Preparation method for forging and rolling lining plate with longitudinal streamline

A liner and longitudinal technology, which is applied in the field of preparation of mill wear-resistant liners, can solve the problems of rolling liners that cannot be mass-produced, unsatisfactory strength and toughness, and difficult to be accepted by the market, so as to improve market competitiveness , The effect of increasing the yield and enriching the corner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

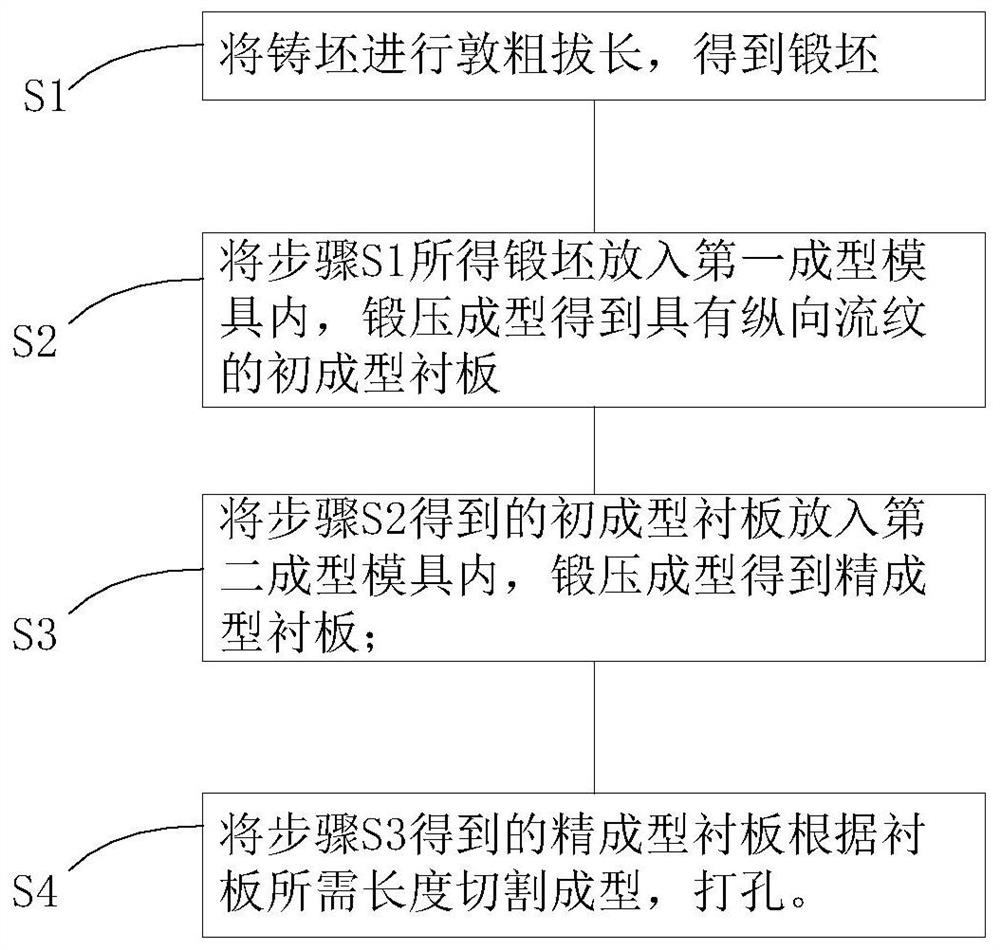

[0057] see Figure 1 to Figure 7 . This embodiment describes the preparation method of the forged rolling liner with longitudinal streamlines, the wear-resistant liner of the mill prepared by this method, and the preparation device of the wear-resistant liner of the mill. The preparation method of the forged liner with longitudinal streamlines includes the step of selecting the alloy elements of the corrosion-resistant steel, the step of smelting / rolling / forging, the step of heat treatment and cooling, the step of tempering, and the step of smelting / rolling / forging is to pass the cast billet through Smelted, rolled and / or forged into liner type. The corrosion resistant steel alloying elements are all known alloying element formulations published before the date of this application. And, this embodiment is to describe the process in detail, all of which are existing processes, such as heat treatment process and quenching process. The purpose of the present invention is to im...

Embodiment 2

[0072] In this embodiment, a 10.37-meter semi-autogenous mill forging liner is taken as an example, and a 3150-ton forging press is used for forming.

[0073] The alloy steel is smelted and refined to make a 9-ton cast billet.

[0074] The forging machine uses a conventional forging machine parallel forging seat to forge the continuous casting billet into a round forging billet with a diameter of 500mm by the process of two piers and two draws, and the round forging billet is forged into an oval forging billet.

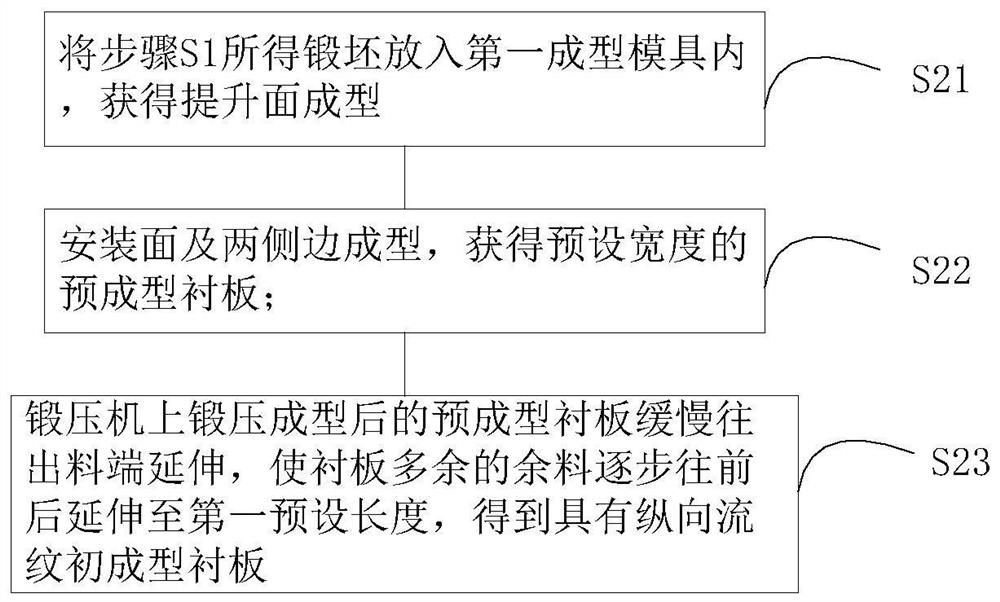

[0075] Replace the parallel forging seat of the forging press, that is, the upper flat template and the lower flat template, with the forging seat of the preforming die, that is, the first forming die, put one long axis end of the oval forging blank into the forging seat of the preforming die for forging, and first carry out lifting of the lifting surface Pre-forming, and then forging and pressing while closing the edges on both sides, and then forming the mounting su...

Embodiment 3

[0081] In this embodiment, a 10.37-meter semi-autogenous mill forging liner is taken as an example, and a 15,000-ton forging press is used for forming.

[0082] The alloy steel is smelted and refined to make a continuous casting billet, rolled or forged into a square forging billet with a side length of 500mm, and the corners of the square billet are chamfered.

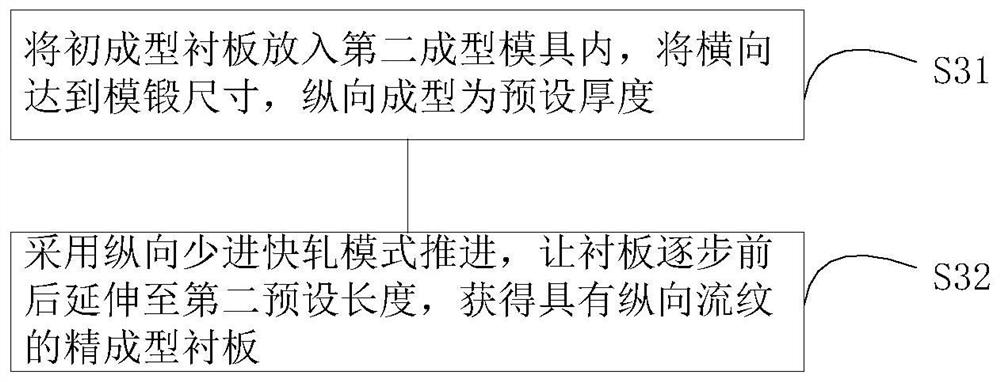

[0083] Replace the parallel forging seat of the forging press, that is, the upper flat template and the lower flat template, with the forging seat of the precision forming die, that is, the second program mold, and put the forging billet with square chamfers diagonally into the forging seat of the preformed mold for forging, first about 0.4 meters in width The narrow upper mold with a circular arc surface with waves or suspended surfaces is gradually extended back and forth to form, ensuring that the lifting surface and the installation surface are all filled in place and formed.

[0084] Change to the required size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com