Patents

Literature

32results about How to "Reduce breakage damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

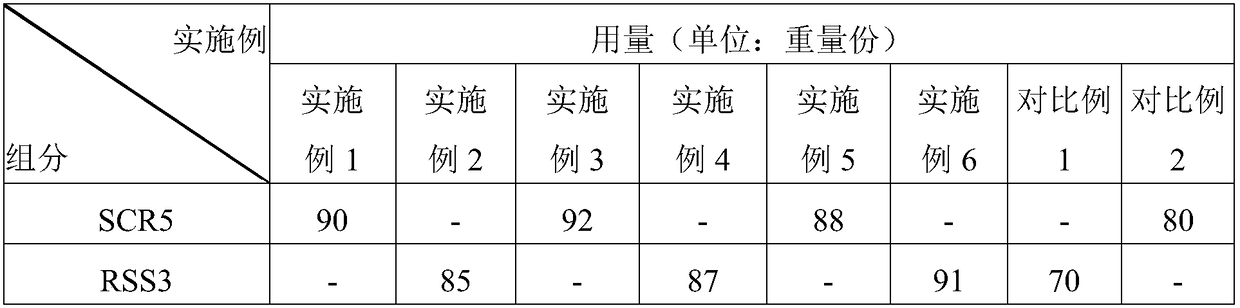

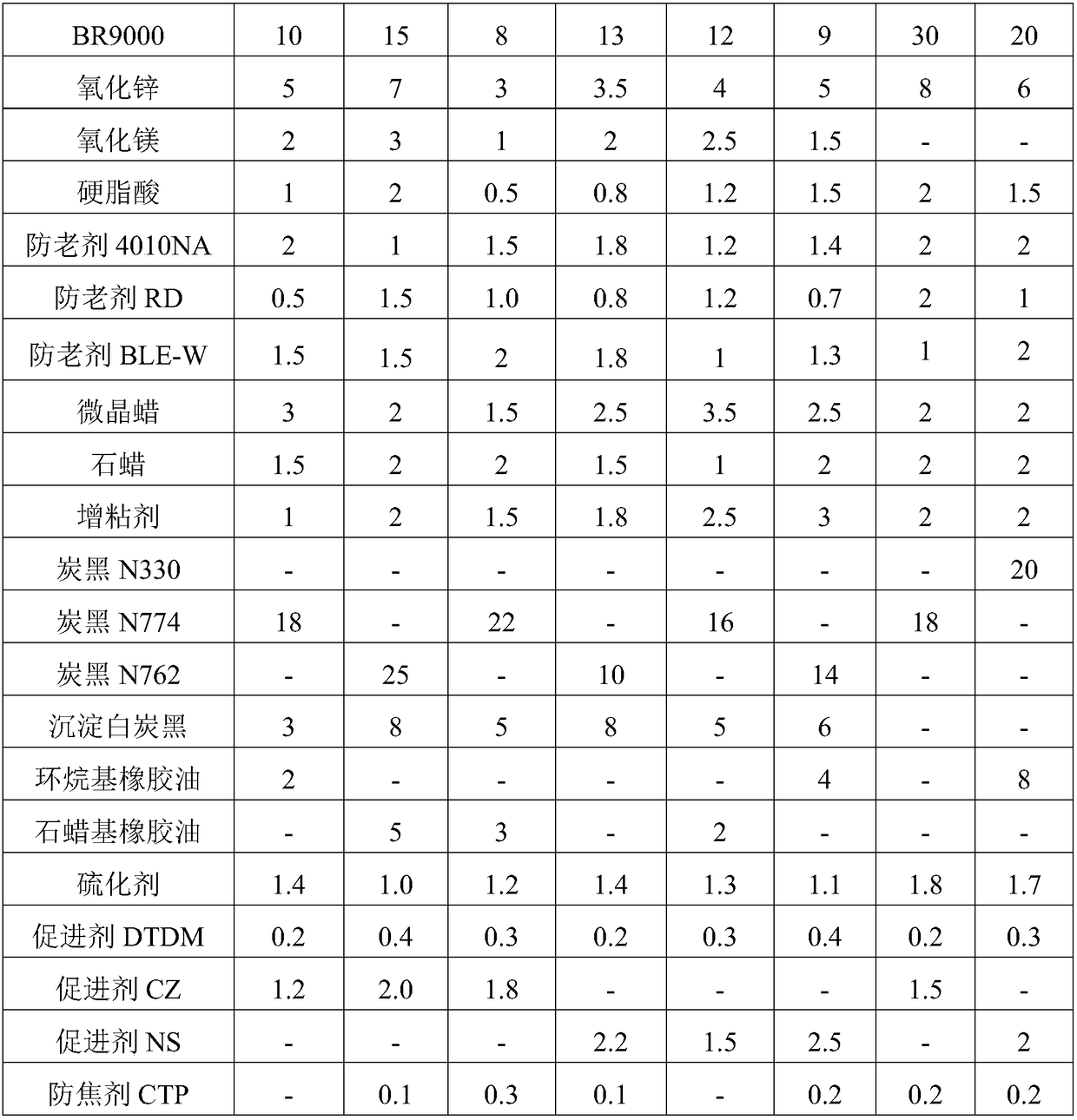

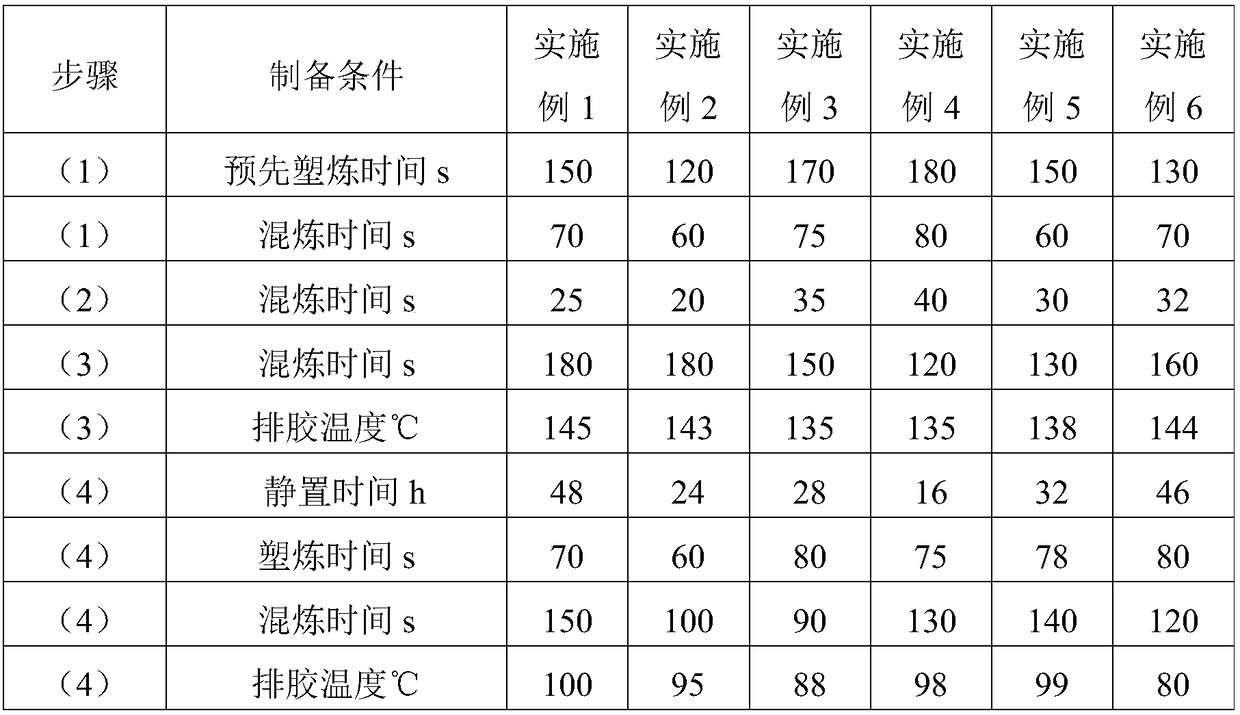

Natural rubber composition material as well as preparation method and application thereof

The invention discloses a natural rubber composition material as well as a preparation method and application thereof. A raw material composition of the natural rubber composition material is preparedfrom the following components according to the parts by weight: 85-92 parts of natural rubber, 8-15 parts of butadiene rubber, 4-10 parts of activator A, 0.5-2 parts of activator B, 2-6 parts of anti-aging agent, 2-4 parts of protective wax, 1-3 parts of tackifier, 10-25 parts of carbon black, 3-8 parts of white carbon black, 1-1.4 parts of vulcanizing agent, 0.1-0.4 parts of accelerant A, and 1.2-2.5 parts of accelerant B. The natural rubber composition material prepared from the invention is low in damping coefficient, and excellent in mechanical property, and capable of improving the fatigue radiating feature of the material, relieving the fracture and damage of a rubber chain caused by the fatigue rapid heating, improving the durability life, improving the high temperature resistancefeature of the vulcanized rubber, and reducing the high temperature creep deformations of the vulcanized rubber. A prepared automobile engine suspension damping material NVH has the good control effect, and the service life of a road test reaches the standard.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

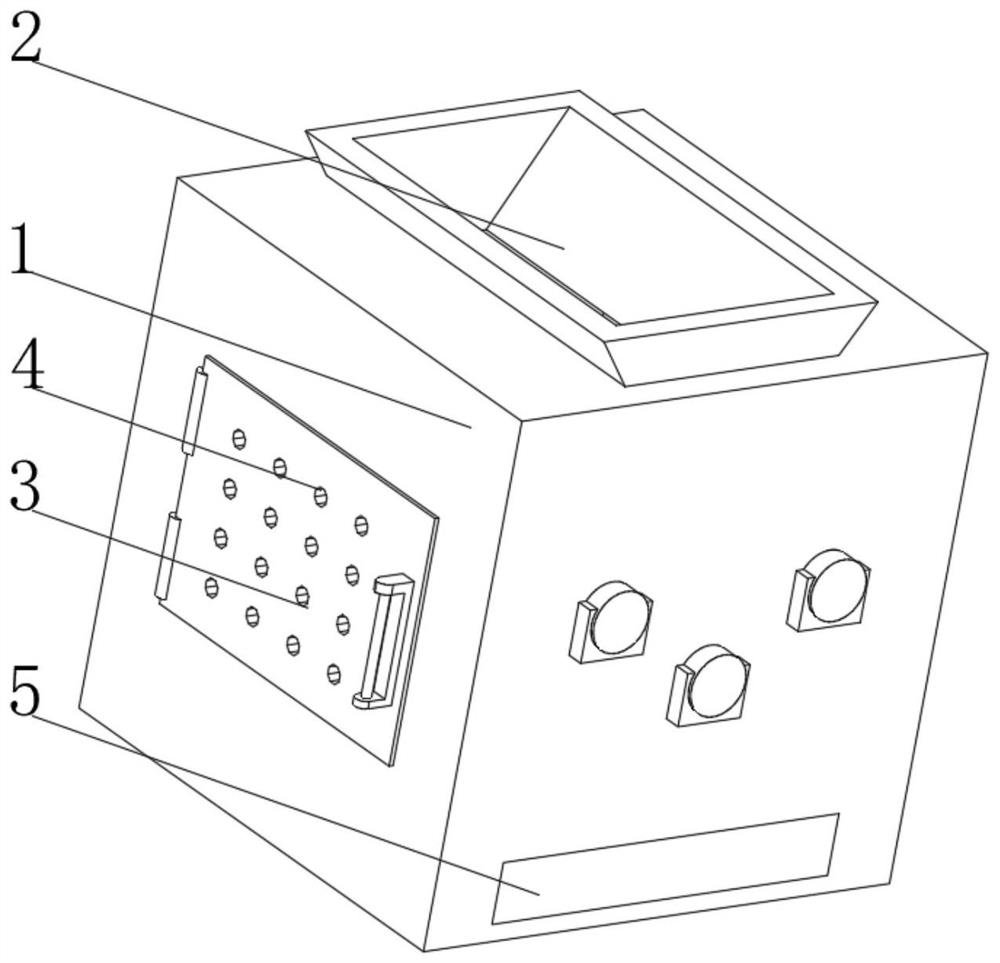

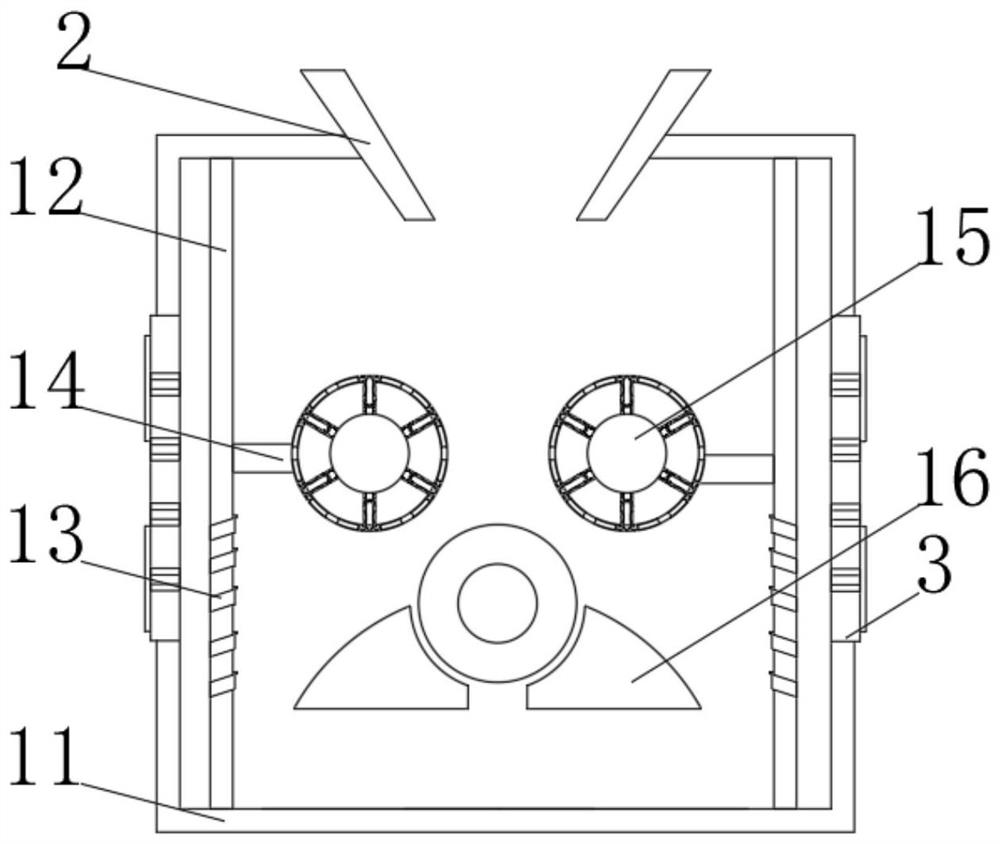

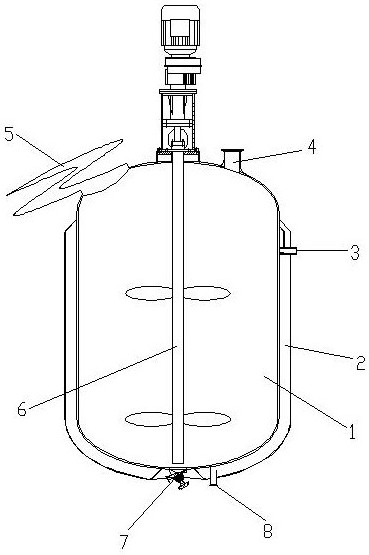

Waste plastic crushing machine

InactiveCN112844692AAffect healthAvoid damageCleaning using toolsCleaning using gasesDust controlCrusher

The invention discloses a waste plastic crushing machine which comprises a crushing main body, the top of the crushing main body communicates with a feeding hopper, the two sides of the crushing main body are rotationally connected with dust removal door plates through hinges correspondingly, a connecting groove is formed in one side of each dust removal door plate, a discharging door plate is arranged at the lower part of one side of the crushing main body, the crushing main body comprises a crushing shell, fixing plates are fixedly connected to the side faces of the inner wall of the crushing shell, a dust discharging device is arranged at the lower part of one side of each fixing plate, a supporting frame is fixedly connected to one side of each fixing plate, a crushing mechanism is arranged at the end, away from the corresponding fixing plate, of each supporting frame, and classification mechanisms are arranged at the lower part of one side, close to the corresponding crushing mechanisms, of the crushing shell. According to the waste plastic crushing machine, flying dust generated during crushing work is prevented from being sprayed out of the feeding hopper and the discharging door plate and is not inhaled into the body of a worker to affect and the body health of the worker.

Owner:何晓静

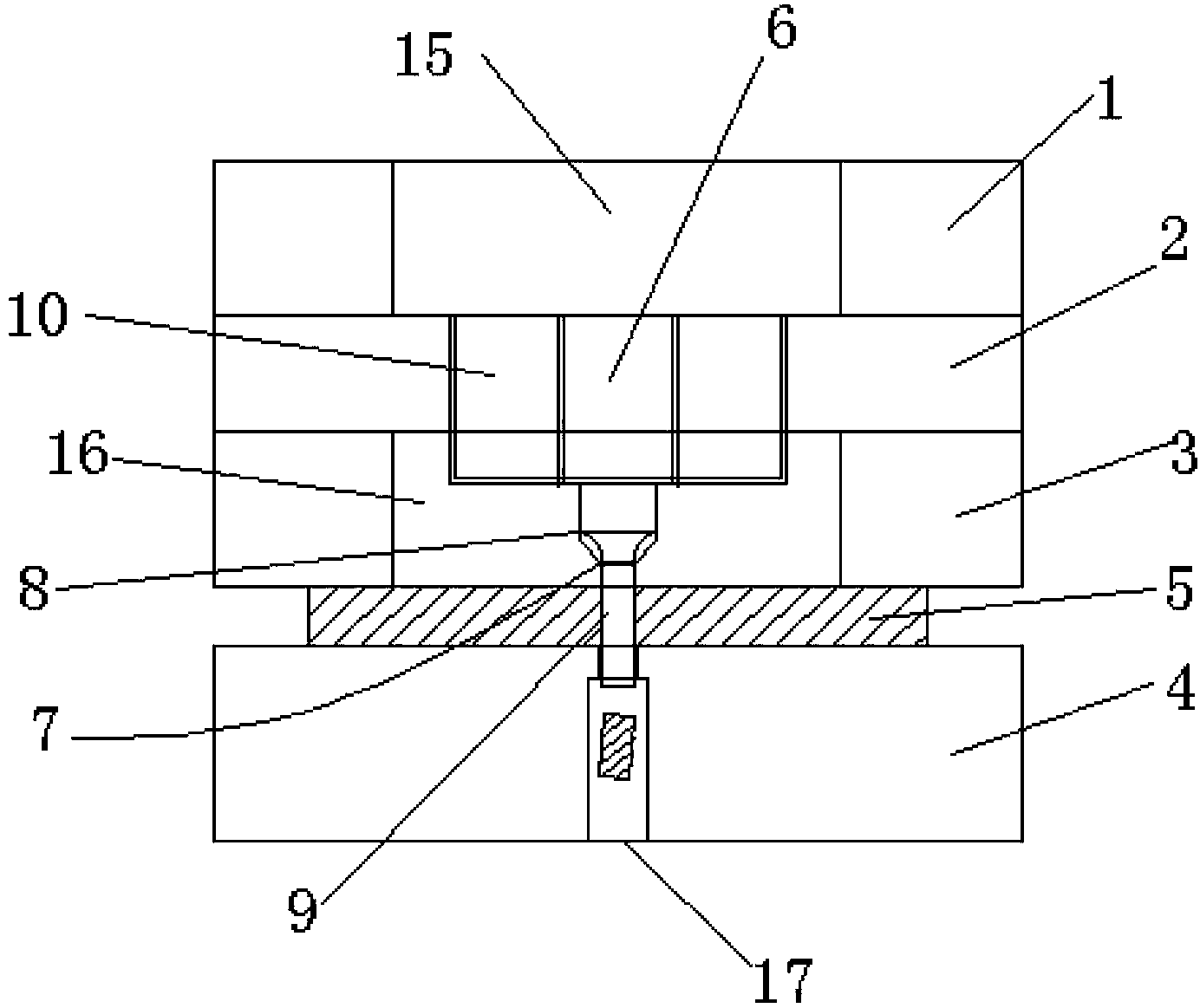

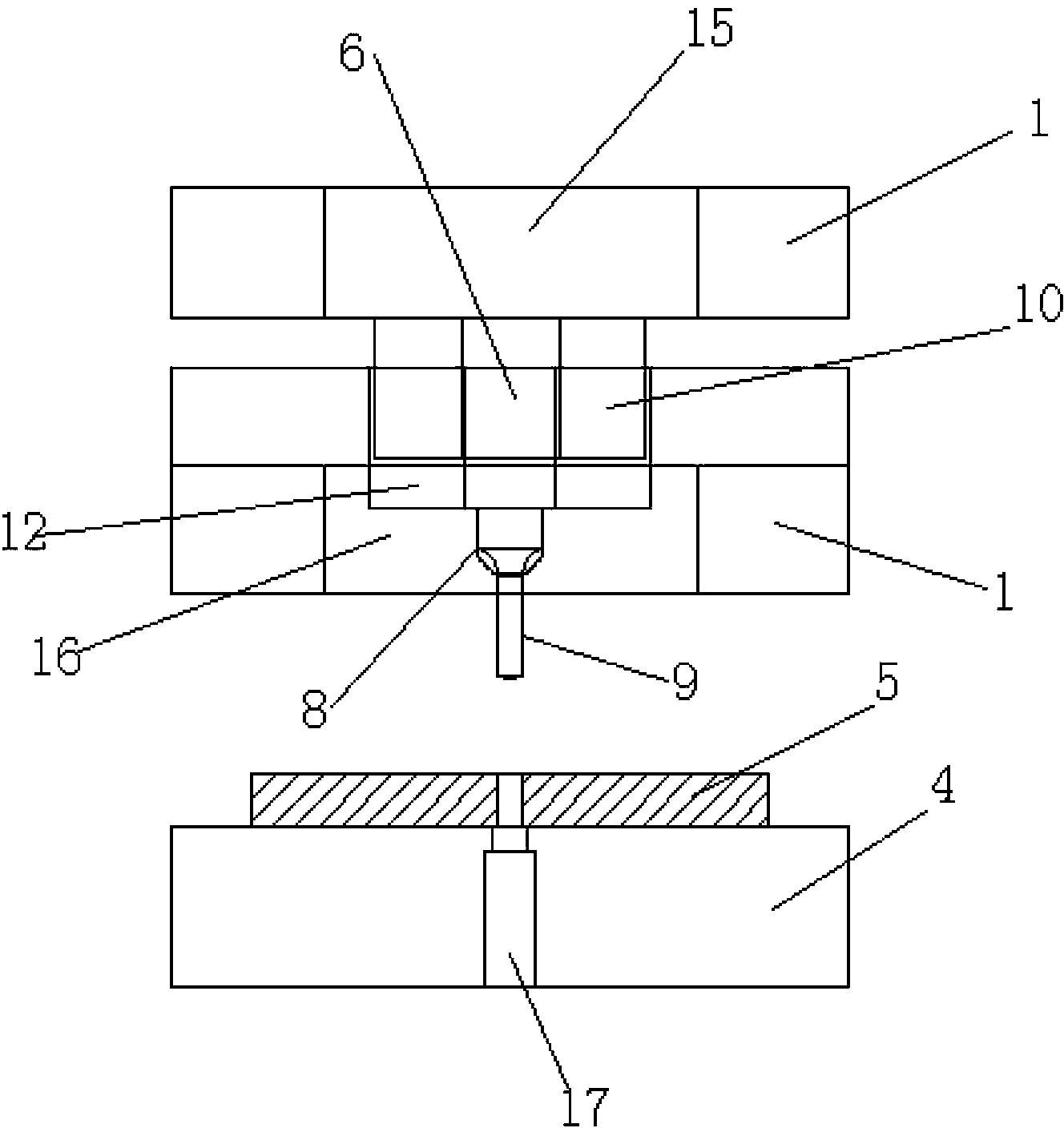

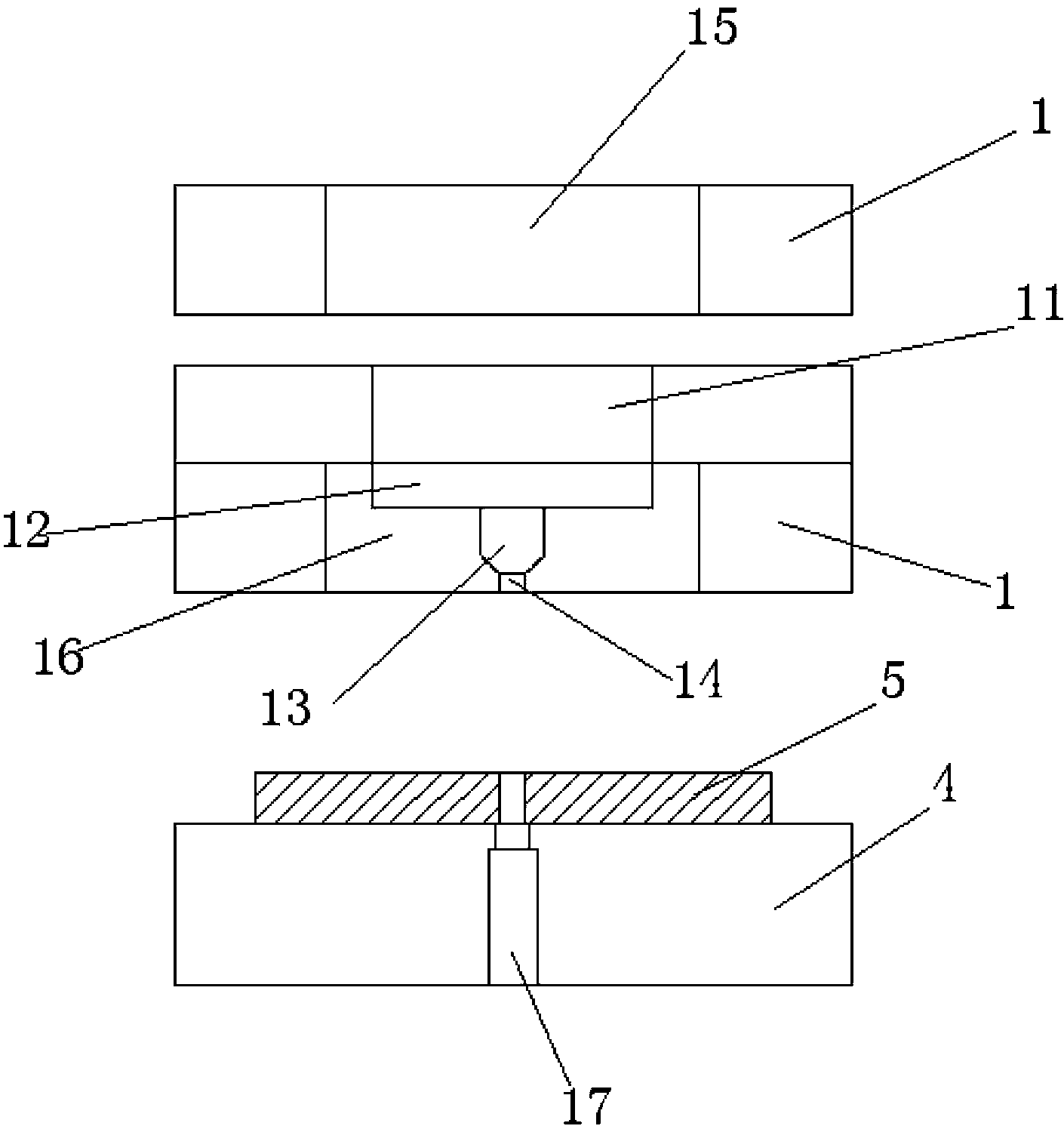

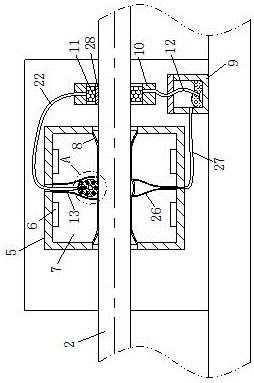

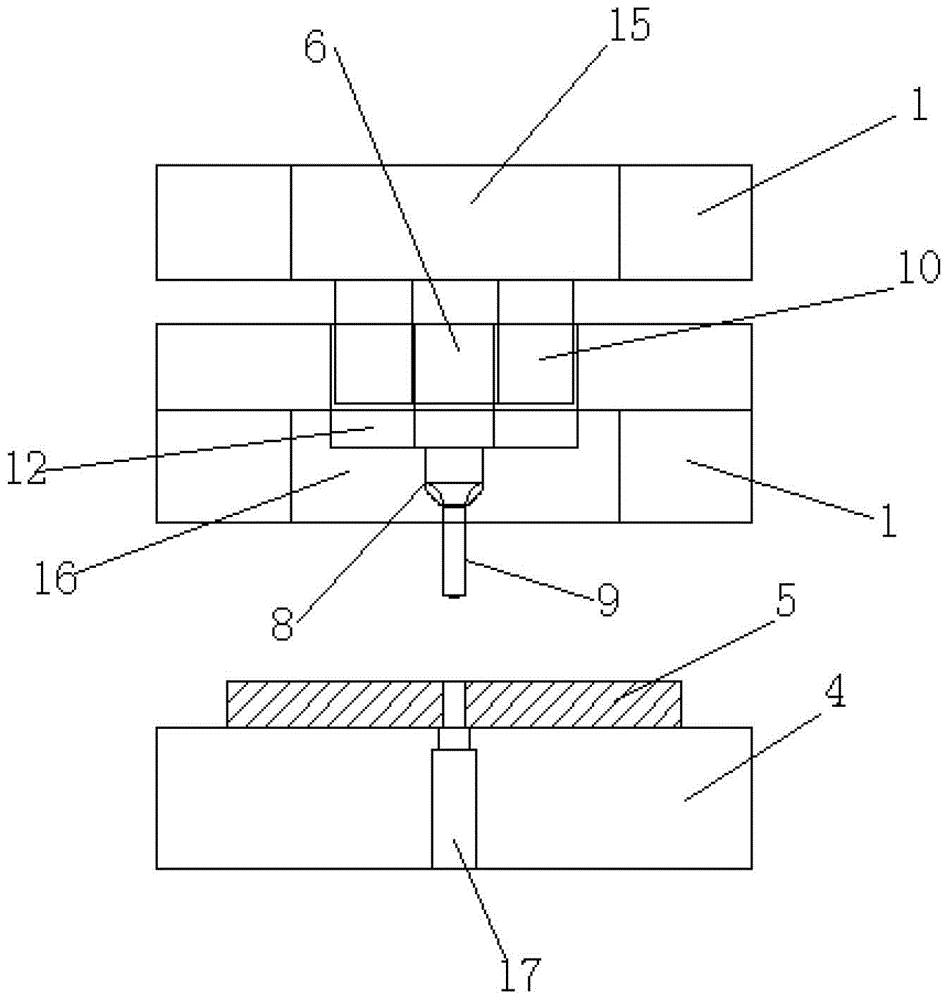

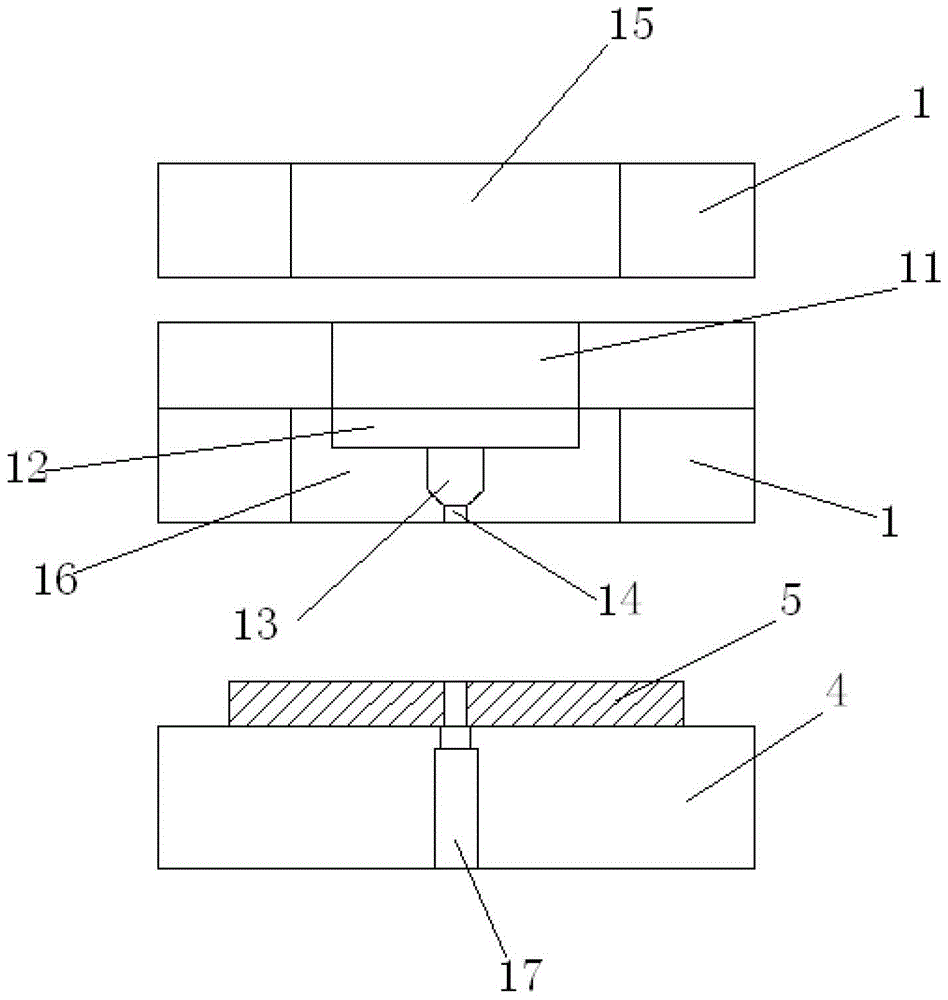

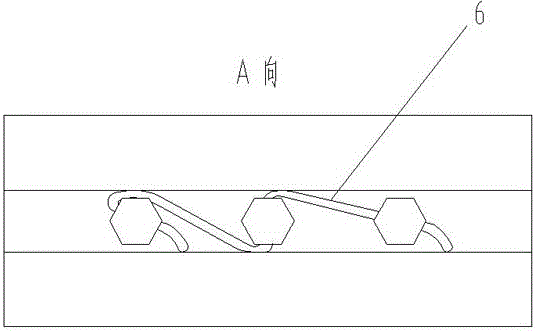

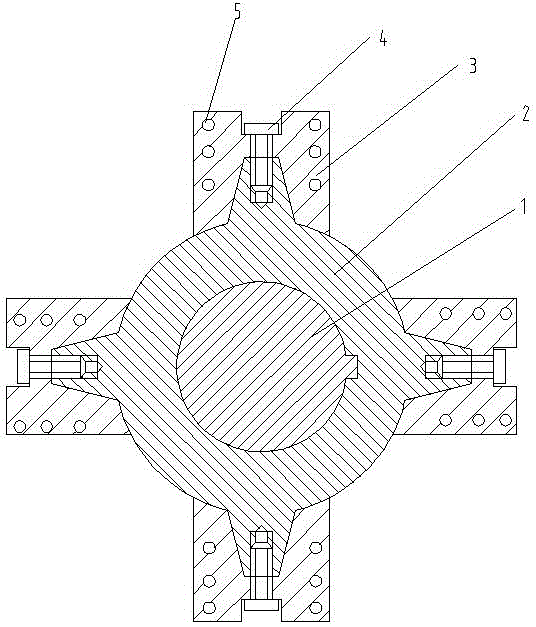

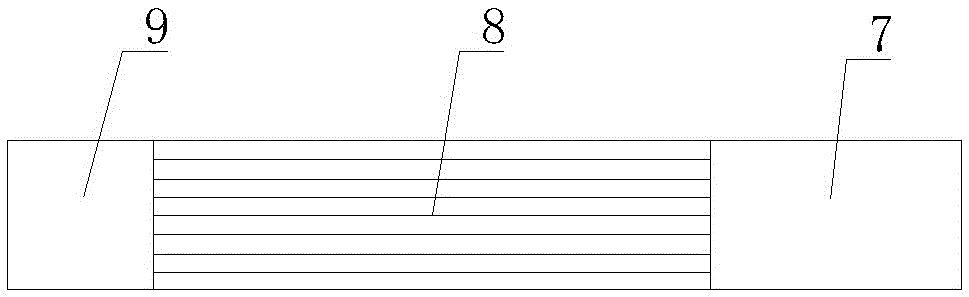

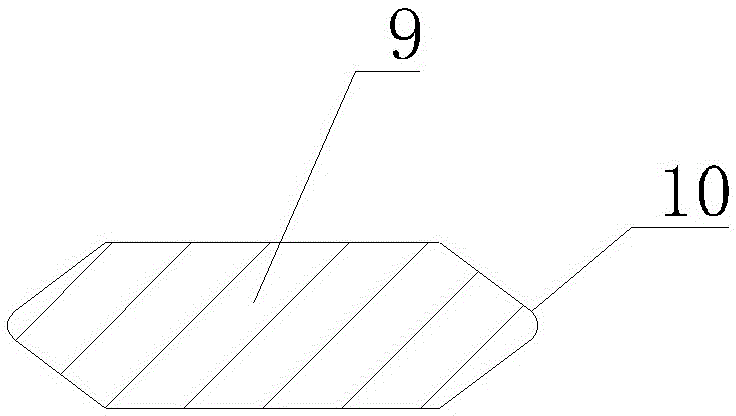

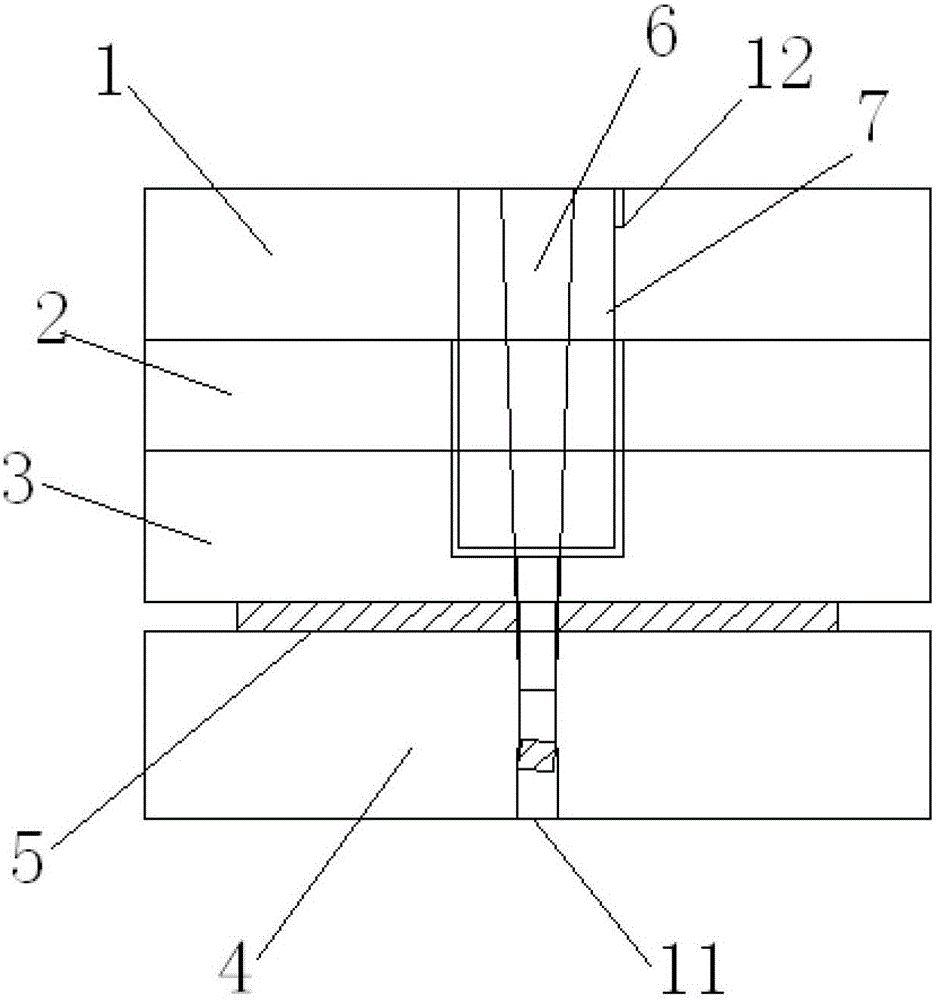

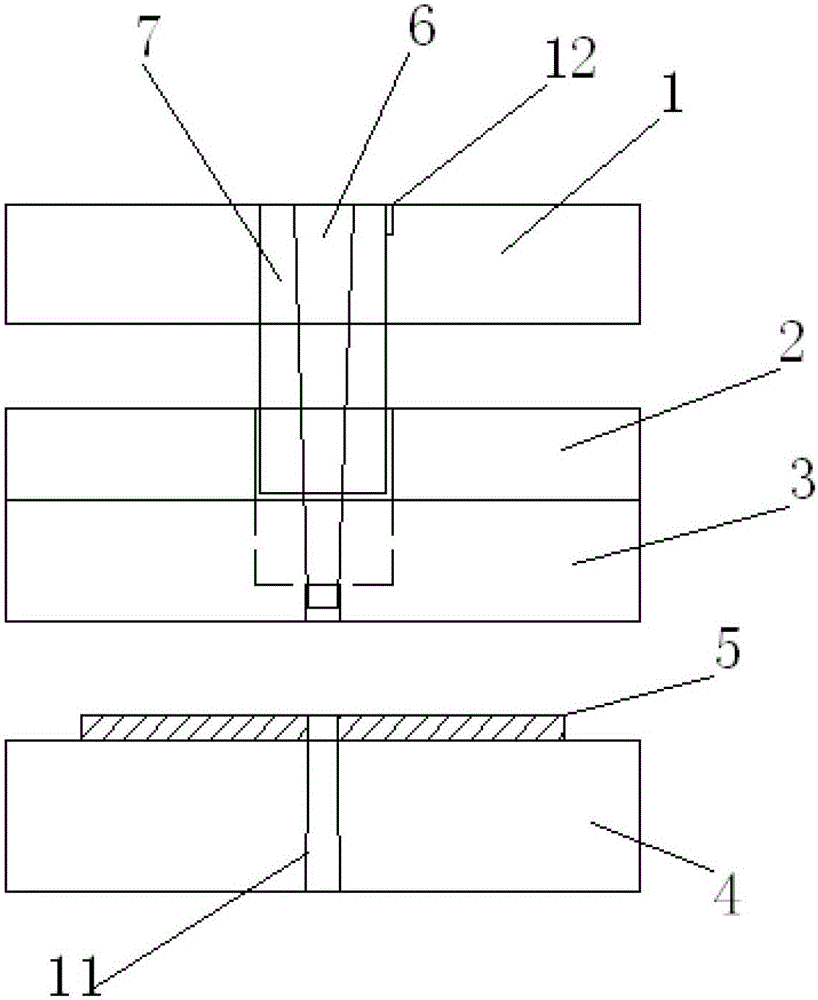

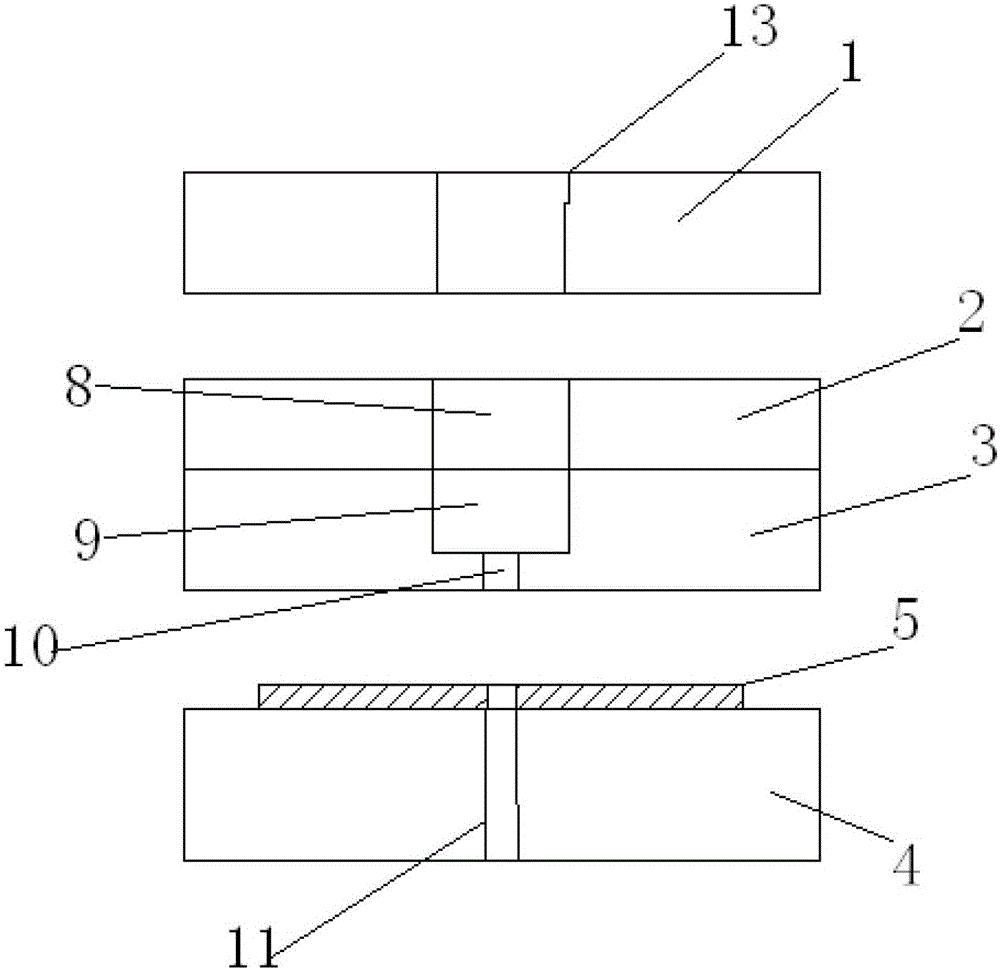

Small hole punch breaking prevention punching die

ActiveCN104338828AReduce breakage damageReduce mold repair timePerforating toolsEngineeringSmall hole

The invention discloses a small hole punch breaking prevention punching die. The die comprises an upper die and a lower die, wherein the upper die comprises an upper clamping plate, a stopping plate and a stripper plate; an elastic space is defined between the upper clamping plate and the stopping plate; the lower die comprises a lower die plate, and a two-segment punch; the punch comprises a columnar knocking rod and a sub-punch which comprises a stopping part and a punch part which is positioned below the stopping part; the radial width of the punch part is smaller than that of the stopping part, and the radial width of the punch part is smaller than that of the knocking rod which penetrates through the stopping plate to be positioned in the stripper plate; the stopping part is positioned in the stripper plate, and the punch part penetrates through the stripper plate; corresponding to the punch part, a waste passing hole is formed in the lower die plate. According to the invention, the breaking loss of the punch can be effectively reduced, the die repairing time is shortened, the high safety of the die is guaranteed, the production efficiency is improved, the production stability is ensured, additional waste during product production can be avoided, the purpose of reducing the production cost of the product is achieved, and the punching die is more convenient to disassemble, assemble and replace.

Owner:JIANGSU BOJUN IND TECH

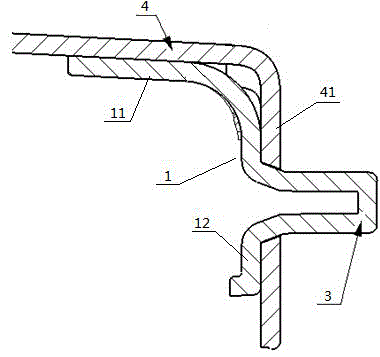

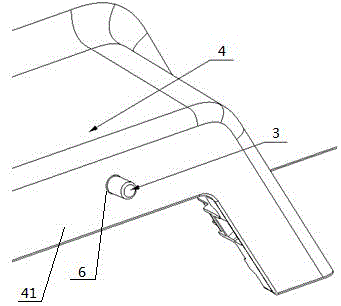

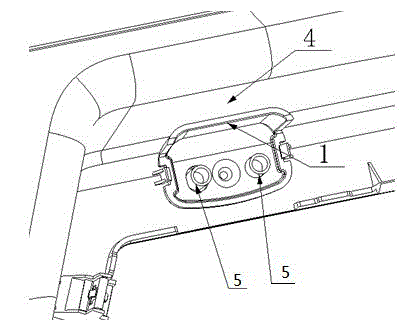

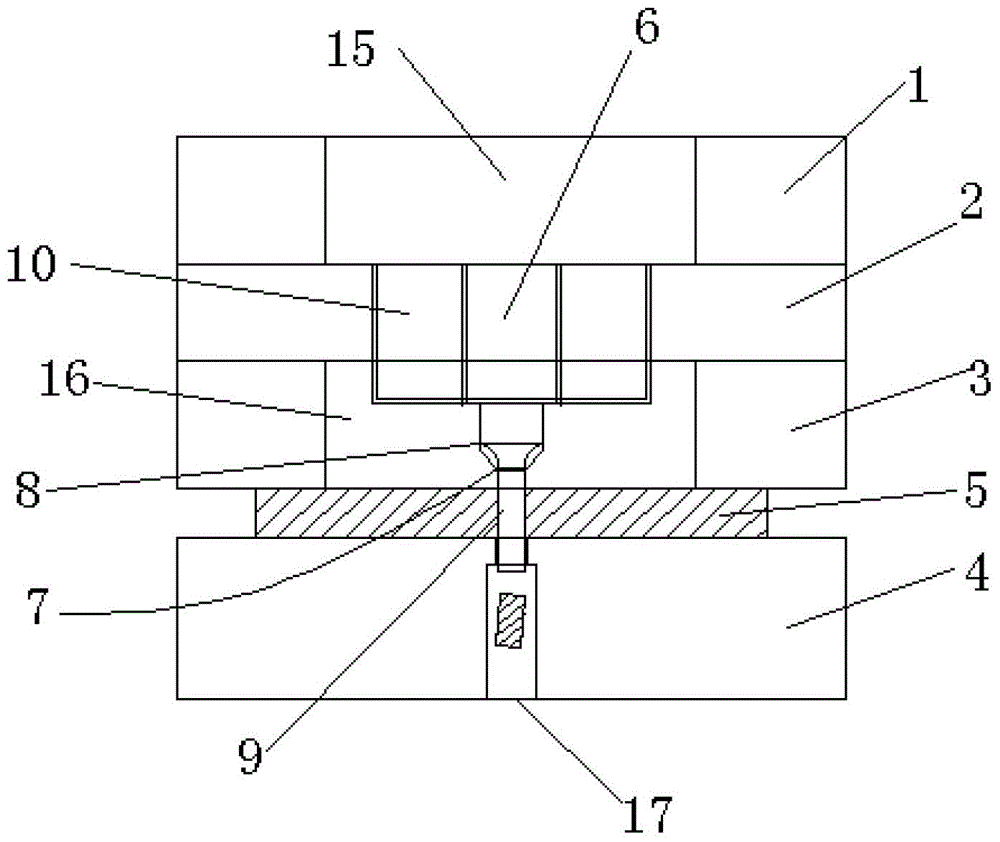

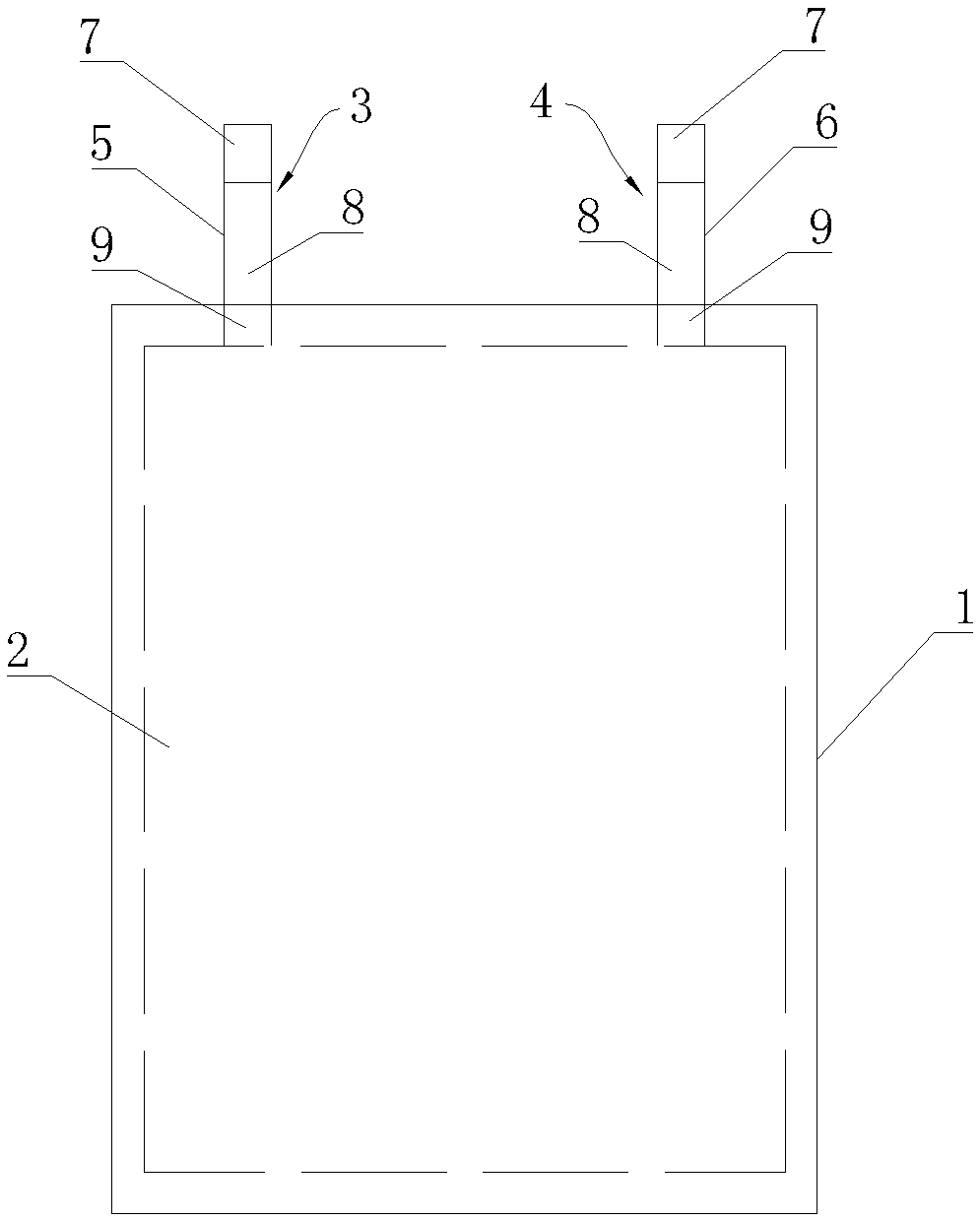

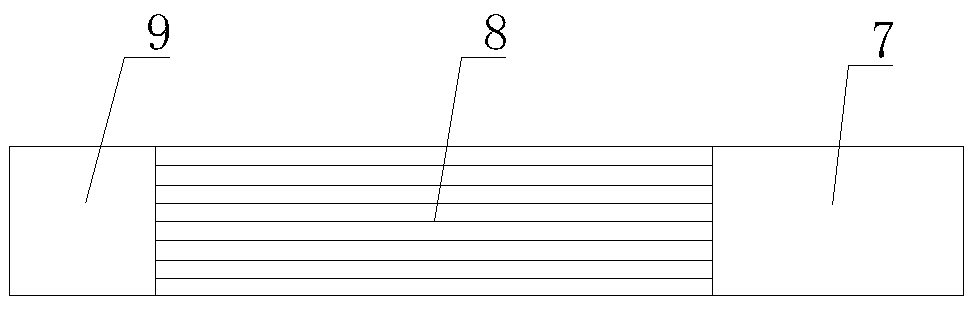

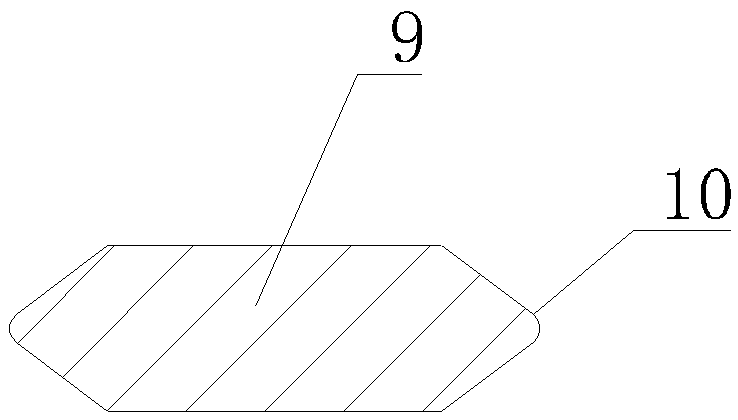

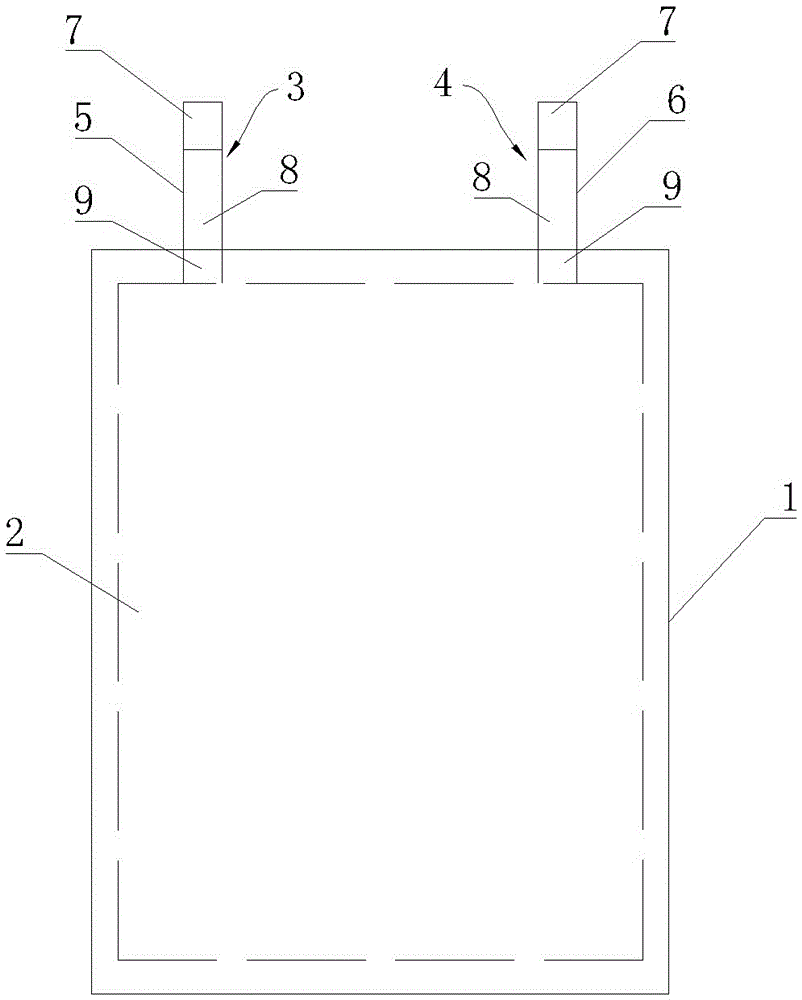

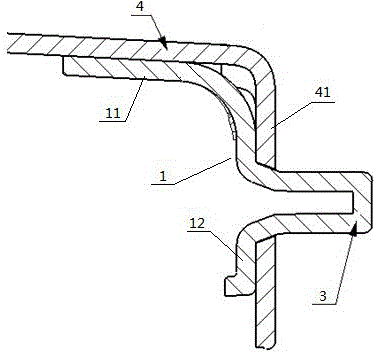

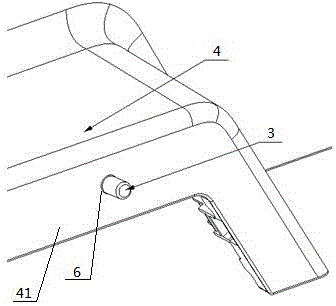

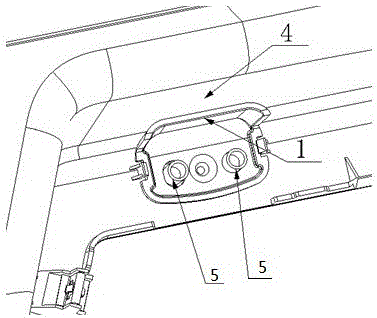

Mounting structure for automobile trunk shelves

ActiveCN104670102AReduce breakage damageImprove carrying capacityVehicle componentsEngineeringMechanical engineering

The invention discloses a mounting structure for automobile trunk shelves, which comprises a side trim panel, a shelf and a mounting part, the shelf is connected with the side trim panel through a rotary shaft, the side trim panel is provided with a bent part, the rotary shaft is integrally arranged on a vertical section, and the vertical section is also provided with welding holes; welding posts are arranged on the inner side of the bent part of the side trim panel, and the bent part of the side trim panel is provided with a through pin hole; the mounting part is located at the inner side of the side trim panel, a pin runs through the through pin hole, the welding posts are located in the welding holes and welded as a whole, the vertical section of the mounting part is in contact with the inner side of the bent part of the side trim panel, and a horizontal section of the mounting part is in contact with the inner side of the side trim panel. The mounting structure can enhance the carrying capability of the rotary shaft, so that the head of the rotary shaft can be prevented from breaking.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

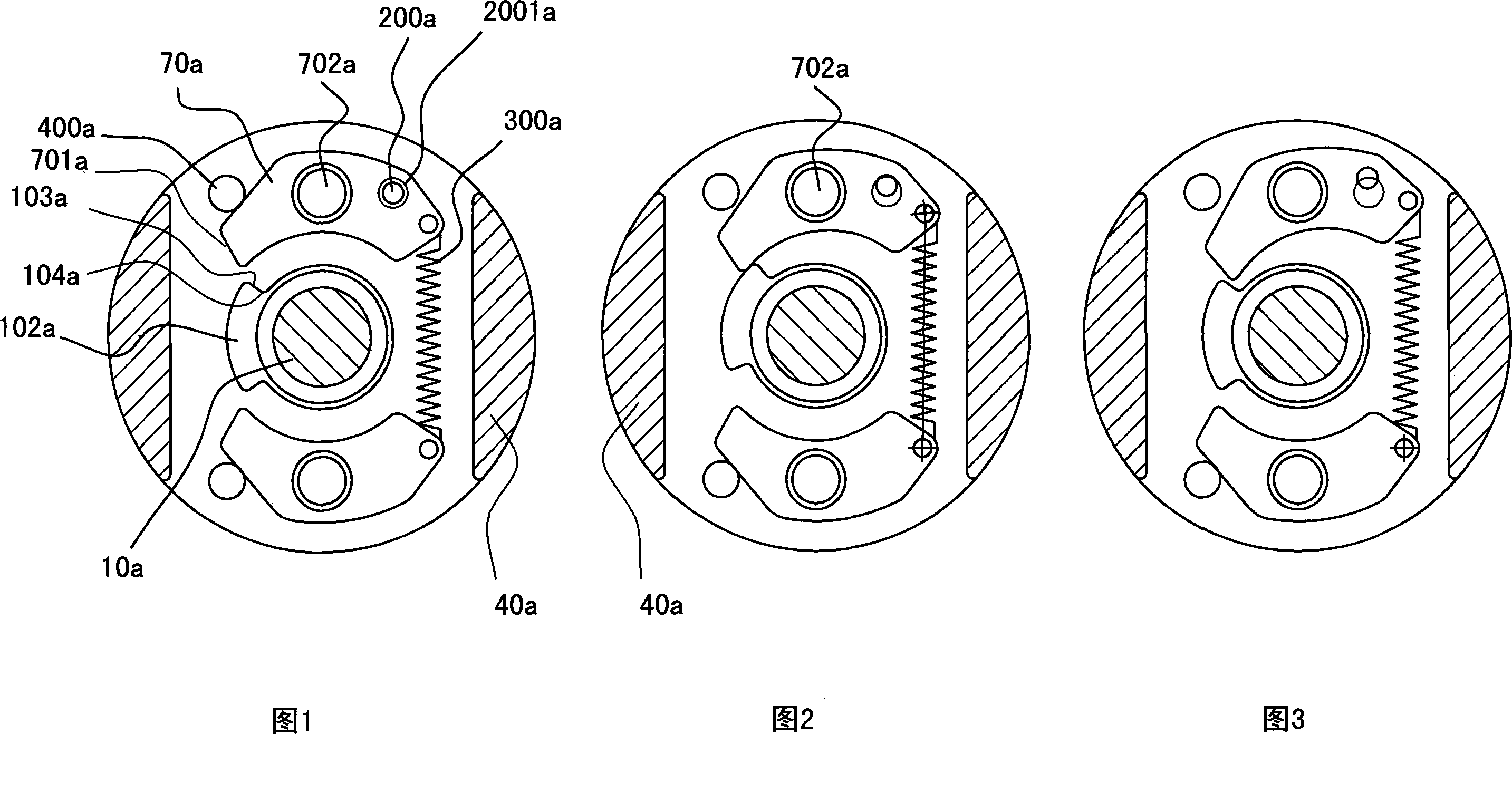

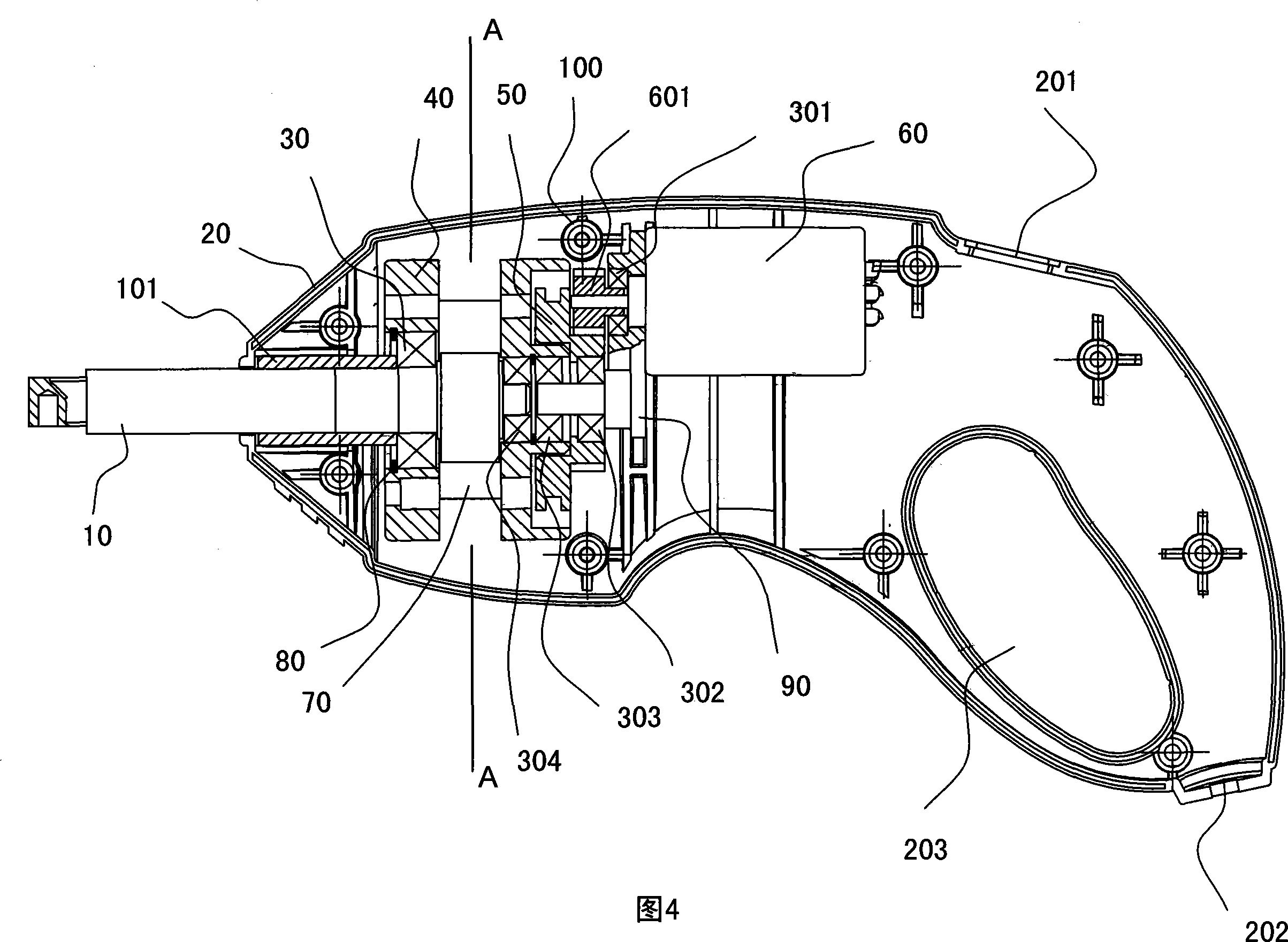

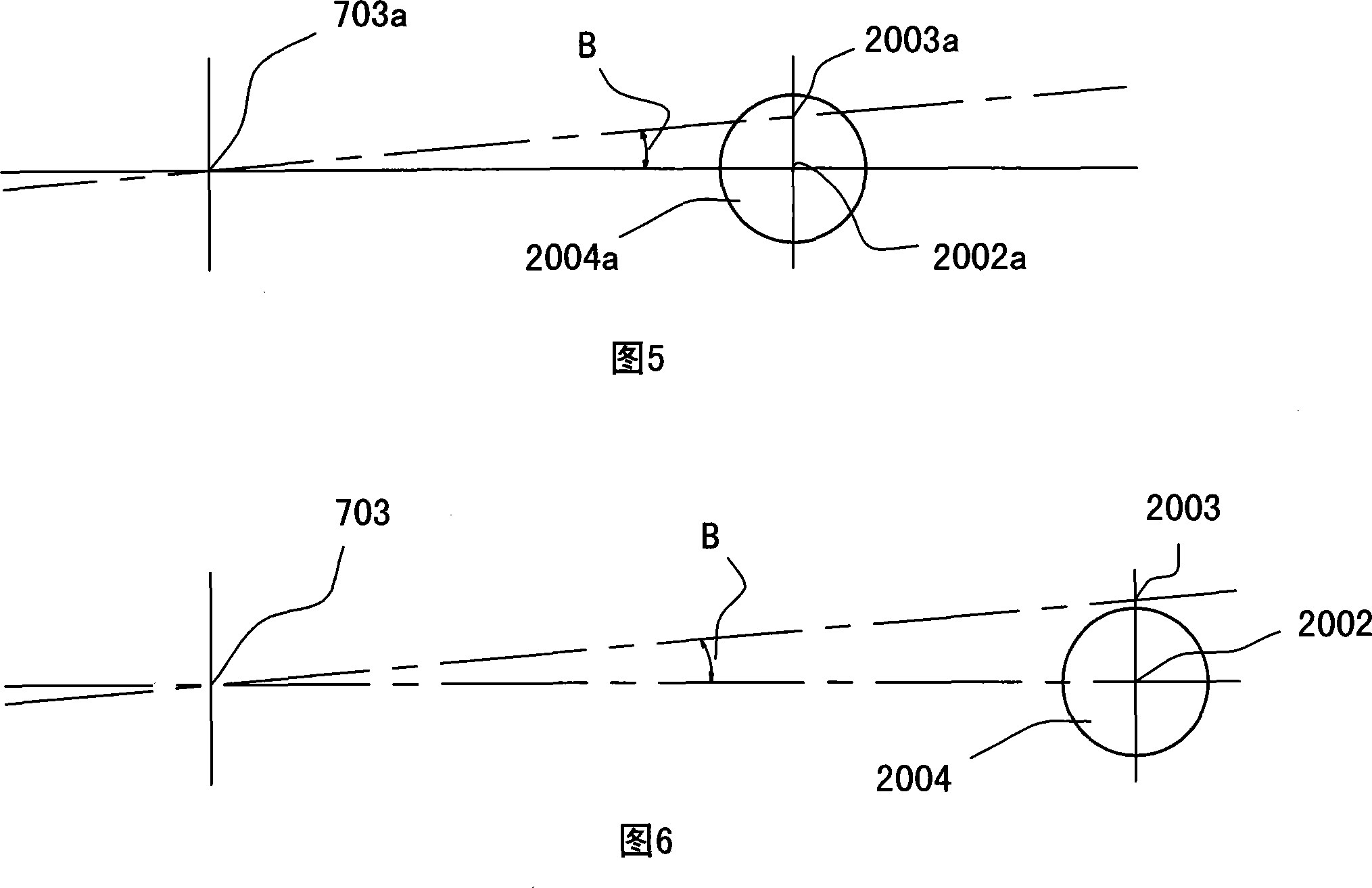

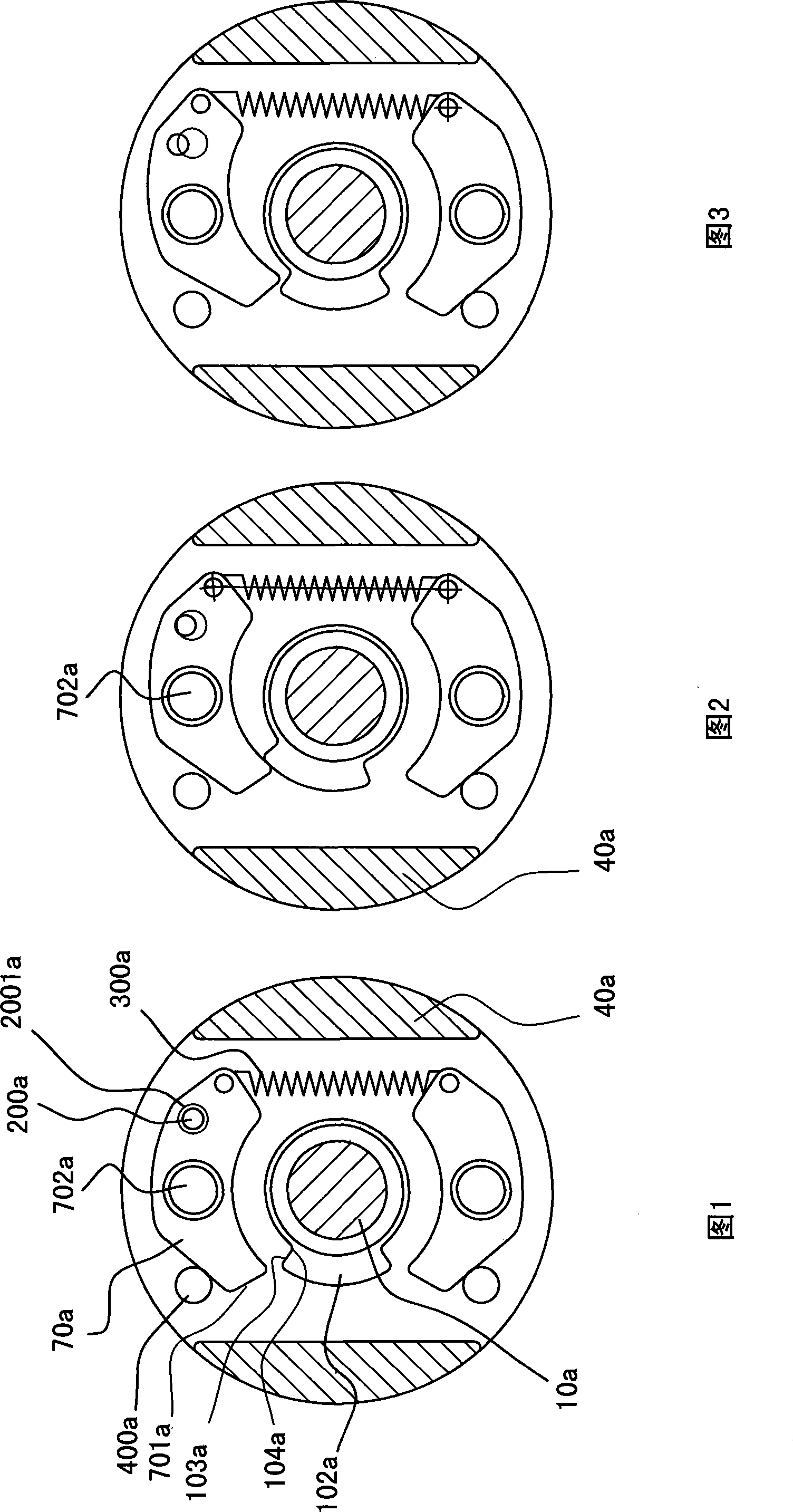

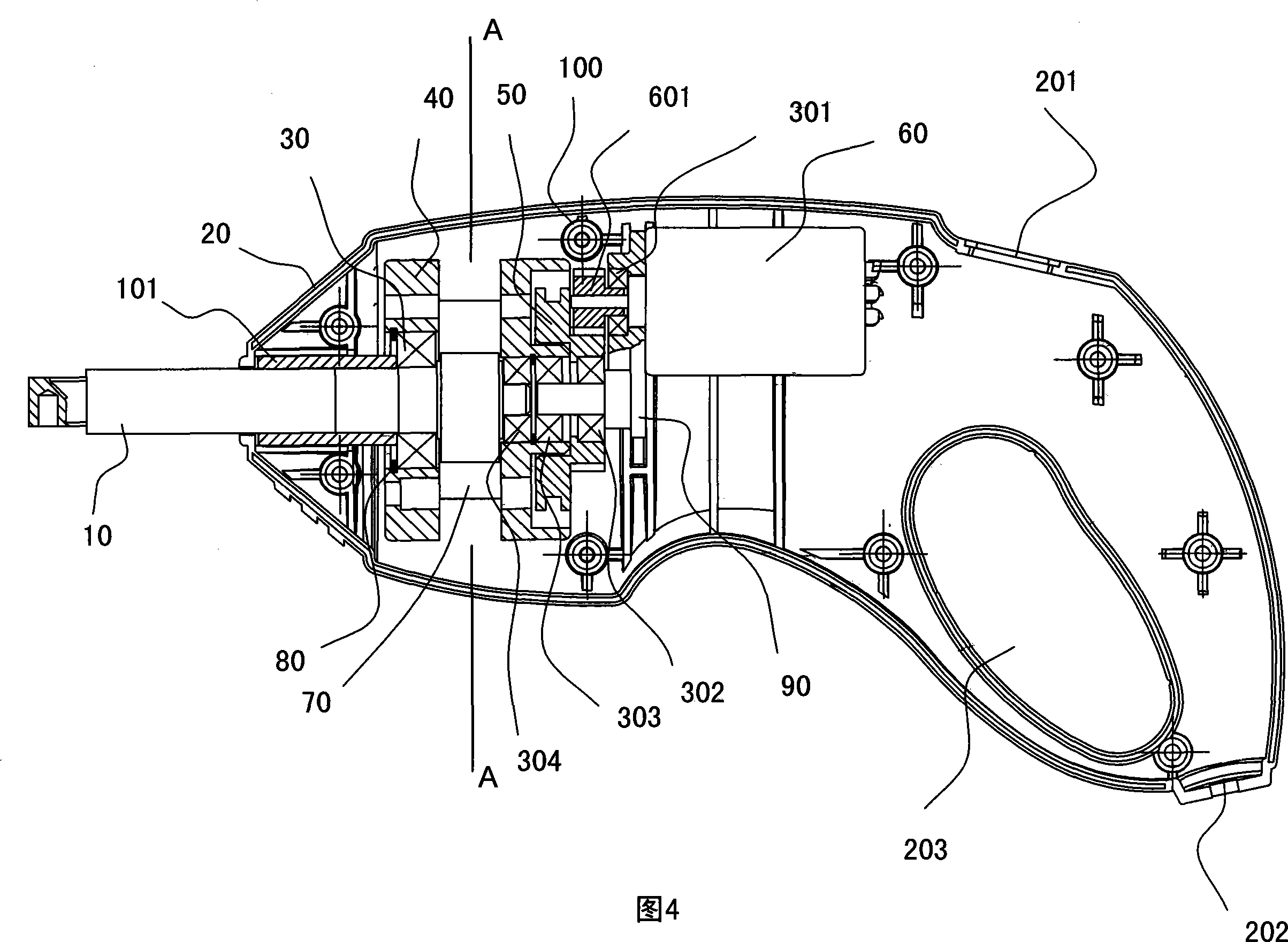

Electric spanner for vehicle

InactiveCN101224567AMeet the impact forceReduce rotation resistancePower driven toolsOn boardSteel ball

The invention provides an on-board electric wrench, comprising a flywheel, an output shaft, a lug boss and an impact block. A pin shaft which is used for positioning the impact block is sheathed with a torsion spring; two forcing ends of the torsion spring are respectively positioned on a position limit retaining pin and the impact block; the distance between the center of the positioning hole of a steel ball and the center of the pin shaft complies with the requirement that the chord length corresponding to the motion track of the steel ball is more than the radius of the positioning hole of the steel ball. The invention replaces a pulling spring with the torsion spring, changes the adjusting position, leads the adjustment of the impact force and the recovery force of the impact block to be realized by the rigidity of the torsion spring and the steel ball supporting spring respectively, solves the contradiction that adjustment of the impact force and the recovery force of the impact block is integrated into a whole on the pulling spring, meets the impact force of the wrench design, leads the recovery of the impact block to be slow, leads the engagement surface of the impact block can always push through the forcing surface of the convex block and convex shoulder before the screw is screwed or after the screw is loosened so as to achieve the continuous operation, and has the advantages of fully automation of loosening and tightening the screw, complete engagement of the impact block and the root of the convex block, and long service life.

Owner:ZHEJIANG SHENGUANG ELECTRICAL

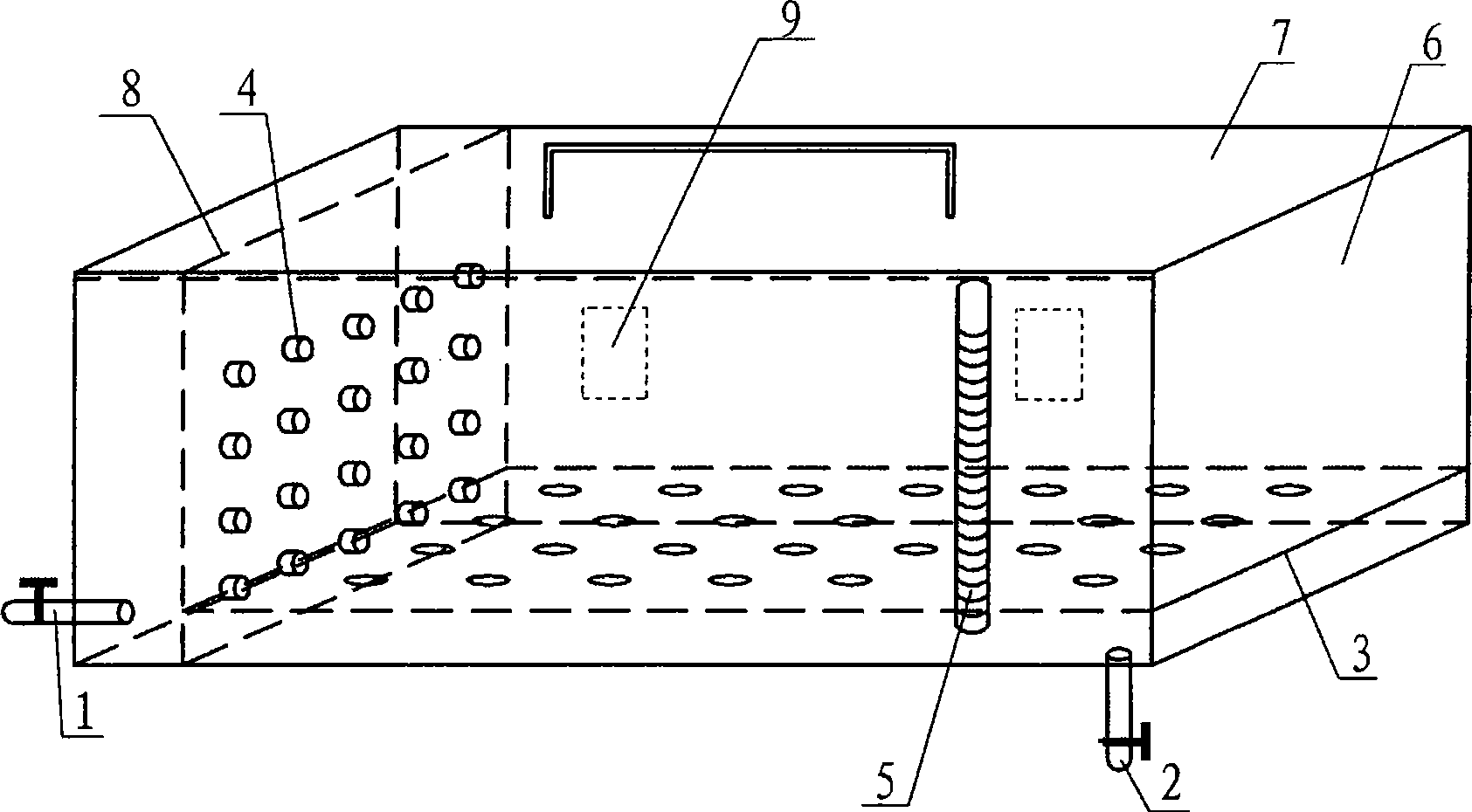

Wall hanging type sterilizing box for screwed conduit of respiration machine

A wall-mounted type respiratory disinfecting box for threaded pipes comprises a box body and an upper cover matched with the box body. A liquid inlet pipe is communicated with the box body; a liquid outlet pipe is arranged at the lower end of the box body; a drainage partition board with a hole is also arranged at the lower part of the box body; a threaded pipe fixed pipe is arranged on another partition board at the water inlet of the box body; and a liquid level meter is also arranged on the box body. In the invention, the threaded pipes can be placed in the disinfecting box in parallel to be dipped completely, and the disinfecting effect is good; because the threaded pipes are fixed in the water pipe and washed continuously, the residual disinfecting fluid can be avoided; the wall-mounted type design does not occupy the room area; the water level in the disinfecting box can be displayed directly through the liquid level meter; the quantity of the disinfecting liquid required to be added is marked by scales in advance; the water level can be determined according to the quantity of the threaded pipes required to be disinfected every day; the disinfecting liquid can be added according to the mark; the operation is simple, and the waste of the disinfecting liquid can be avoided; the hands of an operator can be free from contacting with the disinfecting liquid in the process of disinfecting the threaded pipes, thereby the damage to skins is avoided; and when the threaded pipes are dipped in the disinfecting box, a pipeline can not be bent, so that the cracked damage of the pipeline can be reduced, and the service life of the pipeline is prolonged.

Owner:YICHANG NO 1 PEOPLES HOSPITAL PEOPLES HOSPITAL OF CHINA THREE GORGES UNIV

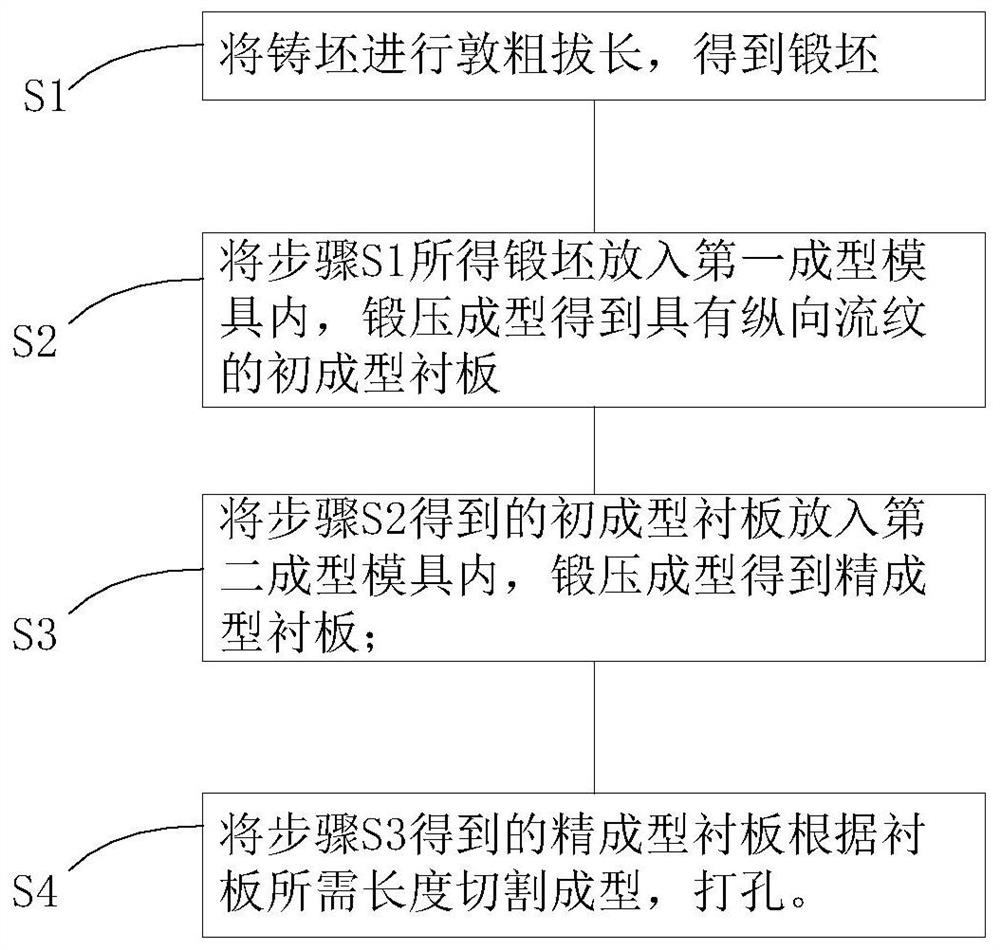

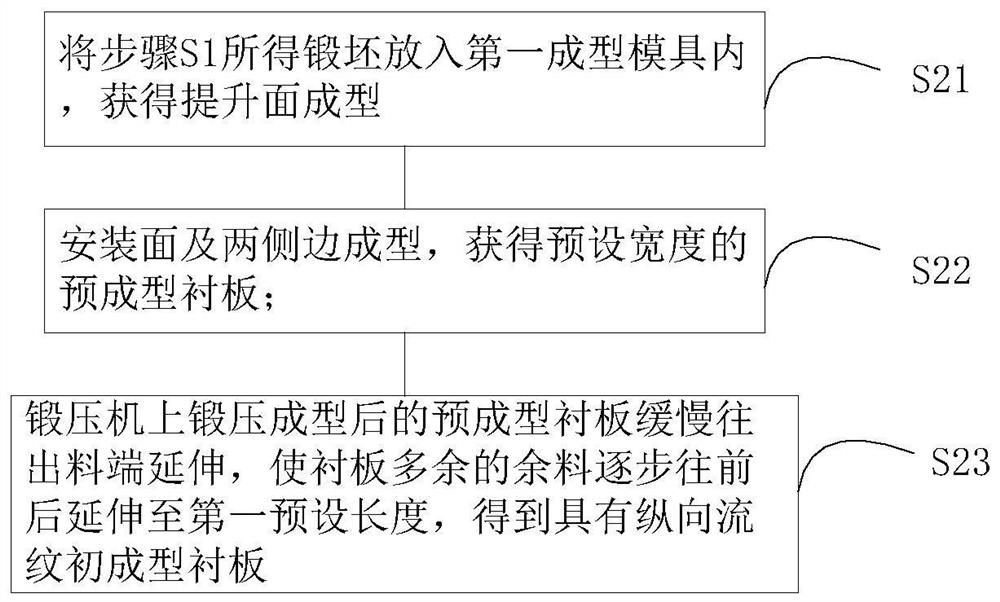

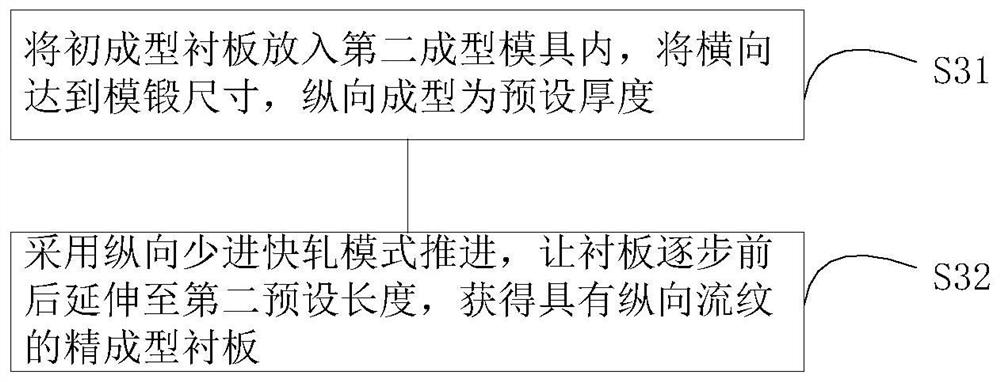

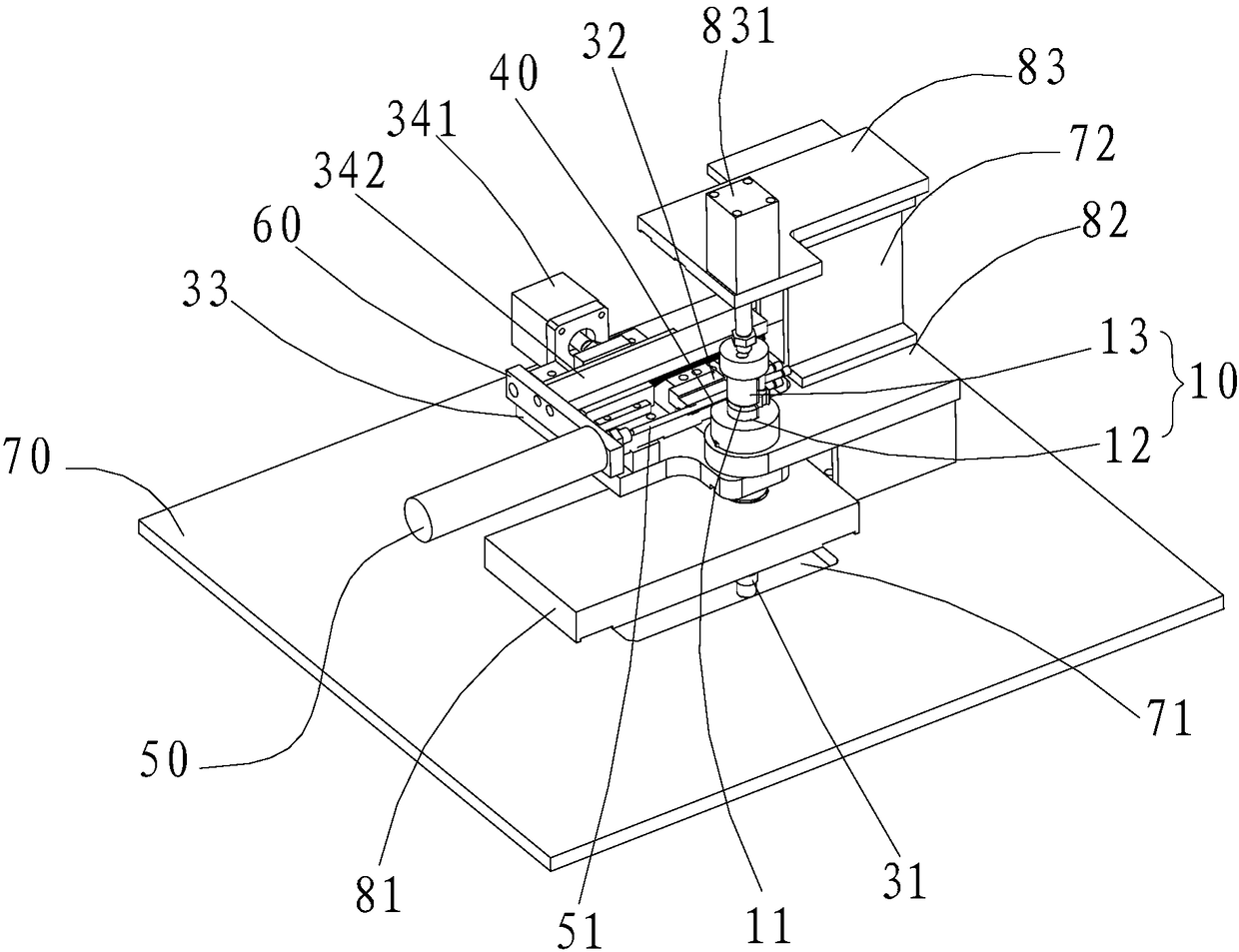

Preparation method for forging and rolling lining plate with longitudinal streamline

ActiveCN111872293AImprove impact resistanceImprove wear resistanceForging/hammering/pressing machinesRecycling and recovery technologiesMechanical propertyMachining

The invention discloses a preparation method for a forging and rolling lining plate with a longitudinal streamline. The preparation method comprises the following steps that a casting blank is upset and drawn out to obtain a forging blank; the forging blank is put into a first forming mold, and is forged, pressed and formed to obtain a primary forming lining plate with longitudinal flow lines; theprimary forming lining plate is put into a second forming mold, and is forged, pressed and formed to obtain a fine forming lining plate; the fine forming lining plate is cut, formed and punched according to the required length of the lining plate; and finally, the mechanical property of the required lining plate is quenched and tempered. The preparation method overcomes the technical defect thatin the prior art, the free forging machining amount is large, and die-forging forming four corners are not fully filled, and the lining plate with the longitudinal flow lines is resistant to high impact and not prone to breakage.

Owner:紫荆浆体管道工程股份公司

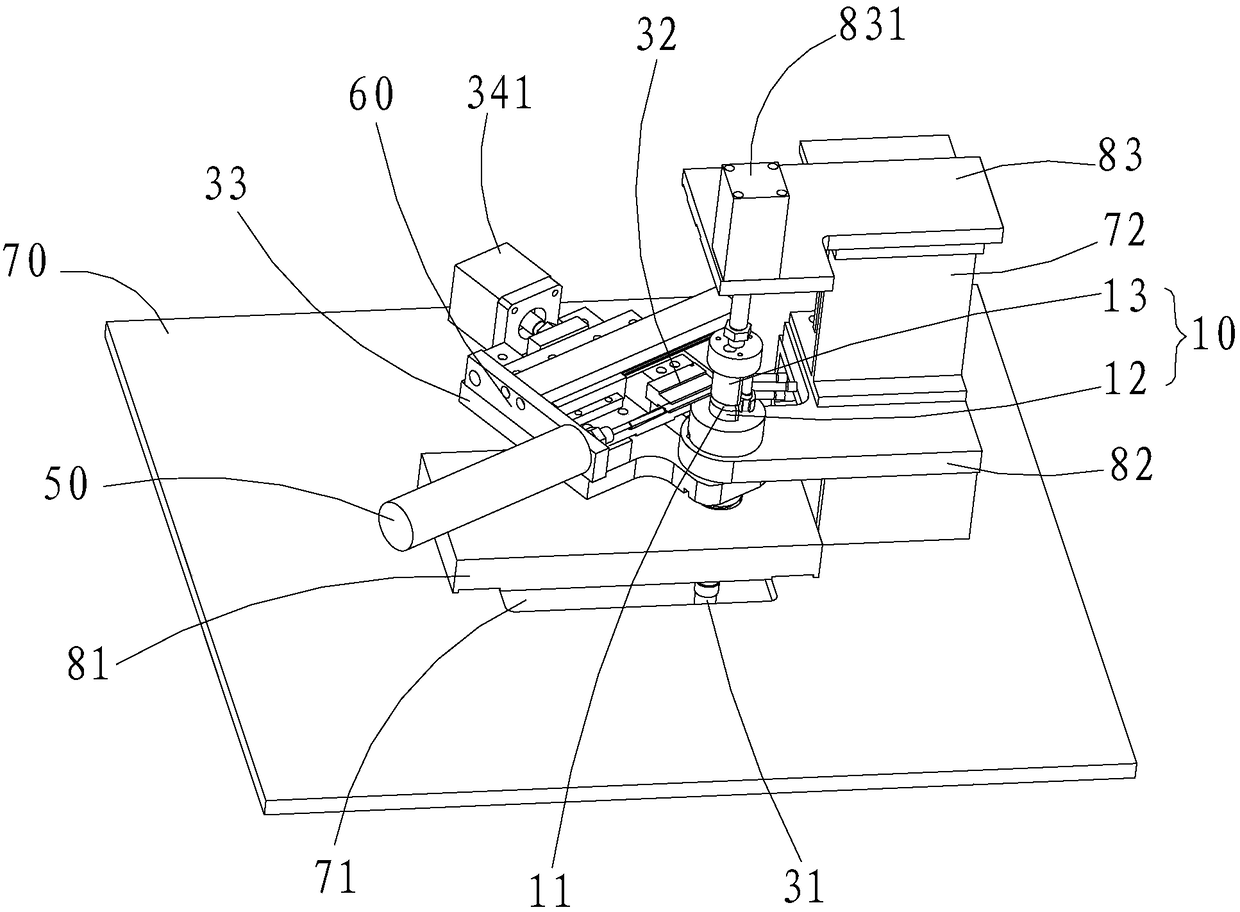

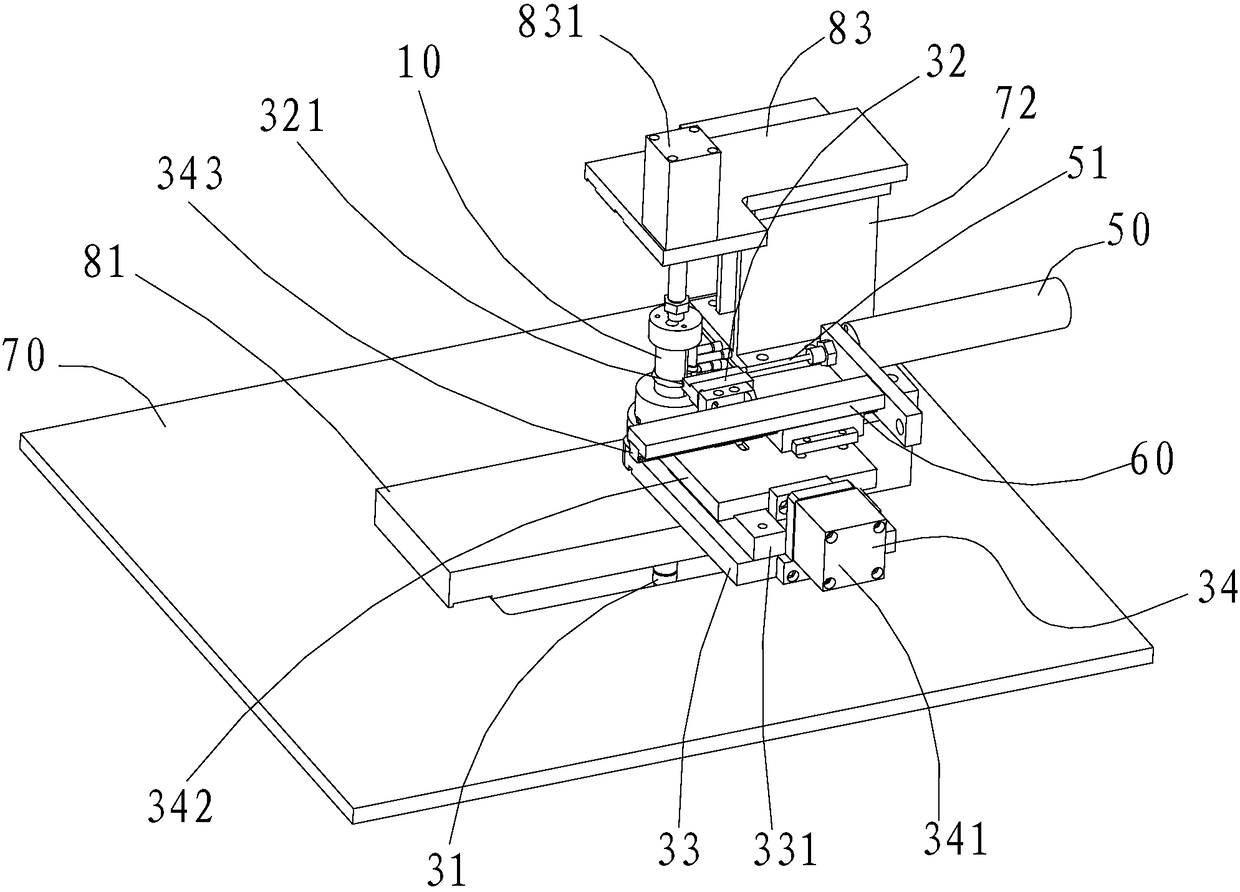

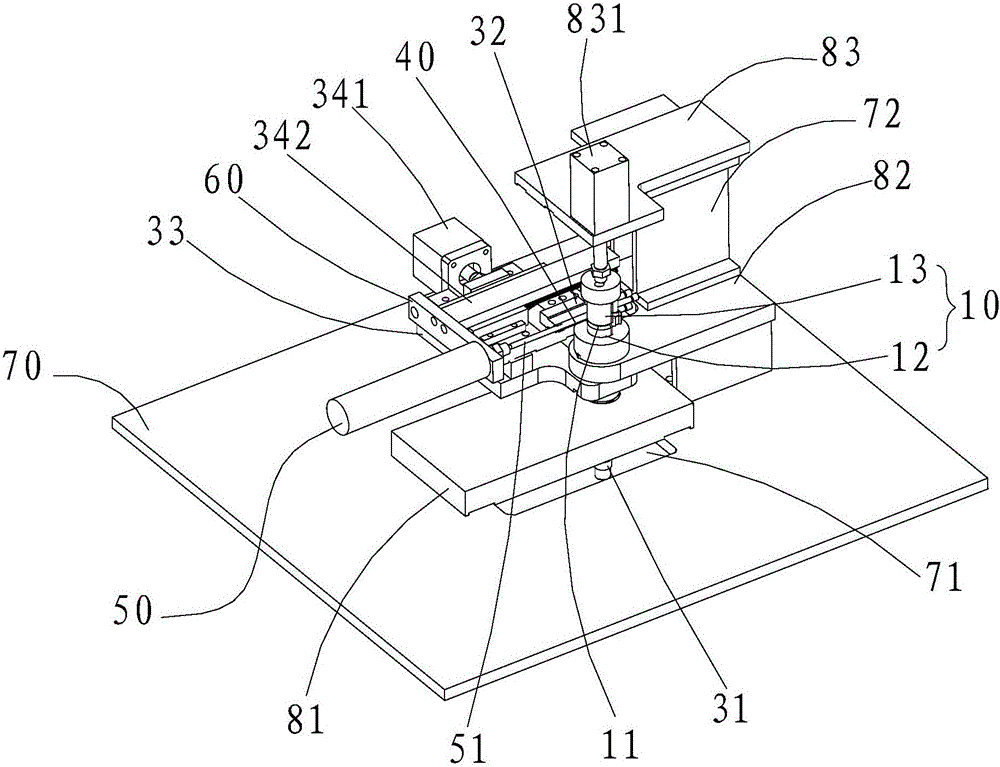

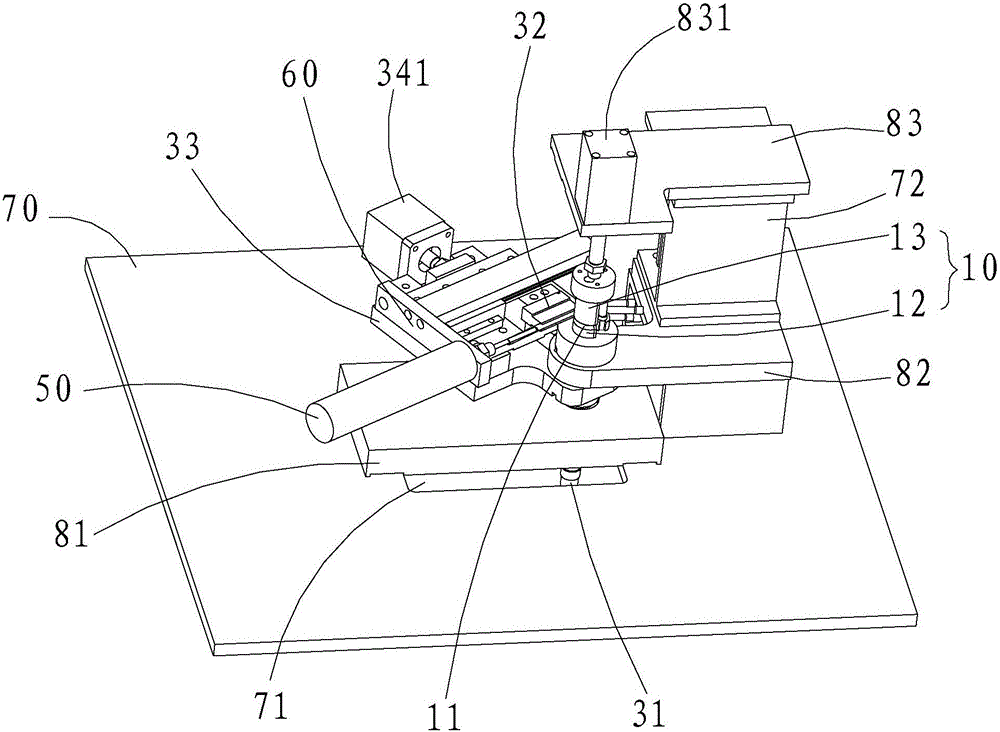

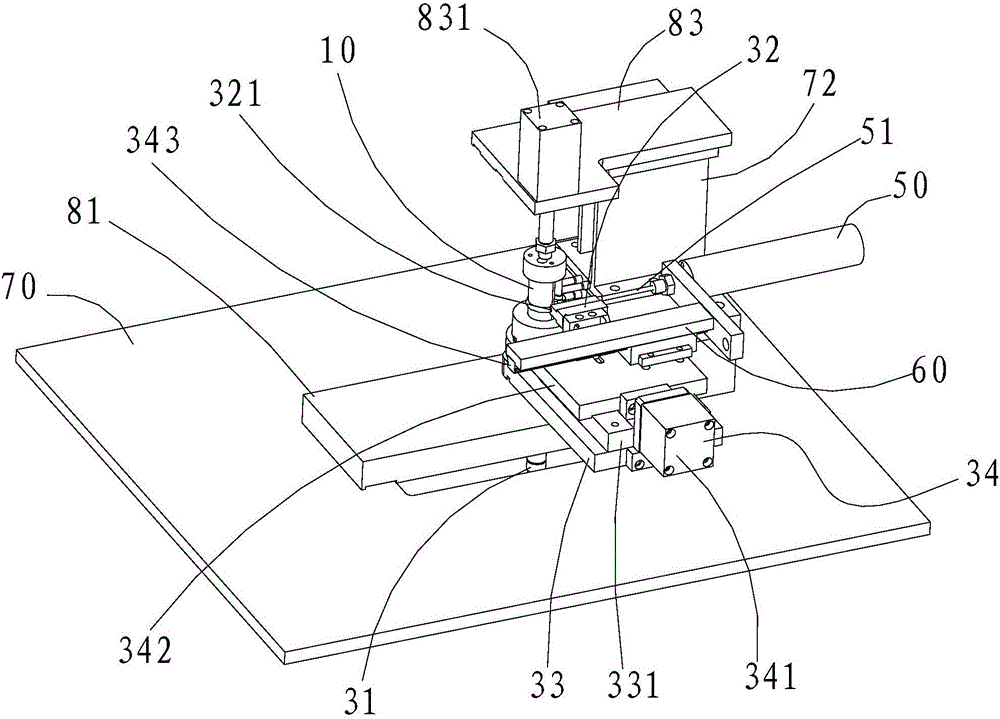

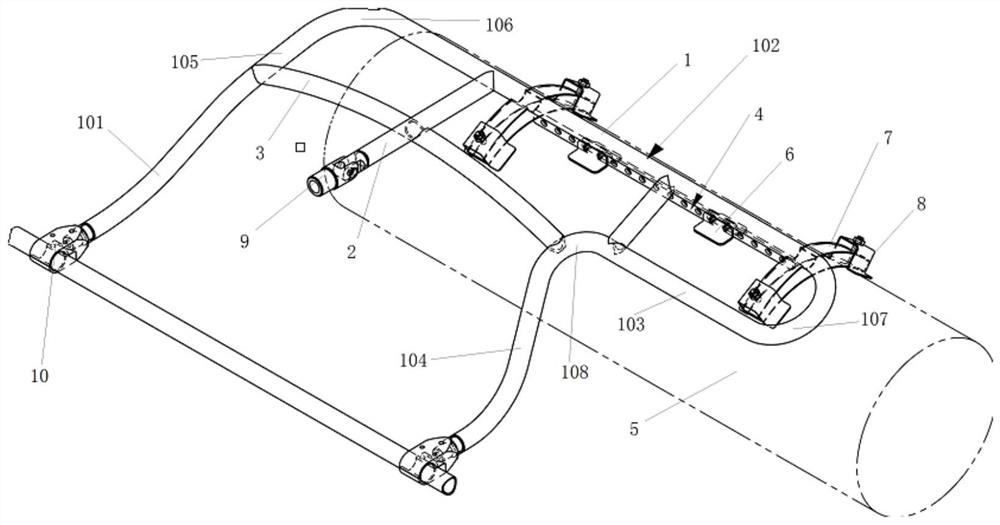

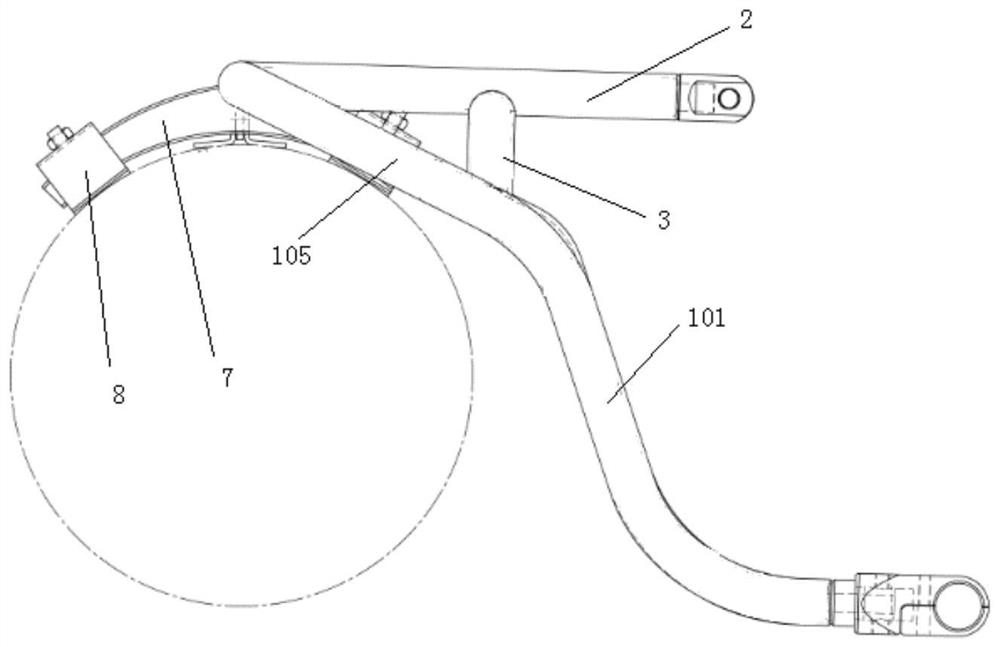

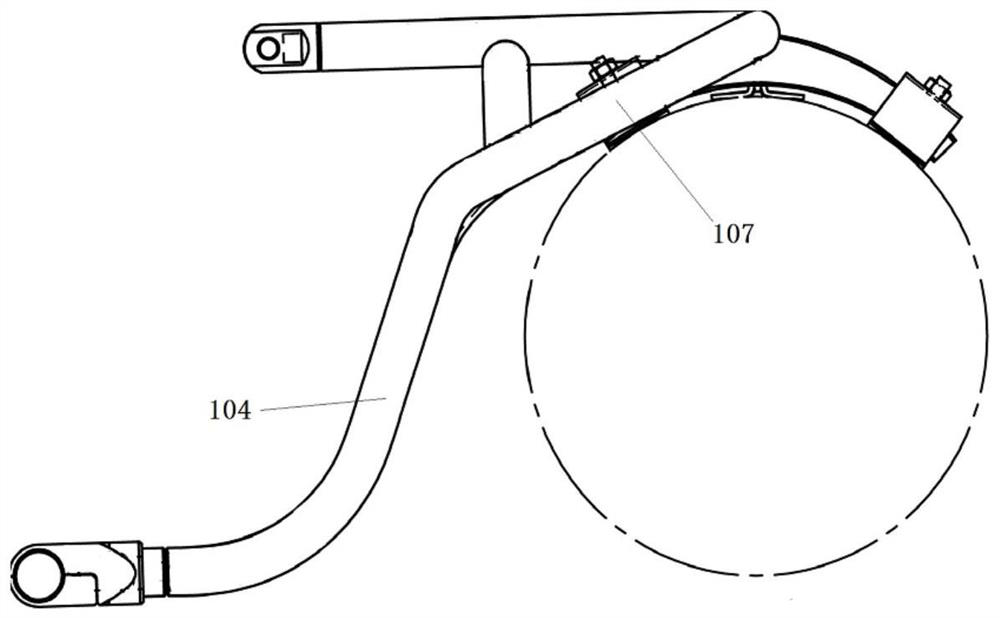

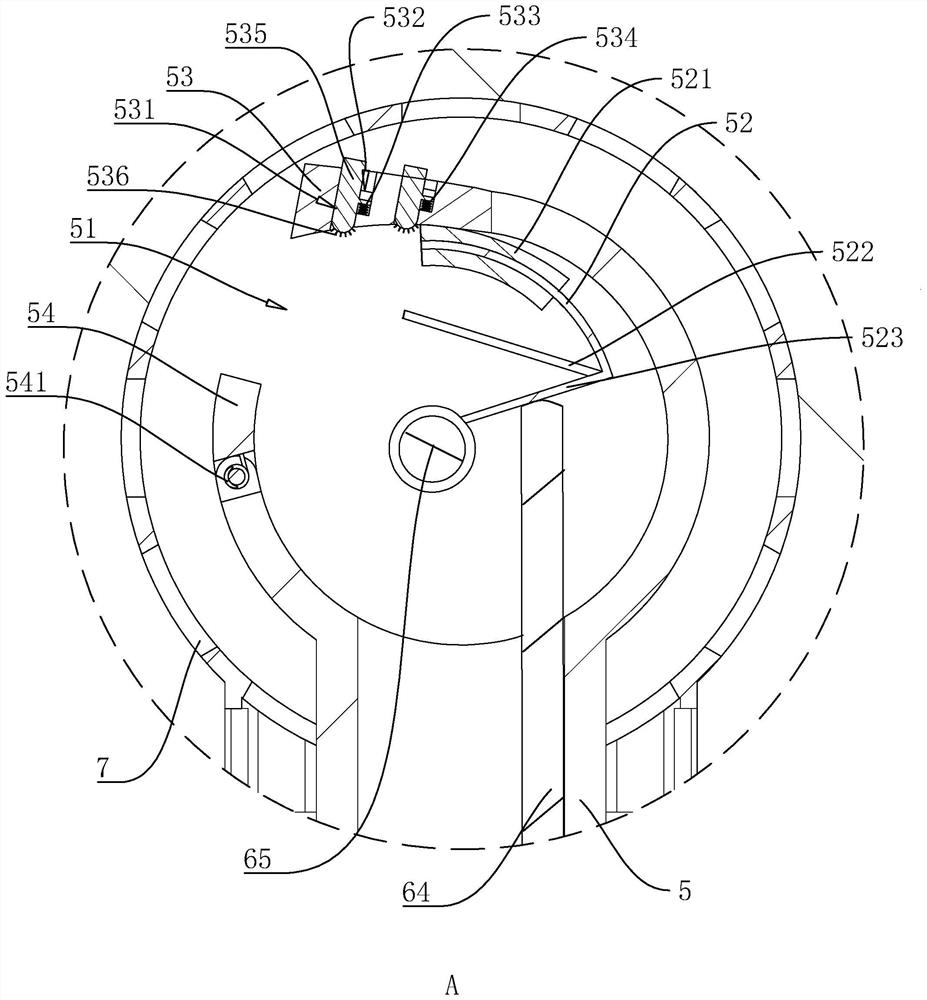

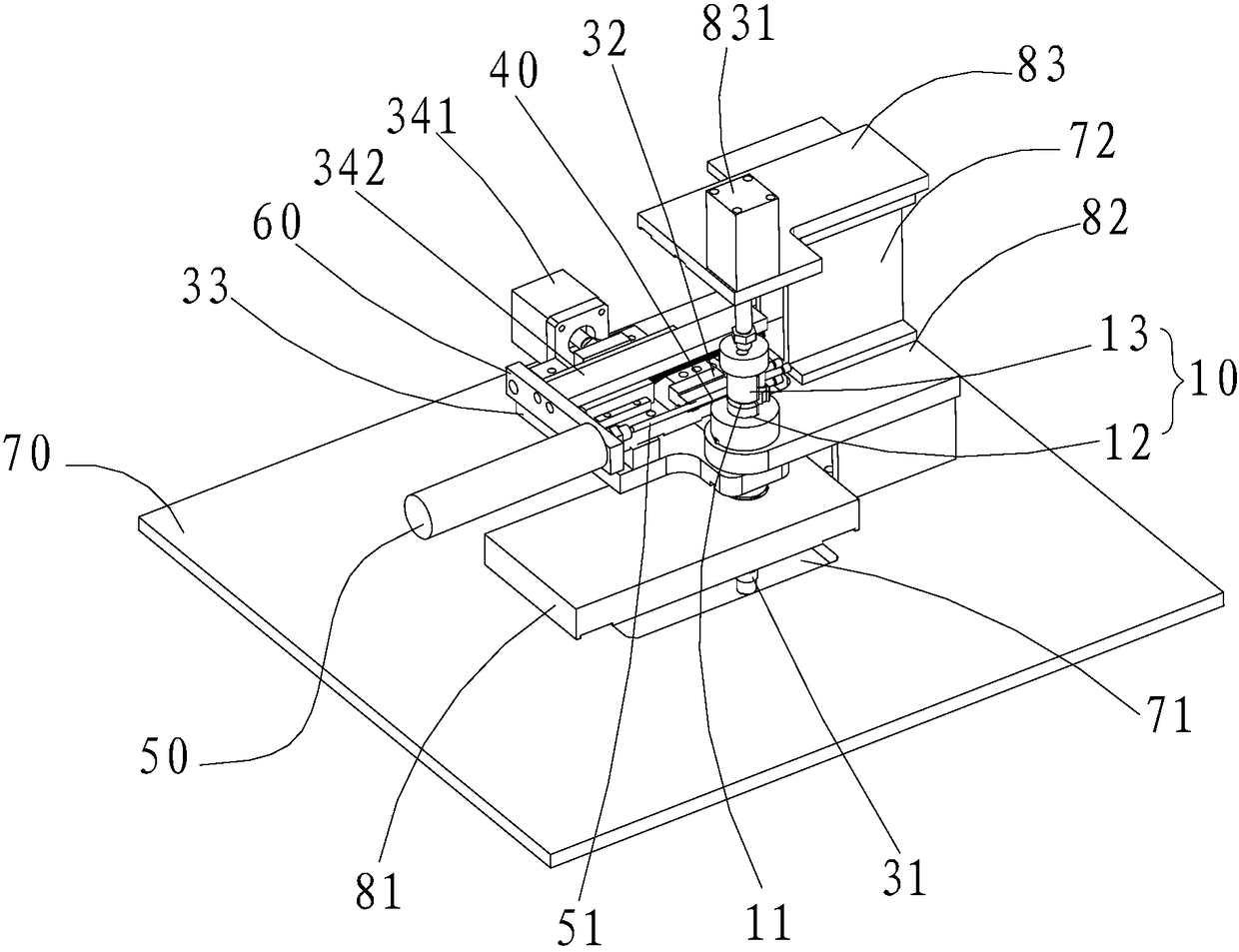

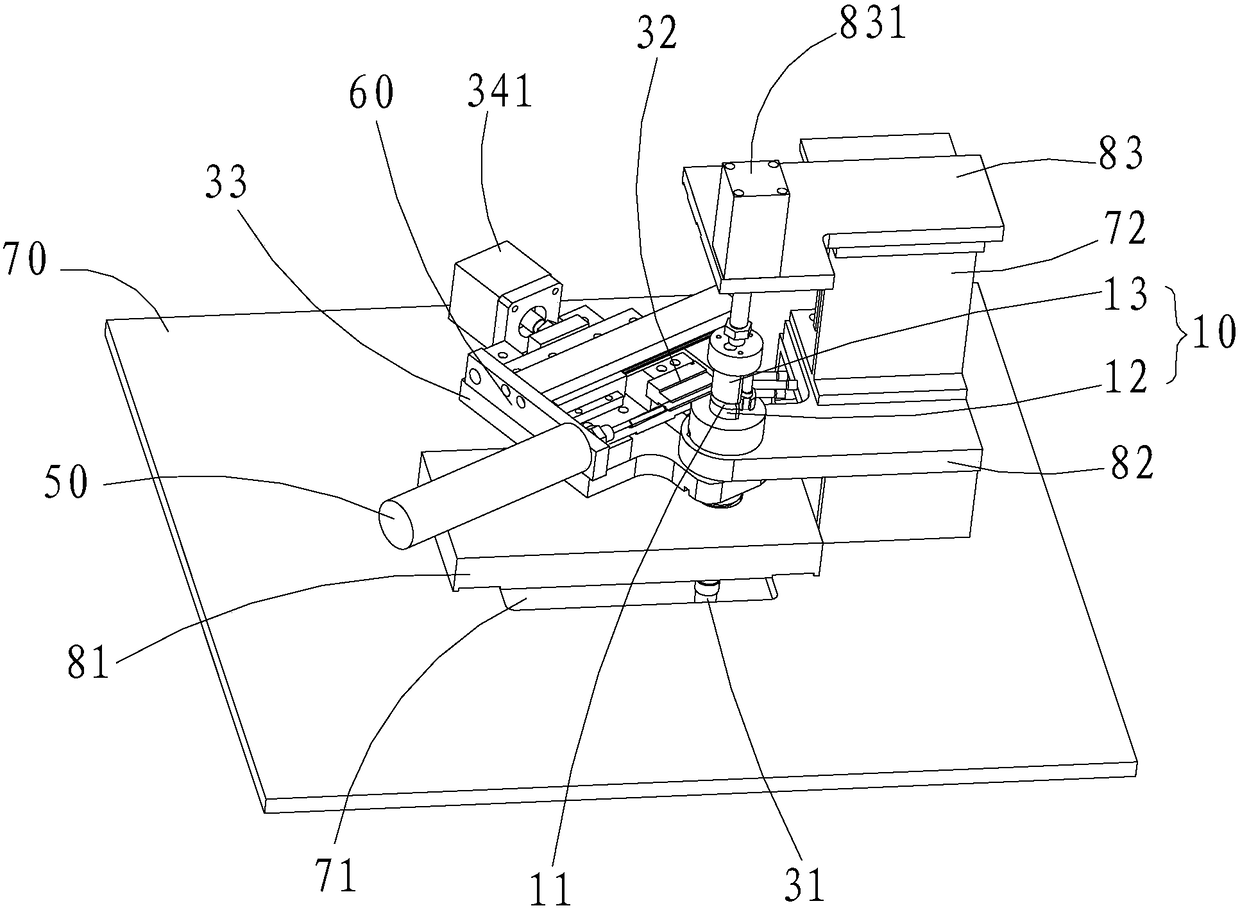

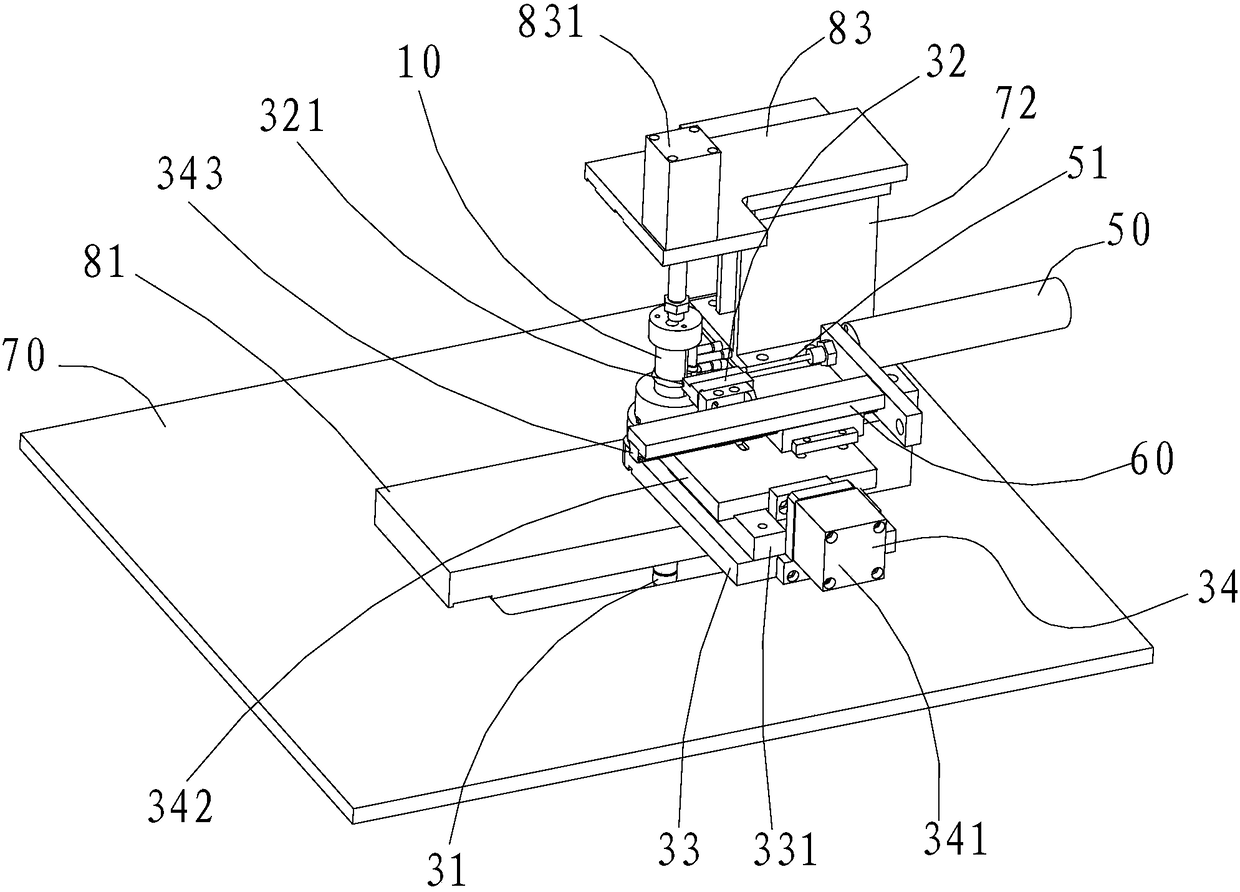

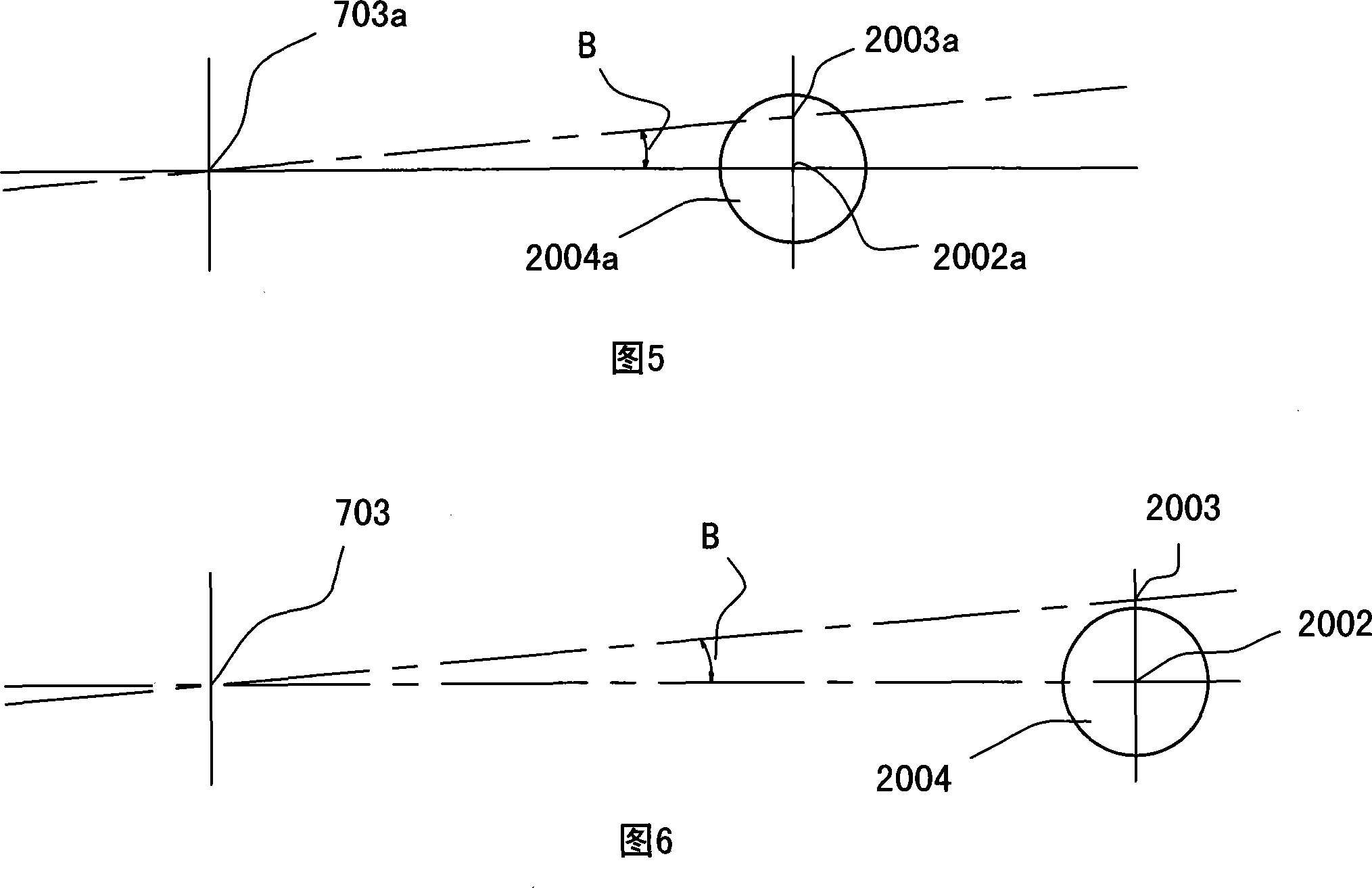

Pipe bending machine and pipe bending method

ActiveCN106001218BImprove bending qualityEasy to take outMetal-working feeding devicesPositioning devicesMechanical engineeringPress brake

Owner:OMS MASCH CO LTD

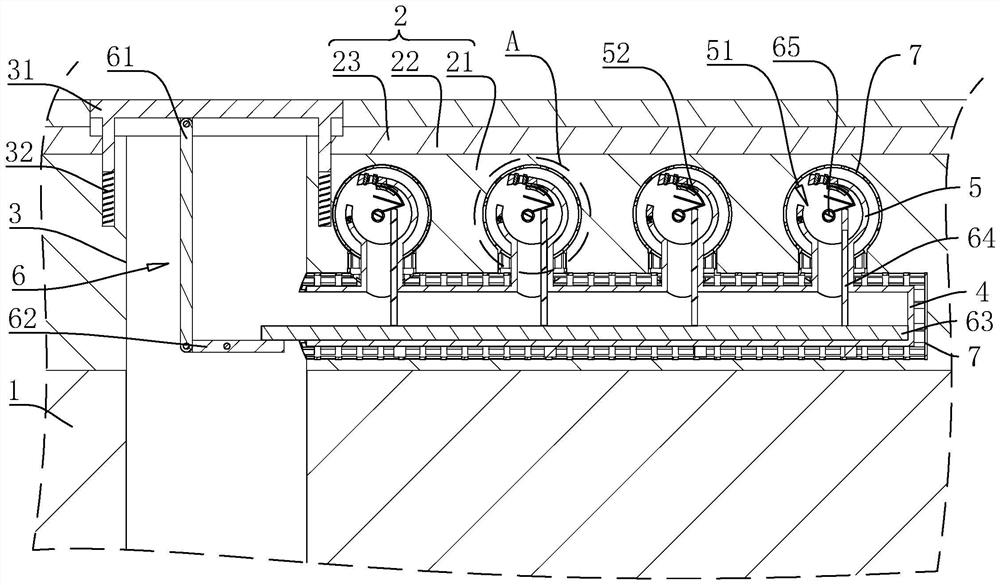

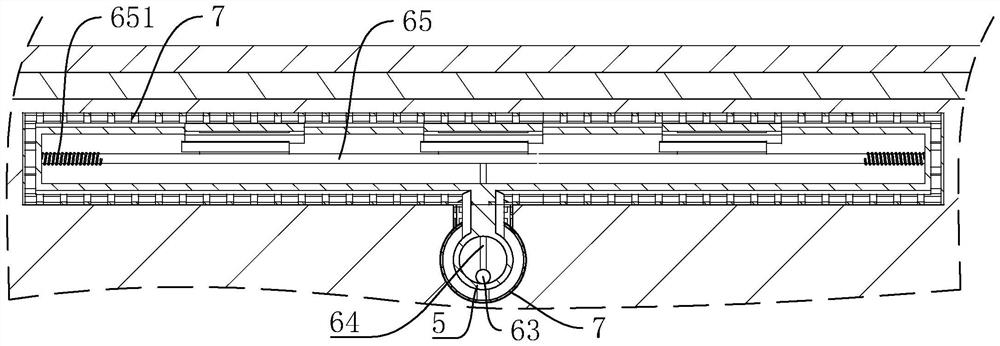

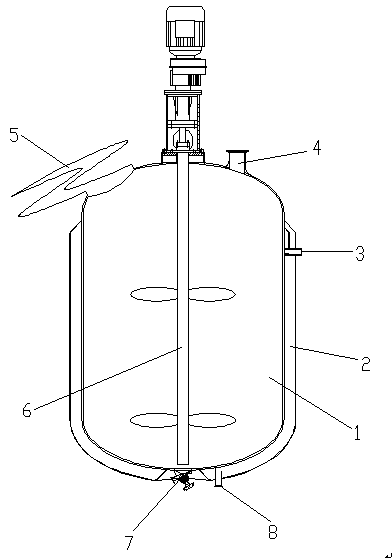

Winding device for cable manufacturing

ActiveCN113697599AReduce breakage damageReduces skin breakoutsFilament handlingEngine lubricationEngineeringCold weather

The invention relates to the technical field of cable manufacturing equipment, in particular to a winding device for cable manufacturing. The winding device comprises a winding table, wherein a winding column is rotatably connected to the winding table, a heating sleeve is arranged on one side of the winding table, a heating assembly is arranged on the heating sleeve, a heating groove is formed in the heating sleeve, and a cable penetrates through the heating groove and can be heated by the heating assembly. According to the winding device, an insulating layer on the outer side of the cable is softened through the heating sleeve, the situation that the cable is difficult to wind due to the hard surface when the cable is processed in cold weather is reduced, and meanwhile, the situation that the cable is broken and damaged in the winding process is also reduced; and meanwhile, debris attached to the surface of the cable can be scraped off and removed through the end, attached to the cable, of the heating groove, particularly, tiny and hard matter on the surface of the cable can be scraped off, the situation that the surface of the cable is punctured by debris under the winding extrusion of the cable in subsequent winding of the cable is reduced, and the working quality of the winding device is improved.

Owner:江苏学霖电缆科技有限公司

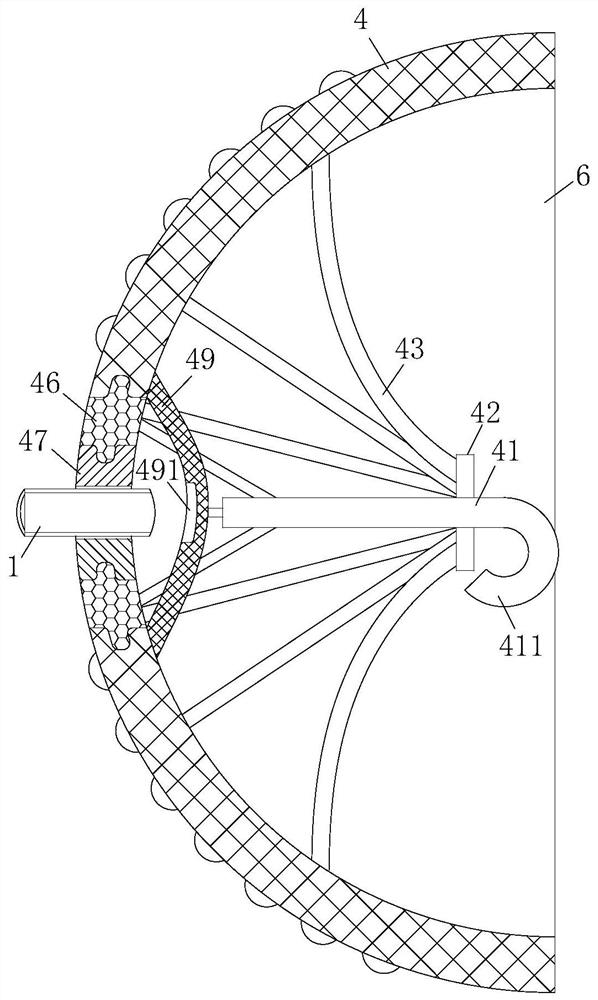

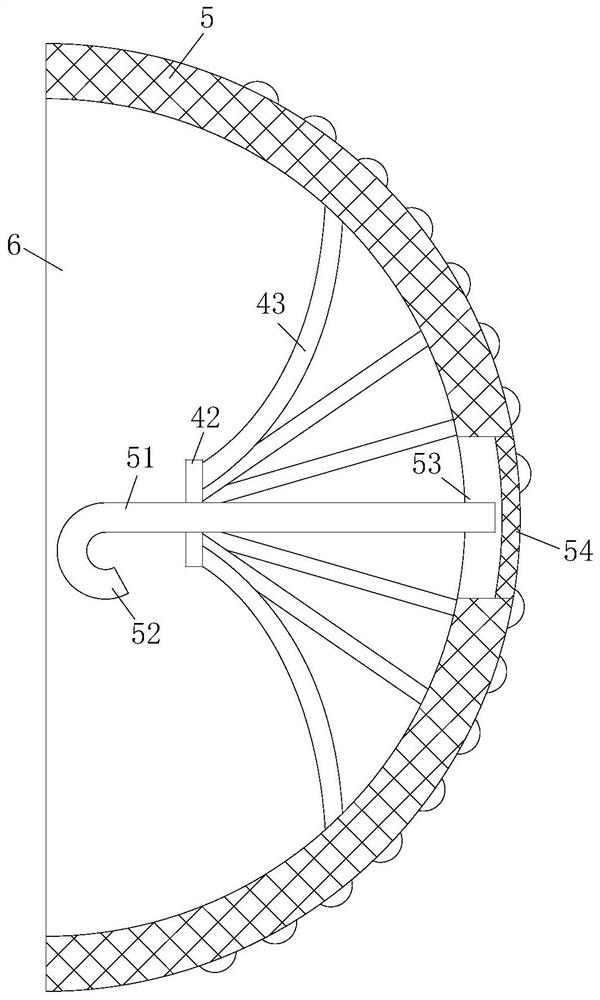

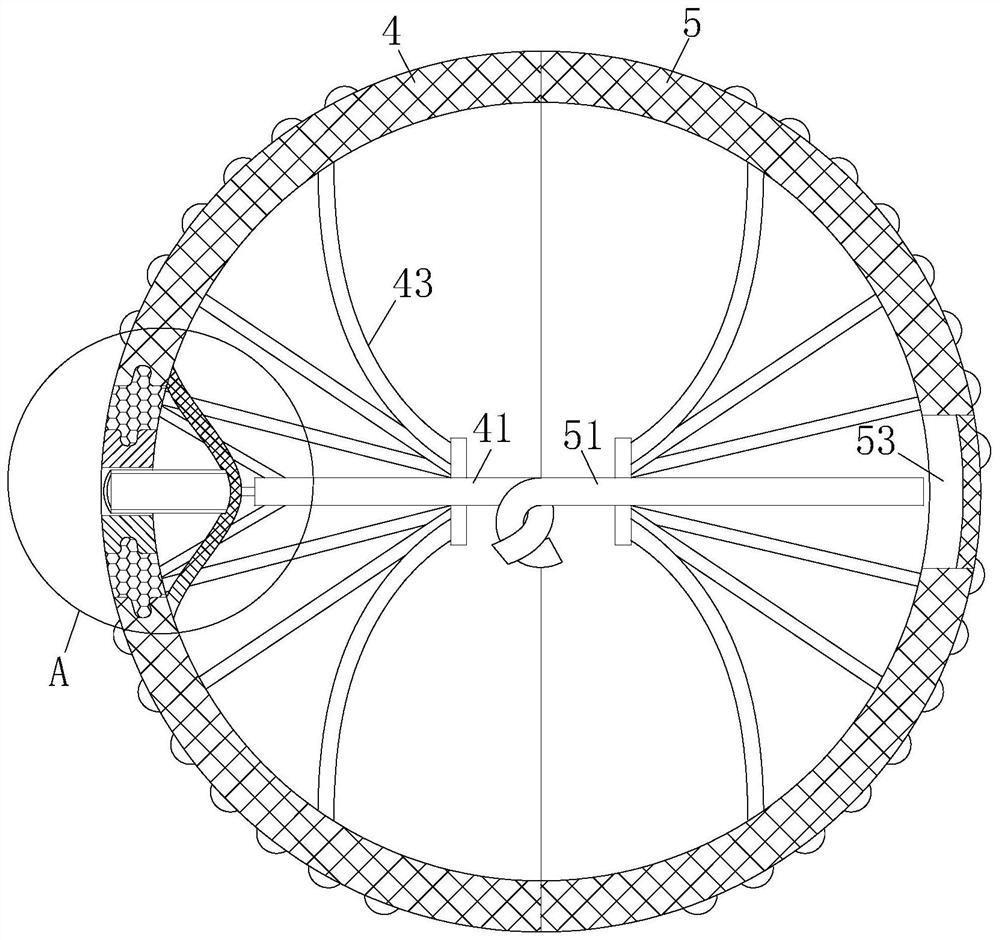

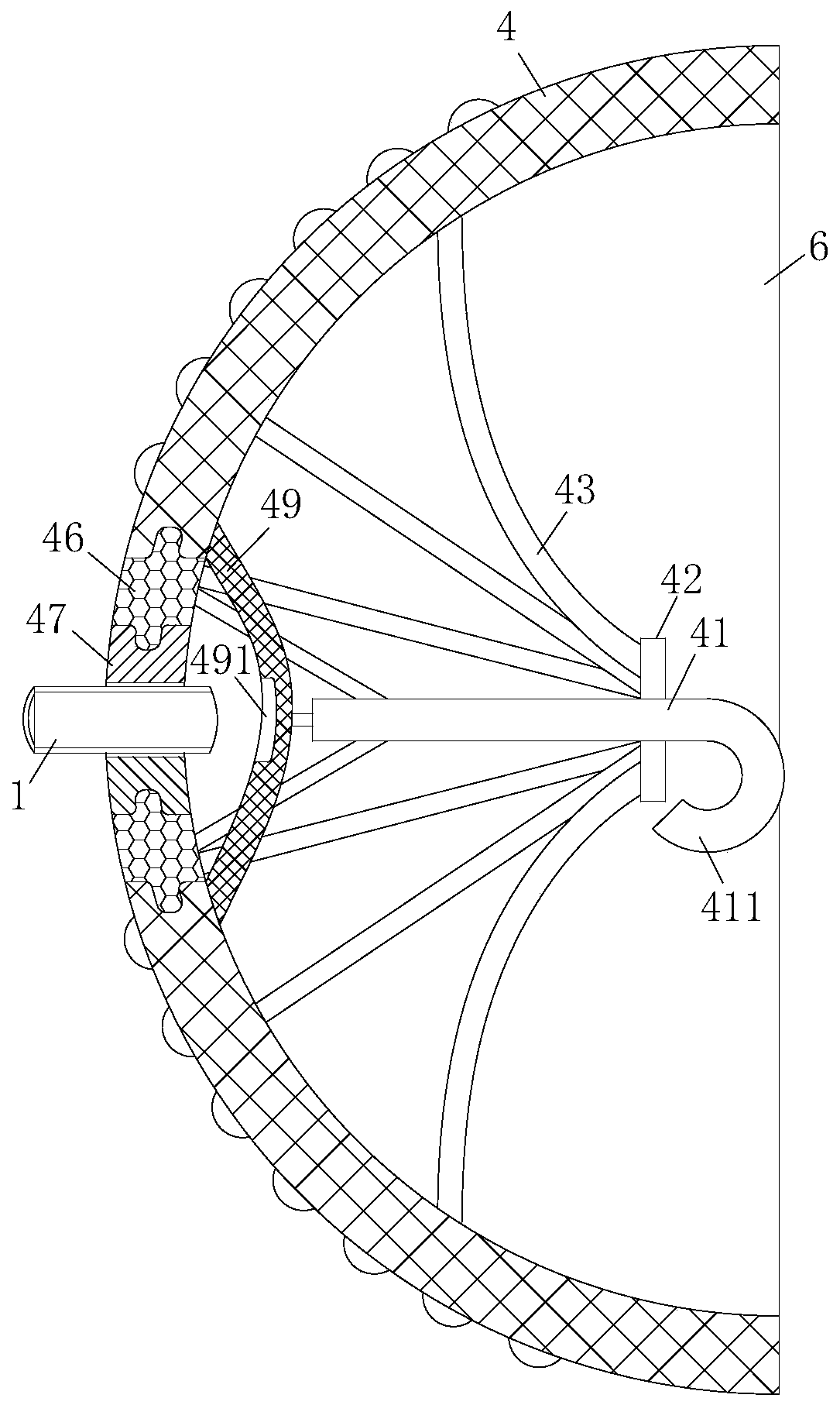

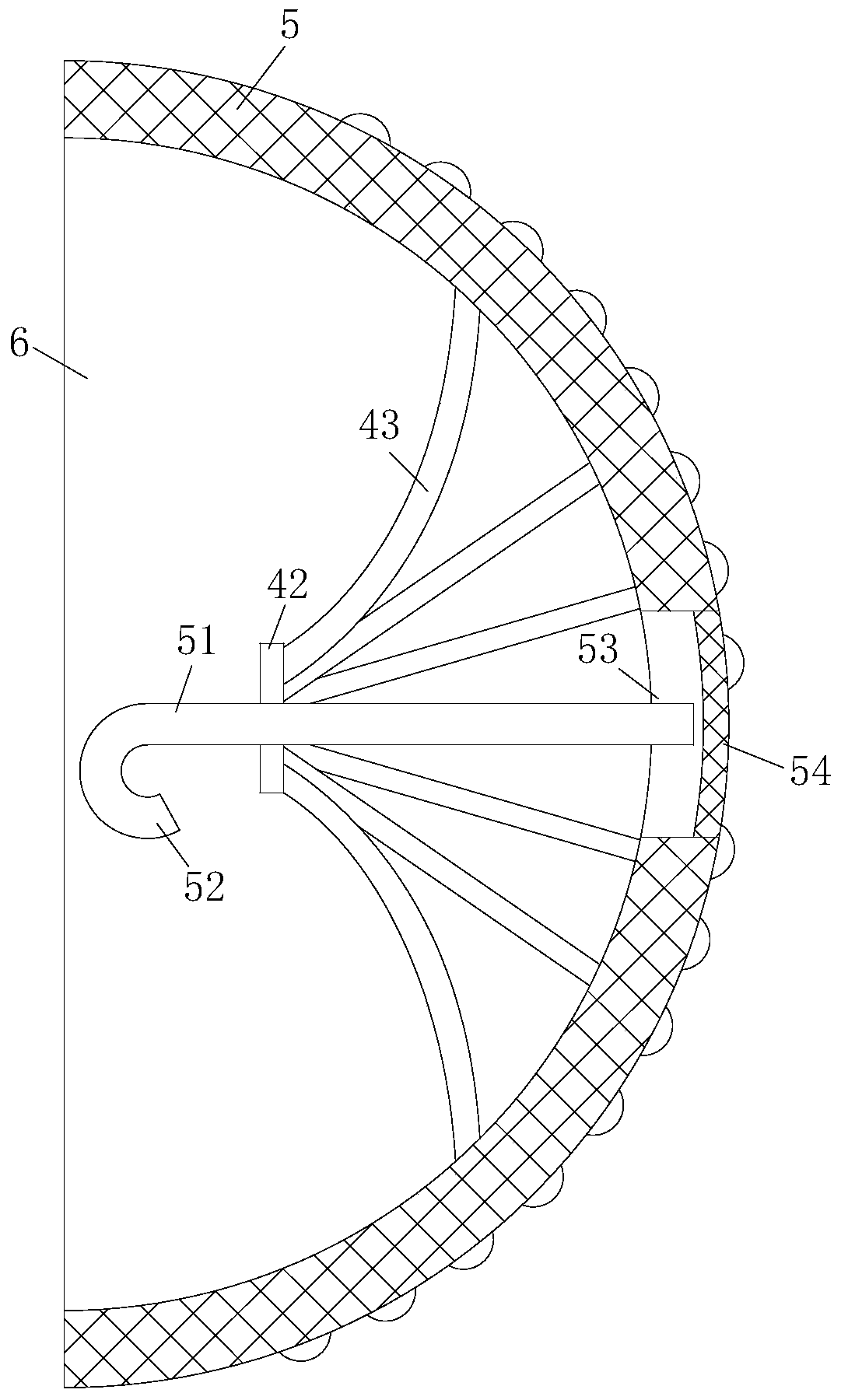

Pipe bending machine and pipe bending method

ActiveCN106001219AQuality improvementReduce breakage damageMetal-working feeding devicesPositioning devicesEngineeringPress brake

The invention discloses a pipe bending machine and a pipe bending method. The pipe bending machine comprises a guiding column, a fixing piece and a rotating mechanism. A first concave part is arranged on the side wall of the guiding column. The first concave part surrounds the guiding column with the axis of the guiding column as the center, and is matched with the outer side wall of a pipe. The fixing piece is used for fixing the pipe to the guiding column. The rotating mechanism comprises a drive piece and an abutting piece. The abutting piece is provided with a second concave part opposite to the first concave part, and the second concave part is matched with the outer side wall of the pipe. The drive piece is used for driving the abutting piece to move along the first concave part of the guiding column. The clamping end, namely the fixing piece of the pipe is in a fixed state, a bending forming mechanism, namely the rotating mechanism is in a dynamic change for the pipe to be gradually bent, and the phenomenon that due to the fact that the clamping end of the pipe is subjected to large acting force for a long time, the end portion of the pipe is fractured and damaged can be avoided. Compared with a bending machine in the prior art, the quality of a bent pipe obtained through the pipe bending machine and the pipe bending method is higher.

Owner:OMS MASCH CO LTD

Winding device for cable manufacturing

ActiveCN113697599BReduce breakage damageReduces skin breakoutsFilament handlingEngine lubricationEngineeringCold weather

Owner:江苏学霖电缆科技有限公司

Small hole punch anti-break punching die

The invention discloses a small hole punch breaking prevention punching die. The die comprises an upper die and a lower die, wherein the upper die comprises an upper clamping plate, a stopping plate and a stripper plate; an elastic space is defined between the upper clamping plate and the stopping plate; the lower die comprises a lower die plate, and a two-segment punch; the punch comprises a columnar knocking rod and a sub-punch which comprises a stopping part and a punch part which is positioned below the stopping part; the radial width of the punch part is smaller than that of the stopping part, and the radial width of the punch part is smaller than that of the knocking rod which penetrates through the stopping plate to be positioned in the stripper plate; the stopping part is positioned in the stripper plate, and the punch part penetrates through the stripper plate; corresponding to the punch part, a waste passing hole is formed in the lower die plate. According to the invention, the breaking loss of the punch can be effectively reduced, the die repairing time is shortened, the high safety of the die is guaranteed, the production efficiency is improved, the production stability is ensured, additional waste during product production can be avoided, the purpose of reducing the production cost of the product is achieved, and the punching die is more convenient to disassemble, assemble and replace.

Owner:JIANGSU BOJUN IND TECH

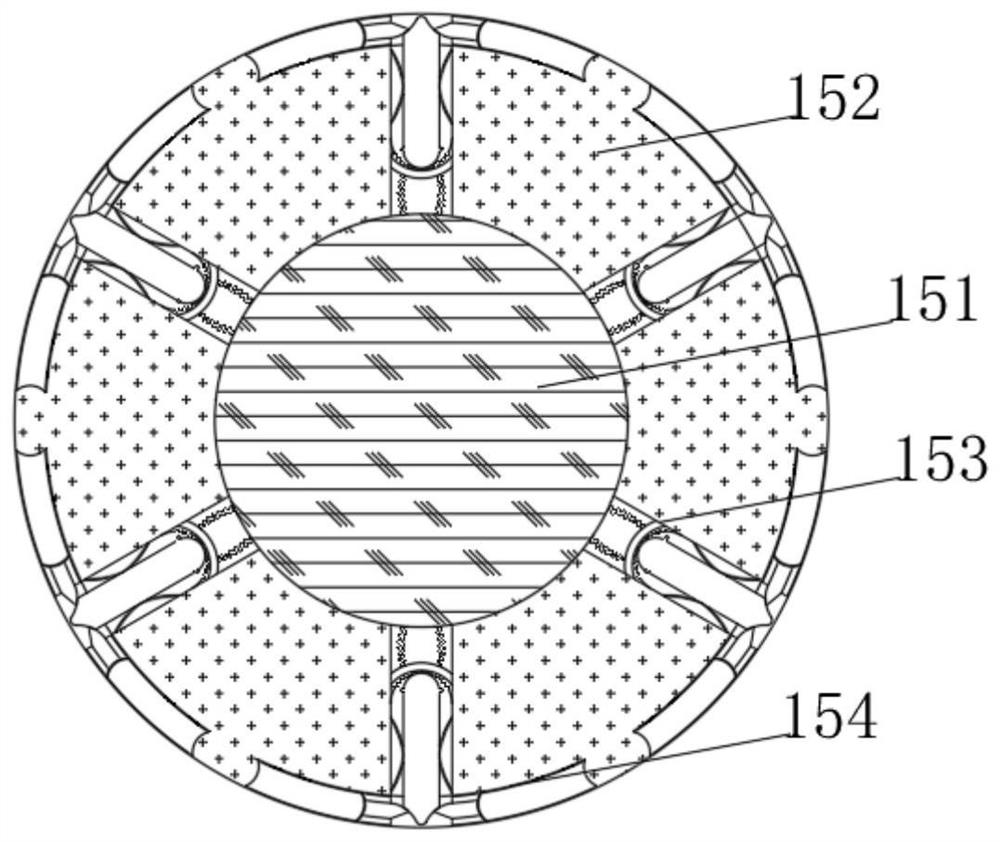

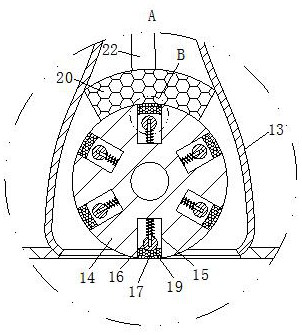

Bi-metal composite plate hammer for impact type ore crusher

InactiveCN105797814AExtended service lifeLow comprehensive use costGrain treatmentsCemented carbideEngineering

The invention discloses a bi-metal composite plate hammer for an impact type ore crusher. The bi-metal composite plate hammer comprises a main shaft and a rotor body arranged on the outer surface of the main shaft. A plurality of protruding trapezoid bodies are evenly distributed on the outer surface of the rotor body in the circumferential direction and provided with plate hammer bodies. Rectangular grooves are formed in the upper end faces of the plate hammer bodies, and trapezoid grooves are formed in the lower end faces of the plate hammer bodies. The trapezoid grooves and the trapezoid bodies are correspondingly arranged and fastened through a plurality of bolts arranged in the rectangular grooves in the axial direction. Nuts of the bolts are further connected with steel wires in series. A plurality of hard alloy bars are further inlaid and cast in the plate hammer bodies. The bi-metal composite plate hammer is long in service life, low in cost, high in safety, suitable for crushing high-temperature materials, capable of facilitating machining, firm in structure and high in utilization rate.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

Technique for producing metal corrugated pipe

The invention discloses a production process of a metal bellows, which comprises the following steps: ① corrugated plate blanking and calendering deformation; ② shot peening treatment; ③ welding; ⑤ heat treatment; ⑥ embedded graphite ring; polishing. The process of the present invention is suitable for single-layer or multi-layer corrugated metal welded bellows. Its main feature is that after shot peening treatment, the corrugated plate will produce a certain micro-deformation, which improves the fatigue life of the corrugated tube and can reduce the corrugated tube in Crack and fracture damage during use; the welding process method invented at the same time increases the welding strength of the bellows, reduces the oxidation of the bellows during welding; the heat treatment process of the present invention reduces the oxidation produced during the heat treatment of the bellows, and Make its elastic properties more stable. Therefore, the invented welding and heat treatment process reduces the loss of bullets, rupture and fracture damage of the bellows during use.

Owner:成都赛乐化新机电有限公司 +1

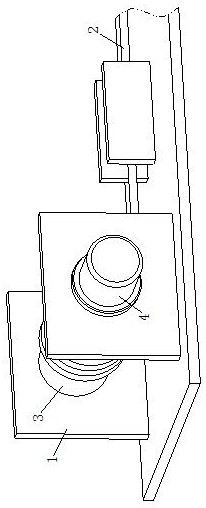

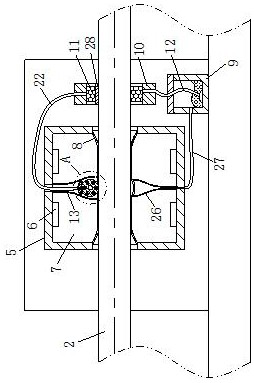

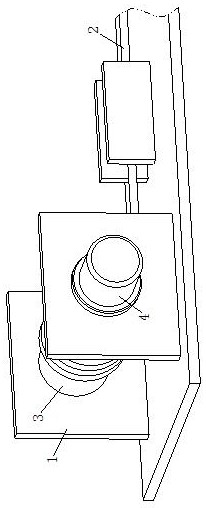

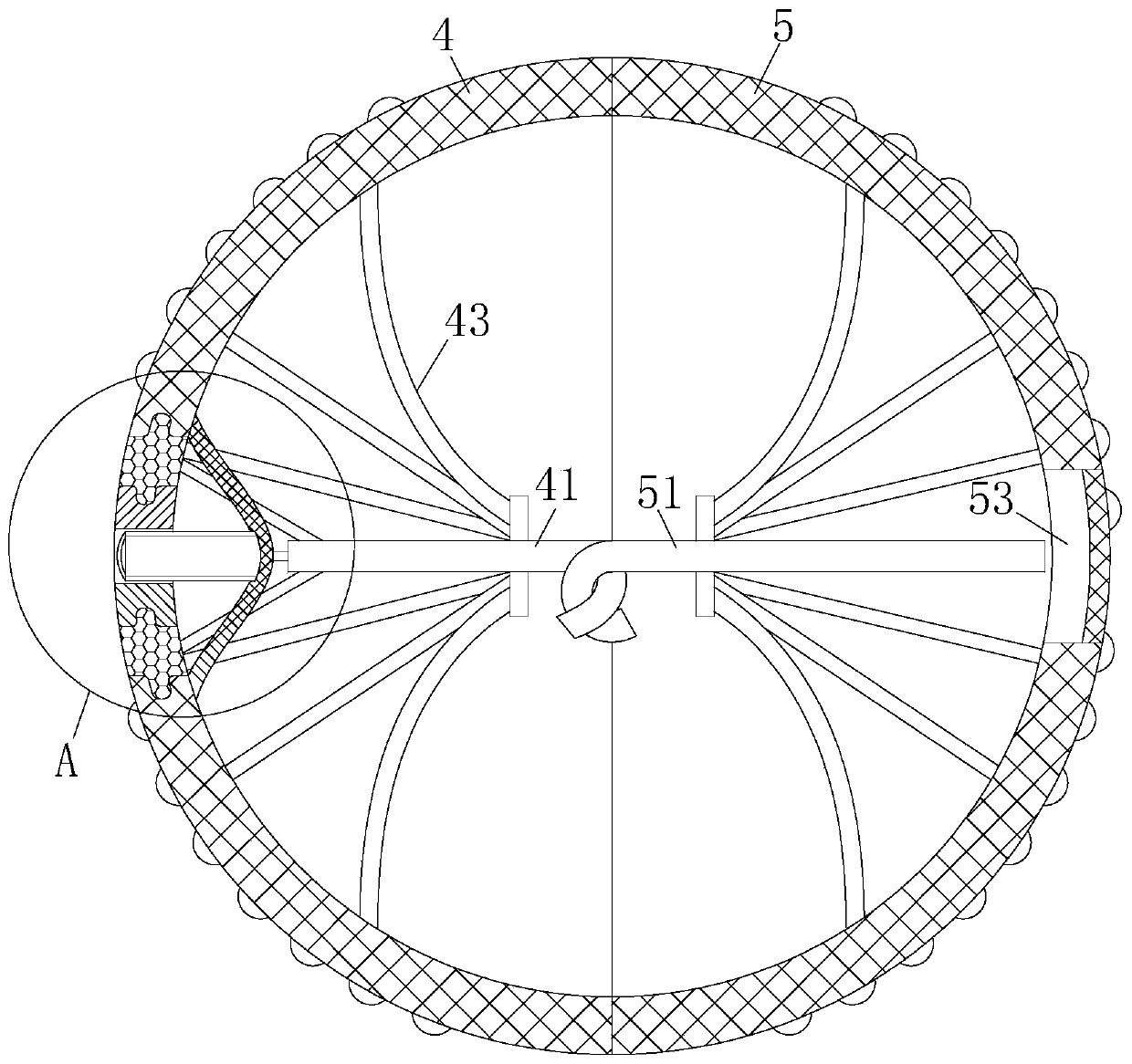

A method for implementing video surveillance and monitoring equipment

ActiveCN110475057BReduce breakage damageImprove locking forceTelevision system detailsColor television detailsVideo monitoringStructural engineering

The invention belongs to the technical field of video surveillance, and specifically relates to a video surveillance implementation method and surveillance equipment. The video surveillance surveillance equipment includes a camera, an infinite network bridge, and a housing. The housing is composed of a No. 1 hemispherical shell with the same diameter and a The No. 2 hemispherical shell, the No. 1 hemispherical shell and the No. 2 hemispherical shell are respectively provided with a No. 1 central rod and a No. 2 central rod, and the No. 1 hemispherical shell and the No. The No. 2 hemispherical shell is fastened and fitted. The No. 1 hemispherical shell is provided with a card plate, and the No. 2 hemispherical groove is provided with a matching card slot. By tightening the card plate and the card slot, the No. 1 The locking force of the mating surface of the hemispherical shell and the No. 2 hemispherical shell enhances the protection ability of the shell to the camera and reduces the rupture damage of the mating surface of the shell when it is hit.

Owner:湖南一鸣科技有限公司

Structure and manufacturing method of a soft package battery

ActiveCN106252540BImprove performanceAvoid damageSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrolytic agentInternal resistance

The invention provides a structure of a soft-packed battery, which can solve the problems of the existing soft-packed battery that the performance of the soft-packed battery is affected due to the large internal resistance, large calorific value and power loss due to the welded connection between the tab and the battery electrode sheet, including Several positive electrode sheets and several negative electrode sheets wrapped in a packaging shell, the positive electrode sheets and negative electrode sheets are separated by a separator, the packaging shell is filled with electrolyte, and the positive electrode sheets are positive electrode substrates coated with positive electrode materials , the negative electrode sheet is a negative electrode substrate coated with negative electrode materials, the positive electrode substrate is provided with a positive electrode lead end, the negative electrode base material has a negative electrode lead end, and it is characterized in that: the positive electrode lead end extends out of the packaging shell to form As for the positive tab, the lead-out end of the negative electrode extends out of the packaging shell to form the negative tab, and also provides a manufacturing method for the soft-packaged battery.

Owner:YIXING HUIHUA COMPOSITE MATERIAL CO LTD

Structure of soft package battery and manufacturing method thereof

ActiveCN106252540AImprove performanceAvoid damageSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectricityInternal resistance

The invention provides a structure of a soft package battery, and solves the problems that the welded connection of tabs and electrode slices in existing soft package batteries causes large internal resistance, large calorific value and electricity loss, and affects the performance of soft package batteries. The structure of the soft package battery comprises several positive plates and several negative plates wrapped in a pack shell, the positive plates and negative plates are separated by diaphragms, the pack shell is filled with an electrolyte solution, the positive plates are a positive material coated positive substrate, the negative plates are a negative material coated negative substrate, the positive substrate is provided with a positive leading-out end, and the negative substrate is provided with a negative leading-out end. The structure is characterized in that the pack shell extends out of the positive leading-out end to form a positive tab, and the pack shell extends out of the negative leading-out end to form a negative tab. The invention also provides a manufacturing method of the soft package battery.

Owner:YIXING HUIHUA COMPOSITE MATERIAL CO LTD

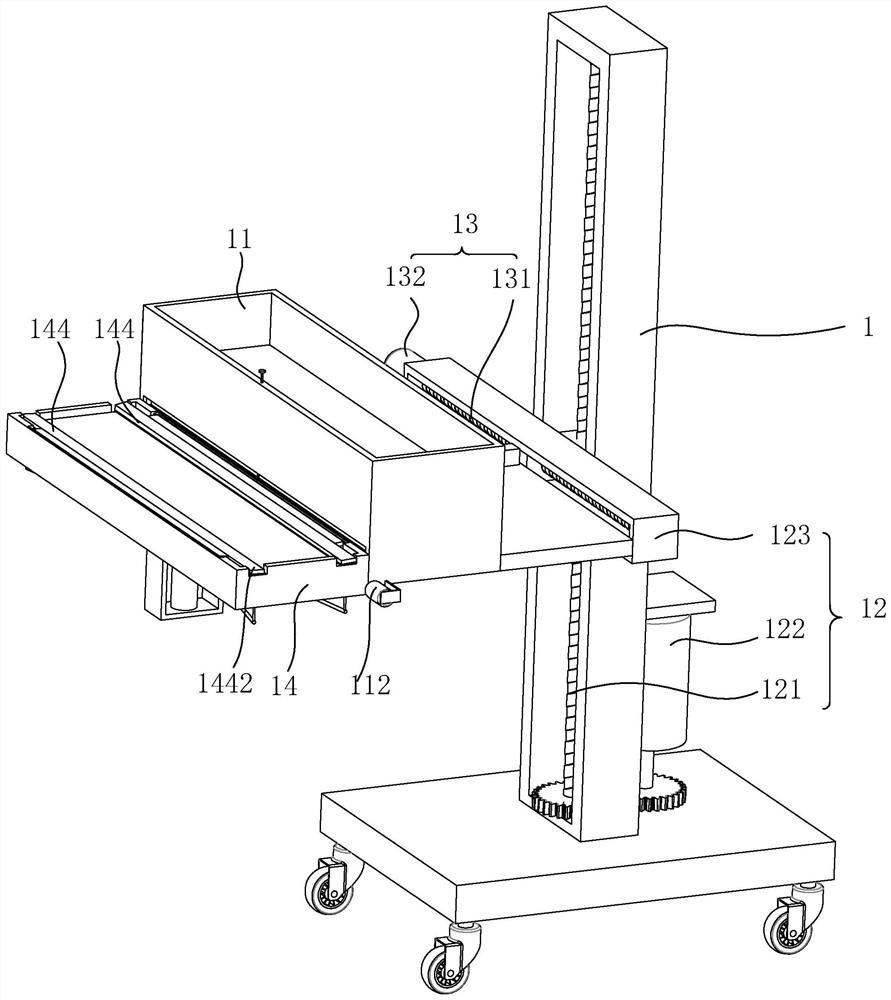

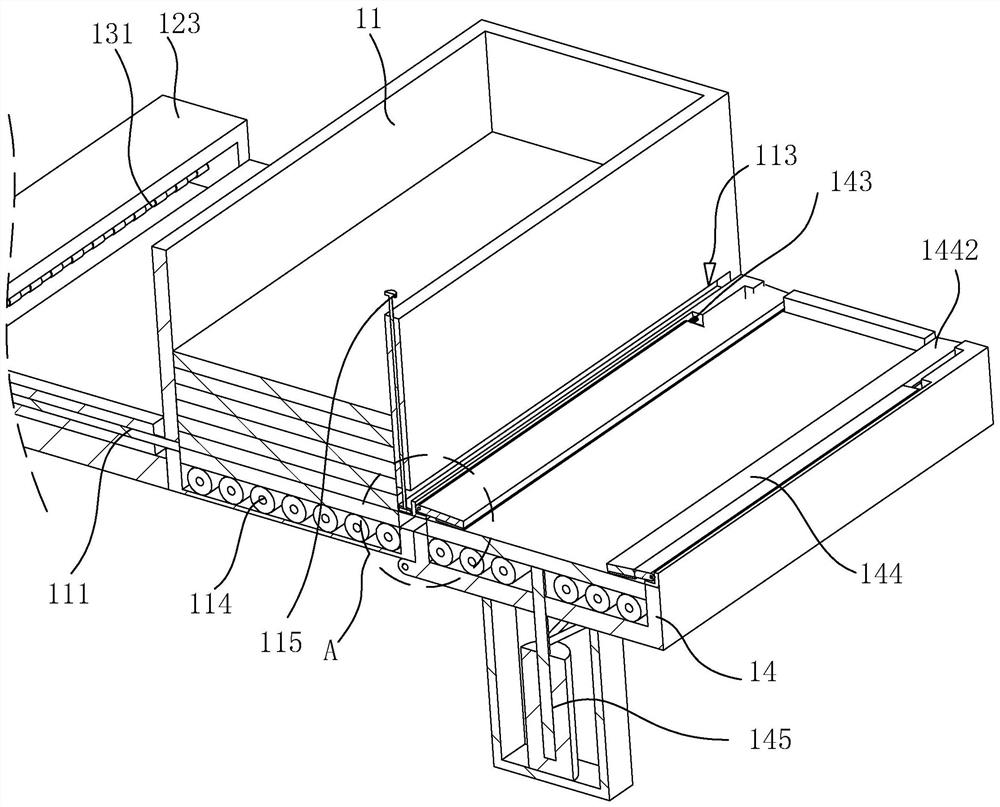

A prefabricated building wall panel installation machine

ActiveCN113137039BReduce labor intensityImprove installation efficiencyBuilding material handlingFixed frameArchitectural engineering

Owner:HENGZUN GROUP

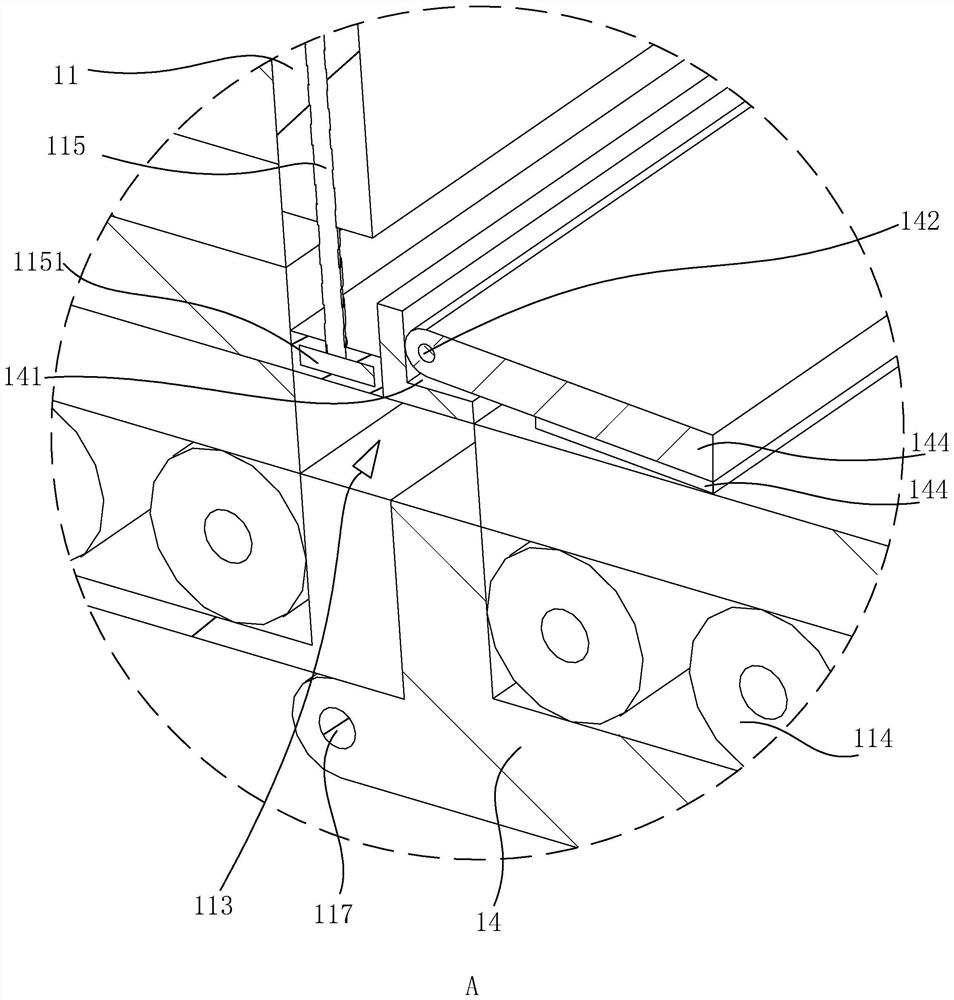

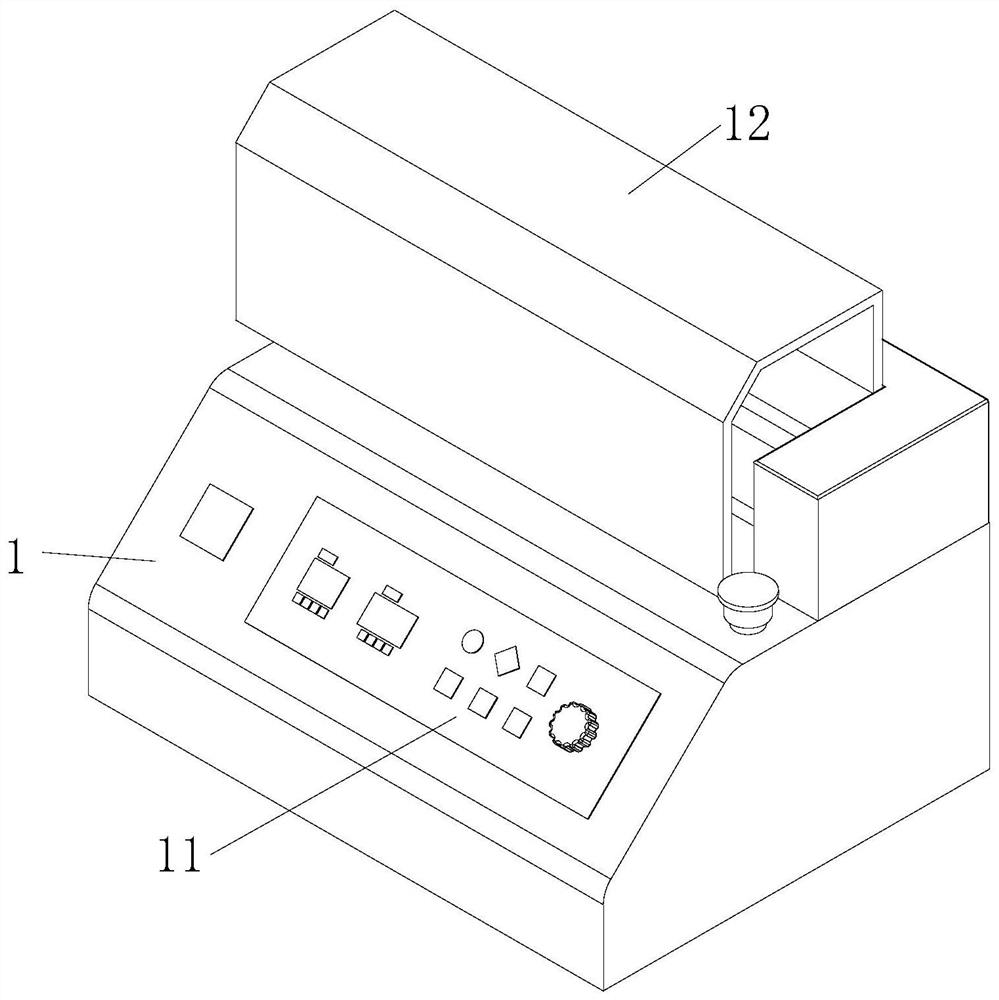

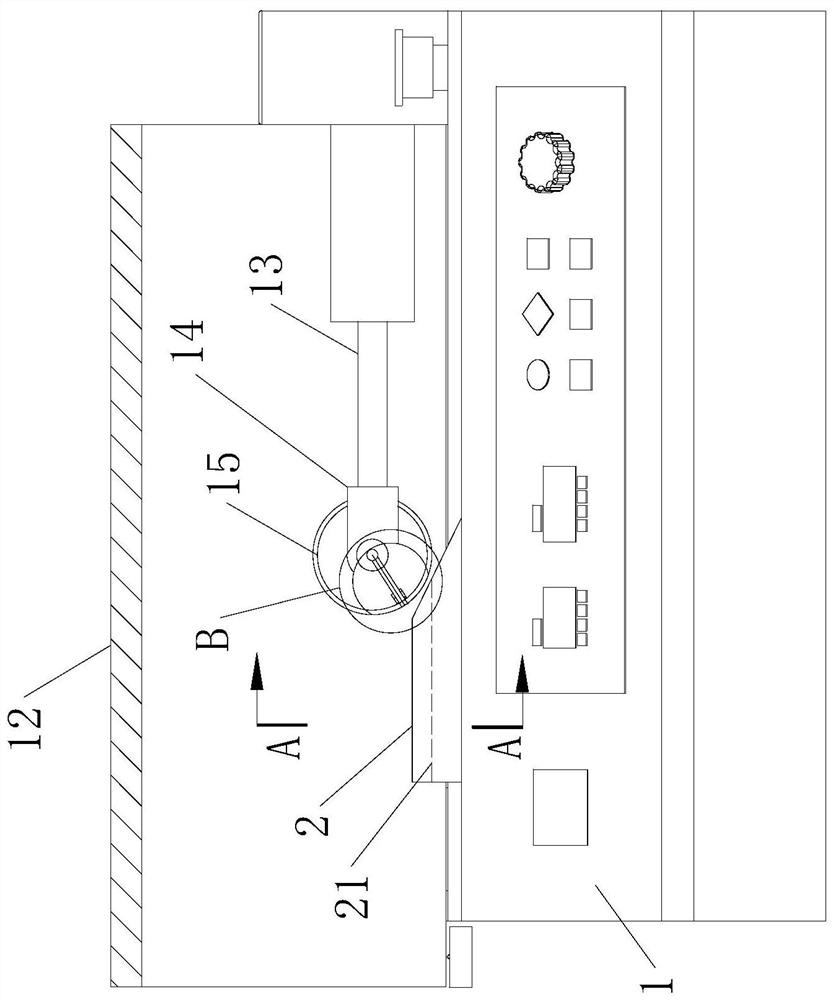

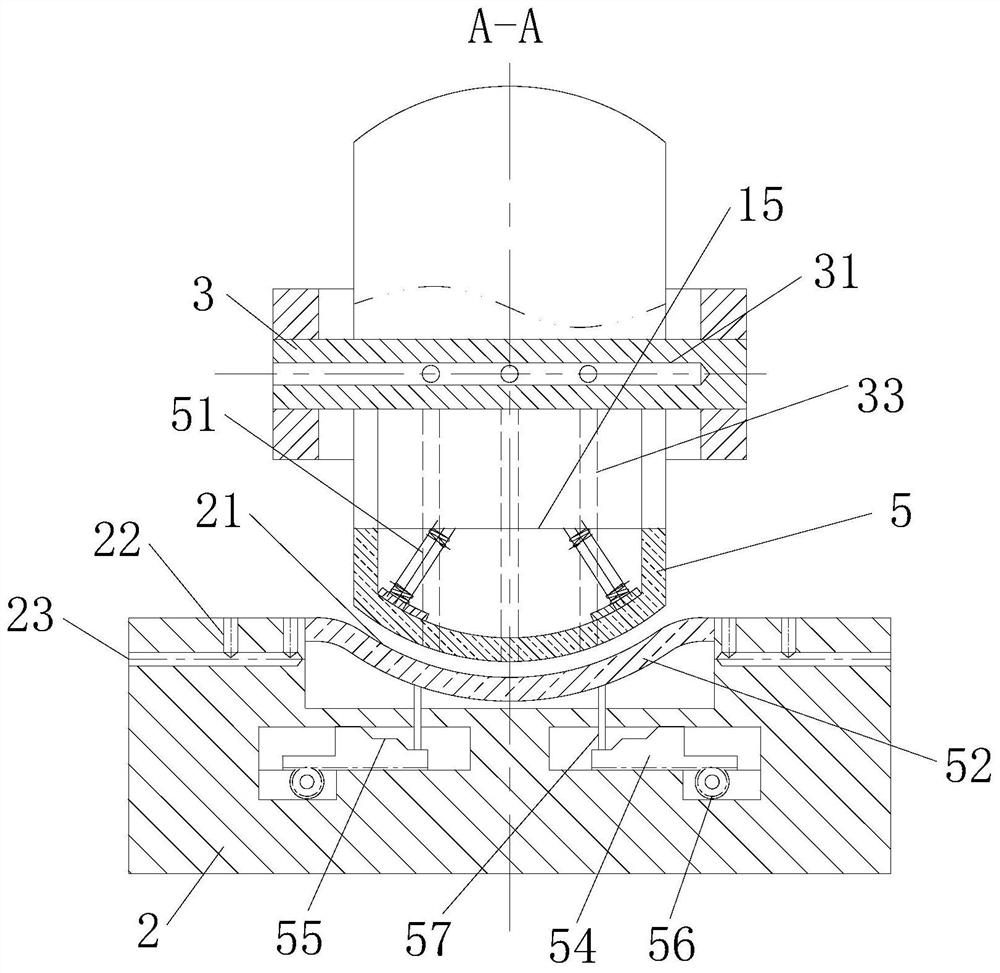

Automatic pre-folding device and method for mobile phone flat cable

PendingCN113147005AImprove extension efficiencyReduce breakage rateEngineeringStructural engineering

The invention belongs to the technical field of industrial automatic processing, and particularly relates to an automatic pre-folding device and method for a mobile phone flat cable. The automatic pre-folding device for the mobile phone flat cable comprises a body, a console and a protective cover, wherein the console is arranged in front of the body, the protective cover is hinged to the top of the body, the body in the protective cover is rotationally connected with a roller through an air cylinder and a support, the periphery of the roller is arc-shaped, a bearing platform is fixedly connected to the position, corresponding to the roller, of the body, an arc-shaped groove matched with the roller is formed in the top of the bearing platform, and negative pressure holes formed in the two sides of the arc-shaped groove communicate with an air extractor through an air extraction hole and a pipeline. According to the automatic pre-folding device for the mobile phone flat cable, the air cylinder drives the roller to move, and then the roller rolls the flat cable fixed through the negative pressure holes, so that the flat cable is bent and deformed towards the bottom of the arc-shaped groove; the flat cable is continuously bent and deformed through repeated rolling, so that the flat cable is slowly bent through repeated rolling, the extension efficiency of the flat cable is improved, the fracture rate of the flat cable is reduced, and the bending quality of the flat cable is improved.

Owner:深圳市磐锋精密技术有限公司

A kind of artificial panel and the manufacturing method of artificial panel

ActiveCN108748651BReduce pollutionImprove installation efficiencyCeramic shaping apparatusThermal insulationSlurry

The invention discloses a method for manufacturing an artificial panel, which comprises the following steps: making a mould; selecting materials; pouring the surface layer; When the slurry is not yet solidified, press a layer of reinforcement mesh on its surface, so that the reinforcement mesh completely enters the slurry, and scrape the surface; maintenance; demoulding; surface treatment. The panel prepared by the invention has two layers of reinforcement nets with complete stress release and a layer of thermal insulation material. The panel has better strength, toughness, and anti-split performance, and has a good heat and sound insulation effect at the same time.

Owner:江苏艾可陶节能科技有限公司

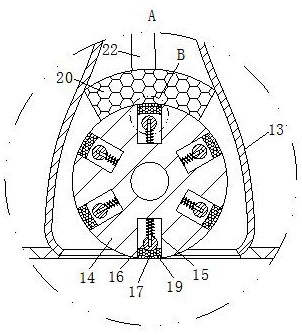

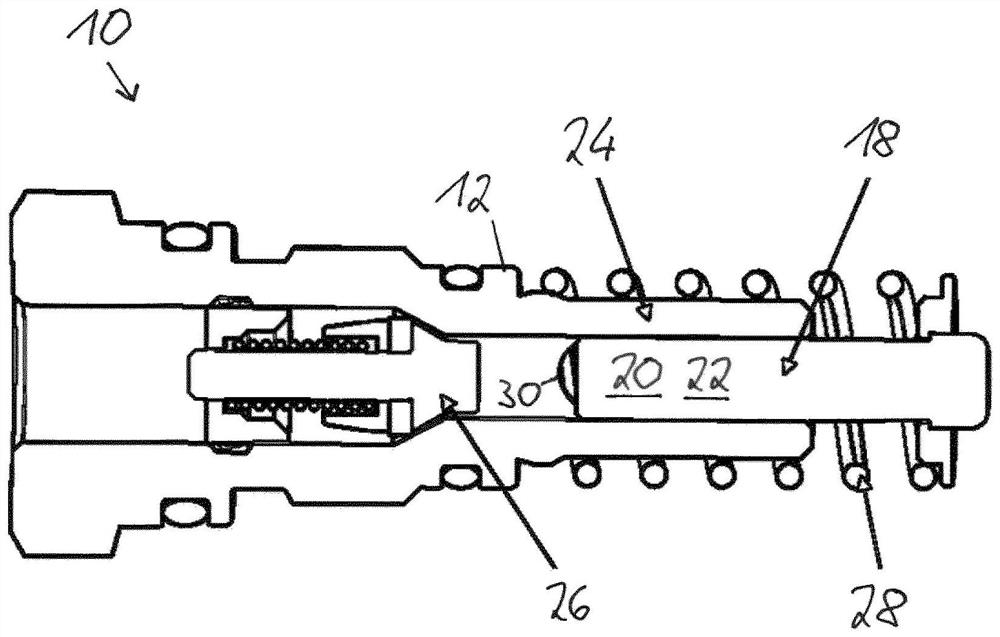

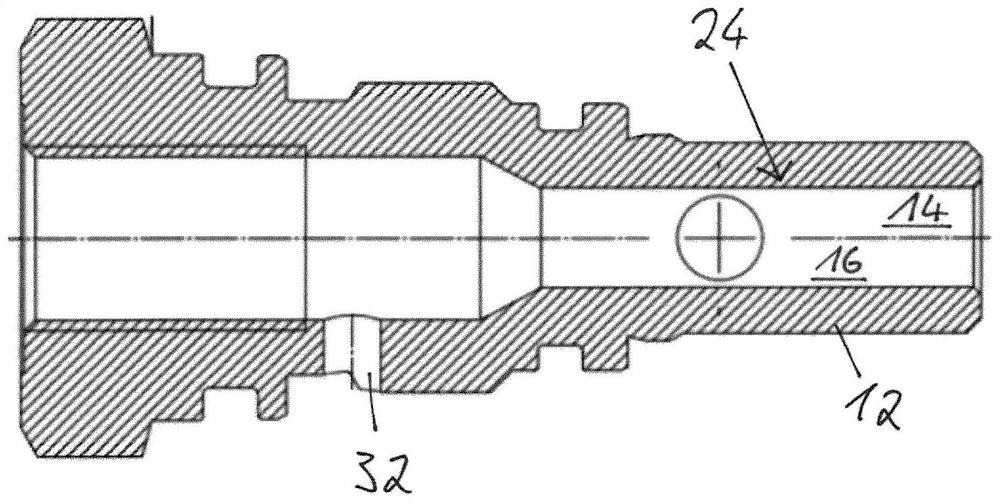

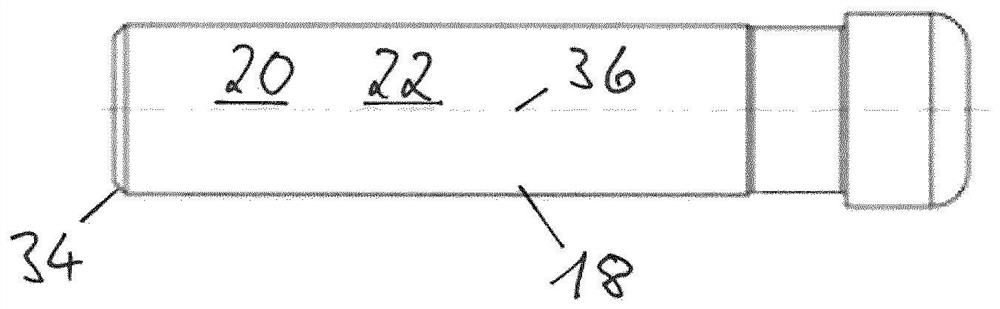

Reciprocating piston lubrication pump

PendingCN114658648ALow costLow cost to obtain little wear and tear during operationPositive displacement pump componentsPumpsEngineeringMechanical engineering

A reciprocating piston lubrication pump (10) with a component (12) is proposed, comprising an opening (14) having at least one cylindrical portion (16), and having at least one piston (18) comprising a radially outer surface (20) at least partially constructed by a coating (22), where when the radially outer surface is located in the cylindrical portion, the coating (22) is coated on the radially outer surface (20). The gap between the radially outer surface of the piston and the component is between 1 [mu] m and 20 [mu] m, wherein the surface hardness of the coating at the radially outer surface is 2 to 10 times higher than the surface hardness of the region (24) of the component forming the cylindrical portion.

Owner:AB SKF +1

Adjustable hanging rack, unmanned aerial vehicle and method for hanging article on unmanned aerial vehicle

PendingCN114084359AGood for stabilityImprove structural strengthAircraft componentsWeight reductionAerospace engineeringUncrewed vehicle

The invention relates to an adjustable hanging rack, an unmanned aerial vehicle and a method for mounting an article on the unmanned aerial vehicle, belongs to the technical field of equipment hanging, and solves the problem that in the prior art, the gravity center of a hanging rack is unstable after inspection equipment is mounted on the hanging rack. The adjustable hanging rack comprises a space bent pipe and a long straight pipe, the space bent pipe is bent to form a preset space, and the long straight pipe is fixedly arranged in the preset space of the space bent pipe; a first connecting end is arranged on the spatial bent pipe, and a second connecting end is arranged on the long straight pipe; a rectangular sheet body is arranged on the space bent pipe and is used for carrying out X-direction adjustment on a hung object; the first connecting end and the second connecting end are provided with threads and used for conducting Y-direction adjustment on a hung object; the first connecting end and the second connecting end are provided with Z-direction angle adjusting devices used for performing Z-direction adjustment on a hung object. By means of the hanging rack, the hung object can be conveniently and practically adjusted, and the safety and reliability of the hanging rack and the hung object are improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

The installation structure of the car trunk shelf

ActiveCN104670102BReduce breakage damageImprove carrying capacityVehicle componentsTrim tabMechanical engineering

The invention discloses a mounting structure for automobile trunk shelves, which comprises a side trim panel, a shelf and a mounting part, the shelf is connected with the side trim panel through a rotary shaft, the side trim panel is provided with a bent part, the rotary shaft is integrally arranged on a vertical section, and the vertical section is also provided with welding holes; welding posts are arranged on the inner side of the bent part of the side trim panel, and the bent part of the side trim panel is provided with a through pin hole; the mounting part is located at the inner side of the side trim panel, a pin runs through the through pin hole, the welding posts are located in the welding holes and welded as a whole, the vertical section of the mounting part is in contact with the inner side of the bent part of the side trim panel, and a horizontal section of the mounting part is in contact with the inner side of the side trim panel. The mounting structure can enhance the carrying capability of the rotary shaft, so that the head of the rotary shaft can be prevented from breaking.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Video monitoring implementation method and monitoring equipment

ActiveCN110475057AReduce breakage damageImprove locking forceTelevision system detailsColor television detailsVideo monitoringComputer science

The invention belongs to the technical field of video monitoring, in particular to a video monitoring implementation method and monitoring equipment. The monitoring equipment for video monitoring comprises a camera, an infinite network bridge and a shell, wherein the shell is composed of a first semispherical shell and a second semispherical shell which are the same in diameter; a first center rodand a second center rod are arranged in the first semispherical shell and the second semispherical shell correspondingly; the first semispherical shell and the second semispherical shell are fastenedand matched in a manner that the first center rod is connected with the second center rod; a clamping plate is arranged on the first semispherical shell; a clamping groove matched with the second semispherical groove is formed in the second semispherical groove; and the locking force of the matching surface of the first semispherical shell and the second semispherical shell is increased through screwing of the clamping plate and the clamping groove. Therefore, the protection capacity of the shell for the camera is enhanced, and cracking damage to the matching surface of the shell when the matching surface of the shell is impacted is reduced.

Owner:湖南一鸣科技有限公司

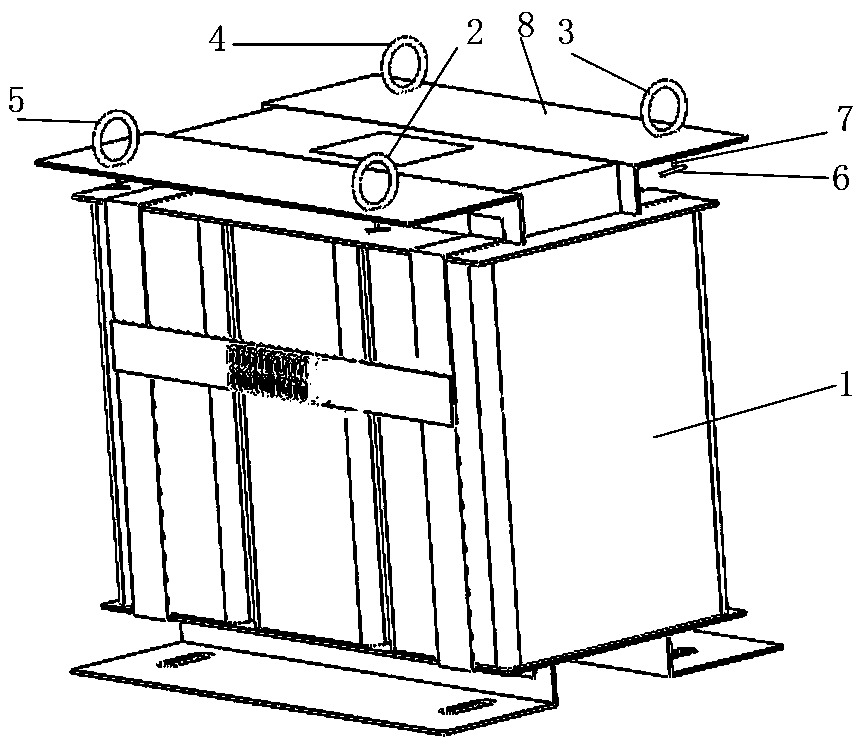

Transformer convenient to lift

InactiveCN110706880AIncrease freedomEasy to carryTransformers/reacts mounting/support/suspensionTransformer transport arrangementsTransformerStructural engineering

The invention provides a transformer convenient to lift. The transformer convenient to lift comprises a transformer body, a first lifting ring, a second lifting ring, a third lifting ring and a fourthlifting ring, bayonet locks are welded to the first lifting ring, the second lifting ring, the third lifting ring and the fourth lifting ring through connecting rods, and the connecting rods penetrate through an upper top plate of the transformer body through holes. The transformer has the beneficial effects that the transformer can be carried by multiple persons and can be carried more conveniently.

Owner:海安隆久机电科技有限公司

Permeable road and paving method thereof

PendingCN114717904APractical dredgingGuarantee the bottom row effectFatty/oily/floating substances removal devicesSewerage structuresStructural engineeringBase course

The invention relates to a permeable road and a paving method thereof, and relates to the technical field of road drainage. The structure comprises a base layer and a permeable layer located above the base layer, a main drainage pipe and a plurality of branch drainage pipes communicated with the upper portion of the main drainage pipe are arranged in the permeable layer, and the end of the main drainage pipe is communicated with a catch basin; a plurality of drainage holes are formed in the side wall of each drainage branch pipe, a blockage clearing strip is correspondingly arranged at the position, located at each drainage hole, in each drainage branch pipe, and the drainage device further comprises a driving assembly which is used for driving each blockage clearing strip to penetrate through the corresponding drainage hole so that the blockage clearing strips can dredge the corresponding drainage holes. The drainage hole dredging device has the effects of dredging drainage holes and optimizing water permeation and infiltration of accumulated water on the surface of a road.

Owner:浙江恒炜建设集团有限公司

Special-shaped small punching punch anti-break punching die

The invention discloses an anti-pull-cut punching die with a deformed small punching head. The punching die comprises an upper die and a lower die, wherein the upper die comprises an upper clamping plate, a stop plate and a stripper plate which are positioned in sequence, and an elastic space is formed between the upper clamping plate and the stop plate; the lower die comprises a lower die plate, a product to be punched is arranged between the stripper plate and the lower die plate, the punching head in the shape of an inverted frustum and a protection sleeve positioned outside the punching head in an axial sleeving manner are additionally arranged, a first via hole is formed in the stop plate in correspondence to the protection sleeve, a place reserving hole is formed in the stripper plate, the protection sleeve is fixedly arranged on the upper clamping plate and penetrates through the first via hole to extend into the place reserving hole, a second via hole is formed in the stripper plate in correspondence to the punching head, a third via hole is formed in the lower die plate, and the punching head penetrates through the second via hole. According to the punching die, the pull-cut damage of the punching head can be effectively reduced, the die repair time is shortened, the safety of the die is guaranteed, the production efficiency is improved, the production stability is ensured, the additional waste of product production is avoided, and the purpose of reducing the production cost of the product is achieved.

Owner:JIANGSU BOJUN IND TECH

Pipe bending machine and pipe bending method

ActiveCN106001219BReduce breakage damageImprove bending qualityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a pipe bending machine and a pipe bending method. The pipe bending machine comprises a guiding column, a fixing piece and a rotating mechanism. A first concave part is arranged on the side wall of the guiding column. The first concave part surrounds the guiding column with the axis of the guiding column as the center, and is matched with the outer side wall of a pipe. The fixing piece is used for fixing the pipe to the guiding column. The rotating mechanism comprises a drive piece and an abutting piece. The abutting piece is provided with a second concave part opposite to the first concave part, and the second concave part is matched with the outer side wall of the pipe. The drive piece is used for driving the abutting piece to move along the first concave part of the guiding column. The clamping end, namely the fixing piece of the pipe is in a fixed state, a bending forming mechanism, namely the rotating mechanism is in a dynamic change for the pipe to be gradually bent, and the phenomenon that due to the fact that the clamping end of the pipe is subjected to large acting force for a long time, the end portion of the pipe is fractured and damaged can be avoided. Compared with a bending machine in the prior art, the quality of a bent pipe obtained through the pipe bending machine and the pipe bending method is higher.

Owner:OMS MASCH CO LTD

Electric spanner for vehicle

The invention provides an on-board electric wrench, comprising a flywheel, an output shaft, a lug boss and an impact block. A pin shaft which is used for positioning the impact block is sheathed with a torsion spring; two forcing ends of the torsion spring are respectively positioned on a position limit retaining pin and the impact block; the distance between the center of the positioning hole ofa steel ball and the center of the pin shaft complies with the requirement that the chord length corresponding to the motion track of the steel ball is more than the radius of the positioning hole ofthe steel ball. The invention replaces a pulling spring with the torsion spring, changes the adjusting position, leads the adjustment of the impact force and the recovery force of the impact block tobe realized by the rigidity of the torsion spring and the steel ball supporting spring respectively, solves the contradiction that adjustment of the impact force and the recovery force of the impact block is integrated into a whole on the pulling spring, meets the impact force of the wrench design, leads the recovery of the impact block to be slow, leads the engagement surface of the impact blockcan always push through the forcing surface of the convex block and convex shoulder before the screw is screwed or after the screw is loosened so as to achieve the continuous operation, and has the advantages of fully automation of loosening and tightening the screw, complete engagement of the impact block and the root of the convex block, and long service life.

Owner:ZHEJIANG SHENGUANG ELECTRICAL

Man-made face plate and manufacturing method of man-made face plate

ActiveCN108748651AReduce pollutionImprove installation efficiencyCeramic shaping apparatusSlurryUltimate tensile strength

The invention discloses a manufacturing method of a man-made face plate. The method comprises the following steps of manufacturing a die, selecting a material, pouring a face layer, laying a middle enhancement net, pouring a middle layer, laying a heat-preserving material, pouring a bottom layer, laying a bottom layer enhancement layer, pressing an enhancement net into the surface of bottom layerslurry when the bottom layer slurry is not solidified to enable the enhancement net to enter the slurry completely, scraping the surface, carrying out maintaining, carrying demoulding and carrying outsurface treatment. According to the method, two layers of enhancement nets releasing stress completely and a layer of heat preserving material are arranged in the manufactured face plate, the strength, the toughness and the split resisting performance of the face plate are better, and meanwhile the face plate has good heat insulating and sound insulating effects.

Owner:江苏艾可陶节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com