Waste plastic crushing machine

A technology of waste plastics and crushing mechanism, which is applied in grain processing, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems that affect the health of workers, metal particles affect the recycling of plastics, and a large amount of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

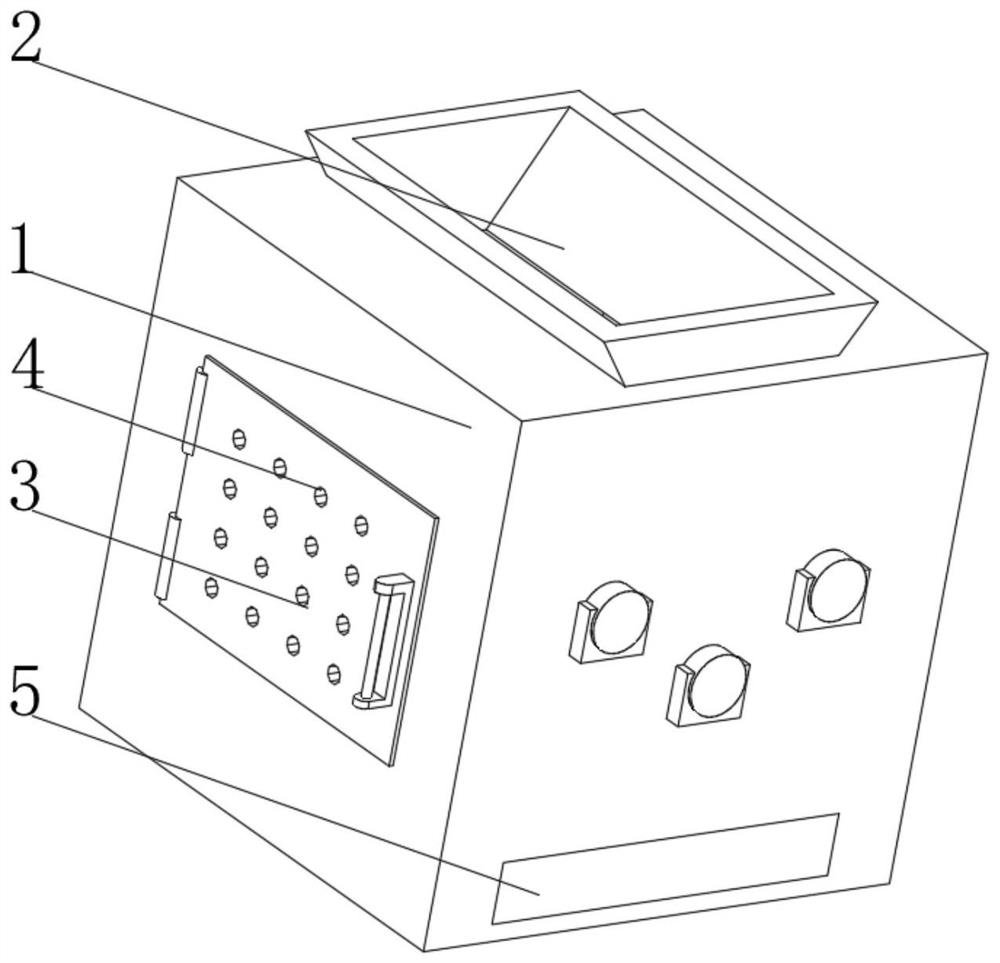

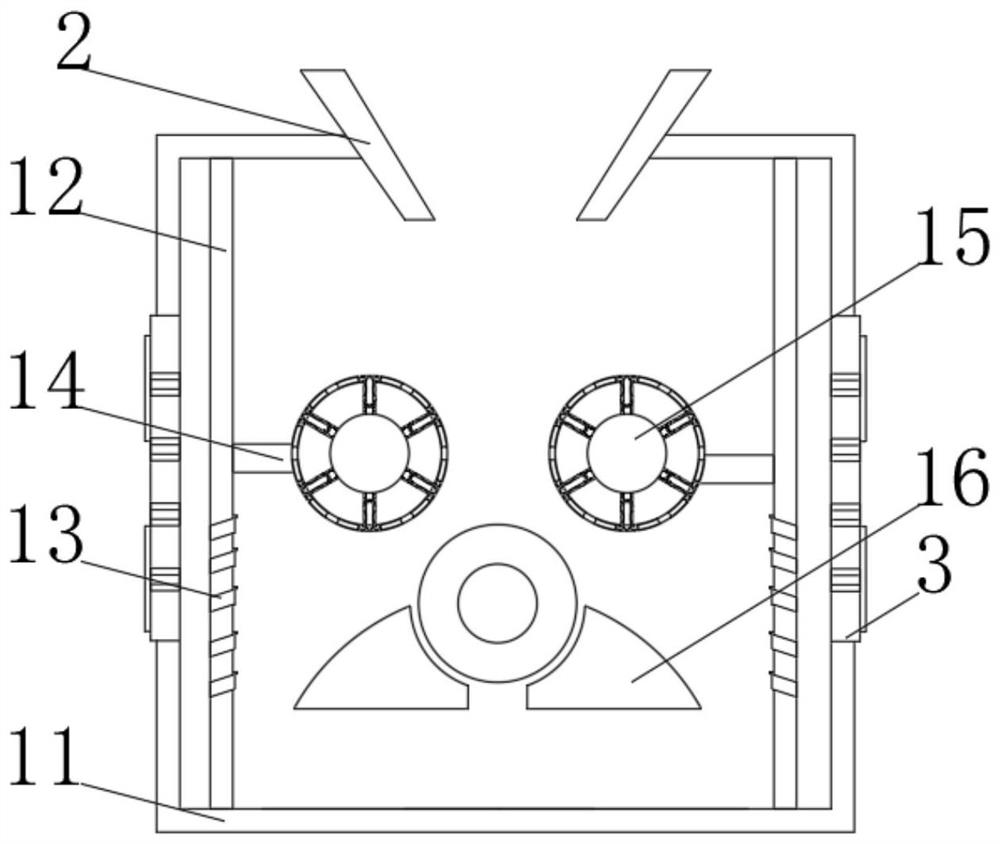

[0034] see Figure 1-2 , the present invention provides a technical solution: a waste plastic crushing machine, including a crushing main body 1, the top of the crushing main body 1 is connected with a feeding hopper 2, and both sides of the crushing main body 1 are connected with dust removal door panels 3 through hinge rotation, and the dust removal door panels One side of the crushing body 1 is provided with a connecting groove 4, and one side of the crushing body 1 is provided with a discharge door panel 5. The crushing body 1 includes a crushing shell 11, and the inner wall side of the crushing shell 11 is fixedly connected with a fixing plate 12, and the fixing plate 12 is provided with a dust exhaust device 13 under one side, and one side of the fixed plate 12 is fixedly connected with a support frame 14, and the end of the support frame 14 away from the fixed plate 12 is provided with a crushing mechanism 15, and the crushing shell 11 is close to one end of the crushing...

Embodiment 2

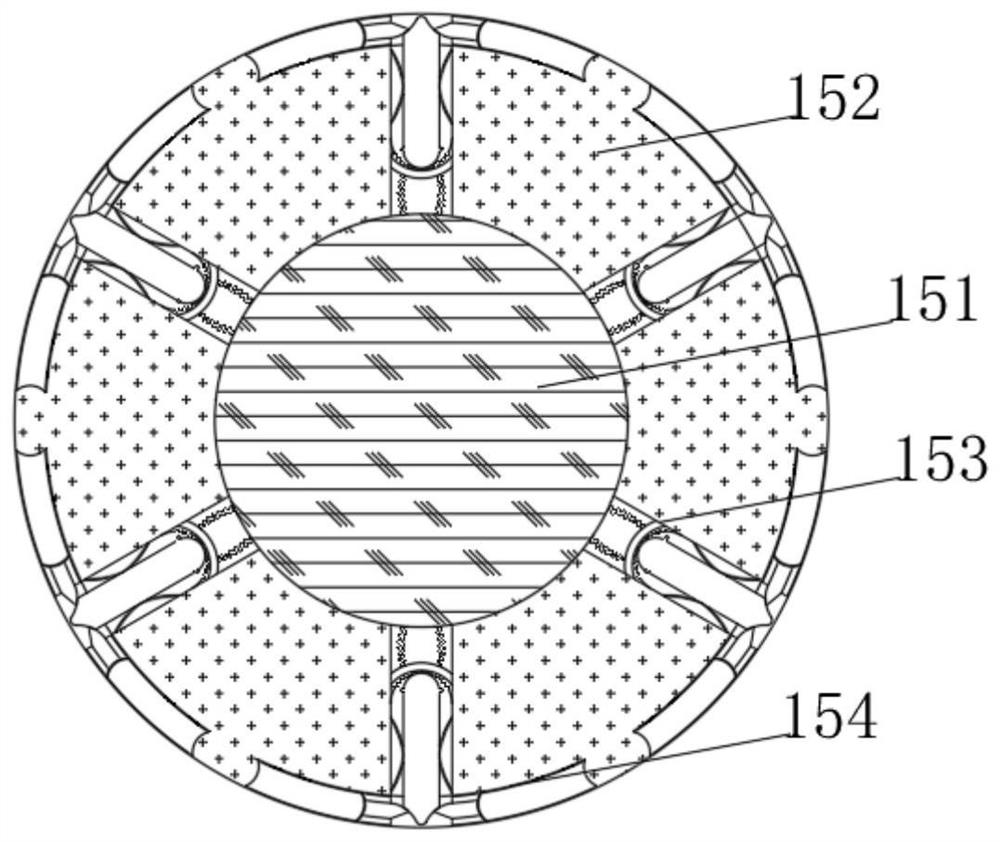

[0037] see Figure 2-4, the present invention provides a technical solution on the basis of Embodiment 1: a waste plastic crushing machine, the crushing mechanism 15 includes a first electric rolling roller 151, the side of the first electric rolling roller 151 is fixedly connected with a fixed connection cylinder 152, One side of the fixed connection cylinder 152 is provided with a rectangular groove 153, and both sides of the rectangular groove 153 are provided with an arc-shaped groove 154. The bottom of the inner wall of the rectangular groove 153 is fixedly connected with an airbag 531, and the end of the airbag 531 away from the rectangular groove 153 is fixedly connected with a A magnet 532, the end of the magnet 532 away from the air bag 531 is provided with a buffer air bag 533, the end of the buffer air bag 533 away from the magnet 532 is provided with a crushing tool 534, both sides of the crushing tool 534 are slidingly connected with guide rods 535, and the crushin...

Embodiment 3

[0040] see Figure 2-6 , the present invention provides a technical solution on the basis of Embodiment 2: a waste plastic crushing machine, the classification mechanism 16 includes a second electric rolling roller 161, the side of the second electric rolling roller 161 is fixedly connected with a magnet cylinder 162, and the magnet One side of the cylinder 162 is provided with a collection housing 163, and the side of the collection housing 163 close to the magnet cylinder 162 is provided with a feed port 164, and the bottom of the inner wall of the collection housing 163 is provided with a scraping device 165, and the scraping device 165 includes a rotating seat 651, the rotating shaft of the rotating seat 651 is connected with the rotating rod 652, and the end of the rotating rod 652 away from the rotating seat 651 is provided with a connection installation groove 653, and the bottom of the inner wall of the connection installation groove 653 is fixedly connected with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com