Method for optimizing site selection of gas detecting alarm instrument of oil refining device by considering conditional risk value

A technology for oil refining equipment and gas detection, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems such as no alarm, no real-time consequence representation model of the scene, and false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in combination with embodiments.

[0068] Specific steps are as follows:

[0069] (1) Taking the leakage source working conditions and wind field conditions as random factors, quantitatively construct a set of hazardous gas leakage scenarios for refinery units. Each scenario in the set is denoted by i, i∈[1,I]. Use historical meteorological data to obtain the joint distribution probability of wind speed and wind direction in the wind field, and obtain the probability of equipment leakage, so as to obtain the approximate probability of leakage scenarios;

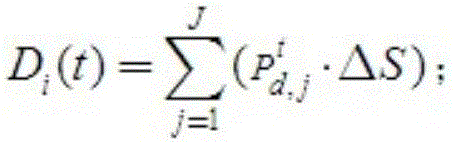

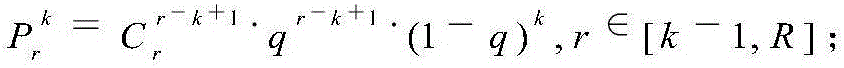

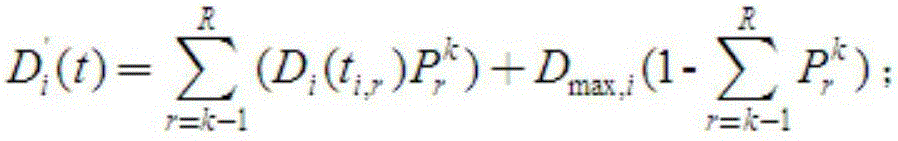

[0070] (2) This patent uses the method of CFD three-dimensional numerical simulation to obtain the real-time concentration data of gas diffusion that conforms to the layout of the on-site device. However, modeling all leakage scenarios in detail would be computationally expensive. Taking the research device as an example, using a high-performance computer (CPU: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com