A kind of automatic sorting garbage bin

A technology for automatic sorting and garbage bins, which is applied in the directions of trash cans, garbage collection, waste collection and transfer, etc. It can solve the problems of heavy odor, inaccurate classification, and high use cost of garbage bins, so as to save use costs, avoid odor diffusion, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

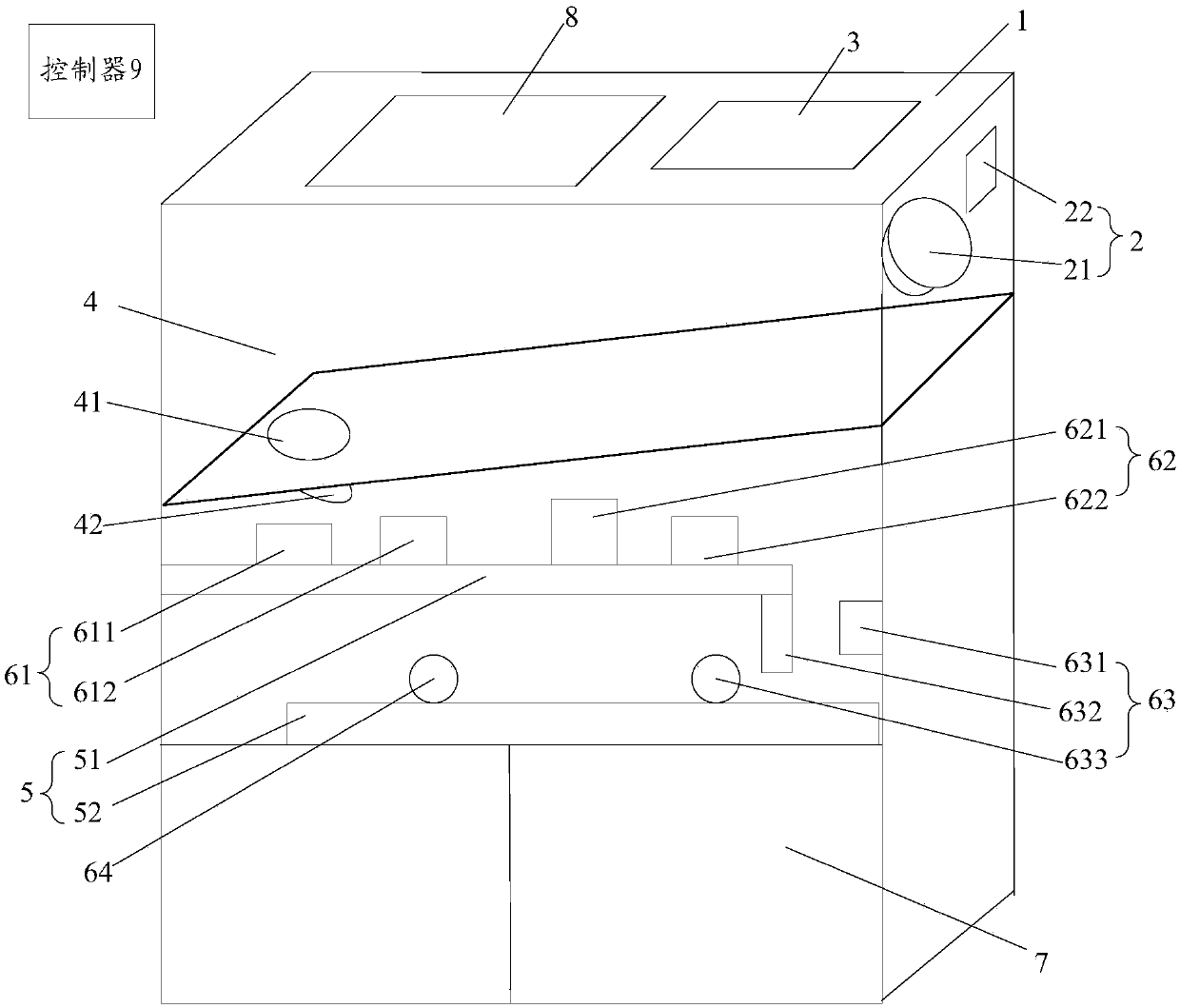

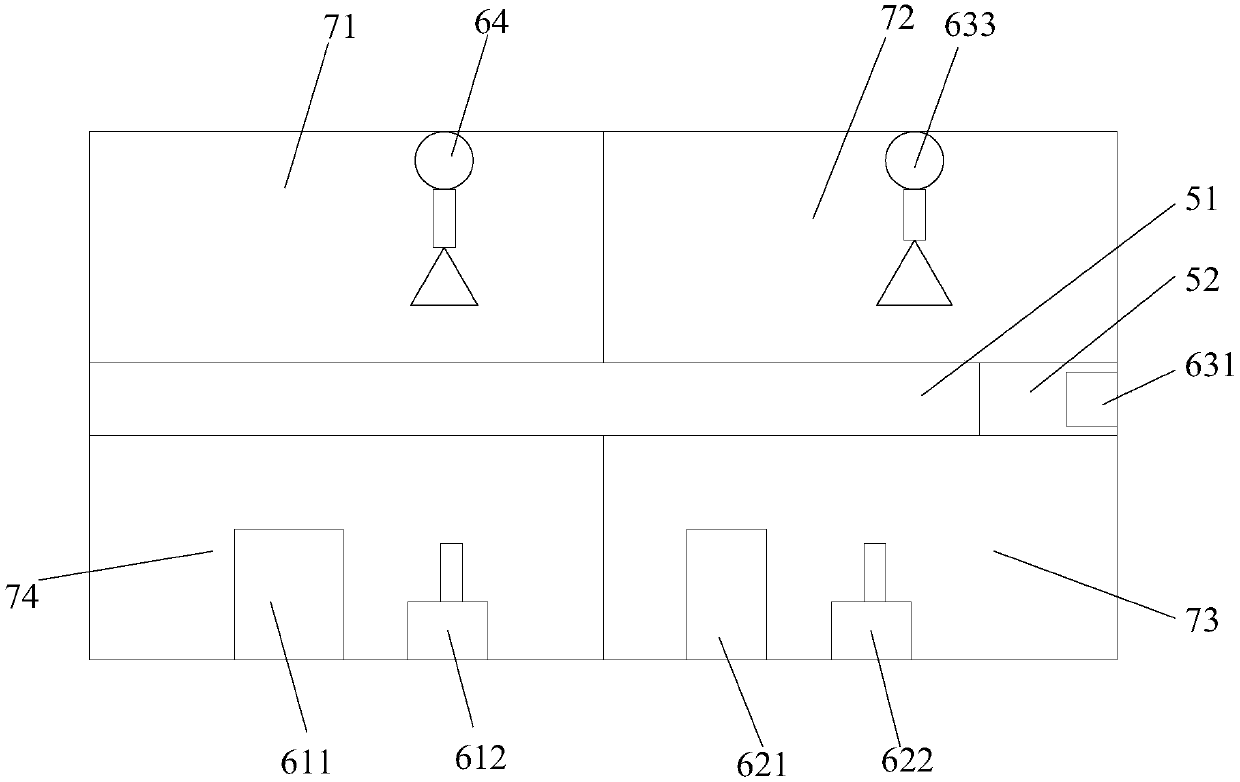

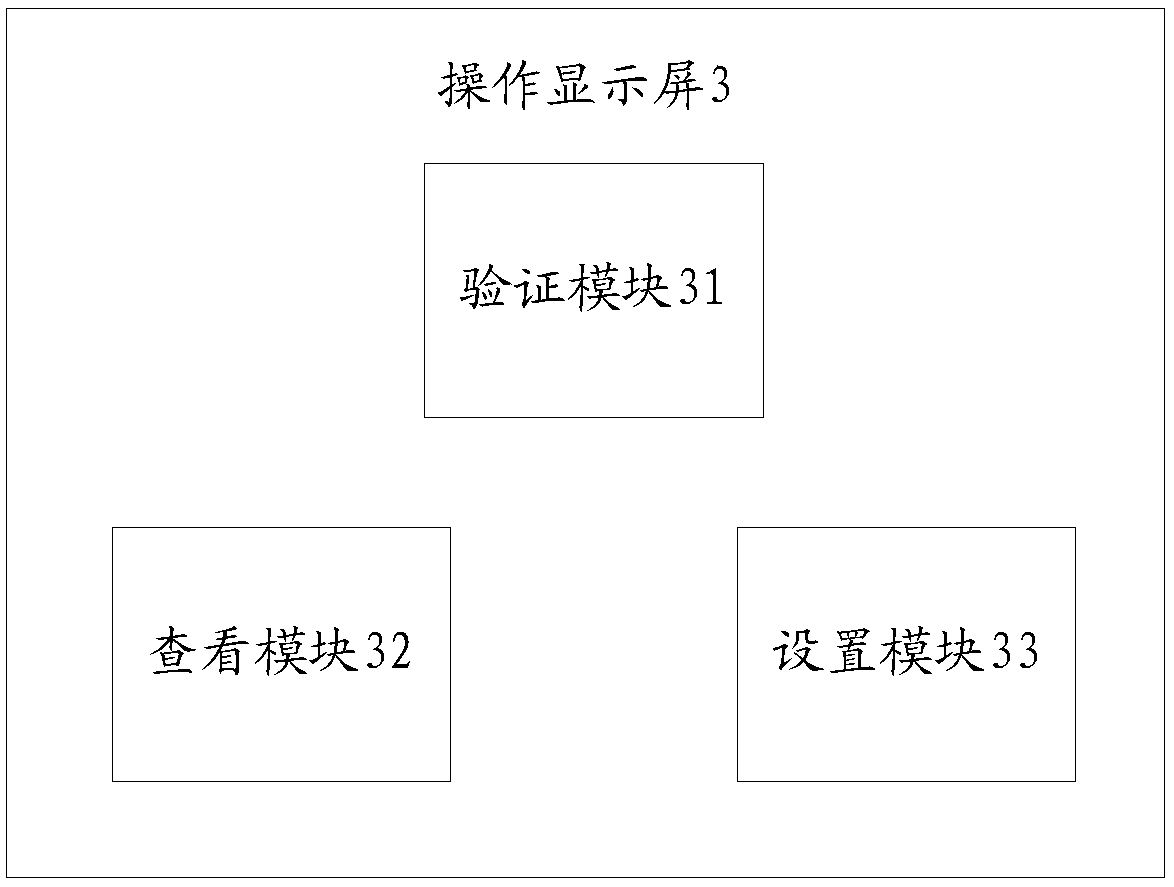

[0022] Such as Figure 1-3 As shown, the present invention provides an automatic sorting garbage bin, including a bin body 1, an infrared induction garbage inlet 2 arranged on the bin body 1, an operation display screen 3, and an intermediate storage bin arranged in the bin body 1 Room 4, a conveying device 5 located below the intermediate storage room 4, a sorting detection device corresponding to the conveying device 5, a sorting storage room corresponding to the sorting detection device and having an upper edge not higher than the conveying device 5 7, and the power supply device 8 and the controller 9 connected with the operation display screen 3, the transmission device 5, and the classification detection device, the power supply device 8 is connected with the controller 9, and the bottom of the intermediate storage room 4 is provided with a position The garbage lower dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com