Man-made face plate and manufacturing method of man-made face plate

A manufacturing method and panel technology, applied in the field of building materials manufacturing, can solve the problems of brittleness in production, processing, transportation, installation and use, lack of reinforcement materials, high transportation and installation costs, and achieve less material waste and lower installation costs , Anchor safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

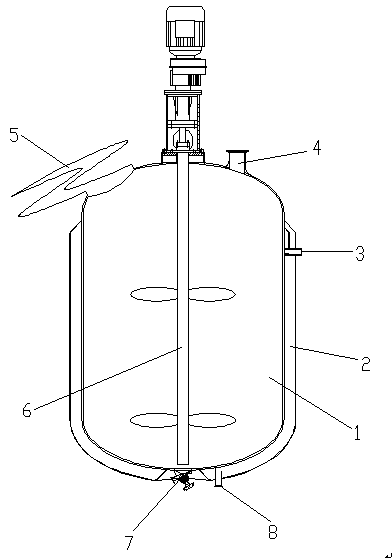

Image

Examples

Embodiment Construction

[0062] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

[0063] The manufacture method of this artificial panel comprises the following steps:

[0064] Step 1: Make the mould: set the baffle plate in sequence around the mold bottom plate end to end, the baffle plate and the mold bottom plate form a mold with an open top and closed surroundings; the height of the baffle plate is 5~200mm.

[0065] Step 2: Select materials: select surface layer pouring raw materials, middle layer pouring raw materials, bottom layer pouring raw materials, as well as intermediate reinforcement mesh and bottom layer reinforcement mesh, and prepare surface layer pouring materials, middle layer pouring materials, and bottom layer pouring materials respectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com