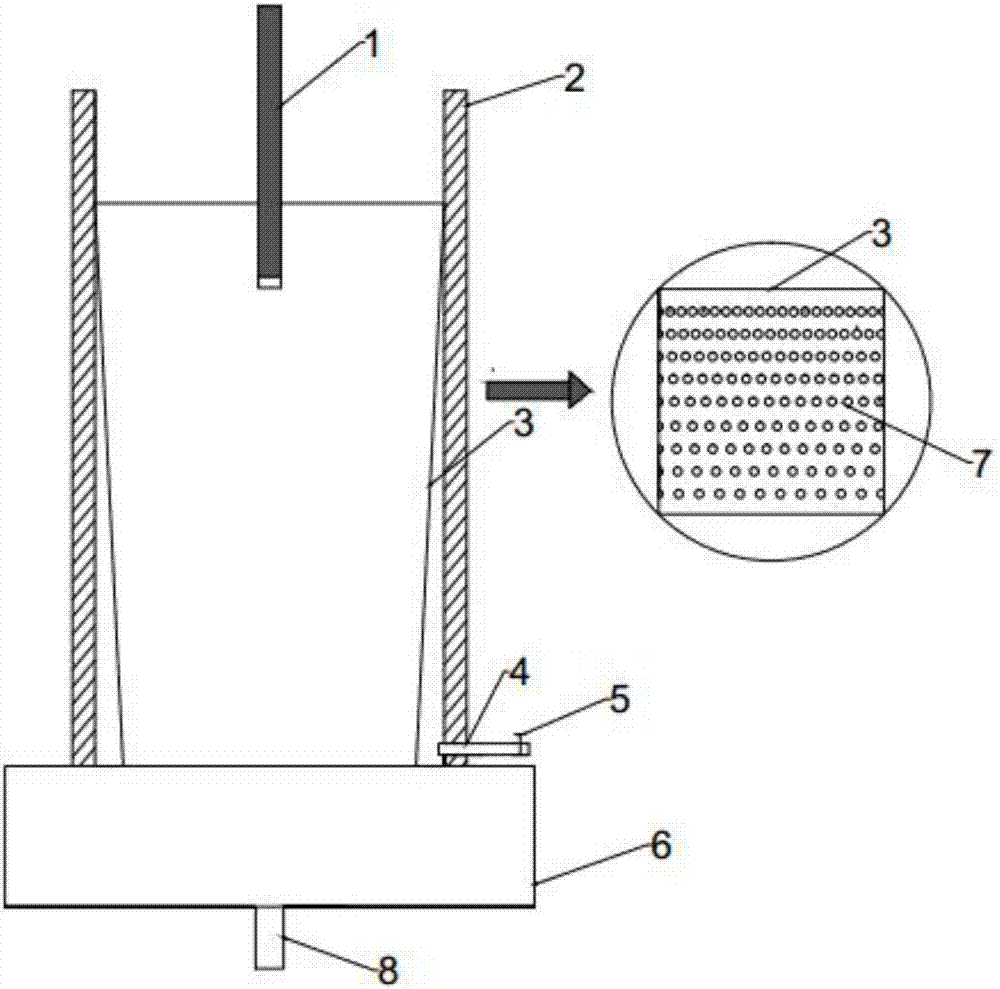

Crystallizer physical simulation method and device based on molten steel static pressure and solidification phenomena

The invention discloses a crystallizer physical simulation method and device based on molten steel static pressure and solidification phenomena. The method comprises the steps that S1, a crystallizer hydraulic simulation model is built, the thickness and the static pressure of a casting blank solidification blank shell are determined, and distribution of small drainage holes at different heights of the inner wall of a crystallizer is designed; and S2, the crystallizer hydraulic simulation model operates, and liquid is injected; drainage is conducted through the small drainage holes to simulate molten steel converted into the casting blank solidification blank shell, and states of all positions of the crystallizer hydraulic simulation model are detected to simulate or correct the crystallizer flow field and the technological parameters during practical continuous casting production. The crystallizer physical simulation device comprises an outer shell simulating the crystallizer in shape, an inner shell is arranged in the outer shell, and the space between the inner shell and the outer shell is an interlayer; and the multiple rows of the small drainage holes are formed in the inner shell from top to bottom, and drainage pipes are arranged on the lower portion of the interlayer. According to the crystallizer physical simulation method and device based on the molten steel static pressure and solidification phenomenon, the molten steel solidification phenomenon and the molten steel static pressure are comprehensively considered, and the crystallizer physical simulation method is more approximate to a practical continuous casting production condition.

Owner:CHONGQING UNIV

Optimization method for site selection of gas detection and alarm equipment in refinery unit considering conditional risk value

ActiveCN106055803BImprove detection efficiencyAvoid blindnessDesign optimisation/simulationSpecial data processing applicationsDependabilityComputer science

The invention discloses a site selection optimization method for a gas detection and alarm instrument of an oil refinery considering conditional risk values, and realizes real-time quantitative characterization of the risk of an oil refinery based on the risk triplet theory and a leakage scene set, and uses this as a risk quantification index for layout decision-making. Then take the minimization of the decision-making risk of the layout as the optimization goal, take the risk value of the optimal condition and the number of detection alarm devices as the constraint conditions, and take the selection of alternative points for the alarm device layout as the binary decision variable to define the objective function and constraints of the optimization model function, a P-median model for decision risk minimization considering reliability, voting logic, and conditional value-at-risk was established. The beneficial effects of the present invention are as follows: when optimizing the scheme, the unavailability and failure of the detection and alarm instrument are fully considered, and the successful detection probability of the detection and alarm instrument is taken into consideration, so that the optimization result is more accurate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com