Weight loss method for monitoring wellhead corrosion status

A state, hollow rod technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of inability to monitor the corrosion status of flat pipes or vertical pipes, and inconvenient hanging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

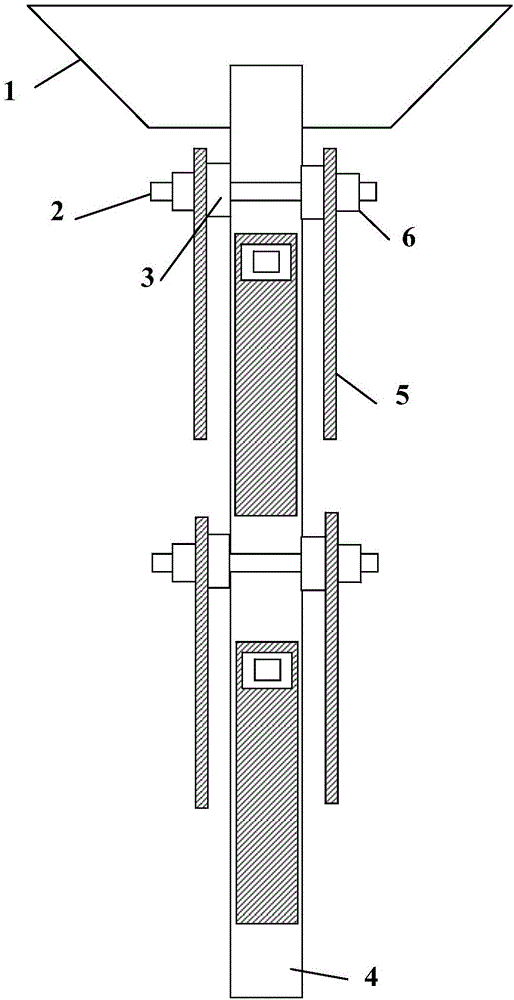

[0014] A hanging piece method for monitoring the corrosion condition of the wellhead, such as figure 1 As shown, remove the plug 1 at the position of the connection pressure gauge on the oil and gas production tree or gas tree, expand the diameter of the inner hole of the plug 1, and process the inner thread on the inner surface of the hole, and insert the hollow The rod 4 is screwed on the inner hole of the plug 1 for fixing. In order to prevent the hollow rod from being corroded during the corrosion monitoring process, the hollow rod is made of corrosion-resistant material, and no galvanic corrosion occurs between the hollow rod and the plug. The part where the hollow rod 4 is connected to the plug 1 is circular, and the part where the sample is suspended is circular. A hollow rod whose entirety is circular is called a circular hollow rod. Drill holes at a certain distance between the hollow rods 4, and use insulating gaskets 3, nuts 6 and screw rods 2 to fix the test piec...

Embodiment 2

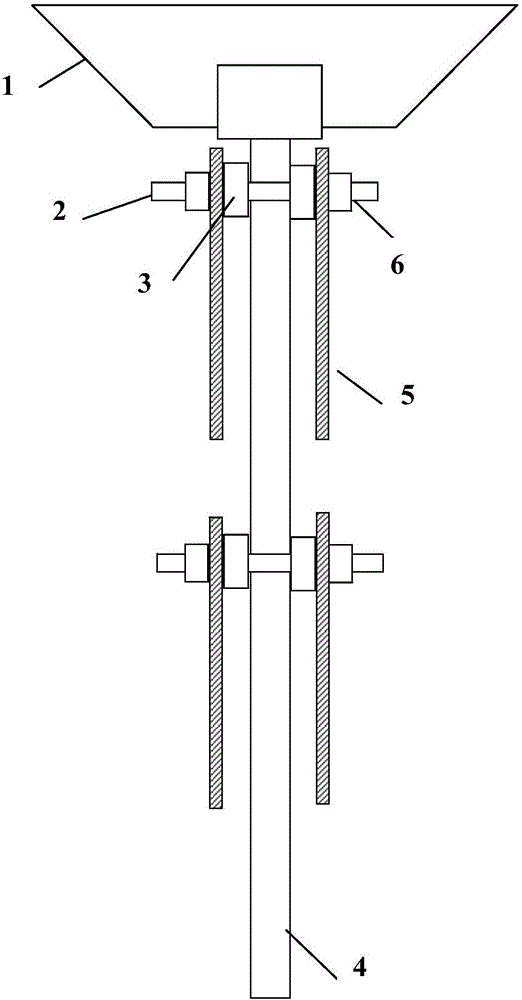

[0016] A hanging piece method for monitoring the corrosion condition of the wellhead, such as figure 2 As shown, remove the plug 1 at the position of the connection pressure gauge on the oil and gas production tree or gas tree, expand the diameter of the inner hole of the plug 1, and process the inner thread on the inner surface of the hole, and insert the hollow The rod 4 is screwed on the inner hole of the plug 1 for fixing. In order to prevent the hollow rod from being corroded during the corrosion monitoring process, the hollow rod is made of corrosion-resistant material, and no galvanic corrosion occurs between the hollow rod and the plug. The part where the hollow rod 4 is connected to the plug 1 is circular, and the part where the sample is suspended is flat. The part where the test piece is suspended is flat and is called a flat hollow rod. Drill holes at a certain distance between the hollow rods 4, and use insulating gaskets 3, nuts 6 and screw rods 2 to fix the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com