Reinforcement connection member for washing machine dual-end drainage pump

A technology for strengthening connectors and drainage pumps, applied in the field of washing machines, can solve problems such as increased manufacturing costs, poor stability, and increased installation complexity, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

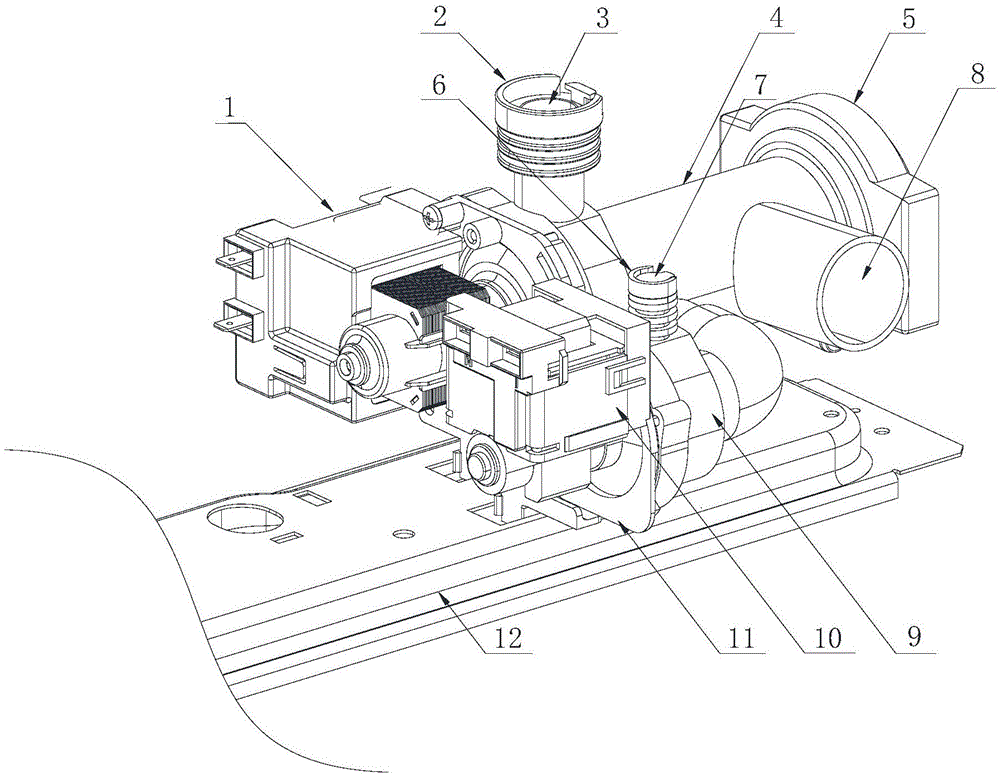

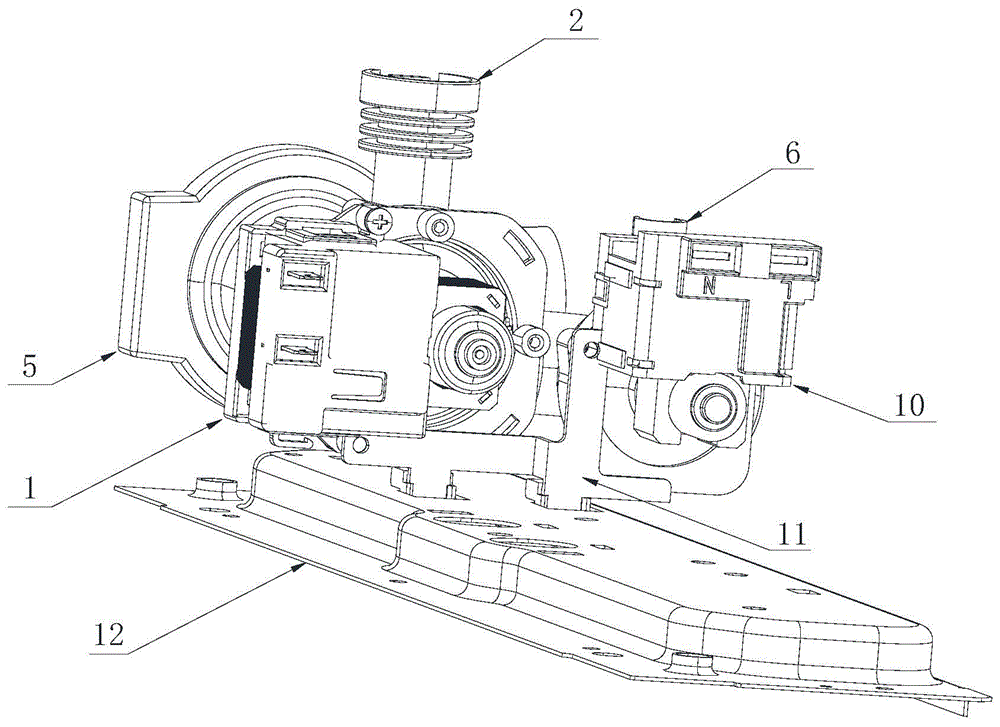

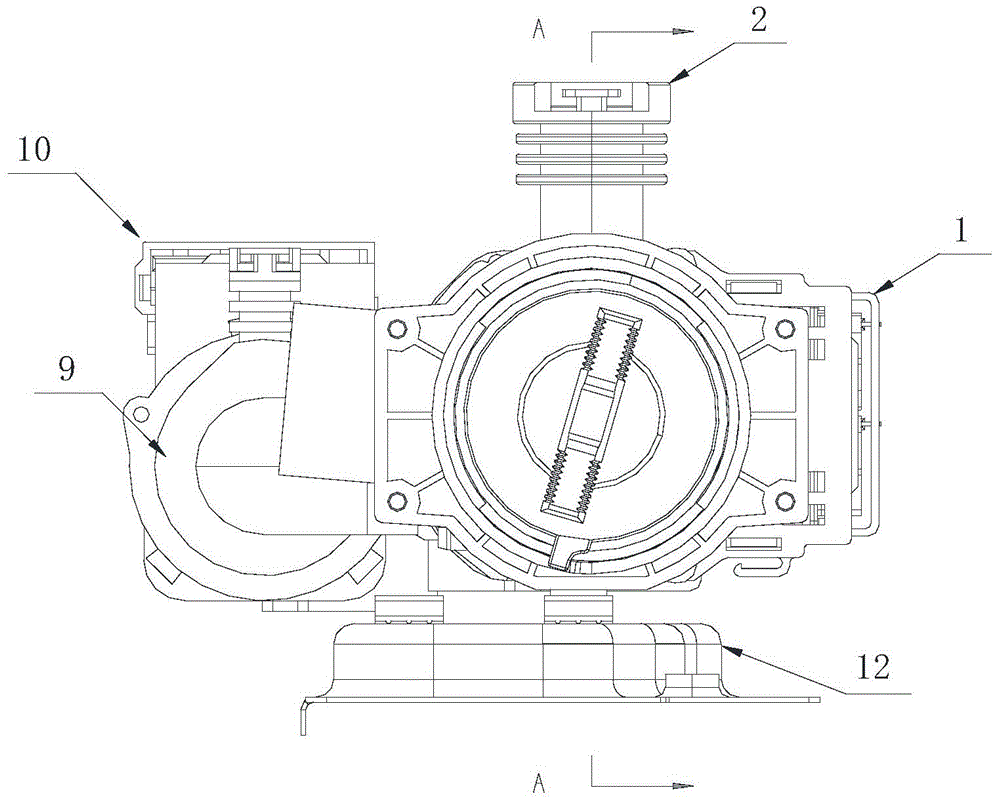

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment is a double-headed drainage pump for a washing machine. Specifically, the following technical solution is adopted:

[0056] A double-head drainage pump for a washing machine, comprising a pump casing, on which a water inlet 8 is arranged, at least one first water outlet 2 and at least one second water outlet 6 respectively arranged on the pump casing, corresponding to the first The water outlet 2 and the second water outlet 6 are respectively equipped with a first drainage motor 1 and a second drainage motor 10, the first drainage motor 1 controls the opening / closing of the first water outlet 2, and the second drainage motor 10 controls the second water outlet 6 on / off.

[0057] A double-headed drainage pump for a washing machine in this embodiment is provided with a first water outlet 2 and a second water outlet 6 sharing a water inlet on the pump casing, the first water ou...

Embodiment 2

[0079] Such as figure 1 , Figure 4 , Figure 9 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, this embodiment is suitable for installing a shock-absorbing device for a double-headed drainage pump of a washing machine. The double-headed drainage pump includes at least two drainage pumps sharing a water inlet 8, and the two drainage pumps are connected through a reinforced connector. The connection is integrated, and the reinforcing connector is installed on the washing machine installation plate 12, and the installation shock absorbing device 14 for relieving the vibration of the double-headed drainage pump is arranged between the reinforcing connector and the washing machine installation plate 12.

[0080] Since the double-head drainage pump includes two drainage pumps with different structures, the two drainage pumps are connected as a whole through a strengthening connector 11, and are fixedly installed on the washing machine mounting plate 12 through ...

Embodiment 3

[0097]Such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, this embodiment is a filter suitable for a double-head drainage pump of a washing machine. The double-head drainage pump includes a pump casing, and the pump casing is provided with a water inlet and at least two water outlets for the common water inlet. The opening / closing of the water outlets is controlled by two drainage motors respectively. A filter 13 is arranged between the two water outlets and the water inlet inside the pump housing. The filter 13 includes at least two corresponding to the two water outlets respectively. The water outlet parts, at least one water outlet part is provided with a filter part.

[0098] The filter 13 of this embodiment is arranged inside the pump casing of the double-head drainage pump and is located between the two water outlets and the water inlet, so that the drain of the washing machine is filtered by the filter and then discharged from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com