Bi-metal composite plate hammer for impact type ore crusher

A composite material plate and ore crusher technology, which is applied in the direction of grain processing, etc., can solve the problems of abrasive wear, short service life, and low material utilization rate, and achieve the effects of improving service life, facilitating processing, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

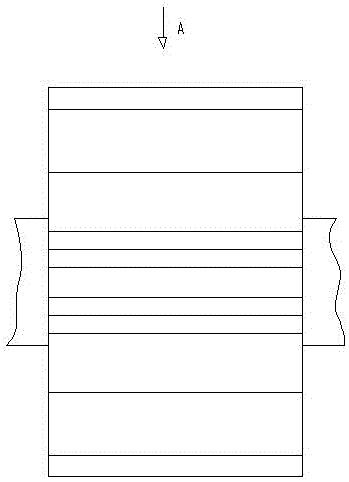

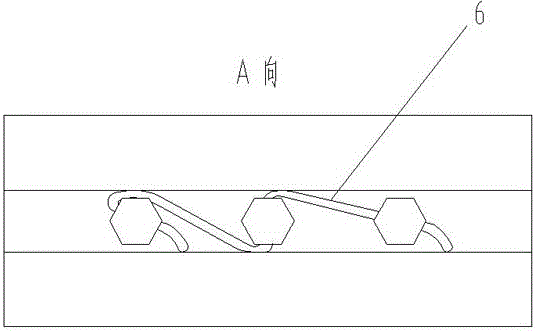

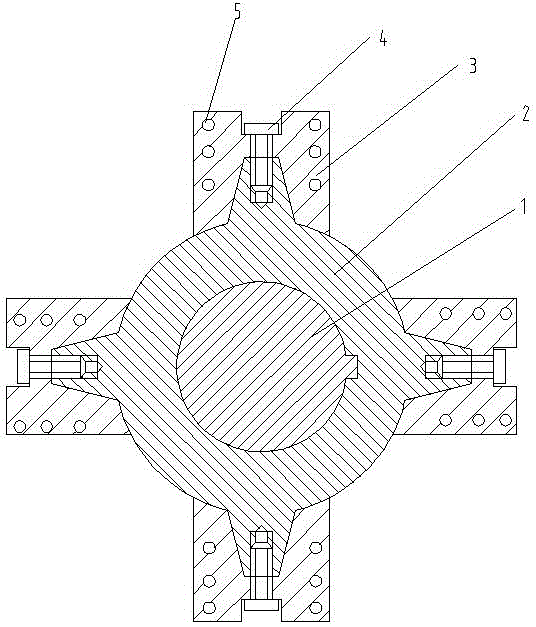

[0014] Described in the present invention is a bimetallic composite material blow bar for an impact type ore crusher, such as figure 1 combine figure 2 , image 3 As shown, it includes a main shaft 1 and a rotor body 2 installed on the outer surface of the main shaft 1 .

[0015] The outer surface of the rotor body 2 is evenly distributed with a plurality of raised trapezoidal bodies along the circumferential direction.

[0016] A blow bar 3 is installed on the trapezoidal body. The blow bar 3 adopts high manganese steel as the matrix and is inlaid and cast with hard alloy rods 5 arranged at intervals in the matrix. The upper end surface of the blow bar 3 is provided with a rectangular groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com