Gas flowmeter

A gas flow meter and flow technology, which is applied in volume measurement, liquid/fluid solid measurement, flow/mass flow measurement, etc. It can solve the problems of unstable support of ultrasonic flow measurement unit and unstable flow measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

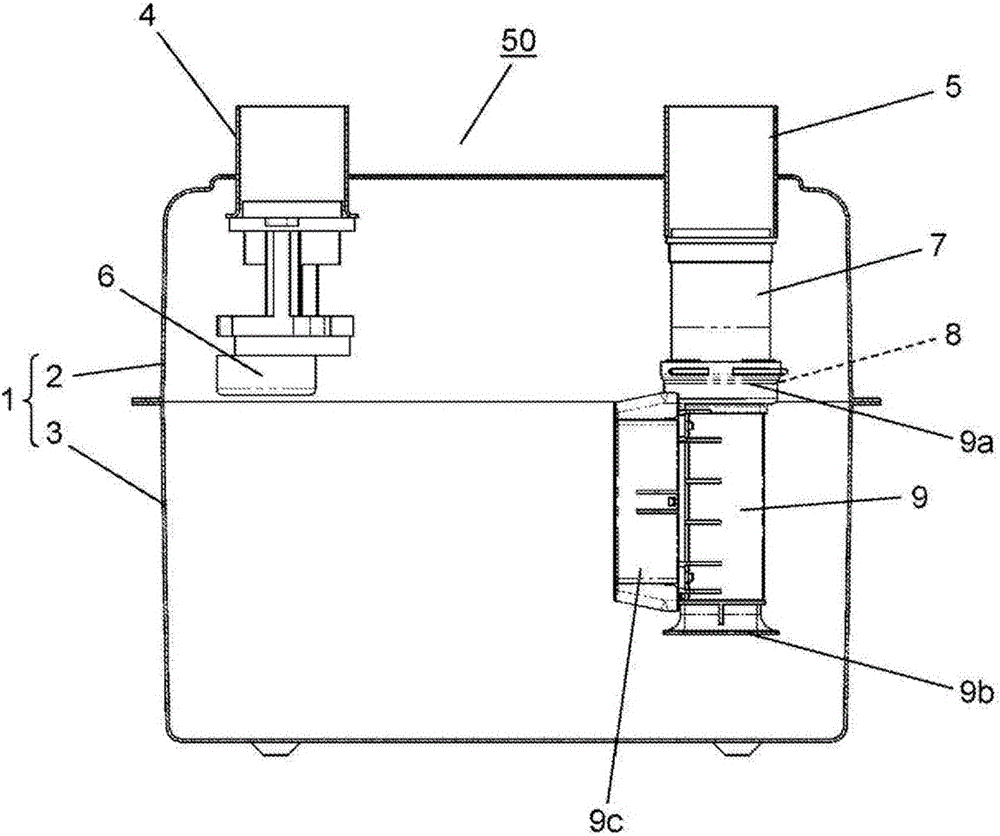

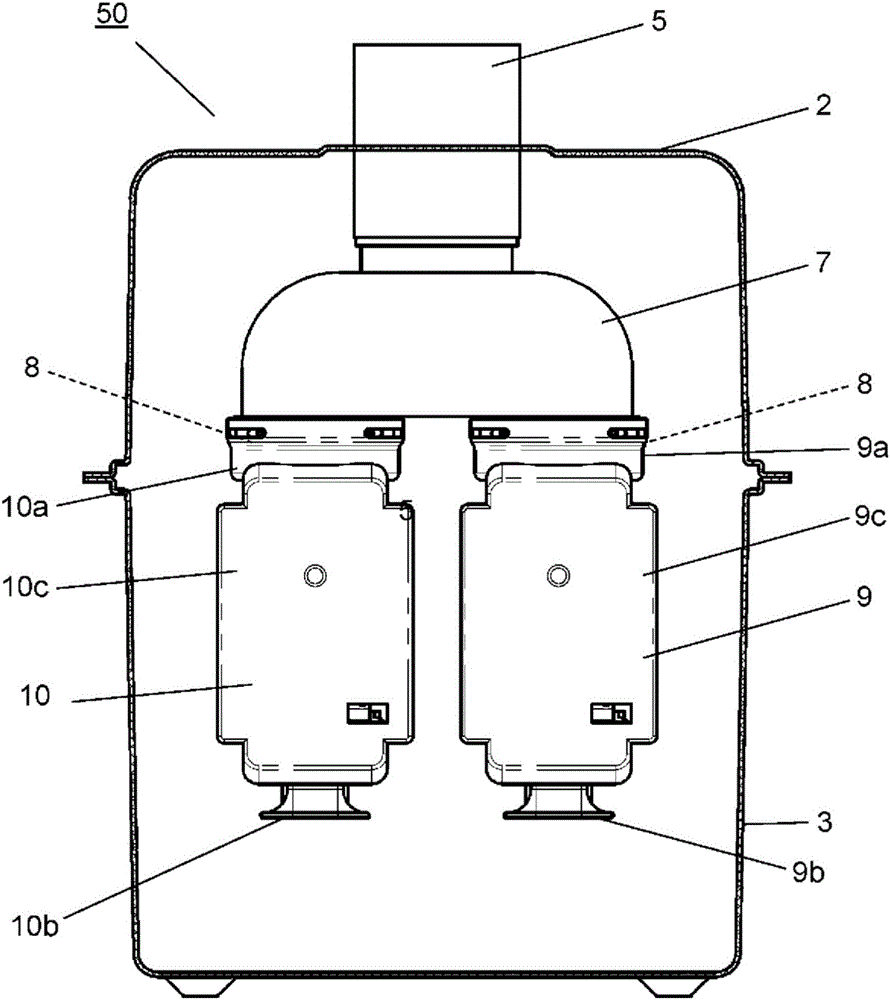

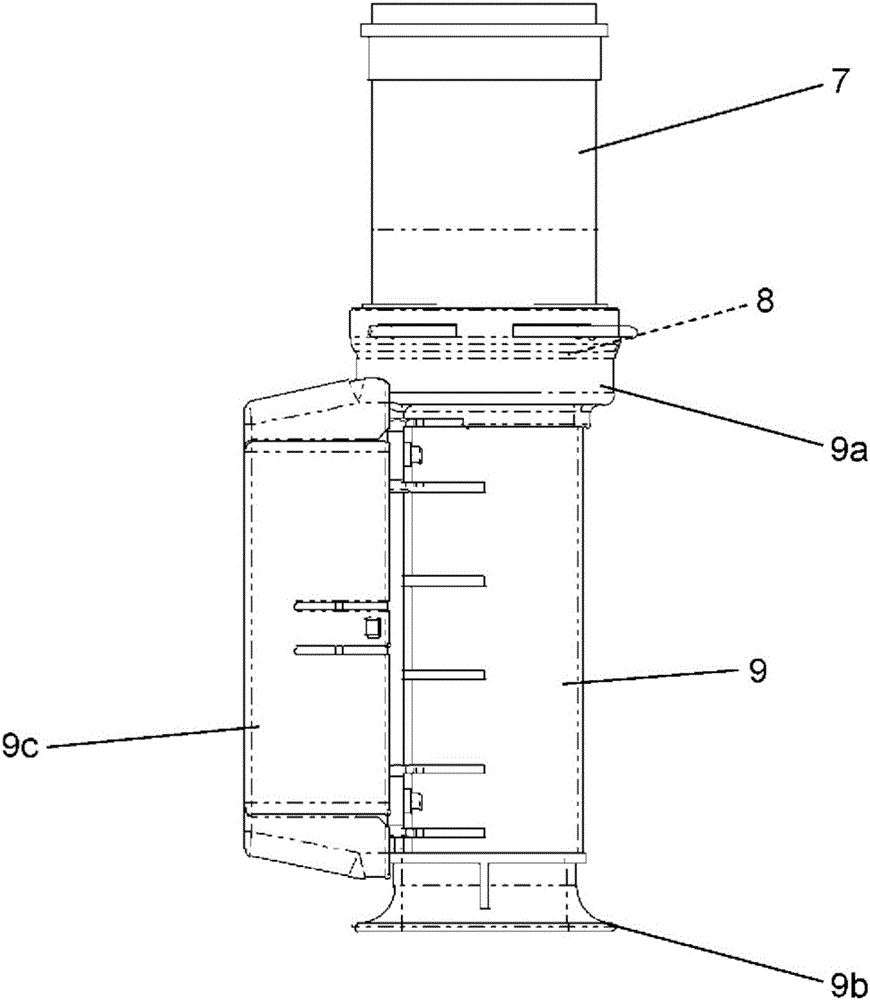

[0033] based on Figure 1 to Figure 5 Embodiment 1 of the present invention will be described. figure 1 It is a sectional view of the gas flow meter according to Embodiment 1 of the present invention. figure 2 is a cross-sectional view illustrating the same gas flowmeter, obtained from the same figure 1 Cross-sectional views viewed from different directions. image 3 It is a side view of the main part of the same gas flowmeter. Figure 4 It is a perspective view of the main part of the same gas flow meter. Figure 5 It is an exploded perspective view of the main parts of the same gas flowmeter.

[0034] The casing of the gas flow meter 50 is constituted by the device main body 1 . The device main body 1 includes an upper case 2 and a lower case 3 formed by pressing metal. The upper surface of the upper case 2 is provided with: an inlet 4 through which the fluid to be measured can be introduced into the device body 1; and an outlet 5 through which the fluid to be measu...

Embodiment approach 2

[0047] Next, use Figure 6 and Figure 7 A gas flow meter according to Embodiment 2 of the present invention will be described. Figure 6 It is a perspective view of main parts of the gas flow meter according to Embodiment 2 of the present invention. Figure 7 It is an exploded perspective view of the main parts of the same gas flowmeter. In addition, the description of the same structural elements, operations, and the like as those of the gas flowmeter 50 of Embodiment 1 is omitted.

[0048] In this embodiment, the cover body 9c of the flow measurement part 9 and the cover body 10c of the flow path member 10 are integrated to form the support member 12 connecting the flow measurement part 9 and the flow path member 10 . The flow measurement unit 9 and the flow path member 10 are connected by the support member 12 to be integrated, can be handled as a unit, and can improve operability. In addition, since the flow measurement part 9 in the state connected to the connection ...

Embodiment approach 3

[0052] Next, use Figure 8 and Figure 9 A gas flow meter according to Embodiment 3 of the present invention will be described. Figure 8 It is a sectional view of main parts of the gas flow meter according to Embodiment 3 of the present invention. Figure 9 It is a perspective view of the main part of the same gas flow meter. In addition, the description of the same structural elements, operations, and the like as those of the gas flowmeter 50 of Embodiment 1 is omitted.

[0053] In the present embodiment, the flow path member 13 has an adjustment valve 14 . The outflow port 13 a of the flow path member 13 is connected to the attachment portion 8 of the connection portion 7 , and the flow path member 13 is arranged vertically below the connection portion 7 with the inflow port 13 b facing downward.

[0054] The adjustment valve 14 has an operation part 15 operable from the outside. By operating the operation part 15 , the flow rate of the fluid to be measured in the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com