Electric spanner for vehicle

A technology for electric wrenches and vehicles, applied in power tools, manufacturing tools, etc., can solve the problems of breakage and damage of impact blocks and bumps, accelerated impact of impact blocks, and mismatched motion trends, so as to reduce breakage damage and speed up meshing. speed, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

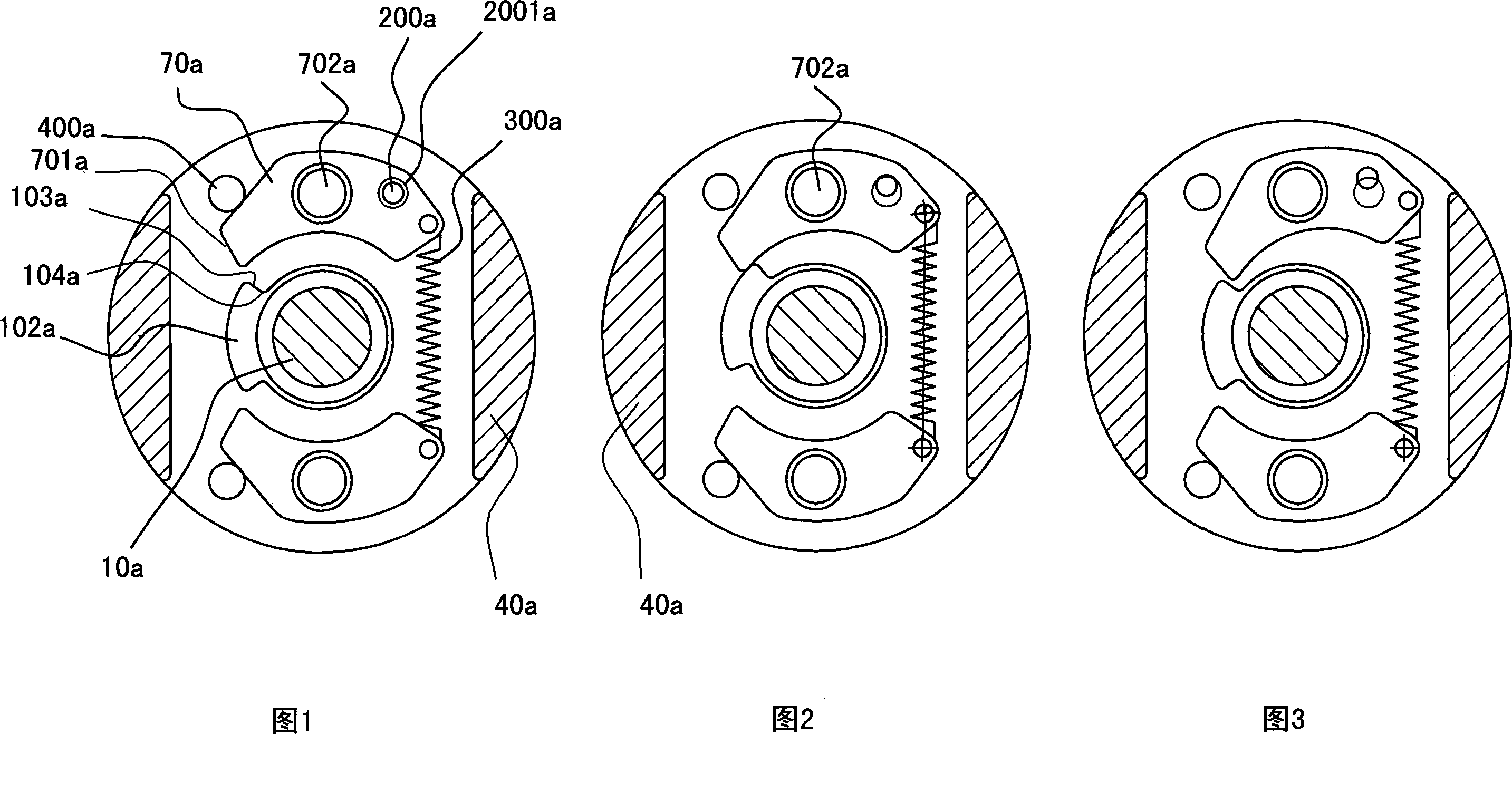

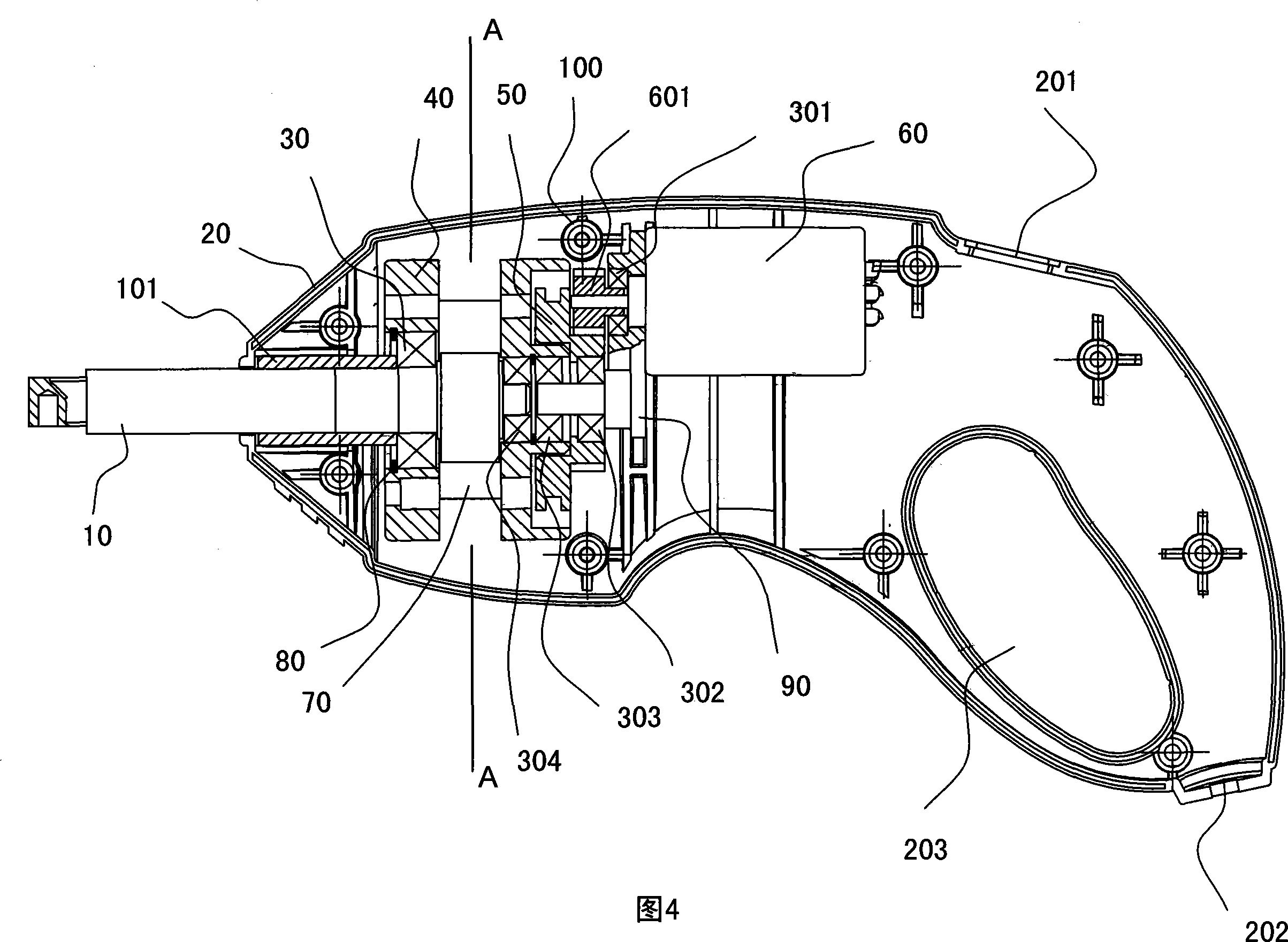

[0030] See Figure 4. The wrench of the present invention includes a casing 20, a bushing 101, a motor 60, a clutch 50, a flywheel 40, an output shaft 10 and the like. All parts are placed in the casing 20, and the casing is composed of upper and lower parts, which are fixed together by fixing bolts through a plurality of fixing seats 100. The output shaft 10 protrudes out of the casing 20, and the front of the outer end of the output shaft 10 forms a shape consistent with the work object, such as a sleeve shape, which is convenient to be connected with a fastener. All other parts are all fixedly positioned on the bracket 90 of the casing inner wall, and the DC12 DC motor 60 is connected with the inner kinematic pair including the pinion 601 through the motor shaft, and drives the flywheel 40 after the speed change. The flywheel is installed on the inner wall of the casing through a bearing at one end and a support sleeve at one end.

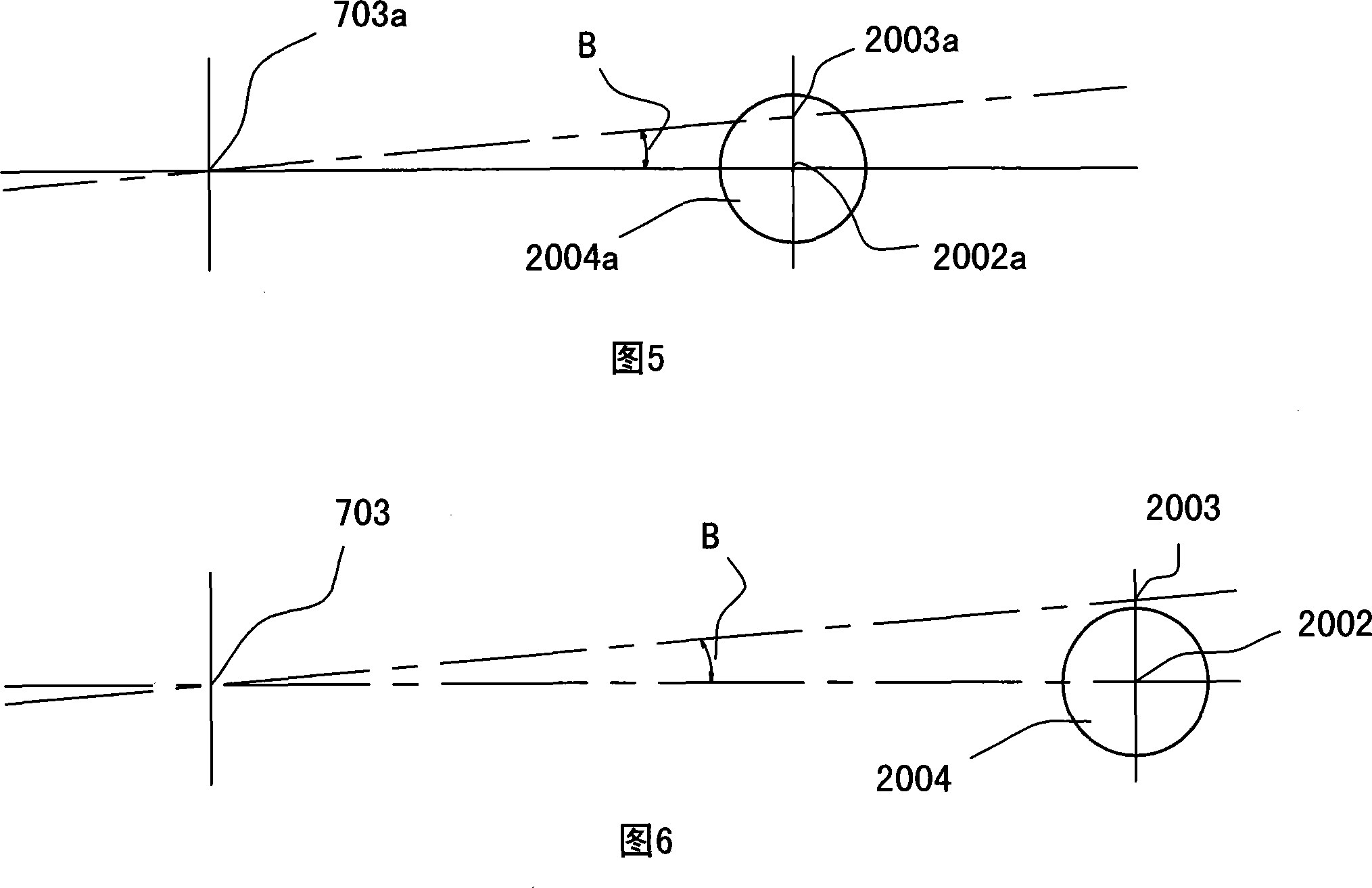

[0031] Referring to FIG. 7 , the flywhee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com