Air-cracker single piece and string composed of the pieces

A tandem, firecracker technology, applied in the direction of simulating fireworks, etc., can solve the problems of difficult control, difficult automatic reset of sliding sleeves, affecting use, etc., and achieve the effect of saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

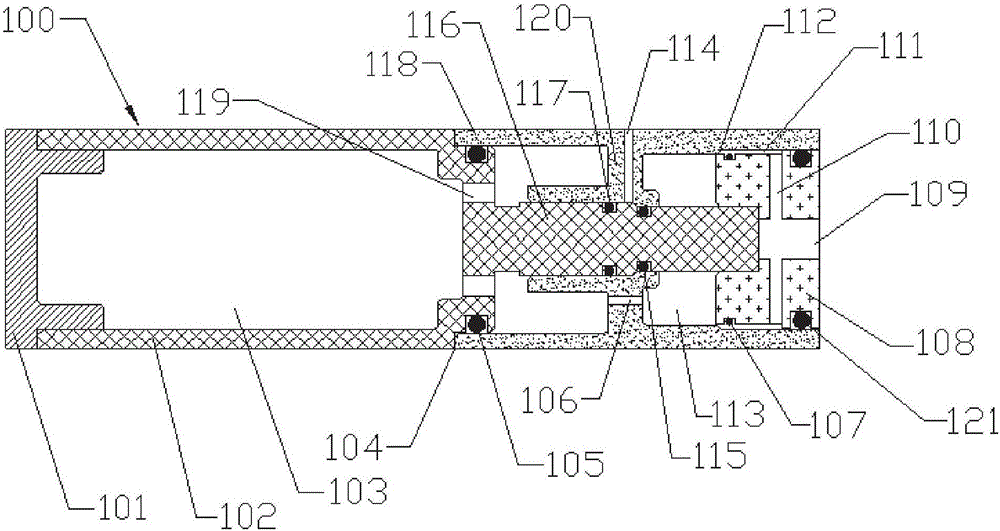

[0029] Such as figure 1 as shown, figure 1 It is a schematic diagram of the first embodiment of the air firecracker unit 100 of the present invention. In this embodiment, the air firecracker unit 100 includes a cannon body 102 , a sliding sleeve 118 , an end cover 101 and a nozzle 108 . The left side of the cannon body 102 is hollow, and the end cap 101 is packaged in the opening on the left side of the cannon body 102 through screw connection, so that the left side of the cannon body 102 forms a lower air chamber 103 . It can be understood that the end cap 101 can also be packaged on the left opening of the cannon body 102 by clamping, bonding or other means, but is not limited thereto; in other embodiments, the end cap 101 can also be It can be integrally formed with the cannon body 102, but is not limited thereto. The middle of the right side of the gun body 102 is integrally formed with a mounting column 116, and a plurality of air inlets 119 are provided along the circu...

Embodiment 2

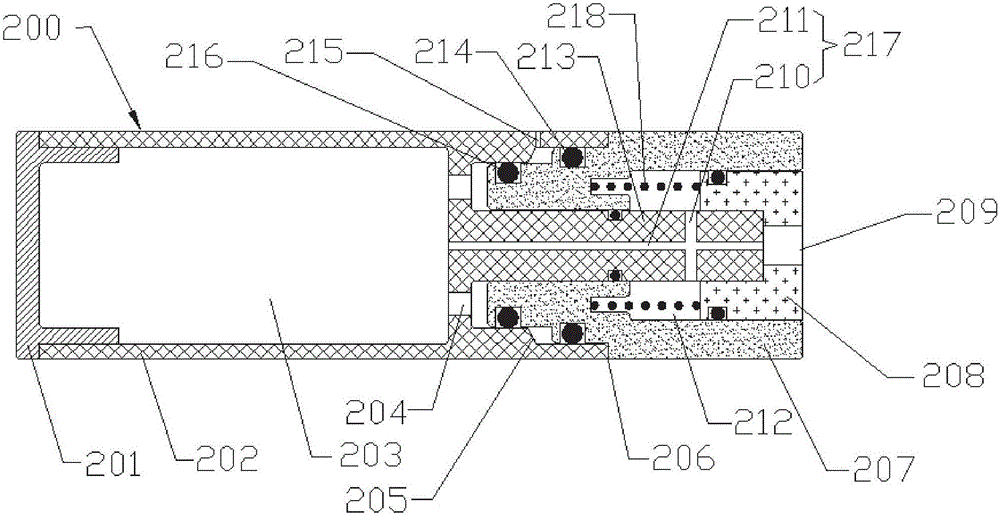

[0035] Such as figure 2 as shown, figure 2 It is a schematic diagram of the second embodiment of the air firecracker unit 200 of the present invention. The same structure of this embodiment and the first embodiment will not be repeated here. hole 209, the connection hole 217 of the upper air chamber 212 and the lower air chamber 203, the connection hole 217 includes a first connection hole 210 and a second connection hole 211, and the first connection hole 210 vertically passes through all The mounting column 213 , the second connecting hole 211 runs through the mounting column 213 transversely, and the first connecting hole 210 communicates with the second connecting hole 211 . The first connecting hole 210 communicates with the air inlet 209 and the upper air chamber 212; the second connecting hole 211 communicates with the air inlet 209, the upper air chamber 212 and the lower air chamber 203 . The end of the sliding sleeve 207 close to the air inlet 204 is provided wi...

Embodiment 3

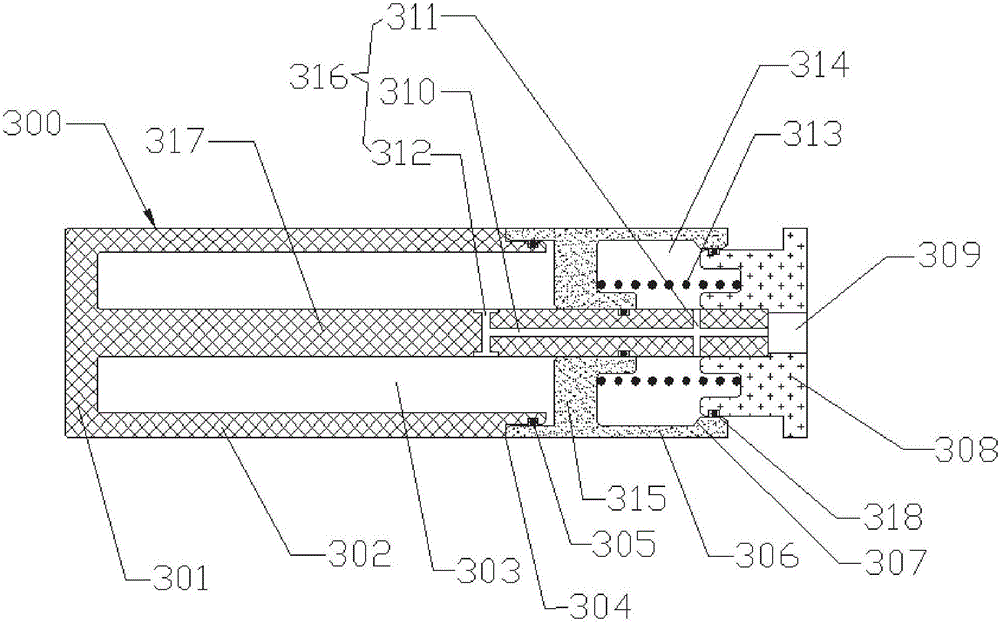

[0038] Such as image 3 as shown, image 3 It is a schematic diagram of the third embodiment of the air firecracker unit 300 of the present invention. The structure of this embodiment is the same as that of the first embodiment and the second embodiment. The difference is that the end cover 301 is integrally formed on the On the left side of the body 302, the mounting post 317 is integrally connected to the end cover 301; a spring 313 is installed between the sliding sleeve 306 and the nozzle 308, and the left end of the spring 313 is connected to the sliding sleeve 306 , the right end is connected with the nozzle 308 to provide thrust for the reset of the sliding sleeve 306 . The connection hole 316 includes a first connection hole 310, a second connection hole 311 and a third connection hole 312 (equivalent to the air inlets 119, 204 in Embodiment 1 and Embodiment 2); the first connection hole 310 The air inlet 309 , the second connection hole 311 and the third connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com