Reciprocating piston lubrication pump

A piston lubricating and reciprocating technology, applied in the field of lubricating pumps, can solve problems such as accelerated wear, reduced pump service life, and fracture of pump parts, achieving high service life, less breakage and damage, and effective design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

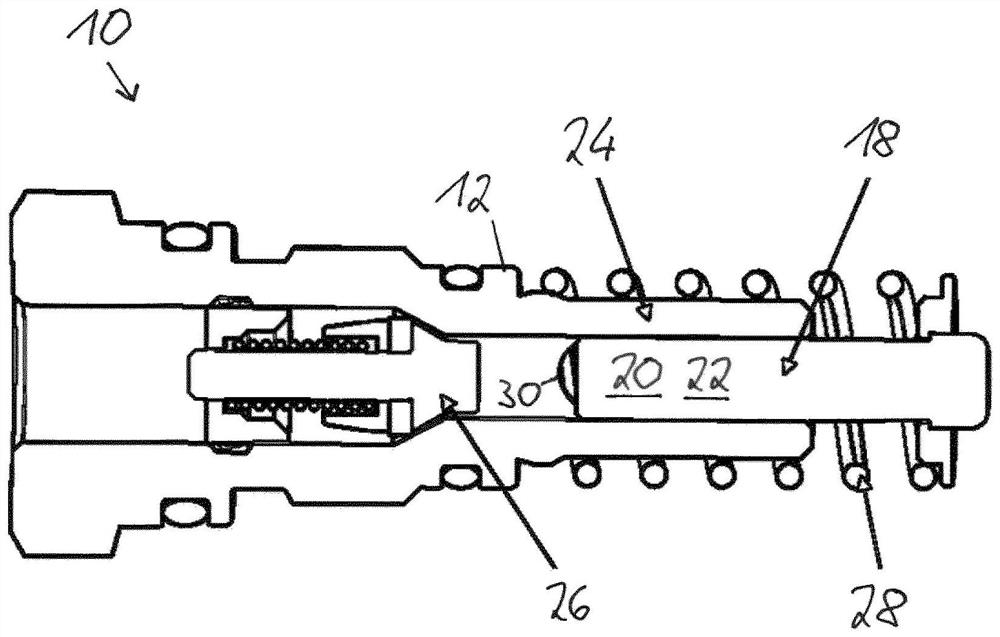

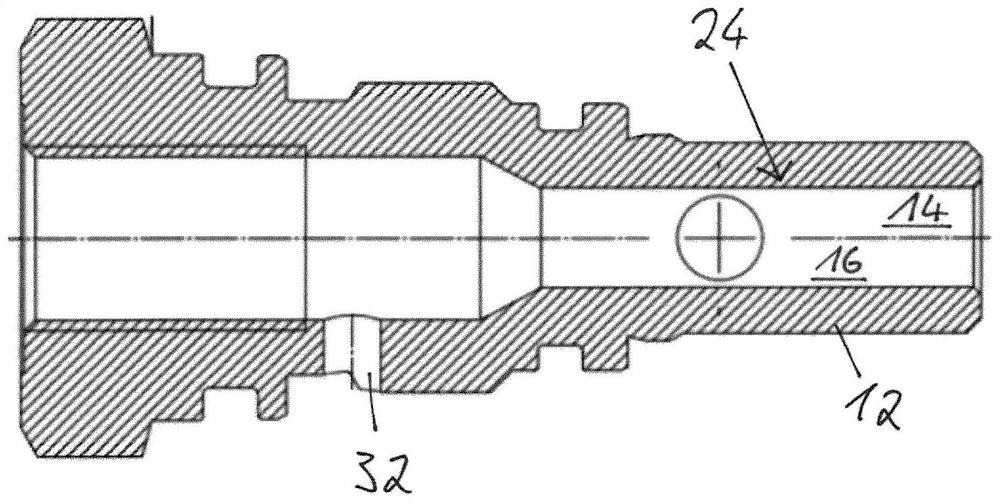

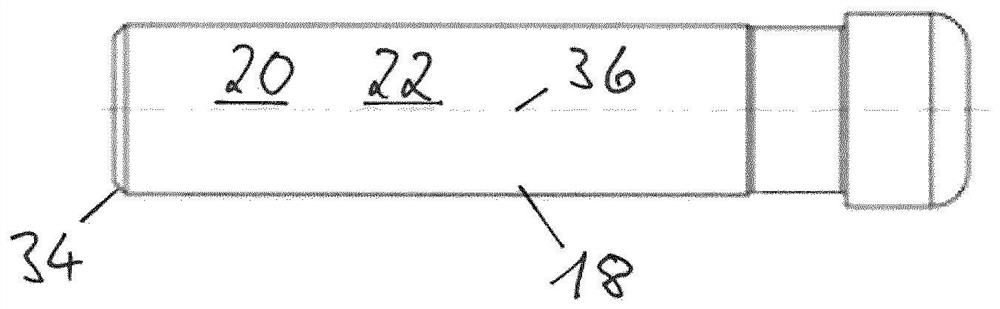

[0028] figure 1 An axial partial section is shown of the reciprocating piston lubrication pump 10 according to the invention, which includes the part 12 with the opening 14 ( figure 2 ). The opening 14 has a cylindrical portion 16 . The piston 18 of the reciprocating piston lubrication pump 10 is located partially within the region 24 of the part forming the cylindrical portion 16 . Piston 18 has a radially outer surface 20 constructed of coating 22 . When the radially outer surface is located in the cylindrical portion, the clearance between the radially outer surface of the piston and the component is between 2 and 10 microns. The surface hardness of the coating at the radially outer surface is 4 to 8 times higher than the surface hardness of the area of the part forming the cylindrical portion.

[0029] The part includes holes 30 ( figure 1 ) and another hole (not shown) through which lubricant (not shown) is drawn into a portion of the opening between the piston an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com