Preparation method for surface-printed button

A button and resin technology, applied in the field of clothing production, can solve the problems of single font color, cumbersome process, changeable color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

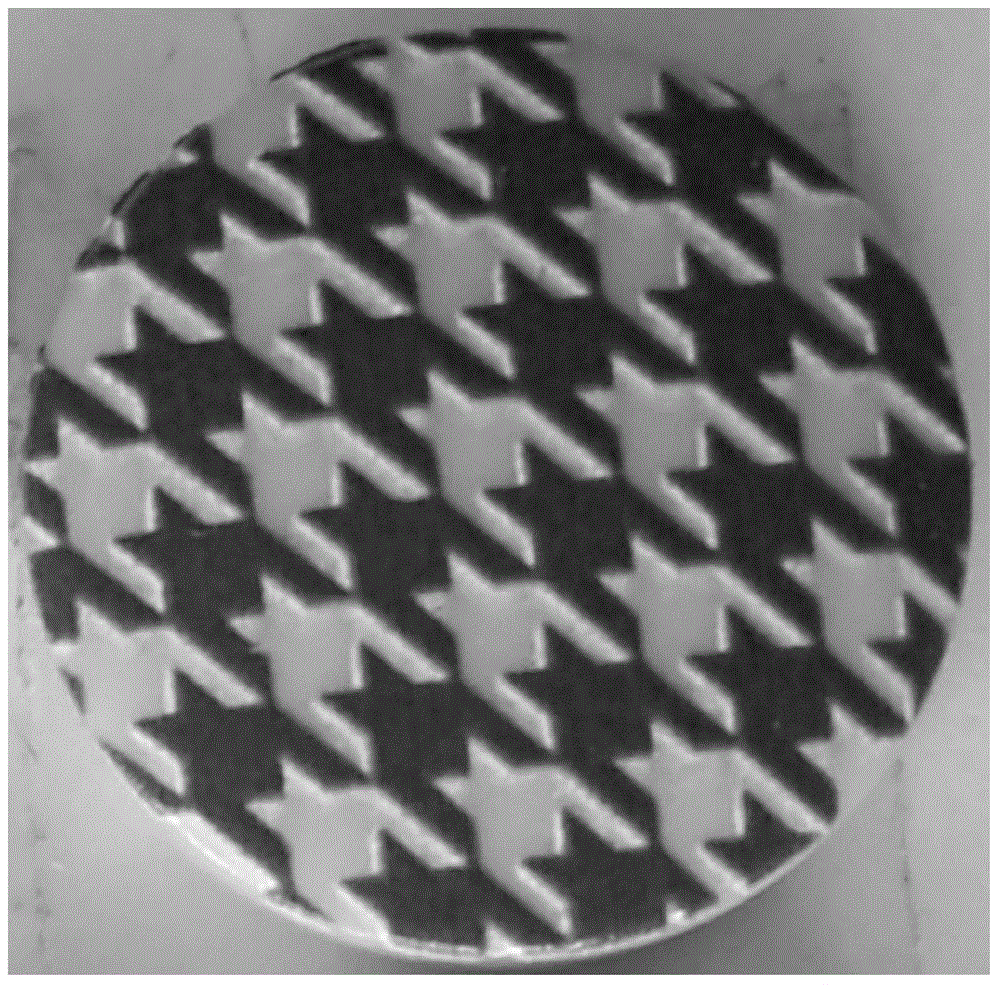

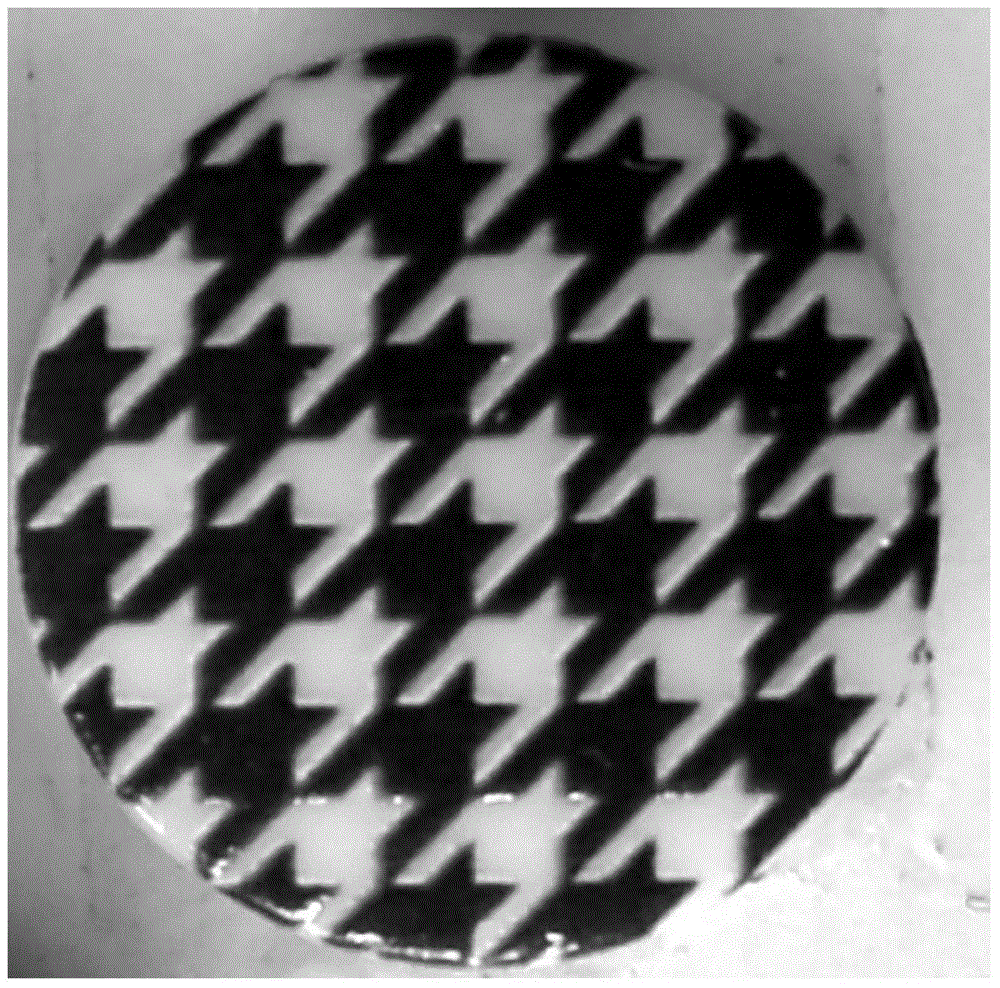

Image

Examples

preparation example Construction

[0030] The invention discloses a method for preparing a surface-printed button, which is characterized in that it comprises the following steps:

[0031] A) After printing the light-cured resin on the surface of the button after degreasing treatment, a semi-finished product is obtained;

[0032] B) After curing the semi-finished product obtained in the above steps, a surface-printed button is obtained.

[0033] In the present invention, firstly, semi-finished products are obtained after printing photocurable resin on the surface of the button after the degreasing treatment; the printing is preferably 3D printing; The method of degreasing treatment is enough; the present invention has no special limitation on the printing equipment, and the 3D printing equipment well known to those skilled in the art can be used, and the present invention is preferably a 3D printer. In order to ensure the stability of printing, the present invention preferably fixes the degreasing buttons on t...

Embodiment 1

[0048] Billet making process: add 10ml of cobalt salt to 1.0kg of unsaturated resin and stir well, then add 10ml of methyl ethyl ketone peroxide and 20ml of styrene, stir evenly, and then crush it through a rod machine to obtain button blanks.

[0049] Button making process: First, the button blank is made into the shape of a button by a button making machine, and it can be shaped according to different review requirements.

[0050] Initial polishing: Pour the button blanks made by the button making machine into the polishing machine, and carry out water rolling polishing with a polishing stone to remove the burrs and uneven knife feet left during the button making.

[0051] Finished product inspection: reject defective button blanks.

[0052] Polishing (cleaning): Pour the button blank into a dry roll polishing machine for further polishing to achieve the required luminosity, and then use ultrasonic cleaning to remove the dust and excess polishing oil on the surface of the bu...

Embodiment 2

[0059] Billet making process: add 8ml of cobalt salt to 1.0kg of unsaturated resin and stir well, then add 10ml of methyl ethyl ketone peroxide and 20ml of styrene, after stirring evenly, go through a centrifuge to make boards, after the boards are made, go through the cutting machine Take the blank.

[0060] Button making process: First, the button blank is made into the shape of a button by a button making machine, and it can be shaped according to different review requirements.

[0061] Initial polishing: Pour the button blanks made by the button making machine into the polishing machine, and carry out water rolling polishing with a polishing stone to remove the burrs and uneven knife feet left during the button making.

[0062] Finished product inspection: reject defective button blanks.

[0063] Polishing (cleaning): Pour the button blank into a dry roll polishing machine for further polishing to achieve the required luminosity, and then use ultrasonic cleaning to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com