A jig for quickly withdrawing drill pins from pcb

It is a quick drill back technology, which is applied in the manufacture of printed circuits, electrical components, and printed circuits. It can solve problems such as difficult manual extraction, small diameter of drill needles, and damage caused by drill needles. It achieves simple structure, improved efficiency, and avoids pop-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

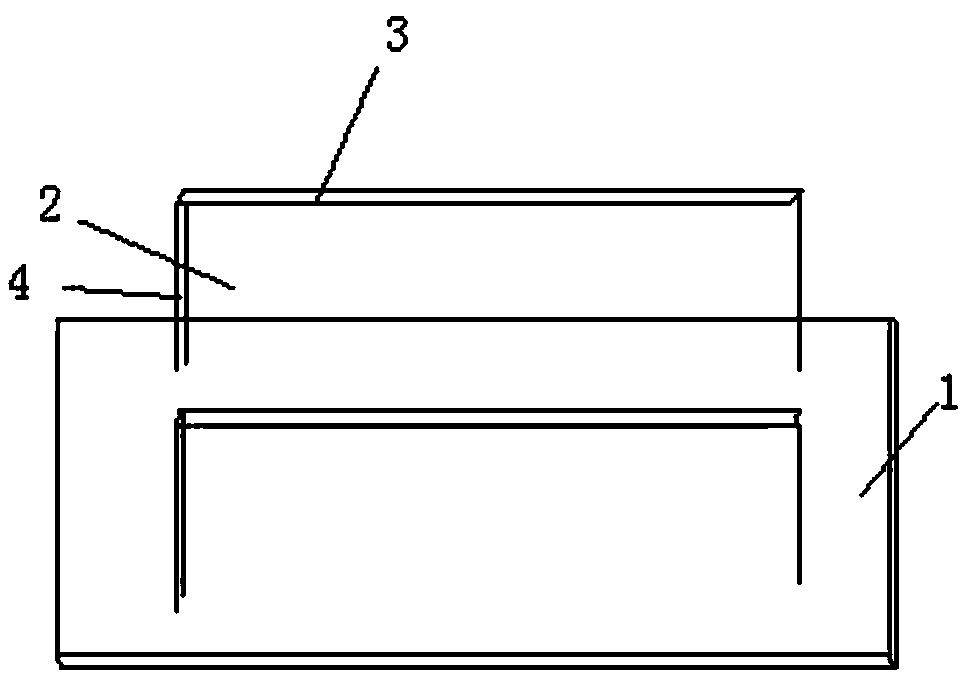

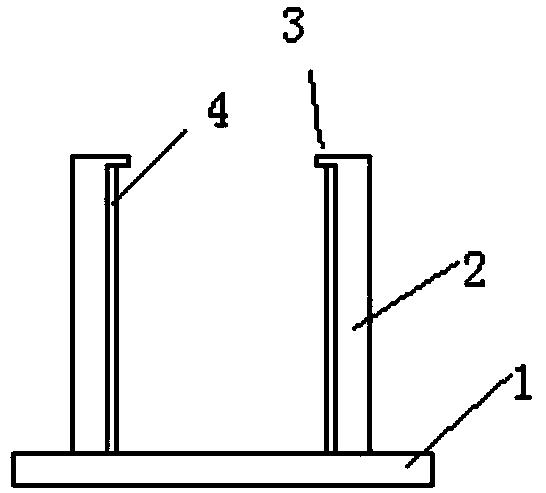

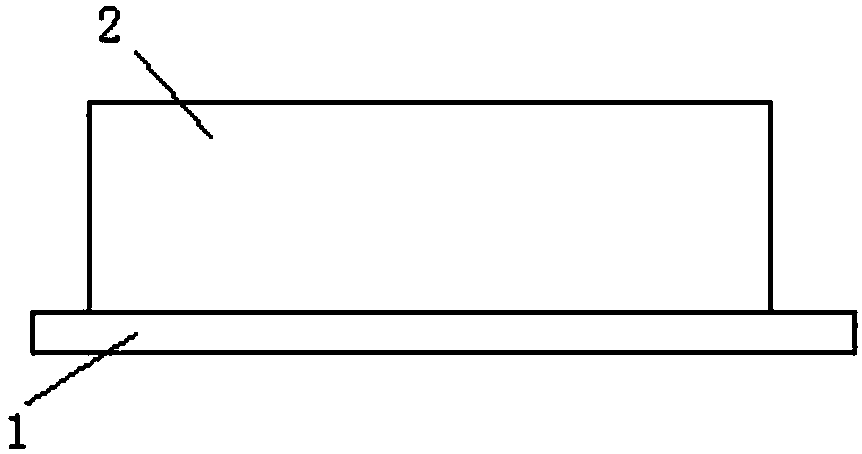

[0016] see figure 1 - image 3 , this embodiment includes a horizontal plate 1, two side plates 2 are arranged on the horizontal plate 1, the two side plates 2 are arranged oppositely, one side plate 2 is fixedly connected with the horizontal plate 1, and the side plate 2 and the side plate can be flexibly adjusted. The distance between the boards 2 expands the scope of application. The front ends of the two side boards 2 are provided with a horizontal baffle 3, and one side of the two side boards 2 is oppositely provided with a vertical baffle 4, which effectively prevents the drill needle magazine from popping up and tying. On the upper arm, the width of the side plate 2 is adapted to the length of the drill, the distance between the two horizontal baffles 3 is less than the diameter of the collar at the upper end of the drill, and the length of the horizontal plate 1 is the same as the drill of the drill clip. The needle capacity is adapted, the length of the side plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com