Cost control method and system of converter steelmaking process based on grnn

A technology of converter steelmaking and cost control, which is applied in the field of steelmaking, can solve the problems of high cost of converter steelmaking and achieve the effect of solving high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

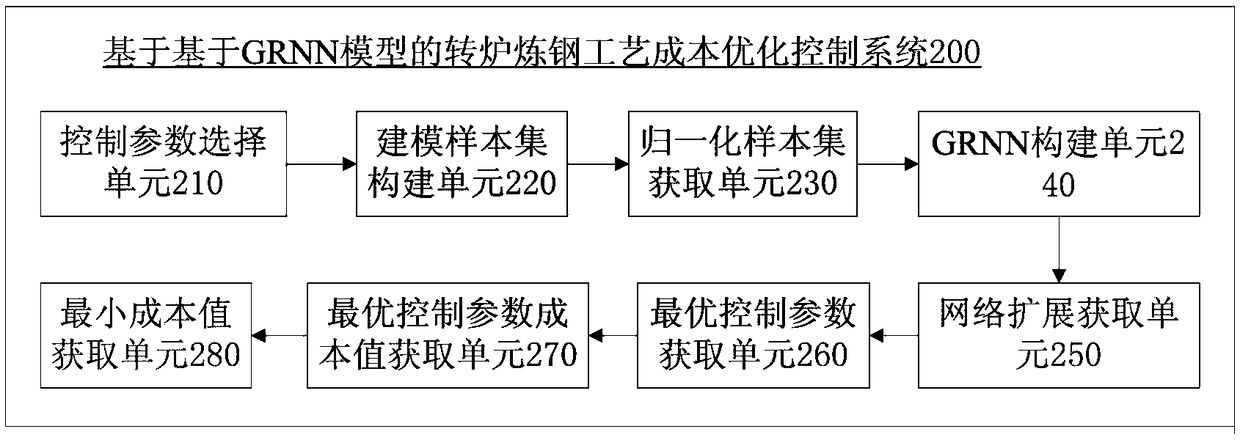

[0033] Aiming at the aforementioned problem of high cost in the iron and steel industry, the present invention proposes a GRNN-based converter steelmaking process cost control method and system, wherein, the present invention proposes to use the production operating parameters in the smelting process as The network method excavates the potential law between raw material formula, operating parameters and steelmaking cost; and uses this law to obtain the operating parameters at the lowest cost through intelligent optimization algorithms, and provides guidance for the actual production of enterprises.

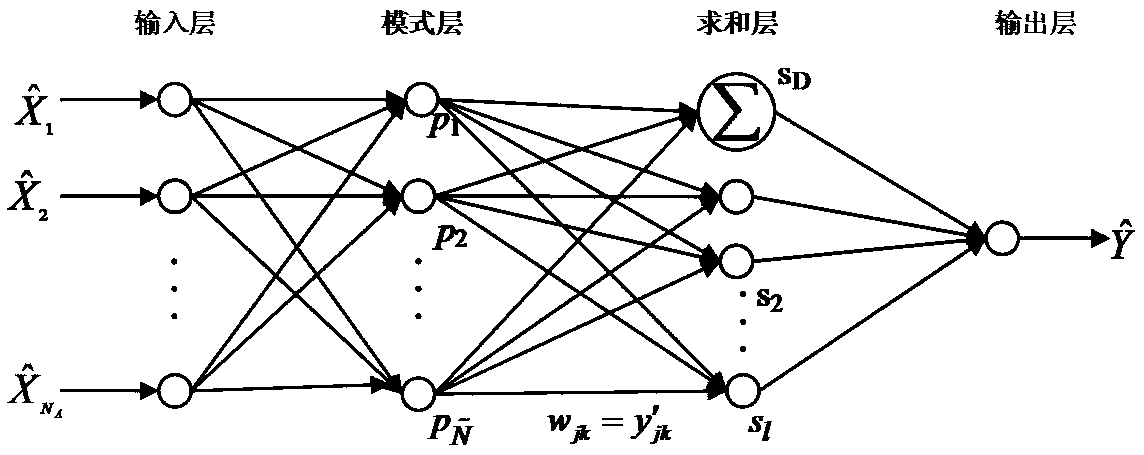

[0034] Among them, it should be noted that the GRNN model is a kind of radial basis neural network, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com