Testing device for rotors of mud pulse generators

A technology of mud pulse and testing equipment, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as shortened service life, eccentric wear, and harsh working environment, and achieve the effect of facilitating analysis and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

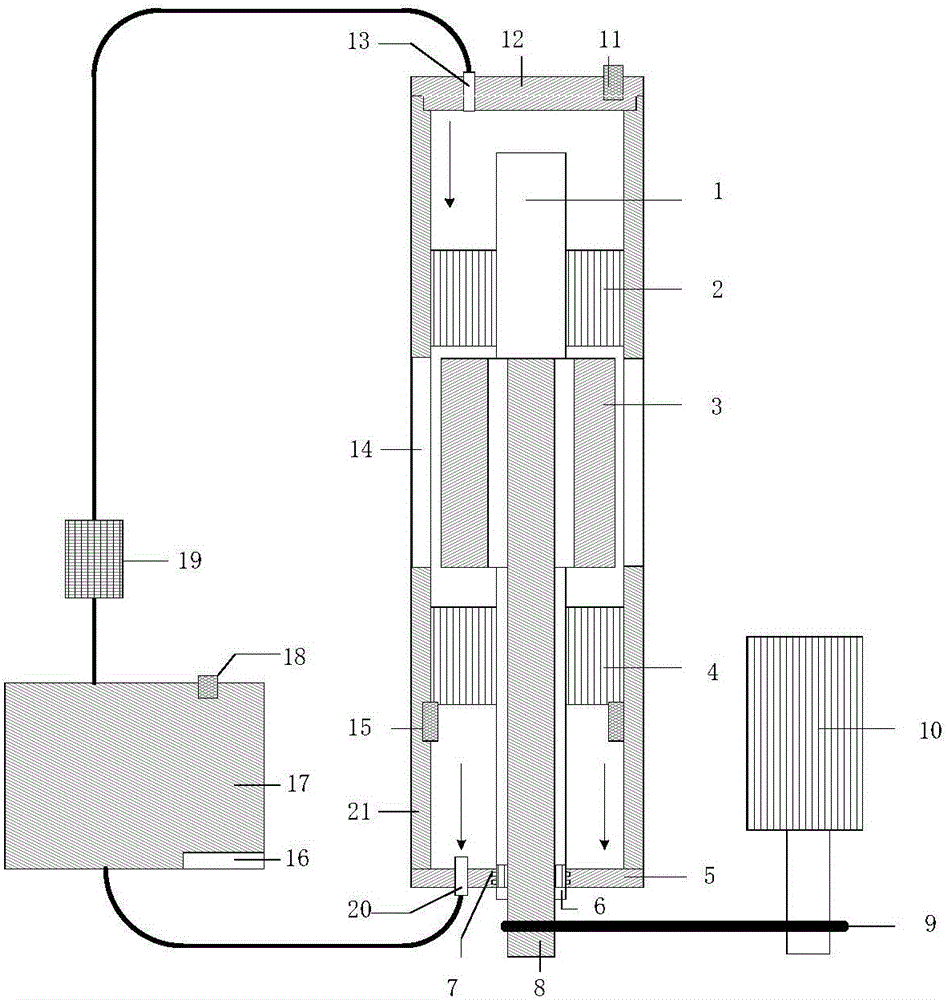

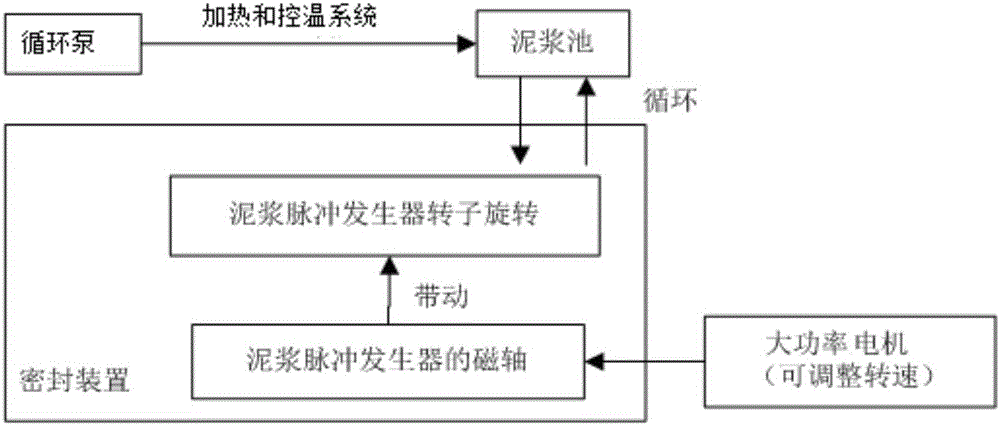

[0019] see figure 1 with figure 2 , The mud pulse generator rotor testing device of the present invention comprises sealing protection casing 1, upper centralizer 2, rotor 3, lower centralizer 4, lower sealing cover 5, bearing 6, sealing ring 7, magnetic shaft 8, transmission belt 9, High-power motor 10, first exhaust hole 11, upper sealing cover 12, mud inlet 13, mud outlet 20, viewing window 14, fixed key 15, heating and temperature control system 16, mud pool 17, second exhaust hole 18 , circulation pump 19, outer cylinder 21.

[0020] The upper centralizer 2, the rotor 3, and the lower centralizer 4 are installed on the outside of the sealed protective shell 1 from top to bottom, wherein the rotor 3 can rotate relative to the sealed protective shell 1, and the upper centralizer 2 and the lower centralizer 4 are connected with the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com