Pipe bending machine and pipe bending method

A pipe bending machine and pipe material technology, applied in the field of pipe bending, can solve the problems affecting the quality of metal bending pipe products, easy to break and damage, etc., and achieve the effect of reducing the fracture damage and high quality of the pipe end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below:

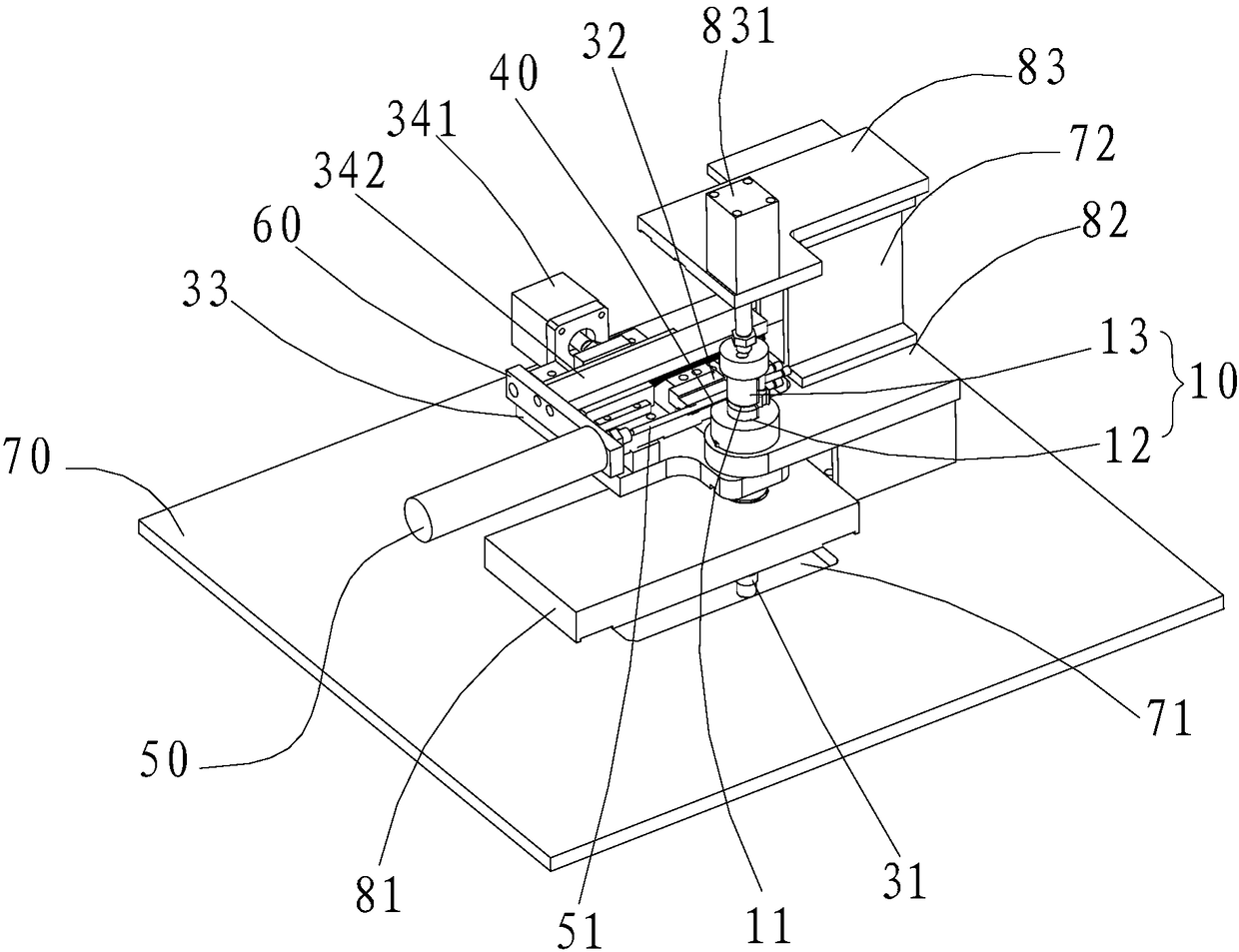

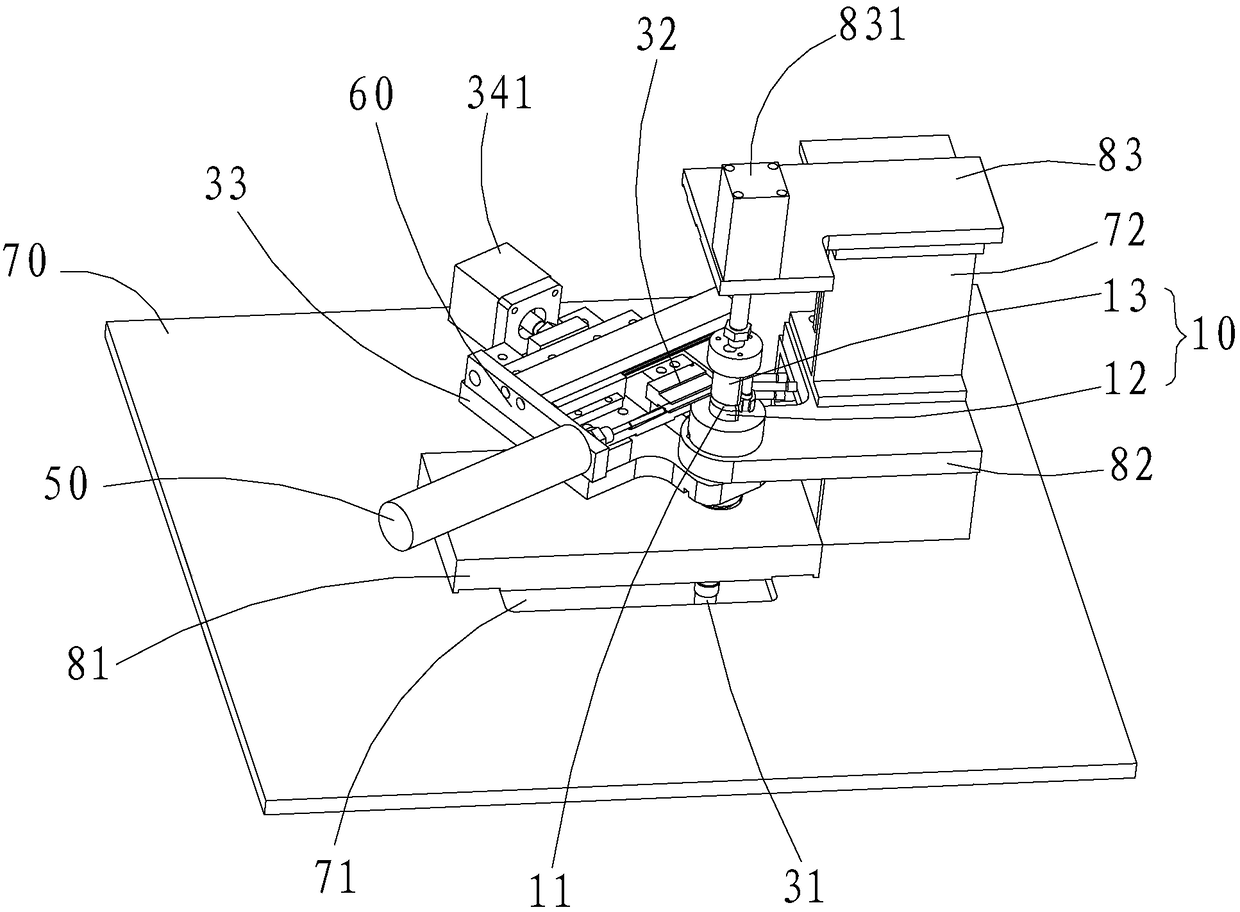

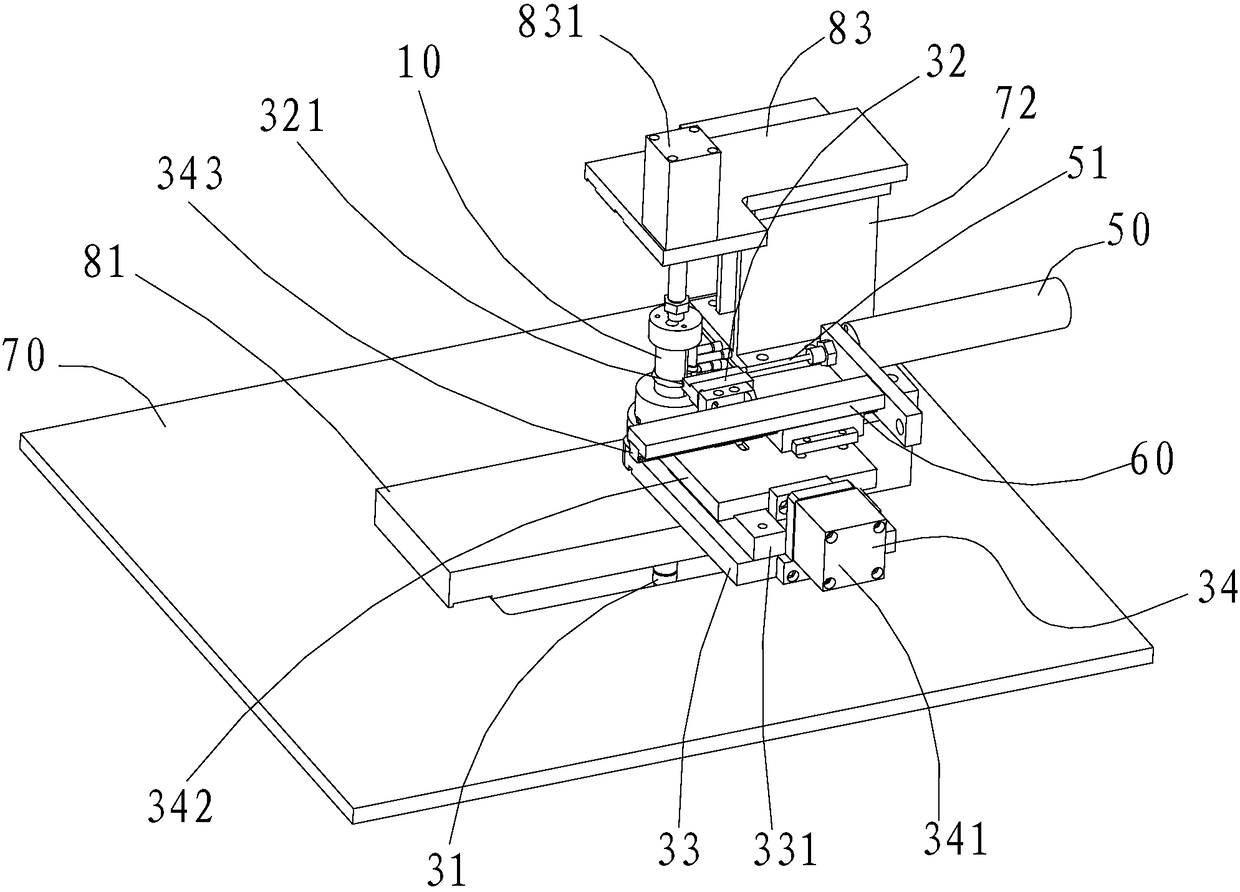

[0037] Such as Figure 1-5 As shown, the pipe bender of the present invention includes a guide column 10, a fixing member 20, a rotating mechanism 30 (in Figure 7-10 There are marks in it) and the first driving part 831. A first recess 11 is formed on the side wall of the guide column 10 . The first recess 11 is arranged around the guide cylinder 10 around the axis of the guide cylinder 10 , and the first recess 11 is adapted to the outer wall of the pipe 40 . Wherein, the guide cylinder 10 includes a first cylinder 12 and a second cylinder 13 arranged coaxially (see Figure 6 ). And the first cylinder 12 and the second cylinder 13 can move towards or back, the outer wall of the end of the first cylinder 12 has a first concave surface 121, and the outer side of the end of the second cylinder 13 is The wall has a second concave surface 131 . The first concave surface 121 is spliced with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com