Small hole punch breaking prevention punching die

An anti-break and punching technology, applied in the field of punching dies, can solve the problems of inability to guarantee product production stability, affecting production and processing efficiency, easy breaking of small hole punches, etc., to achieve rapid disassembly and installation, and reduce mold repair time. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

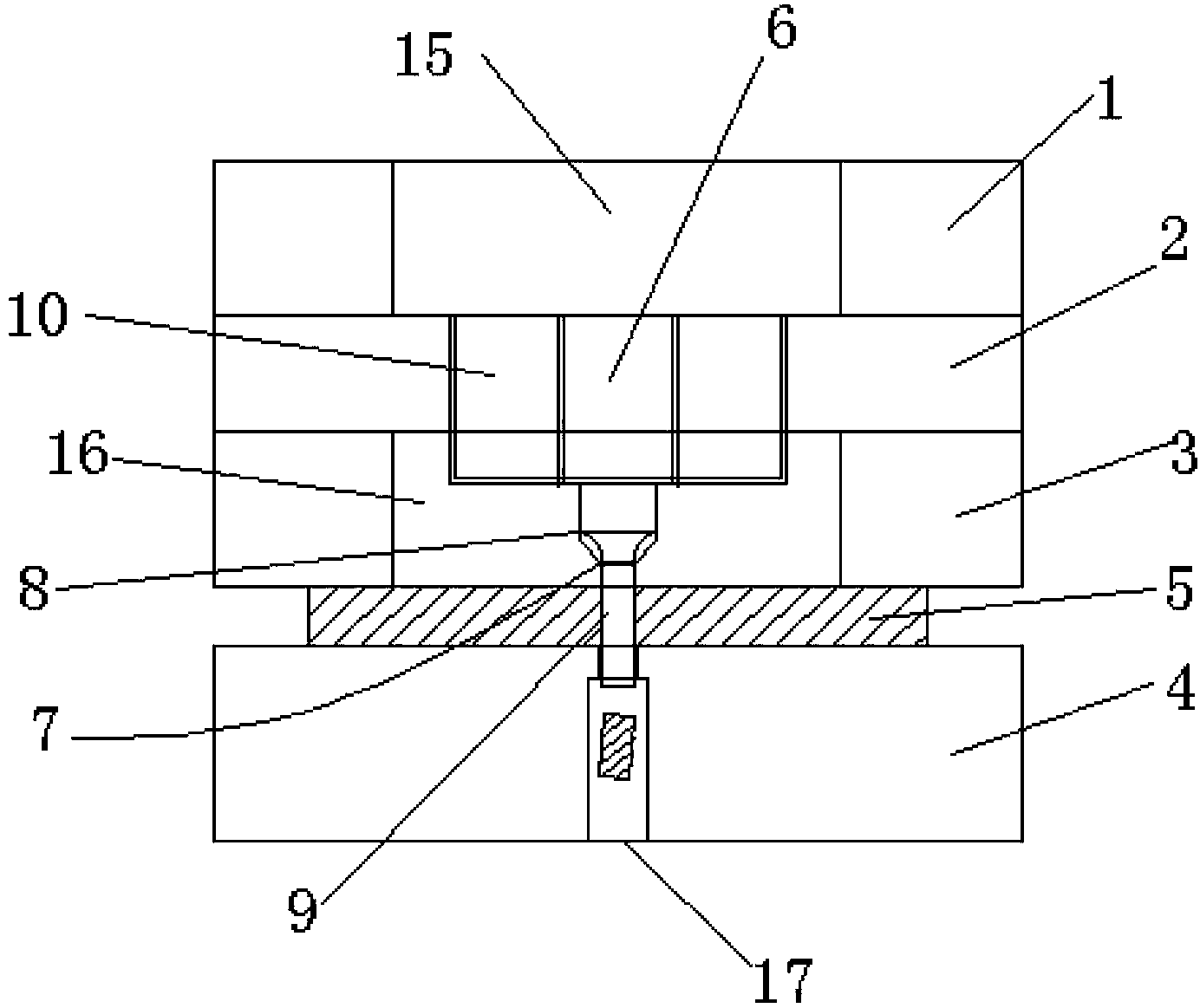

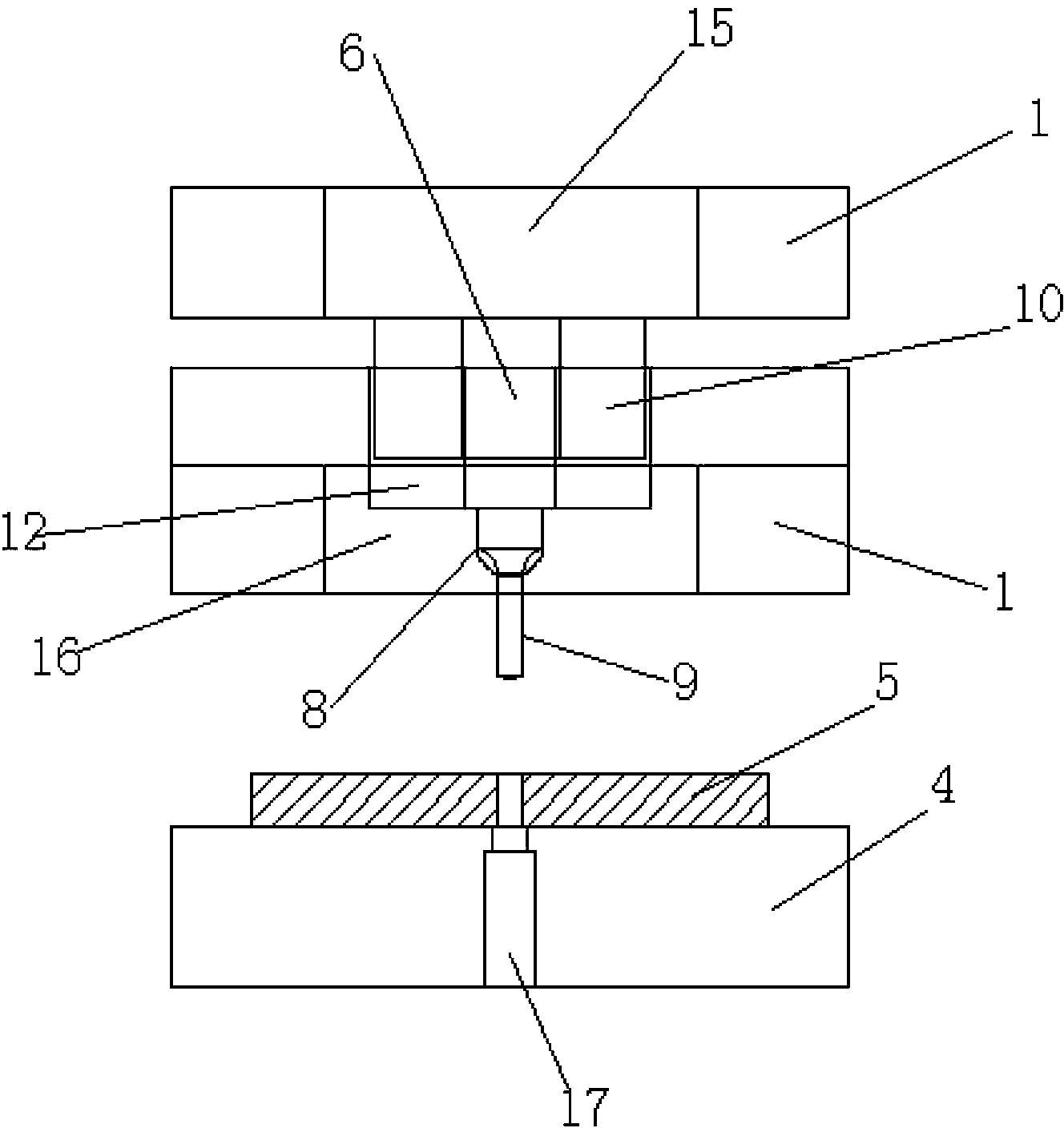

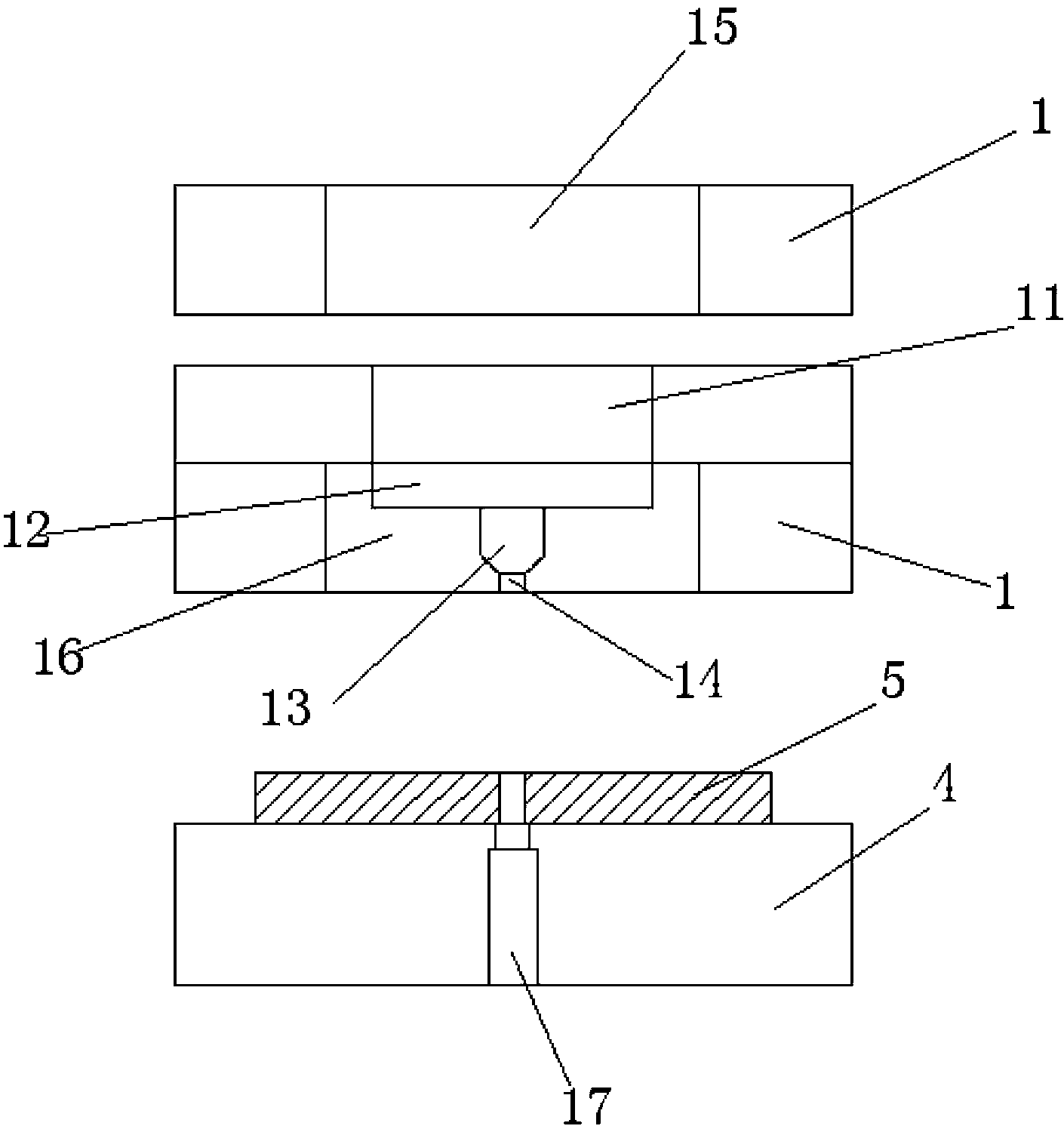

[0016] Such as figure 1 , figure 2 and image 3 As shown, a small hole punch anti-break punching die includes an upper die and a lower die, and the upper die includes an upper splint 1, a stopper plate 2 and a stripper plate 3 positioned sequentially from top to bottom; There is an elastic space between the upper splint and the stop plate, the lower mold includes a lower template 4, and the product 5 to be punched is arranged between the stripper plate and the lower template, and a two-stage Punch head, the punch head includes a cylindrical punching rod 6 and a stepped sub-punch head 7 arranged below the hitting rod, and the sub-punch head includes a stopper 8 and a punch positioned below the stopper part. Head 9, the radial width of the punch part is smaller than the radial width of the stopper part, the radial width of the punch part is smaller than the radial width of the driving rod, and the driving rod passes through the The stop plate is positioned in the stripper pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com