Optimum structural design method for electronic equipment

An electronic equipment and optimization design technology, which is applied in the field of structural optimization design of high-density and complex airborne chassis electronic equipment, can solve problems such as lack of applicability, and achieve the effects of reducing excessive temperature, good heat conduction mode, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

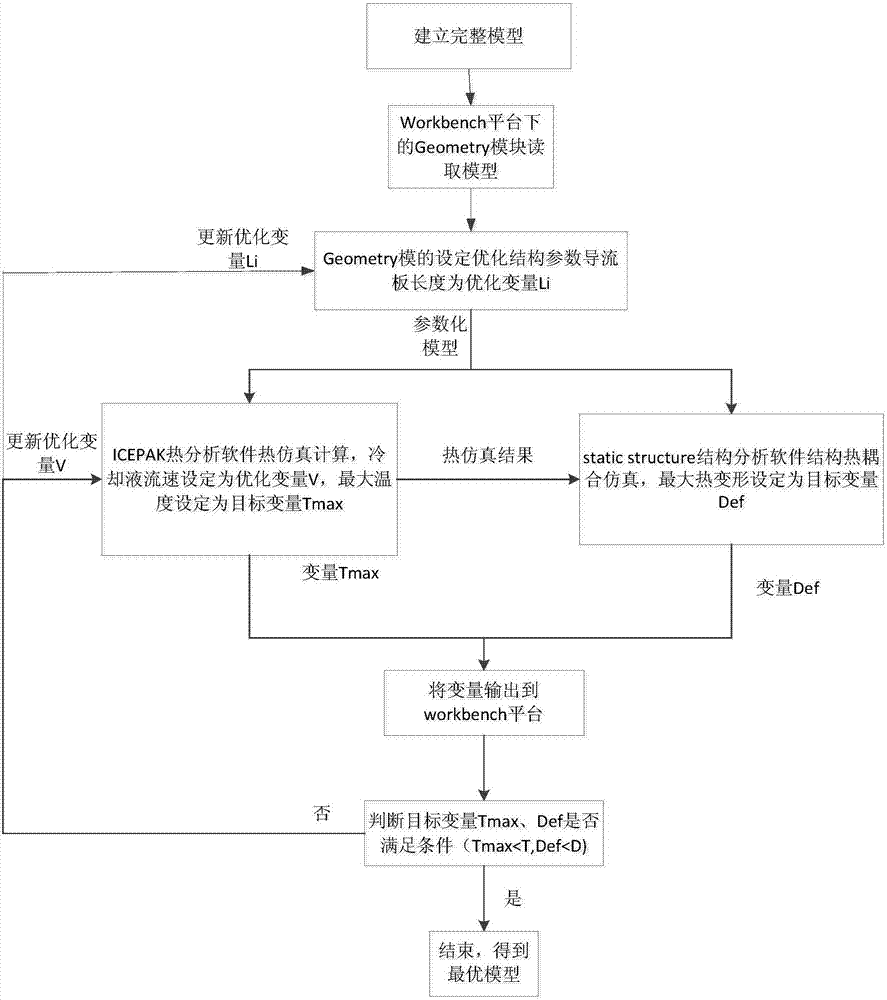

[0041] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

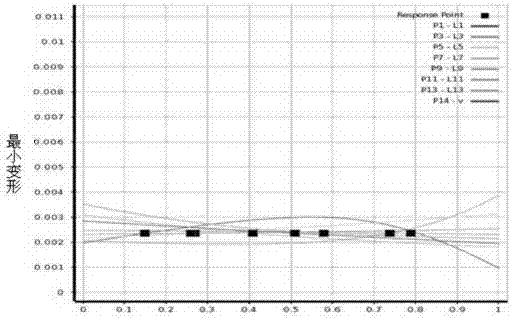

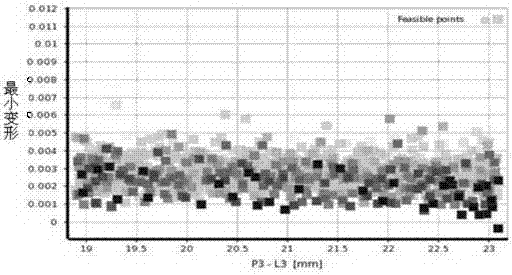

[0042] Such as figure 1 As shown, the electronic equipment structure optimization design method of the present invention includes the following steps:

[0043] (1) According to the structural parameters and dimensions of the electronic equipment, use the three-dimensional modeling software pro / e to establish the electronic equipment model; The flow rate of the liquid.

[0044] (2) Use the Workbench analysis software to read the established electronic equipment model, and use the Geometry module in the Workbench analysis software to remodel the structural parameters of the electronic equipment model, and use the sequence secondary optimization algorithm provided by the ISIGHT optimization software to perform structural optimization. The parameters are optimized to obtain the optimized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com