Manufacturing and using method of reed type toilet bowl

A toilet and reed-type technology, applied in flush toilets, water supply devices, buildings, etc., can solve the problems of small pipe cross-section, thick and long excrement, high hardness, etc., and achieve the effect of shortening the length, smooth defecation, and expanding the cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

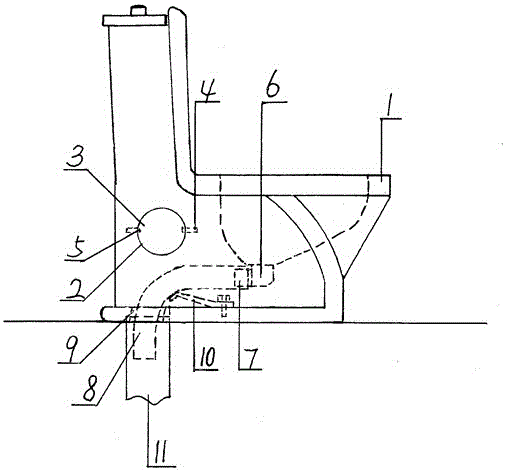

[0014] Such as figure 1 As shown, a method for manufacturing and using a reed type toilet is developed, which is reformed from the existing toilet 1 (referring to the toilet with the water trap hidden in the toilet body); , a side door 2 is provided on the embryo side of the toilet 1, and the side door 2 is made into a square, round or oval shape; the position of the side door 2 is corresponding to the (original) trap; A door plug 3 is made in the opening of the toilet, and the profile of the door plug 3 is matched with the overall shape and color of the toilet 1; One body, the plugged door plug 3 and the periphery of the side door 2 are tightly seamed and on the same plane; opening the door plug 3 can expose the (original) water trap; there are several bead holes on the section around the side door 2, The bead hole is used for installing the bead 4, and the door plug 3 is provided with a groove 5, which corresponds to the position of the bead 4, and the groove 5 can accommo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap