Topological optimization design method for high-speed vertical machining centre long-span beam

A vertical machining center and topology optimization technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as expensive, restricting the development speed of automobiles and energy, and affecting the rapid development of the national economy, so as to ensure availability and improve The effect of optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] (1) Preliminary basic analysis

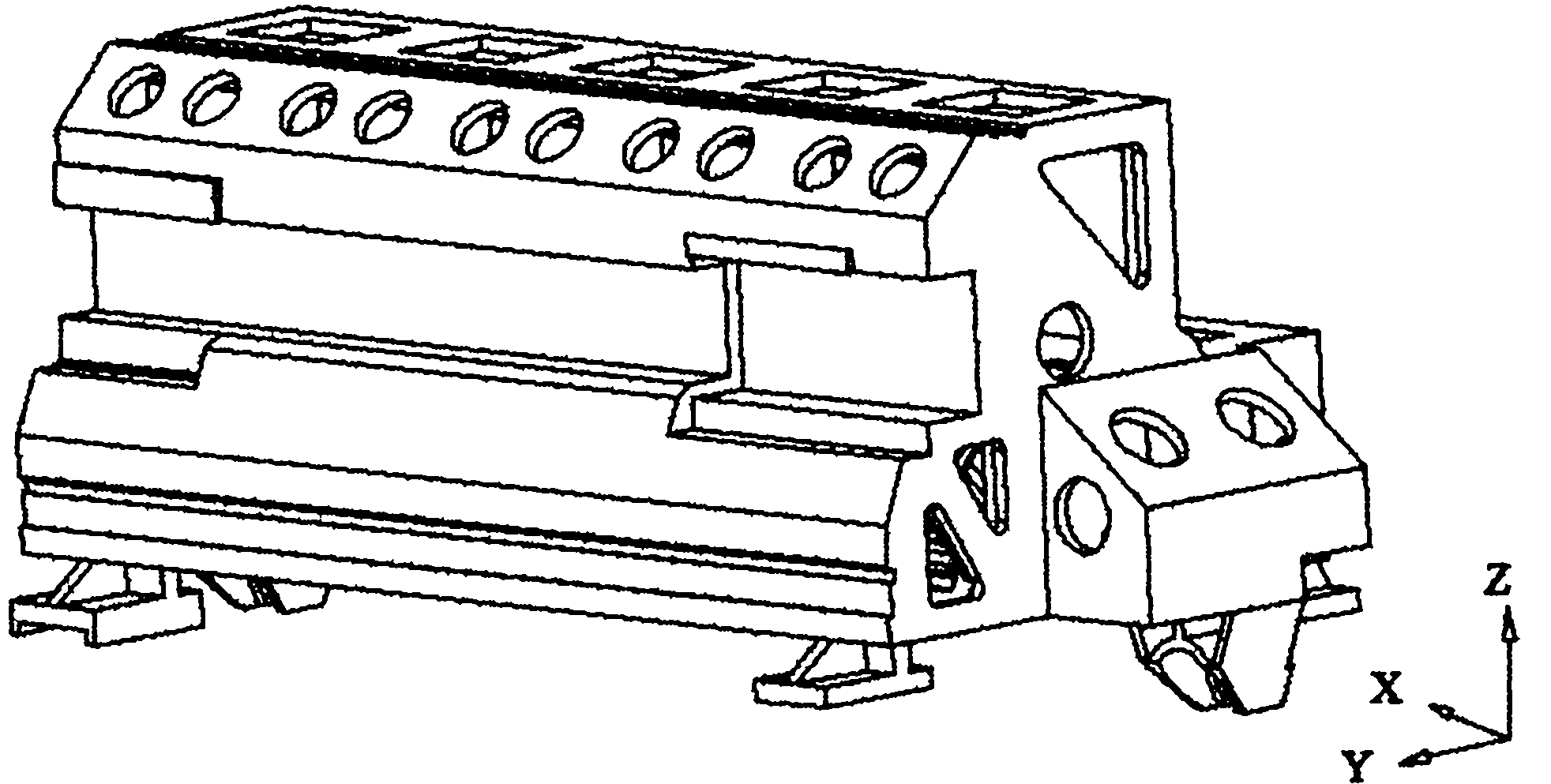

[0043] (1) Model simplification: The beam of the high-speed machining center is a structural casting, so according to the principle of model simplification, remove all chamfers in the model, remove holes with a diameter of less than 10mm and bosses with a height of less than 10mm, and remove parts that are not directly stressed. Positioning assembly structure such as cavity.

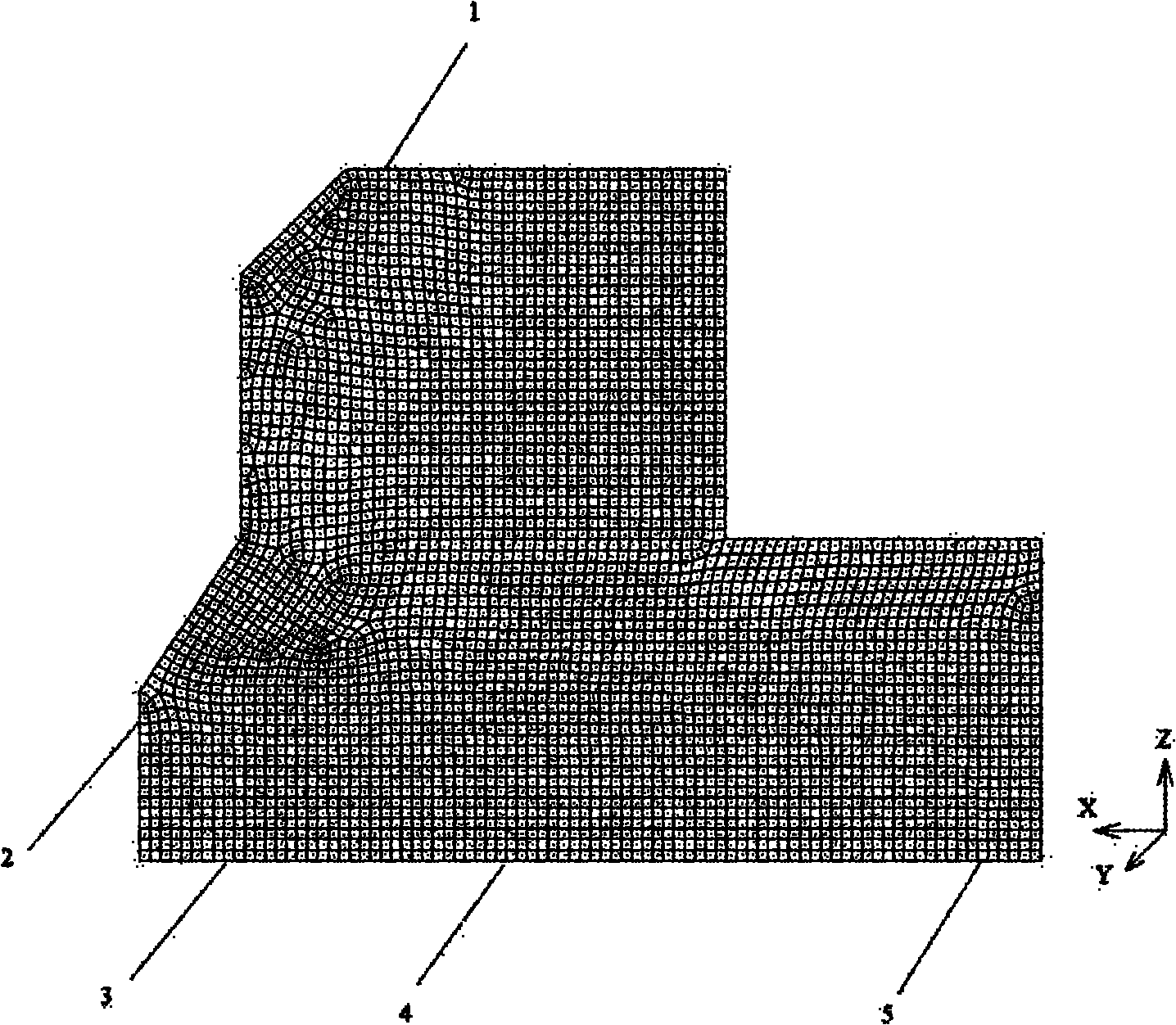

[0044] (2) Meshing: Before meshing, material properties need to be defined. The beam material is cast iron, the material density is 7.2g / cm 2 , Poisson's ratio is 0.28, and Young's modulus is 1.1E5 MPa. The specific steps of meshing are as follows: firstly perform free meshing of the overall structure and select default values for the mesh density parameters; then perform mesh refinement on the beam constraints and load application positions to refine the area mesh density to 3 times. The final number of finite element meshes is 76522 and the number of nodes is 147...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com