Crystallizer physical simulation method and device based on molten steel static pressure and solidification phenomena

A technology for hydrostatic pressure and physical simulation of molten steel, applied in the field of metallurgical process simulation, can solve problems such as large differences in production conditions, ignoring the solidification phenomenon of molten steel, etc., and achieve the effect of accurate optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with specific embodiments.

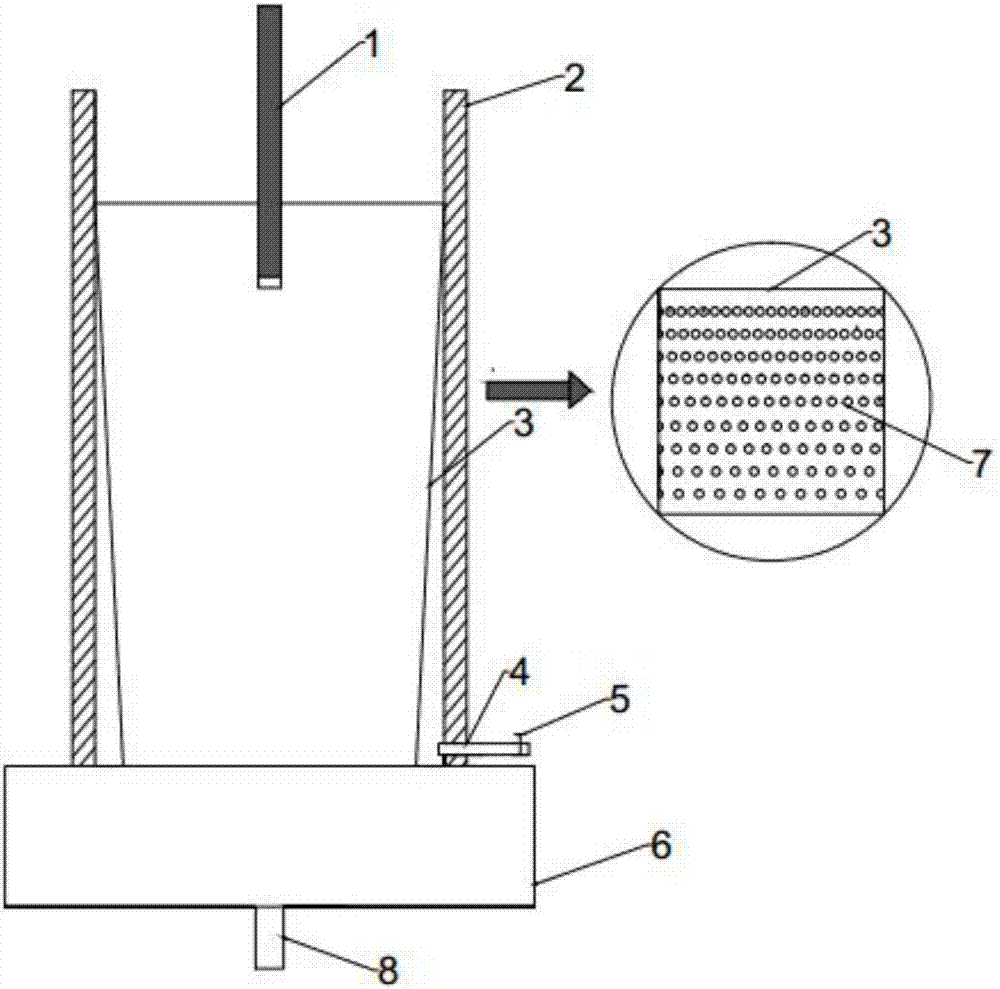

[0040] In order to truly reflect the flow field changes in the mold during continuous casting and obtain more accurate optimization results, the solidification of molten steel in the mold under the action of molten steel static pressure was considered in the physical simulation study. This is due to the existence of the solidification phenomenon of molten steel in the crystallizer, which has a great influence on the change of the flow state of molten steel. First of all, the flow space of molten steel in the mold is reduced, and the flowing molten steel will interact with the solidified billet shell, so that the flow state in the mold changes significantly; secondly, the total amount of molten steel flowing in the mold will be accompanied by the solidified billet Formation and reduction, resulting in the reduction of turbulent kinetic energy of molten steel flow, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com