A damping buffer structure

A buffer structure and damping technology, applied in building structures, door/window fittings, wing fan components, etc., can solve the problems of the complex structure of the automatic opening device, the inability to meet the needs of users, the inability to use sliding doors, etc., and achieve small shaking. , Improve the internal use position, the effect of sliding opening and closing smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

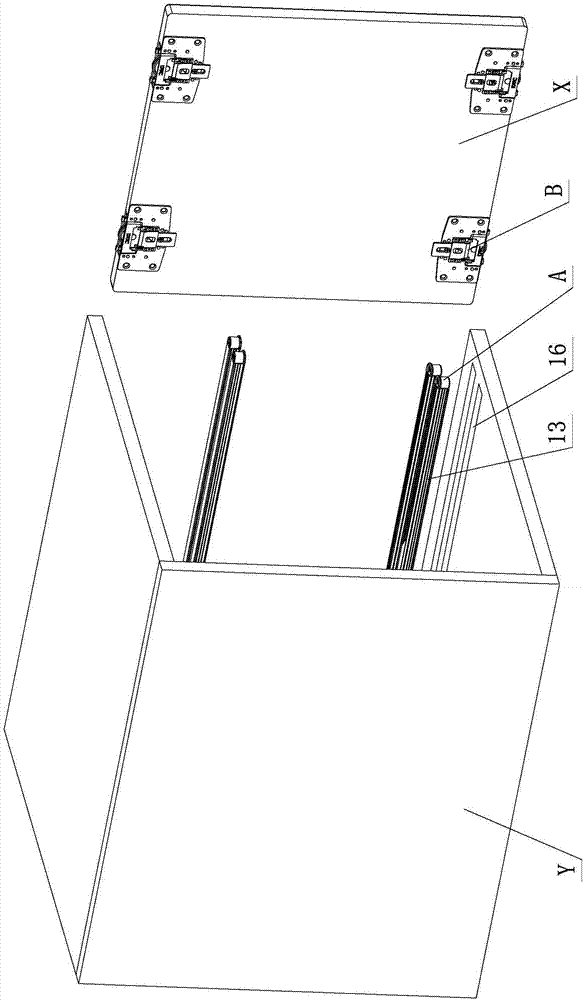

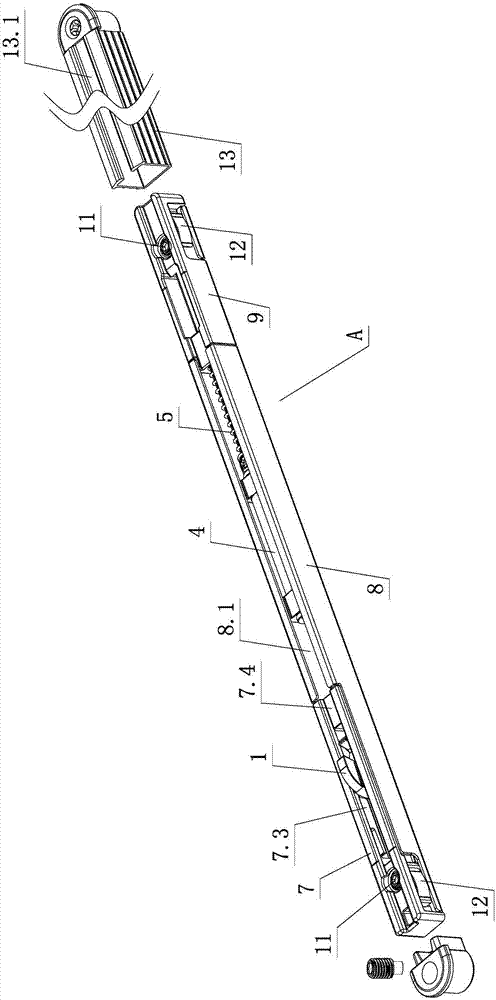

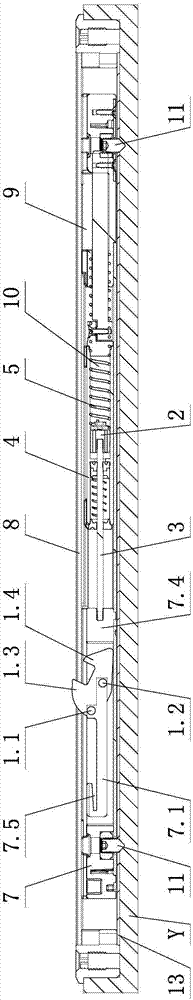

[0026] see Figure 1-Figure 9 , the damping buffer structure includes a damping buffer device A, the damping buffer device A includes a sliding bracket assembly, a pendulum bolt 1, a damper, a spring 5, the damper includes a piston 2, a piston rod 3 and a cylinder 4, and the piston 2 is arranged on In the cylinder body 4, one end of the piston rod 3 is arranged in the cylinder body 4 and connected with the piston 2, and the other end extends out of the cylinder body 4 and is fixedly arranged on the sliding bracket assembly, and the cylinder body 4 is slidably arranged on the sliding bracket assembly Above, the cylinder 4 is provided with a spring guide 10, the spring 5 is sleeved on the spring guide 10, and one end elastically acts on the cylinder 4, and the other end elastically acts on the sliding bracket assembly, and interacts with the cylinder 4 L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com