Assistant locating device of numerical control lathe spindle

An auxiliary positioning, CNC lathe technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reducing production efficiency, difficult to guarantee the workpiece processing accuracy, taking a long time, etc., to achieve convenient operation, The effect of improving the processing efficiency and saving the time of clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

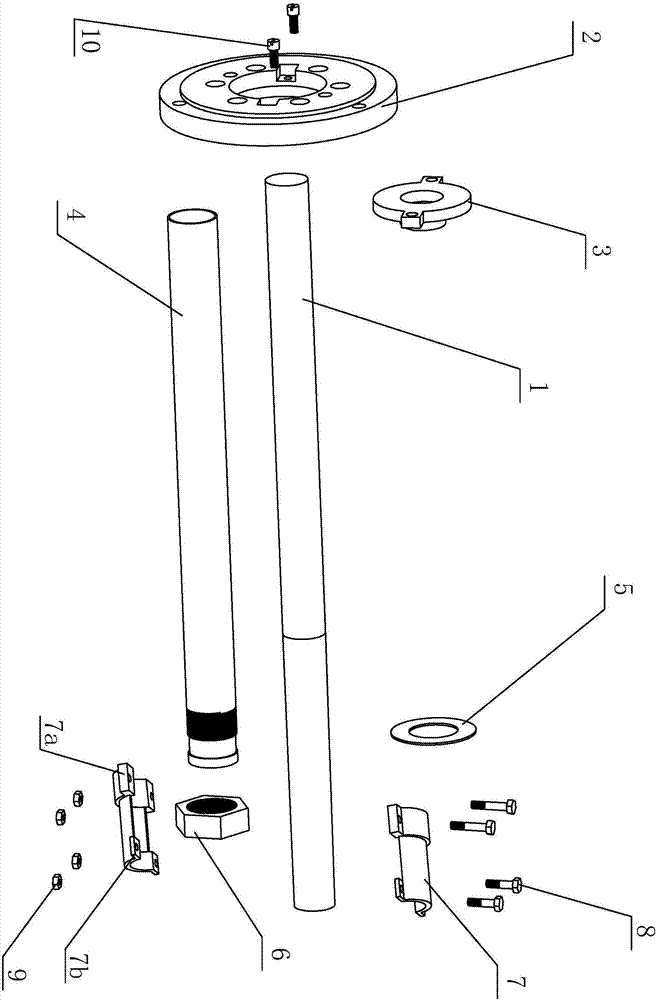

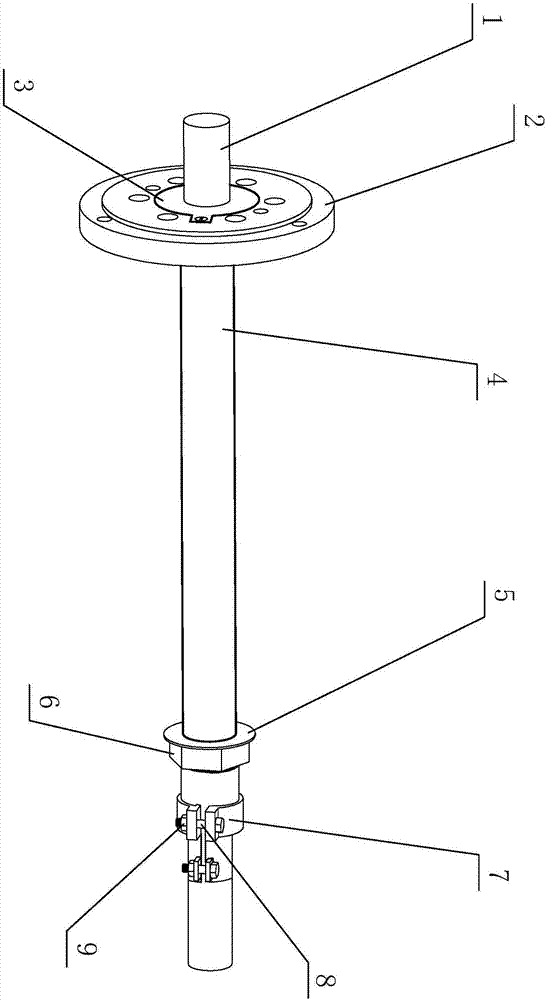

[0015] like figure 1 , figure 2 As shown, the auxiliary positioning device for the spindle of a CNC lathe includes an adjusting fixture, a mounting piece, and a positioning shaft 1 and a long cylinder 4, both of which are hollow structures. The positioning shaft 1 is coaxially installed in the long cylinder 4 and the length of the positioning shaft 1 is greater than the length of the long cylinder 4 . One end of the long cylinder 4 is provided with a flange device for synchronously fixing the long cylinder 4 and the positioning shaft 1, and the other end of the long cylinder 4 is provided with the installation piece and the adjusting fixture in sequence. One end of the adjusting fixture is clamped on the long cylinder 4 , and the other end is clamped on the positioning shaft 1 . In this embodiment, the mounting part includes a washer 5 and a lock nut 6 that can be freely screwed on the long cylinder 4, and the outer wall of the long cylinder 4 is provided with a screw threa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap