Biodegradable coffee-ground composite material and its product

A composite material, coffee grounds technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

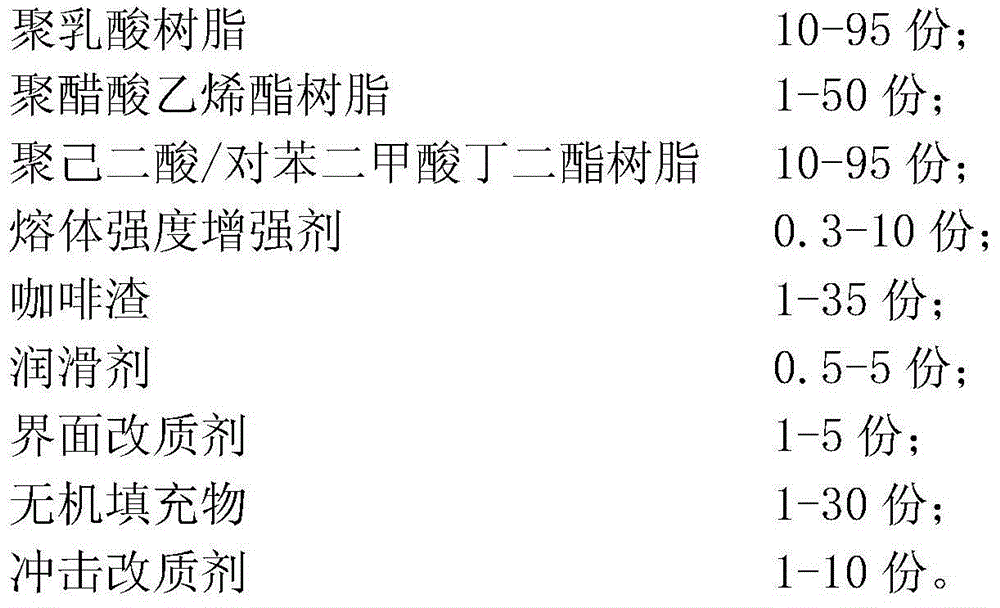

Method used

Image

Examples

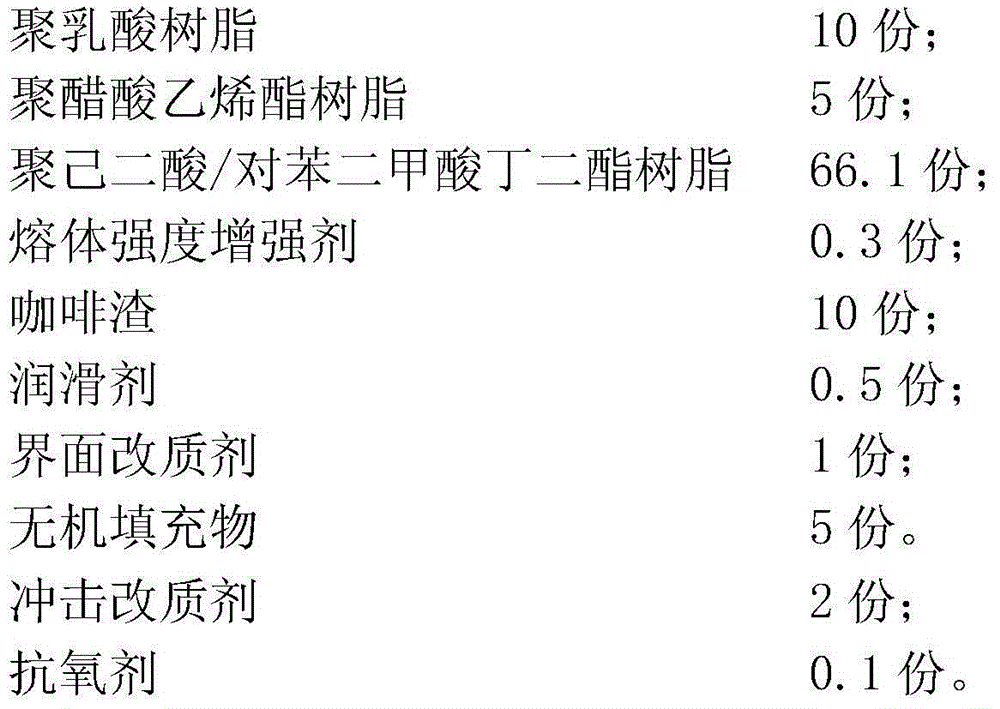

Embodiment 1

[0032]

[0033] First, weigh the coffee grounds, and stir the coffee grounds through a high-speed mixer to remove water. The temperature of the high-speed mixer is set at 110 ° C. After the temperature reaches 15 minutes, the weighed interface modifier is added to stir and mix. The fixed stirring time is 10 minutes; then, the moisture content of the polylactic acid resin needs to be reduced to below 0.05-0.1% during the processing; The material was stirred for 10 minutes with a single-shaft mixing bucket, and the weighed polyvinyl acetate resin, lubricant, impact modifier and inorganic filler were stirred for 10 minutes with a single-shaft mixing bucket; the above mixtures were respectively added to the twin-screw extruder Melt extrusion granulation in the machine.

Embodiment 2

[0035]

[0036]

[0037] First, weigh the coffee grounds, and stir the coffee grounds through a high-speed mixer to remove water. The temperature of the high-speed mixer is set at 110 ° C. After the temperature reaches 15 minutes, the weighed interface modifier is added to stir and mix. The fixed stirring time is 10 minutes; then, the moisture content of the polylactic acid resin needs to be reduced to below 0.05-0.1% during the processing; The material was stirred for 10 minutes with a single-shaft mixing bucket, and the weighed polyvinyl acetate resin, lubricant, impact modifier and inorganic filler were stirred for 10 minutes with a single-shaft mixing bucket; the above mixtures were respectively added to the twin-screw extruder Melt extrusion granulation in the machine.

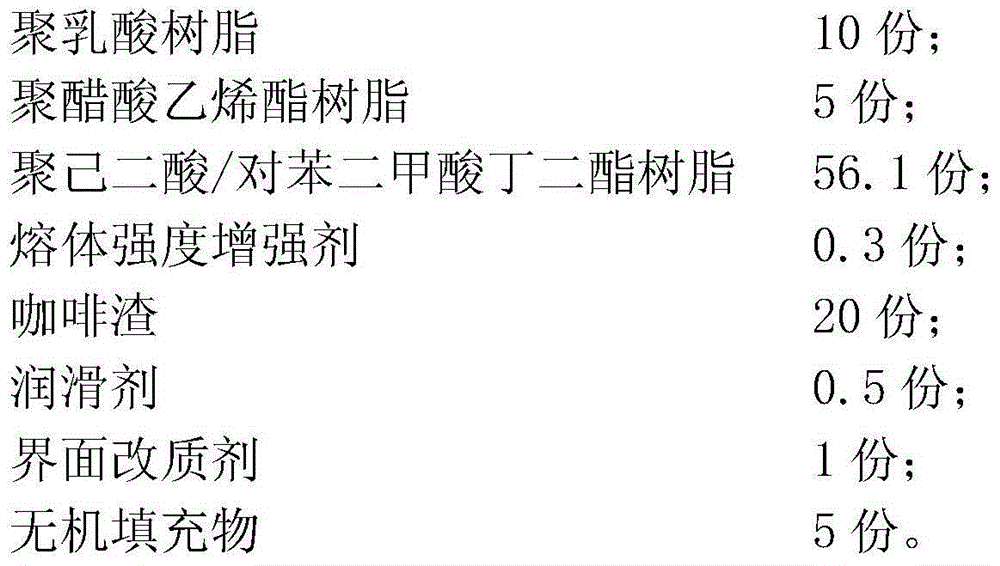

Embodiment 3

[0039]

[0040] First, weigh the coffee grounds, and stir the coffee grounds through a high-speed mixer to remove water. The temperature of the high-speed mixer is set at 110 ° C. After the temperature reaches 15 minutes, the weighed interface modifier is added to stir and mix. The fixed stirring time is 10 minutes; then, the moisture content of the polylactic acid resin needs to be reduced to below 0.05-0.1% during the processing; The material was stirred for 10 minutes with a single-shaft mixing bucket, and the weighed polyvinyl acetate resin, lubricant, impact modifier and inorganic filler were stirred for 10 minutes with a single-shaft mixing bucket; the above mixtures were respectively added to the twin-screw extruder Melt extrusion granulation in the machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com