Special-shaped small punching punch anti-break punching die

A punching and breaking prevention technology, applied in the field of punching molds, can solve the problems of inability to guarantee the production stability of products, complex shapes of special-shaped holes, affecting production and processing efficiency, etc., to achieve simple structure and reduce mold repair time. , Reduce the effect of breaking damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

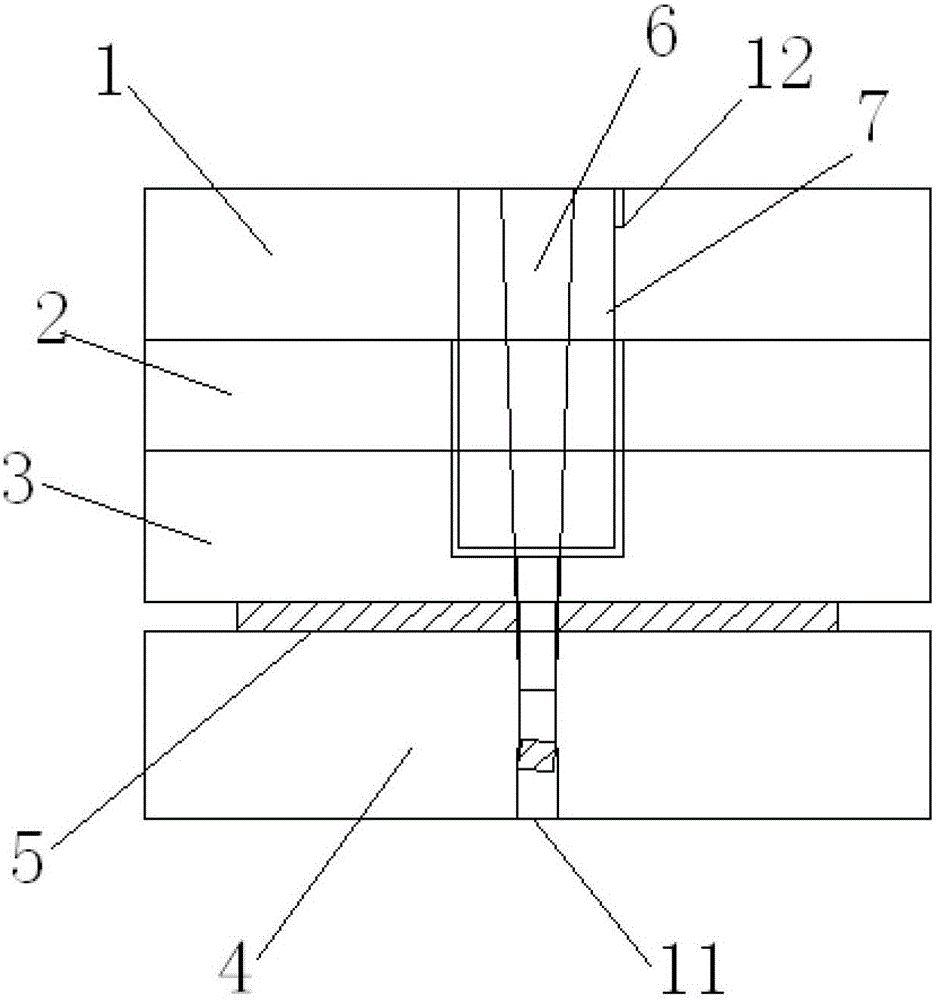

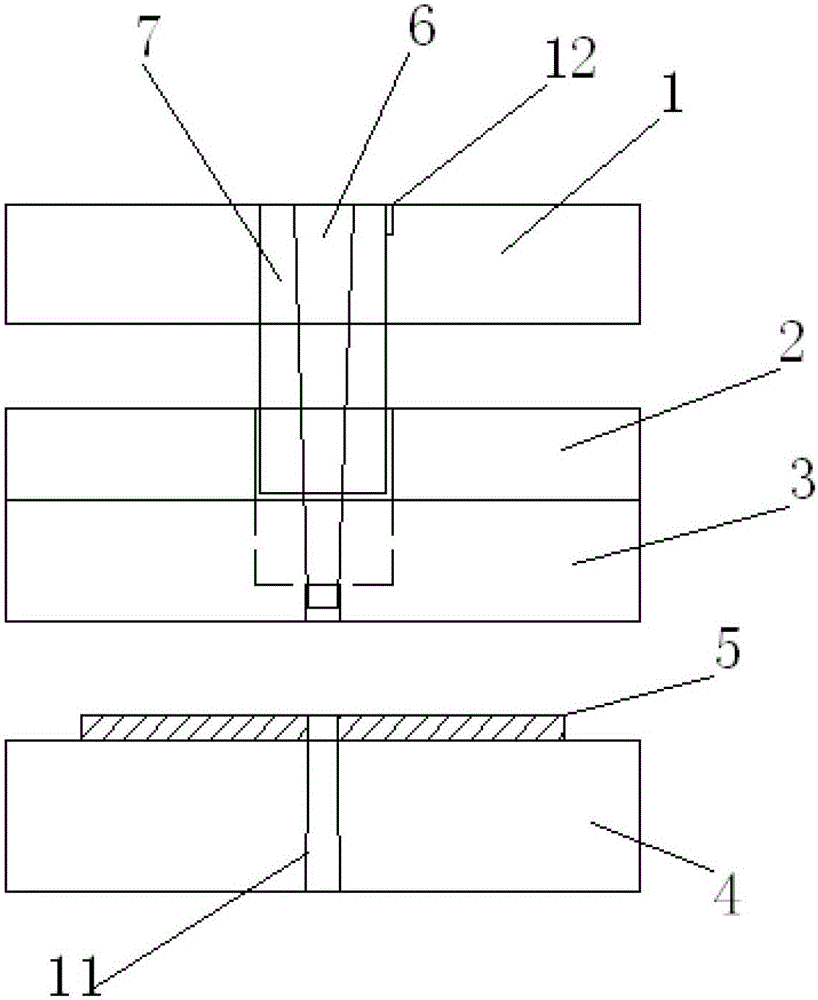

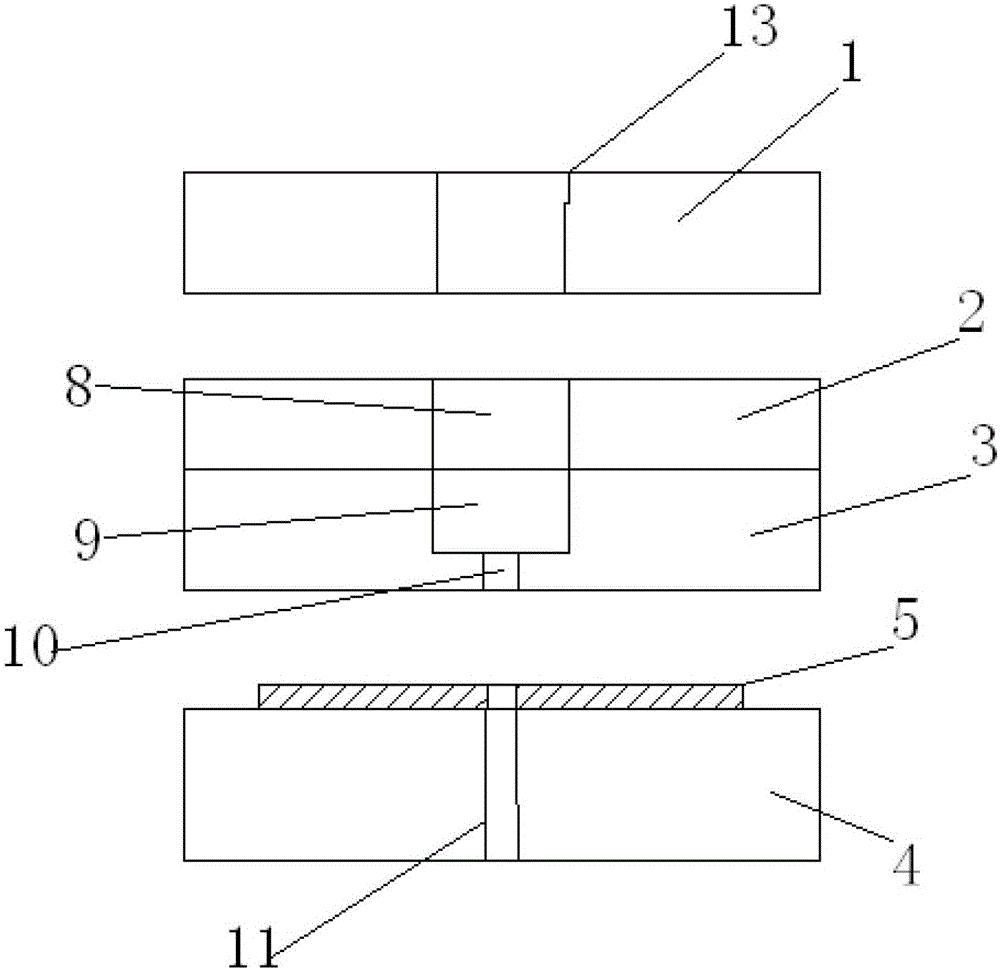

[0022] like figure 1 , figure 2 and image 3 As shown, a special-shaped small punching punch anti-break punching die includes an upper die and a lower die, and the upper die includes an upper clamping plate 1, a stopper plate 2 and a stripper plate 3 positioned in sequence, and the There is an elastic space between the upper splint and the stop plate; the lower mold includes a lower template 4, and the product 5 to be punched is arranged between the stripper plate and the lower template, and an inverted cone The shaped punch 6 and the axial sleeve are set on the sheath 7 outside the punch, corresponding to the sheath, the stopper plate is provided with a first through hole 8, and the stripper plate is provided with The relief hole 9, the sheath is fixed on the upper splint, and extends through the first through hole into the relief hole, corresponding to the punch, the stripping plate is provided with There is a second via hole 10, and a third via hole 11 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com