A roasting process that effectively prevents leaking air from contacting roasted materials

A roasting process and roasting technology, applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as affecting product quality and difficult control of production operations, reducing pressure fluctuations and ensuring roasted products. Quality, the effect of simplifying the roasting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

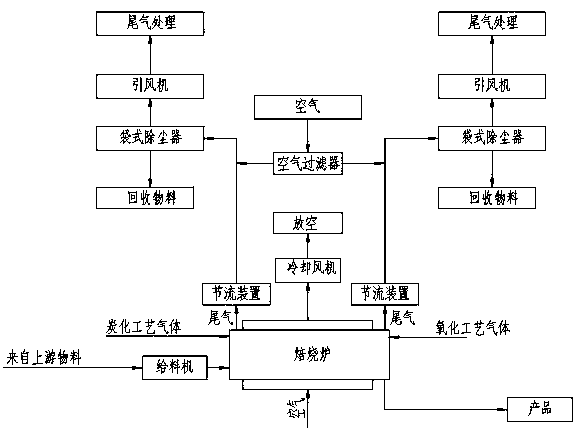

[0036] A single roasting furnace realizes carbonization and oxidation reactions, and the structure is as follows image 3 shown. The carbonization process gas (process nitrogen) is added from the feed end 15, and the oxidation process gas is added from the discharge end 12; the dynamic and static seals 4 and 11, the dynamic and static seal 4 is the joint between the feed box and the furnace cylinder, and the feed The box does not move, and the furnace drum rotates; the dynamic and static seal 11 is the joint between the discharge box and the furnace drum.

[0037] The amount of induced air in the furnace is adjusted according to the size of the incoming air, which is generally different; when a furnace realizes the carbonization and oxidation process, the induced air 5 at the feed end is generally the carbonization process gas (such as process nitrogen) from the feed end + the movement of the feed end Air leakage at the sealing part 4 + gas generated by the carbonization reac...

Embodiment 2

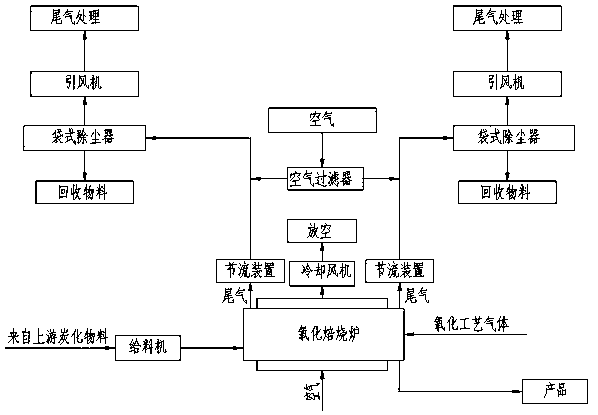

[0040] like figure 1 Shown, the zeolite catalyst roasting technique involved in the present invention is described as follows:

[0041] This example adopts single roasting furnace roasting (the single roasting of example one) zeolite catalyst, and concrete technological process is as follows:

[0042]The zeolite catalyst is fed by the feeder 2 from the feed box 3 of the roaster. When the material moves to the discharge box 13 in the roaster, the material first enters the carbonization zone for drying, carbonization and roasting of the material, and then enters the oxidation zone for oxidation of the material. Reaction, the roasted material is discharged from the discharge end, if the furnace temperature is controlled at 610°C to 670°C, the roasting temperature can be controlled at about 600°C to 650°C.

[0043] During the drying and carbonization process of the material, the roasting furnace is fed with process gas, and the process nitrogen enters the carbonization zone from ...

Embodiment 3

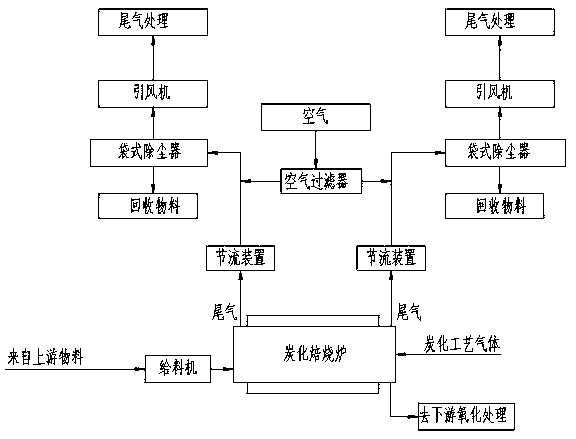

[0048] In this example, two roasting furnaces are used in series to complete the roasting of the zeolite catalyst, which are respectively a carbonization roasting furnace and an oxidation roasting furnace. The specific process is as follows:

[0049] like Figure 2a , the zeolite catalyst is fed into the carbonization roaster from the feeder, and the carbonization reaction is completed during the process of the material moving to the discharge end in the carbonization roaster, and the carbonized material goes downstream for oxidation treatment. If the furnace temperature of the carbonization roasting furnace is controlled at 650°C to 700°C, the roasting temperature can be controlled at about 630°C to 680°C.

[0050] The process gas of the carbonization reaction enters the carbonization zone from the central tube of the carbonization process gas at the discharge end of the carbonization roasting furnace, and contacts with the roasted material countercurrently. The ambient air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com