Device and method for gem three-dimensional blank reconstruction design based on machine vision

A technology of machine vision and gemstones, applied in the field of gemstone blank design system, can solve problems such as difficult to achieve optimal design, does not support automatic design, and relies on designer experience, etc., to achieve easy purchase and application, flexible cutting design, and convenient measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

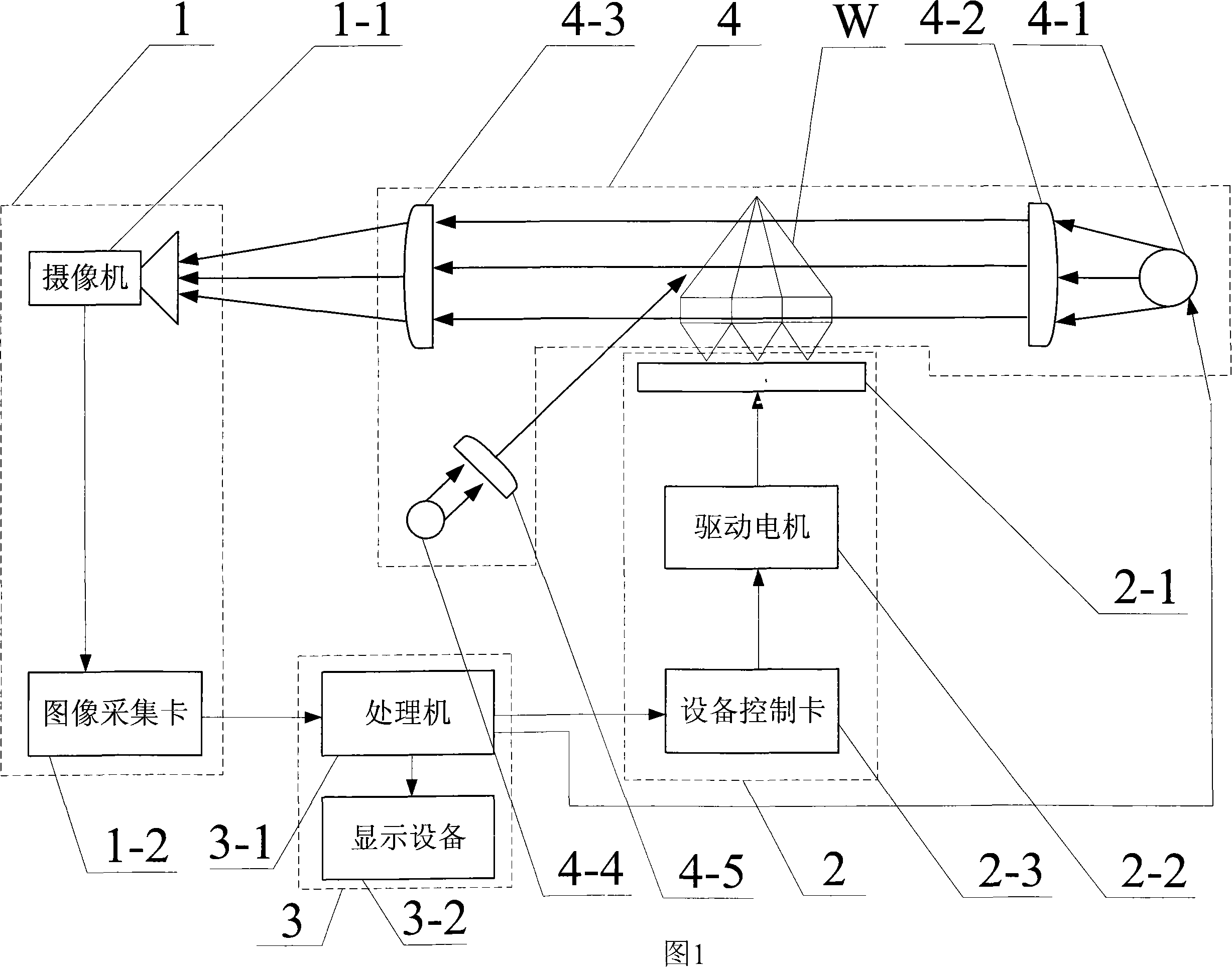

[0017] Specific embodiment one: referring to Figure 1, the device of this embodiment is composed of an image acquisition device 1, a rotating platform device 2, a processing system 3, and a lighting device 4. The signal output terminal of the image acquisition device 1 and the signal input terminal of the processing system 3 Connected, the control input end of the rotating platform device 2 and the lighting device 4 are connected to the control output end of the processing system 3, and the output light of the lighting device 4 is supplied to the input end of the image acquisition device 1, which is composed of the camera 1-1 It is composed of an image capture card 1-2. The signal output end of the camera 1-1 is connected to the signal input end of the image capture card 1-2. The rotating platform device 2 is composed of a platform body 2-1, a driving motor 2-2, and a device The control card 2-3 is composed of the transmission output end of the drive motor 2-2 and the platform bod...

specific Embodiment approach 2

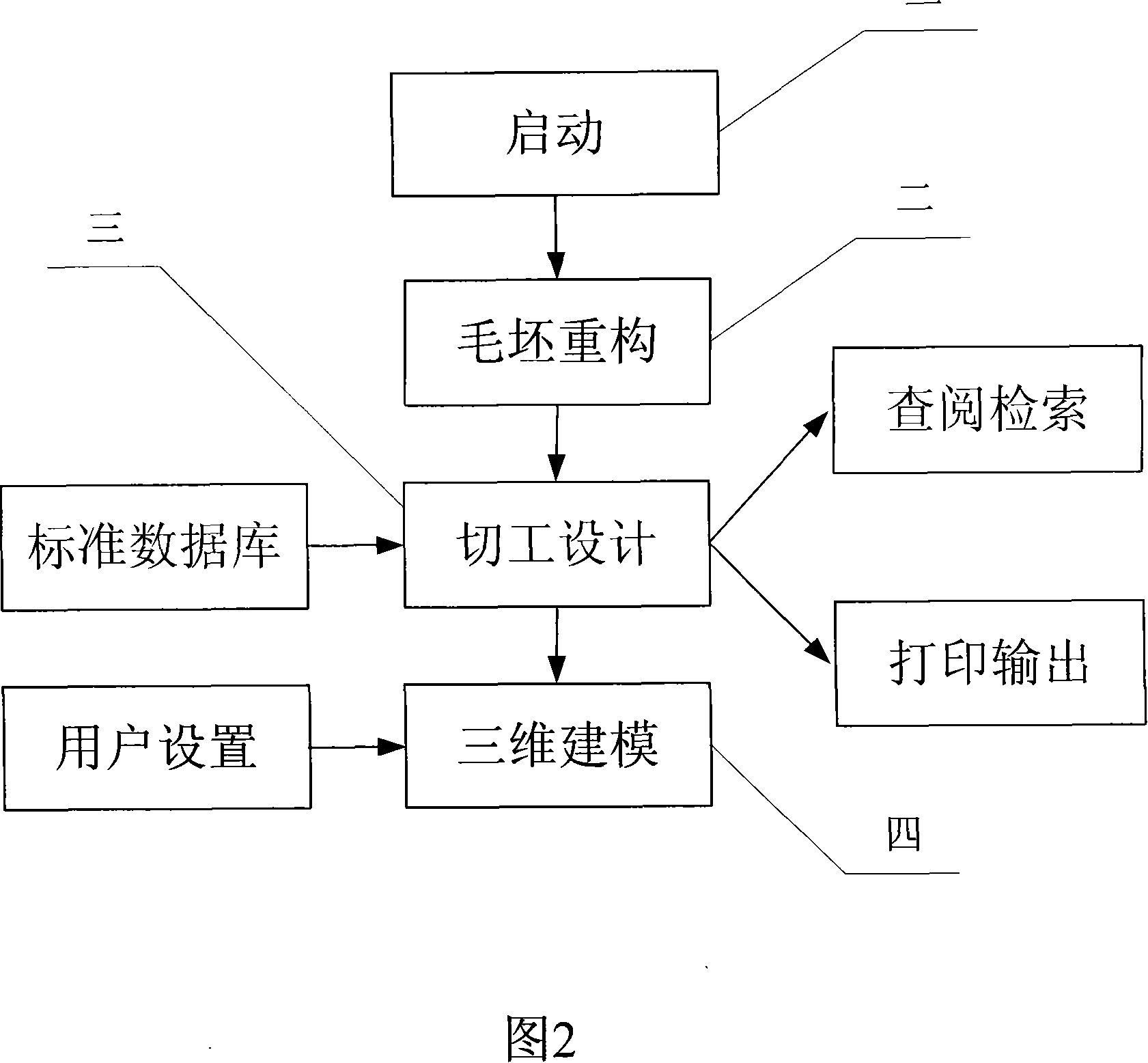

[0018] Specific implementation manner 2: Referring to FIG. 2, the method steps of this implementation manner are:

[0019] Step 1. Startup: Place the gemstone blank W to be tested on the platform body 2-1, and the processor 3-1 will issue a control command to the auxiliary light source 4-1 to provide backlighting for the platform body 2-1;

[0020] Step 2: Reconstruction of the blank: The processor 3-1 controls the drive motor 2-2 through the device control card 2-3 to drive the platform body 2-1 to rotate with high precision at a specified rate, and collects the gem blank W to be tested by the camera 1-1 Video from all angles, the collected video is converted into a multi-frame digital image sequence by the image capture card 1-2 and sent to the processor 3-1, and the multi-frame digital image sequence is calculated by the processor 3-1 to obtain the gemstone blank W to be tested 3D surface and shape parameters of, and reconstruct the shape of the gem blank in the processor 3-1; ...

specific Embodiment approach 3

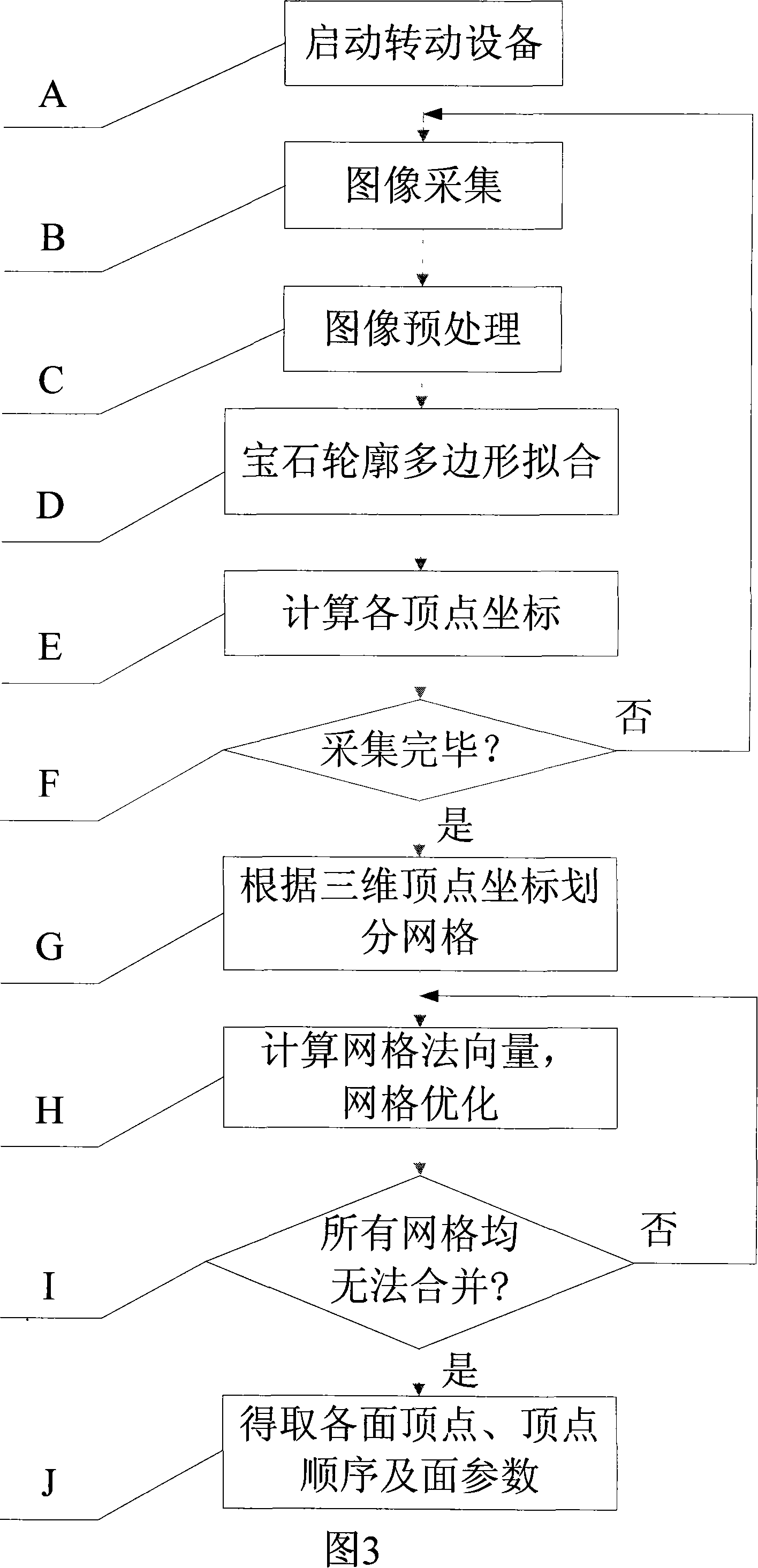

[0023]Specific embodiment three: referring to Fig. 3, the difference between this embodiment and the specific embodiment two is that the steps of the blank reconstruction in step three are as follows: Step A, start the rotating equipment: start the camera 1-1 and the rotating platform body 2-1 , The device control card 2-3 controls the drive motor 2-2 to drive the platform body 2-1 to rotate with high precision at a specified rate; Step B, image acquisition: the camera 1-1 performs image acquisition on the gem blank W to be tested, and passes The image capture card 1-2 transmits the captured image to the processor 3-1; Step C, image preprocessing: noise removal, thresholding, image segmentation of the gem blank W to be tested; Step D, gem contour polygon fitting: Starting from the quadrilateral, gradually increase the number of sides until the surrounding error between the polygon and the gemstone contour is less than the specified value; Step E. Calculate the coordinates of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com