Pipe network leak detecting method in combination with resistance identification

A leak detection and pipe network technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of artificial neural network method such as small number of samples, difficult automatic monitoring system integration, a large number of instruments and equipment manpower, etc. , to achieve the effect of reducing the labor intensity of manual inspection, reducing the inspection time, and reducing the cost of leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

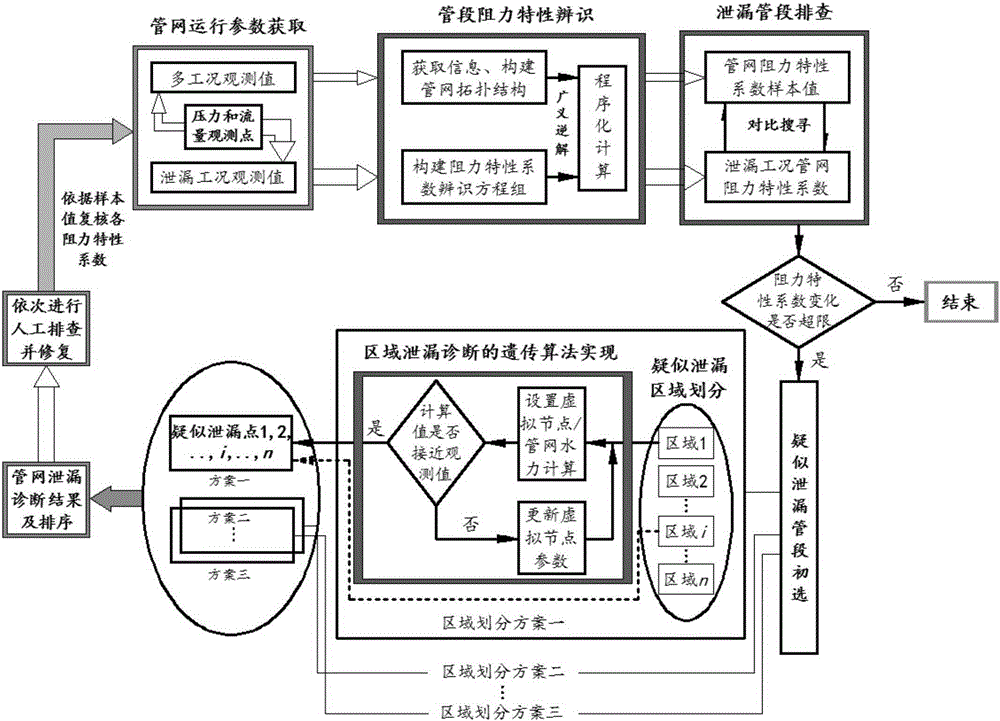

[0032] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0033] A pipe network leak detection method combined with resistance identification, comprising the following steps:

[0034] Step 1. Obtain topological structure: By collecting design materials such as design and construction drawings of water supply or gas supply (heat supply) pipe network systems, obtain information on nodes and pipe sections of the pipe network system, that is, topological structure; among them, nodes, pipe sections, and resistance characteristic systems are involved. Count three concepts: node refers to the connection node at the branch of the pipe network, and the flow rate of the pipe segment connected to the node is different; the pipe segment generally refers to a pipe segment, and there is actually a branch at the connection of two pipe segments but there is no leakage at the branch, that is to say Two connected pipe sections with the same flow rate are also reg...

specific Embodiment approach 2

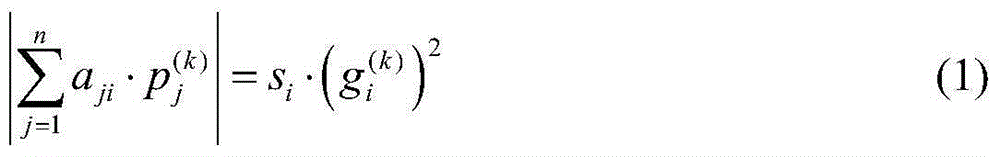

[0052] The process of establishing a system of equations including resistance characteristic coefficients described in step 2 of the present embodiment is as follows,

[0053] The resistance characteristic coefficient equation is shown in formula (1)

[0054] | Σ j = 1 n a j i · p j ( k ) | = s i · ( g i ( k ) ) 2 - - - ( 1 )

[0055] In the formula, i is the serial number of th...

specific Embodiment approach 3

[0058] The process of finding out the pipe section whose variation range exceeds the set value described in step 2 of this embodiment is as follows,

[0059] Under some different working conditions, the change of the resistance characteristic coefficient of the pipe section is caused by observation errors. The limit value is considered to be suspected of leakage; the degree of influence of leakage on the resistance characteristic coefficient of the pipe section is not only affected by the leakage itself, but also related to the pipe diameter. The allowable change range of the resistance coefficient of the pipe section under the suspected leakage condition is as follows:

[0060] For a pipe section with a pipe diameter of 100-200mm, the allowable change range is [0, 50%] of the set value of the resistance coefficient of the corresponding pipe section under normal working conditions;

[0061] For a pipe section with a pipe diameter of 250-400mm, the allowable variation range is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com