Heat removal system and method for removing residues from the inner surface of steel pipes using the same

A cleaning system and technology for steel pipes, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as difficult removal of residues on the inner surface of steel pipes, simplify manufacturing procedures, increase processing speed, and clean The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

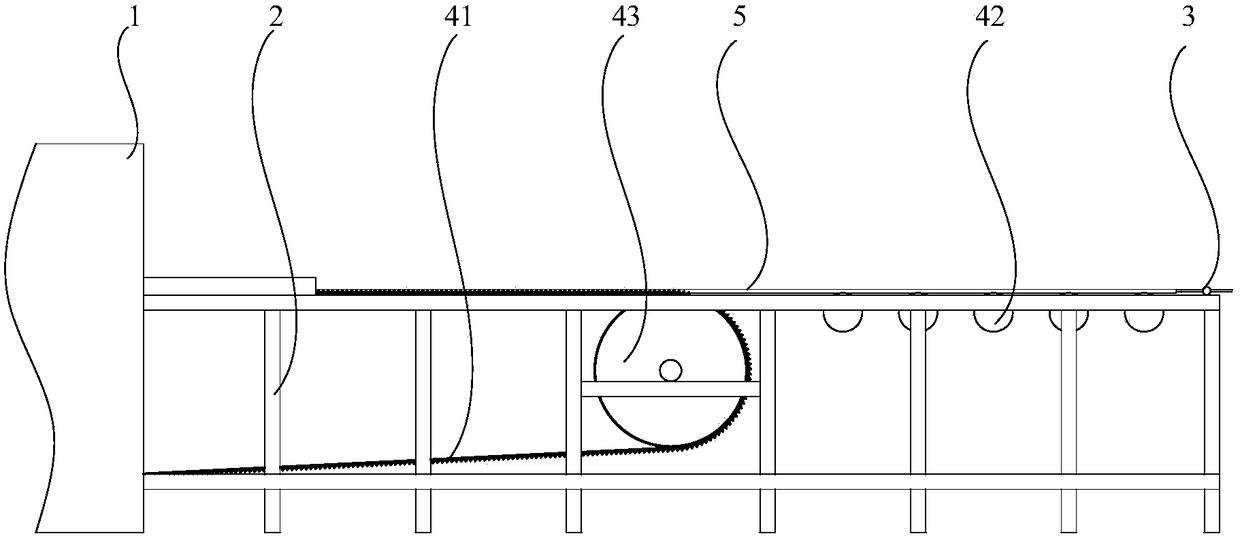

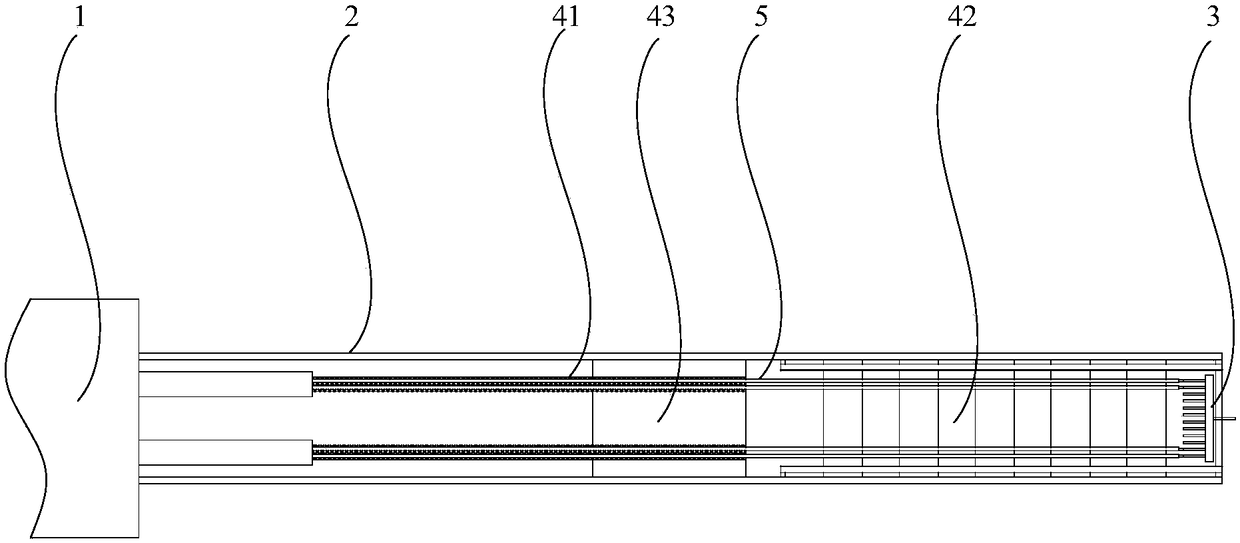

[0054] Please combine figure 1 , figure 2 and image 3 It should be understood that this embodiment provides a heat removal system, including a bright annealing furnace 1, a support 2, a gas delivery device 3, a transfer device and a gas device (not shown in the figure).

[0055] The bright annealing furnace 1 is connected to one end of the support 2 .

[0056] The gas delivery device 3 is detachably connected to the other end of the bracket 2, and the gas delivery device 3 is used to deliver the gas to be combusted into the steel pipe 5 to be processed. The gas to be burned is a mixed gas of 75% hydrogen and 25% nitrogen. Other gases are also possible in other embodiments.

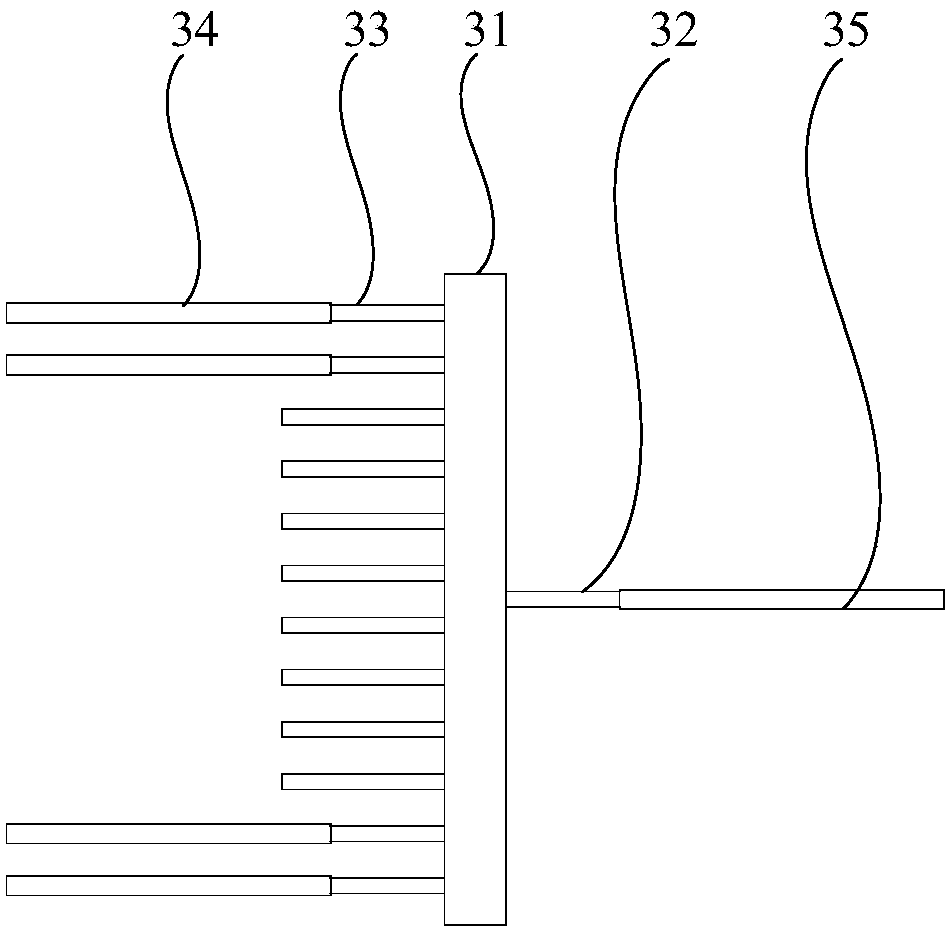

[0057] The gas delivery device 3 includes: a frame 31 , an input pipe 32 and several output pipes 33 .

[0058] The frame 31 is provided with a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com