The installation structure of the car trunk shelf

A technology of installation structure and storage board, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of shaft deformation, damage, and easy breakage of the shaft, reduce the problem of shaft fracture and damage, and enhance the ability of the downforce moment. Strong and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

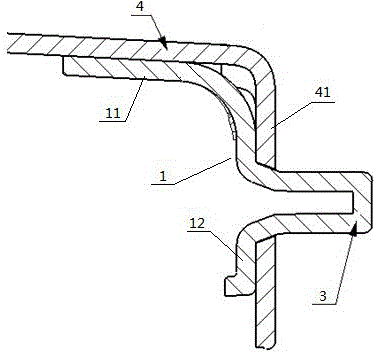

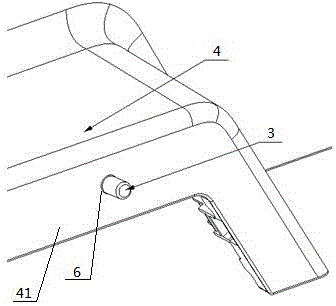

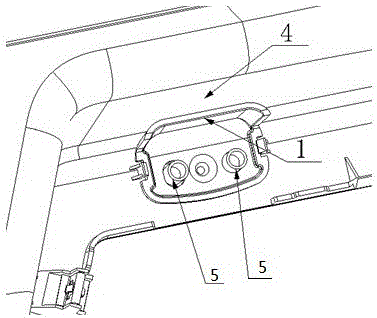

[0013] see Figure 1 to Figure 4 As shown, the installation structure of the trunk shelf of the car includes a side panel 4, a shelf (not shown in the figure) and an L-shaped installation part 1 . The mounting part 1 is integrally provided with a rotating shaft 3, which is integrally injection-molded with nylon and glass fiber material. The shelf board is connected to the side panel 4 through the rotating shaft 3. The side panel 4 is provided with a bent part 41. The installation part 1 includes a horizontal section 11 and a vertical section 12. The rotating shaft 3 is integrally arranged on the vertical section 12. On the vertical section 12 there is also a welding hole 2 . Welding posts 5 are arranged inside the bent portion 41 of the side wall trim, and pin shaft holes 6 are opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com