A three-arm double-column lift

A lift and support arm technology, which is applied in the field of three-support arm type double-column lift, can solve the problems of support safety hazards, reduced work efficiency, and unstable support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

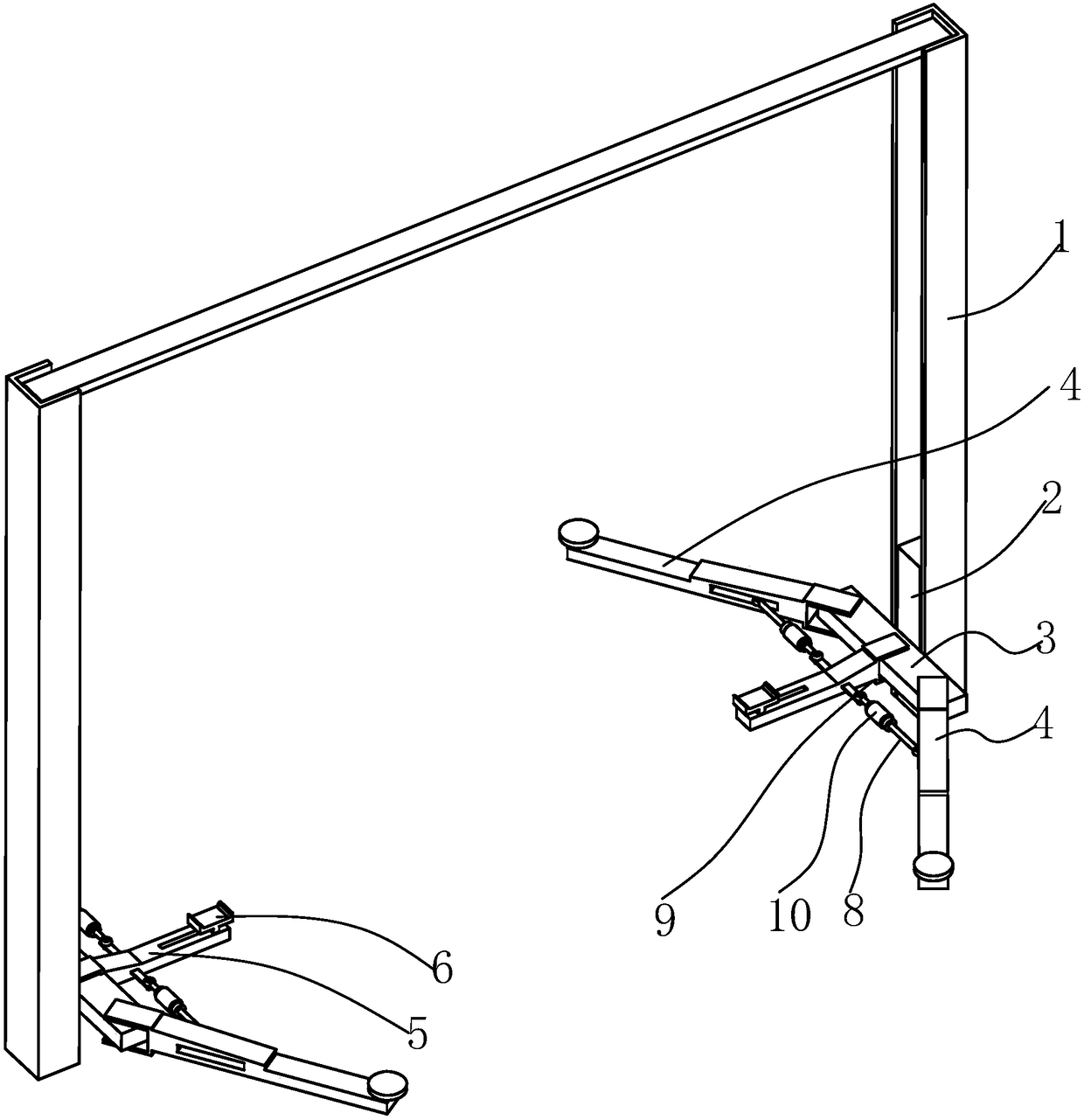

[0014] Such as figure 1 As shown, a three-arm type double-column lift includes two columns 1, the lower ends of the columns 1 are provided with motors, and the columns 1 are provided with screw rods connected to the corresponding motors through bevel gears. A sleeve 2 is fitted on the screw rod, and a longitudinally placed bearing arm 3 is fixed on the inner surface of the sleeve 2, and a lifting arm is installed at the front and rear ends of the bearing arm 3 in a hinged manner. 4. The center of the carrying arm 3 is hingedly equipped with a positioning arm 5, and the positioning arm 5 is provided with a horizontal bar-shaped hole penetrating in the vertical direction, and the bar-shaped holes are slidably fitted with The positioning seat 6 adapts to different vehicle models by adjust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap