A wiring auxiliary device for high-altitude high-voltage test

An auxiliary device, high-voltage test technology, applied in the direction of measuring device, measuring device casing, instrument, etc., can solve the problems of increased workload of test personnel, hidden dangers of on-site work, and influence of high-voltage leads, so as to reduce the influence of stray capacitance and ensure Accuracy, quick hook effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

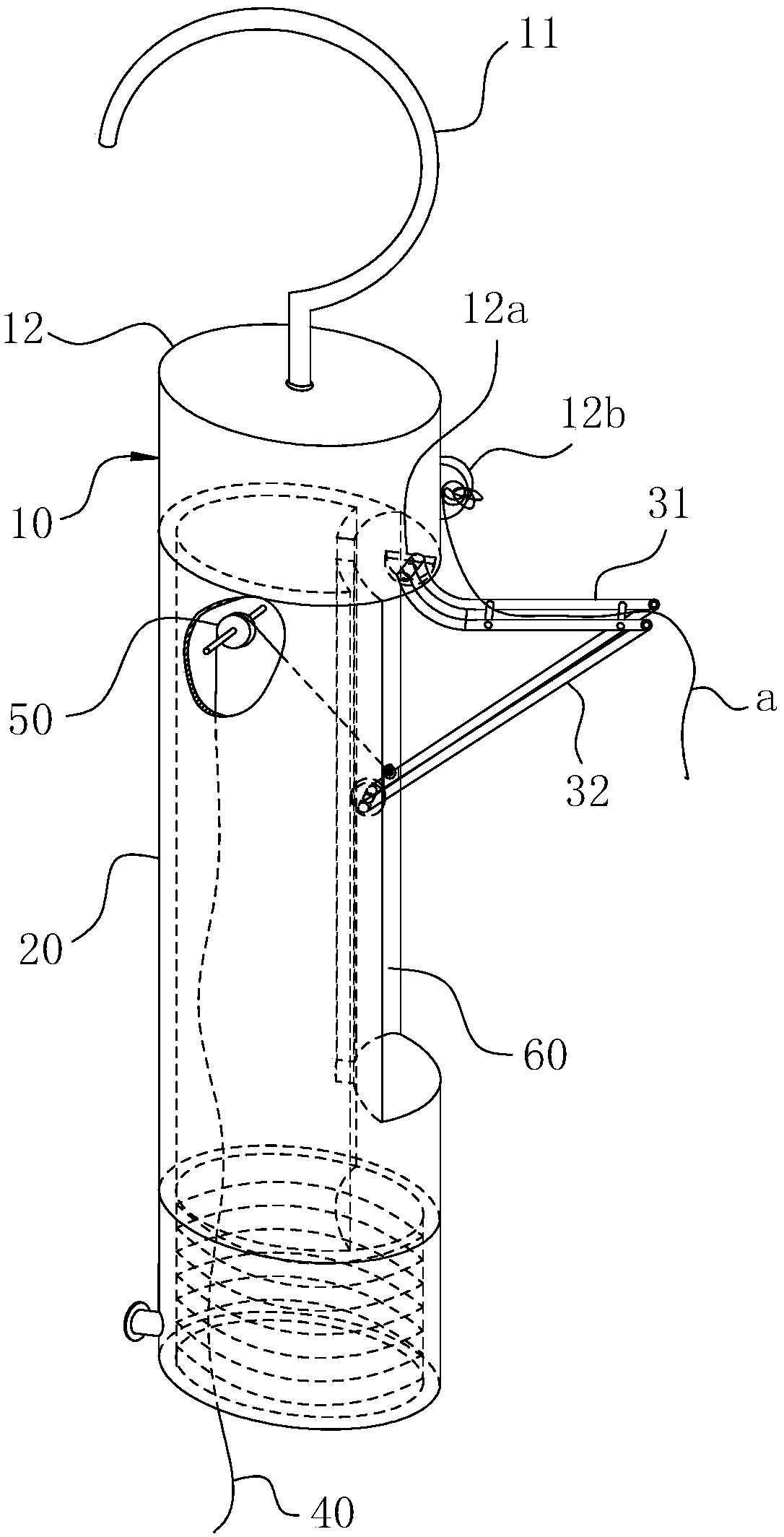

[0037] For ease of understanding, combined here Figure 1-4 Concrete structure of the present invention and work flow are described further as follows:

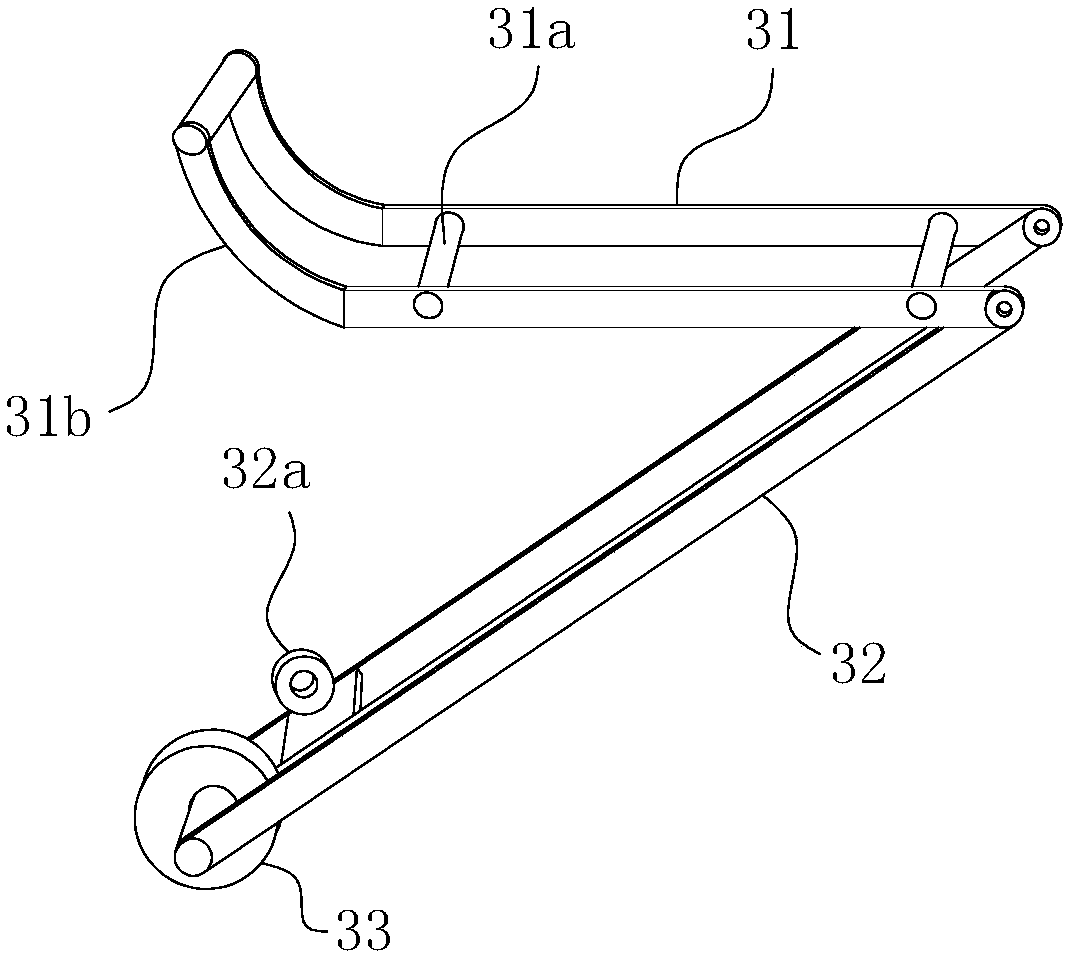

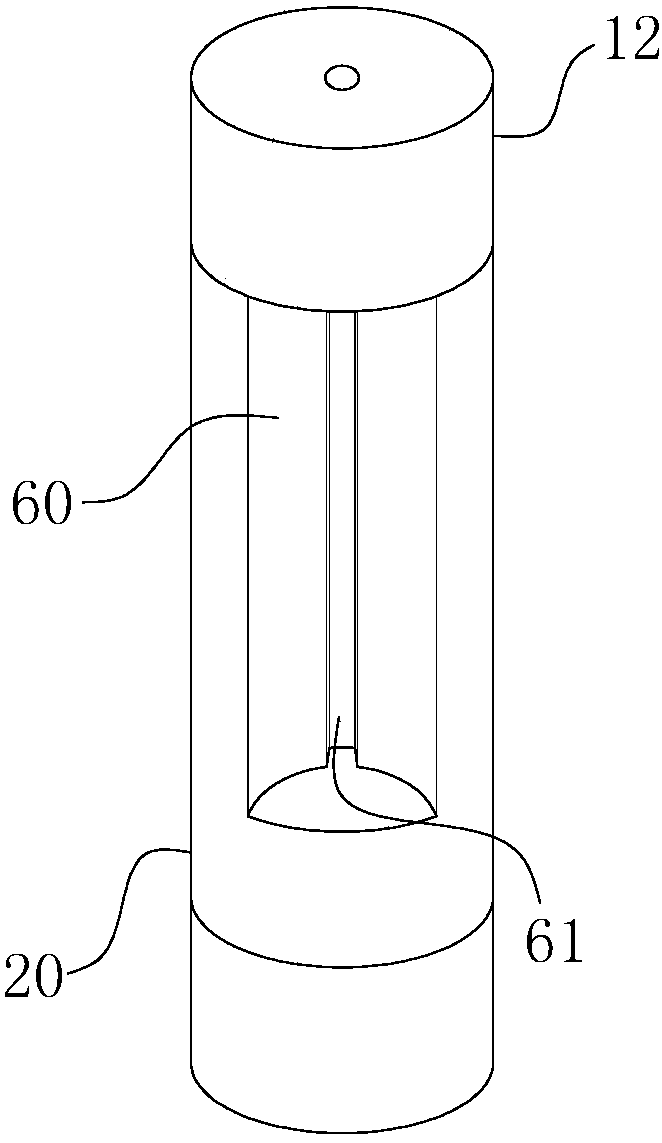

[0038] In actual application, the present invention mainly includes a metal hook 10 , an insulating rod 20 and an extension rod 70 which are fixed sequentially from top to bottom. Wherein: metal hook 10 is made of hook head and metal guide cover 12, as figure 1 and image 3 As shown, there is a 3-5 mm deep internal threaded hole at the center of the metal guide cover 12 for detachable threaded connection with the bottom end of the hook head. The outer wall of the metal guide cover 12 is welded with a high-voltage lead wire terminal, that is, a lead wire fixing pile 12b for connecting the high-voltage lead wire a. A hinge ear 12a is welded to the inner wall of the same side of the fixed lead wire fixing pile 12b of the metal guide cover 12 for hinged connection to the supporting rod 31 . The top of the insulating rod 20 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com