Accurate constraint condition-based cylindrical gearing optimization design method and accurate constraint condition-based cylindrical gearing CAD (computer-aided design) optimization design system

A constraint condition, cylindrical gear technology, applied in belt/chain/gear, calculation, mechanical equipment, etc., can solve problems such as heavy workload, inaccuracy, incomplete optimization results, etc., to improve design efficiency and optimize results accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

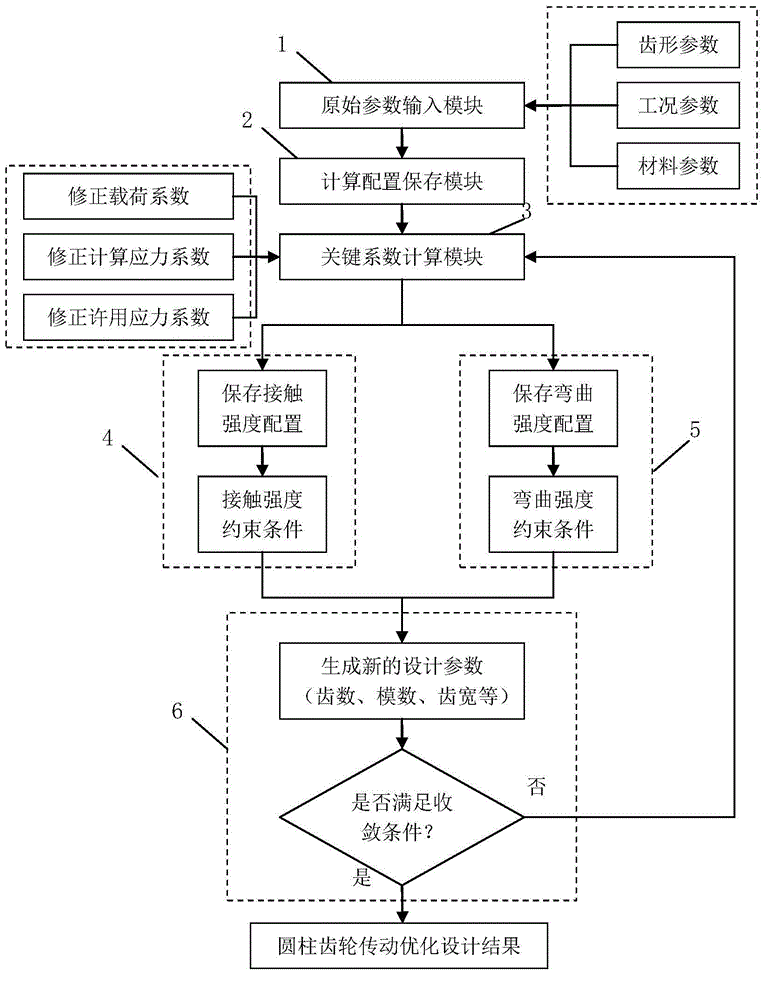

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0022] An optimal design method of cylindrical gear transmission based on precise constraints, including:

[0023] Step 1: Input the original parameters. According to the requirements of the working conditions, input the tooth shape parameters, working condition parameters and material parameters of the cylindrical gear pair. The tooth shape parameters include the number of teeth, modulus, tooth width, pressure angle, helix angle, and addendum height coefficient, head clearance coefficient; working condition parameters include input torque, input power, service coefficient, etc.; material parameters include elastic modulus, Poisson's ratio, density, contact fatigue limit, bending fatigue limit;

[0024] Step 2: Calculation configuration saving step, the parameters input in step 1 are saved to parameter files according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com