2-Bagging packaging method and device

A packaging method and a cutting device technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of being flattened by fillings and unstable cutting, and achieve the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

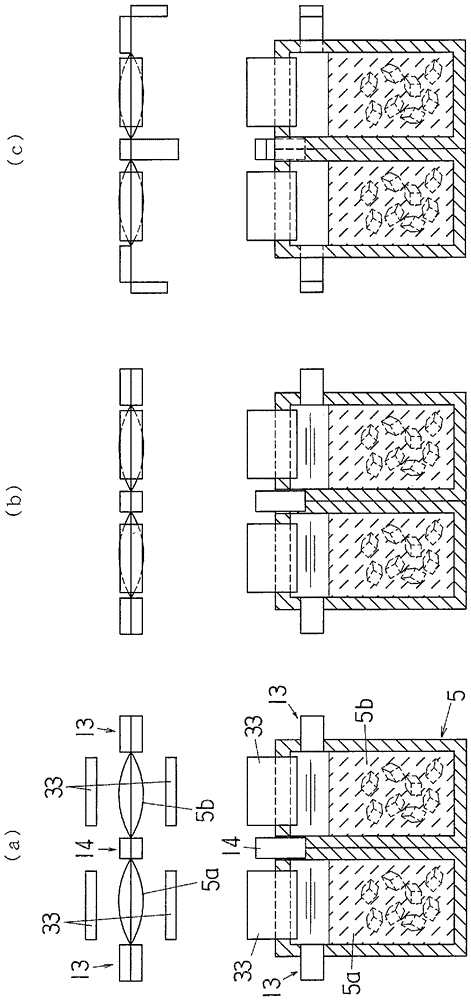

[0048] figure 1 The shown double-rotor type vertical packaging processing machine consists of a bagging and packaging device 1 and a vacuum processing device 2, and a cutting device (not shown) that is arranged between the two devices as a part of the aforementioned bagging and packaging device 1. The conveyor 3 that conveys the product bags discharged from the vacuum processing device 2 toward the next process (for example, packing process) and the control device 4 that controls the operations of all these devices are constituted.

[0049] This double-rotor type vertical packaging processor has the following structure: use bagging and packaging device 1 to double-link bag 5 (refer to figure 2 Each bag 5a, 5b of ) is filled with the stuff to be filled, and the filled double-linked bag 5 is transferred to a predetermined position with the aforementioned cutting device and handed over to the vacuum processing device 2. During the transfer process, the aforementioned cutting dev...

no. 2 Embodiment approach ]

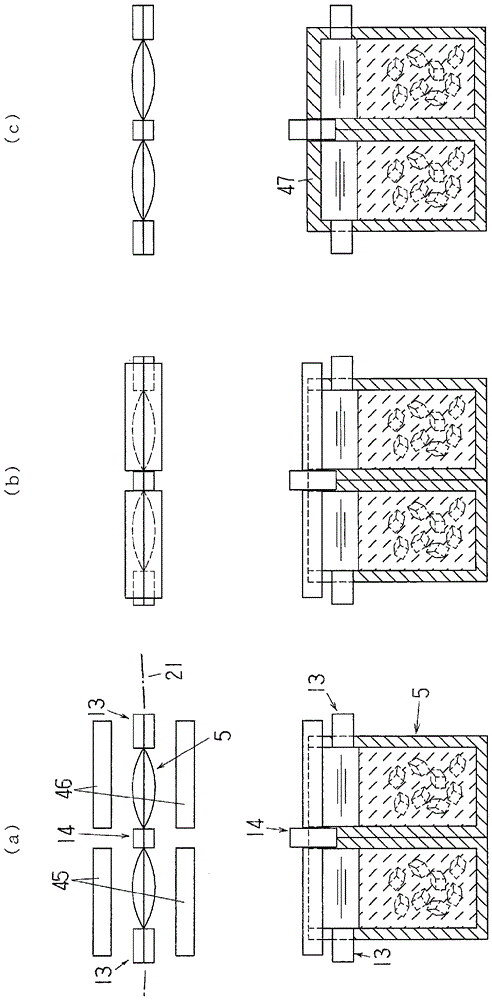

[0075] In the above-mentioned first embodiment, the packaging treatment process performed by the bagging and packaging device 1 is until the filling process, and the double bag 5 (bag 5a, 5b) with the bag opening not sealed is transferred to the vacuum processing device 2, and The perforation line 11 is cut during this transfer.

[0076] On the other hand, in such a bag-filling and packaging device, the bag opening may be sealed after the filling object is filled. In this case, the sealed double bags 5 (bags 5a, 5b) are transferred from the aforementioned bagging and packaging device to a predetermined position (for example, a position for discharging the separated bags 5a, 5b). The perforation line 11 is cut. Hereinafter, it is assumed that the sealing of the bag mouth is performed at the aforementioned stop position 6 of the bagging and packaging device 1 (a sealing device is provided near the stop position 6), refer to Figure 8 ~ Figure 10 The packaging treatment process...

no. 3 Embodiment approach ]

[0085] In addition, in the example described above, the cutting device for cutting the perforation line 11 of the double-linked bag 5 is arranged near the stop position 7 of the bagging and packaging device 1, but the cutting device may also be arranged, for example, at the aforementioned The vicinity of the stop position 10 of the vacuum processing device 2 of the dual-rotor vertical packaging processing machine. In the vicinity of the stop position 7 of the bagging and packaging device 1, a transfer device that does not cut the perforation line 11 of the double bag 5 may be disposed instead of the above-mentioned cutting device. In this case, when the double bag 5 is taken out from the chamber main body 42 of the vacuum processing apparatus 2, the perforation line 11 is cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com