Winding device for cable manufacturing

A winding device and cable manufacturing technology, applied in the directions of transportation and packaging, thin material handling, and transportation of filamentous materials, etc., can solve the problems that cables are prone to breakage and damage, and cables are difficult to coil, so as to improve work quality and reduce The effect of breaking damage and reducing operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

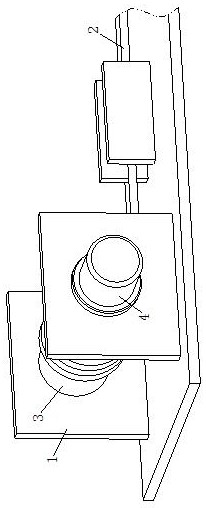

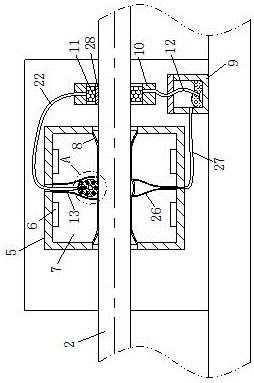

[0029] see Figure 1-5As shown, a winding device for cable manufacturing according to the present invention includes a winding table 1; a winding post 3 for winding up a cable 2 is rotatably connected to the winding table 1, and the winding The table 1 is provided with a driving assembly 4 for driving the winding column 3 to work, and a heating jacket 5 is provided on one side of the winding table 1, and a heating assembly 6 is provided on the heating jacket 5, and a heating assembly 6 is provided inside the heating jacket 5. A heating groove matching the shape of the cable 2, the cable 2 passes through the heating groove and can be heated by the heating component 6; when the cable is processed in a cold environment, its skin is relatively hard due to the cold shrinkage site, making The processed cable is difficult to effectively coil, and the cable is also prone to breakage and damage during the forced coiling process; and the present invention passes the cable 2 through the ...

Embodiment 2

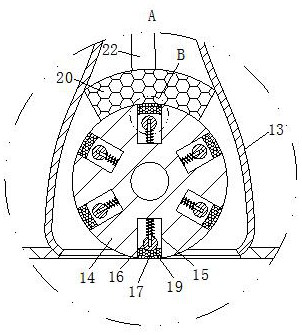

[0039] see Image 6 As shown, there is a gap between the bottom end of the roller 14 and the cable 2, and a group of ring-shaped evenly distributed suction cups 29 are connected on the outer wall of the arc plate 17 and the side wall of the roller 14; the cable 2 is moving The roller 14 can be driven to rotate by the frictional force on the side wall of the sucker 29, and the roller 14 can drive the sucker 29 to be pressed on the surface of the cable 2 gradually when rotating, so that the sucker 29 can be adsorbed on the surface of the cable 2, and then When the cable 2 continues to move, the sucker 29 can drive the roller 14 to rotate more powerfully, so that the roller 14 can perform secondary lubrication on the cable 2 more effectively.

[0040]Working principle: the present invention passes the cable 2 through the heating tank of the heating jacket 5, and at this time, the cable 2 can be fitted to the side wall of the heating tank, and the heating component 6 can touch the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com