Manufacturing and use method of hose type closestool

A toilet and hose-type technology, applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of small pipe cross-section, thick and long excrement, high hardness, etc., and achieve the effect of shortening the length, smooth defecation, and expanding the cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

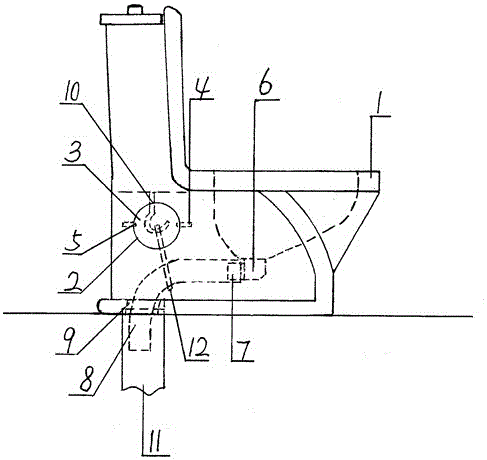

[0014] Such as figure 1 As shown, a method of manufacturing and using a hose-type toilet is reformed from the existing toilet 1 (referring to the toilet with the trap hidden in the toilet body); when making embryos, A side door 2 is provided on the embryo side of the toilet 1, and the side door 2 is made into a square, round or oval shape; the position of the side door 2 corresponds to the (original) trap; A door plug 3 is made in the hole, and the shape of the door plug 3 matches the overall shape and color of the toilet 1; the door plug 3 can be blocked on the hole of the side door 2, and the plugged door plug 3 and the side door 2 are fixedly connected into one body , the blocked door plug 3 and the periphery of the side door 2 are tightly seamed and on the same plane; opening the door plug 3 can expose the (original) water trap; there are several bead holes on the cross section around the side door 2, and the beads The hole is used for installing the bumper 4, and the do...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap