A spraying device for supporting rollers

A technology of spraying device and supporting roller, which is applied in the direction of spraying device, spray booth, etc., which can solve the problems of uneven spraying and unsatisfactory coating effect, and achieve good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

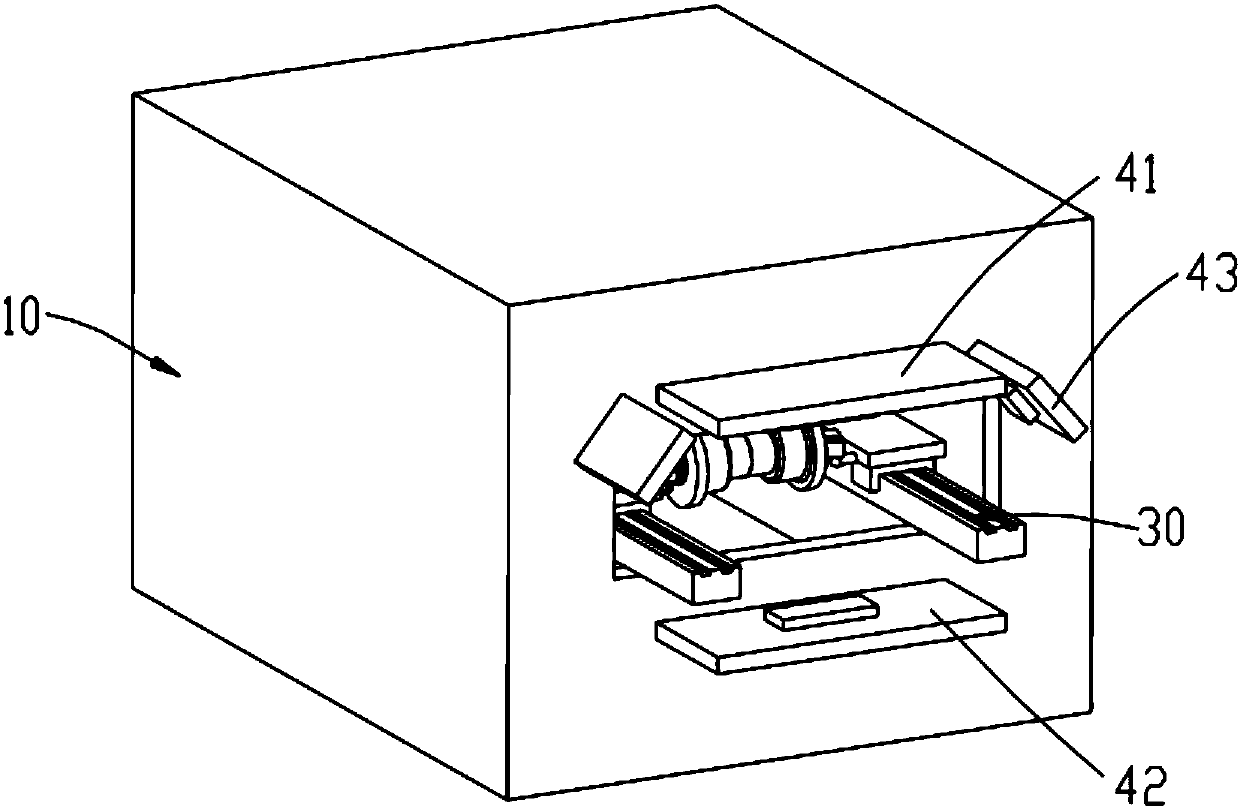

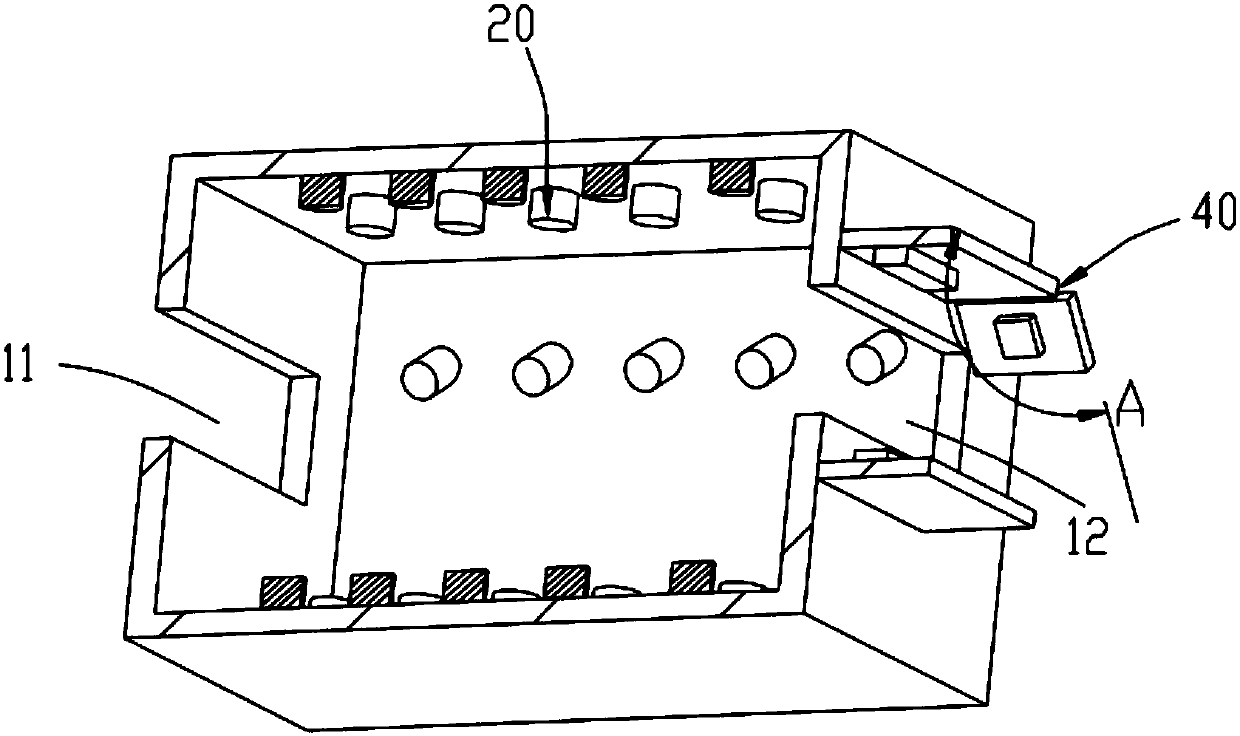

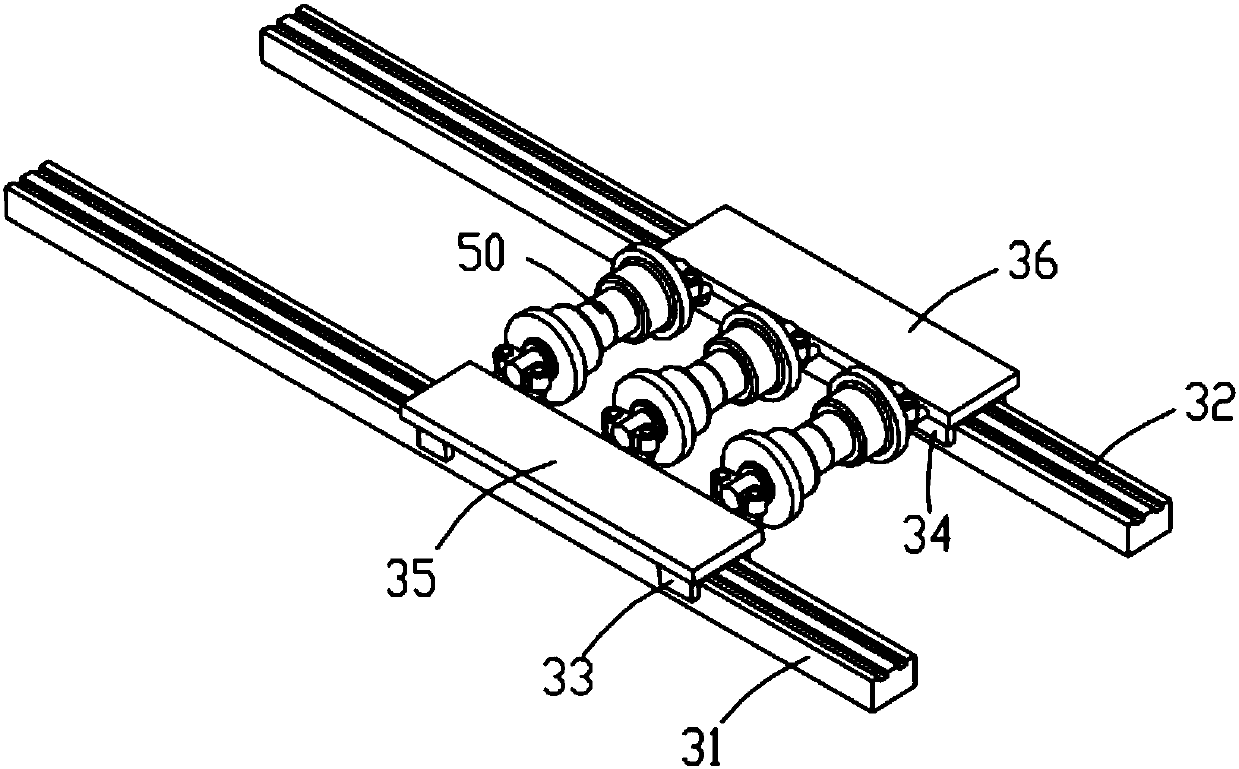

[0019] See Figure 1 to Figure 4 Shown, a kind of spraying device of supporting roller comprises: spraying box 10, an inlet 11 and an outlet 12 are symmetrically arranged on its pair of opposite side walls, and described spraying box 10 is hollow structure, and described spraying box 10 The hollow cavity communicates with the outside through the inlet 11 and the outlet 12; the nozzle unit 20 is installed on the inner wall of the spray box 10; The first slide rail 31 and the second slide rail 32, the first slide block 33 arranged on the first slide rail 31, the second slide block 34 arranged on the second slide rail 32, the second slide block 34 installed on the The first bearing plate 35 on the first slider 33, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com