A damping buffer structure for furniture

A buffer structure and furniture technology, which is applied to furniture parts, home appliances, building structures, etc., can solve the problems of complex structure of automatic opening devices, inability to meet user needs, and lack of anti-fall retention, etc. Simple and reasonable structure, improve the effect of internal use position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

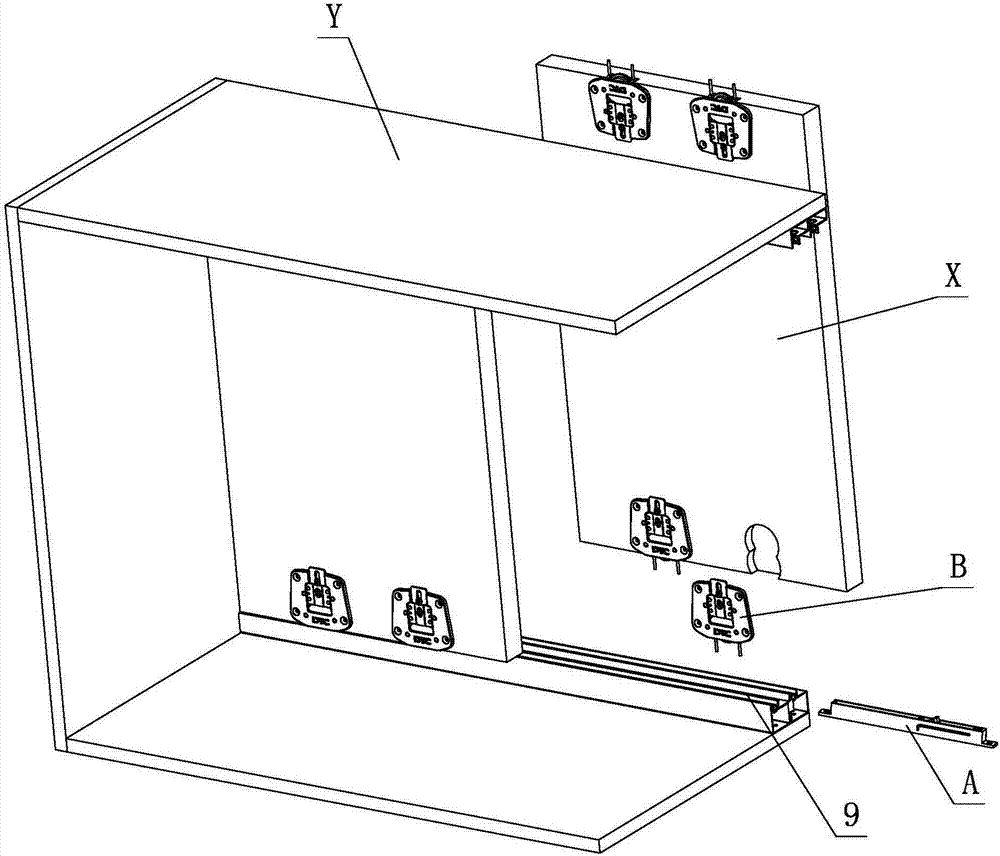

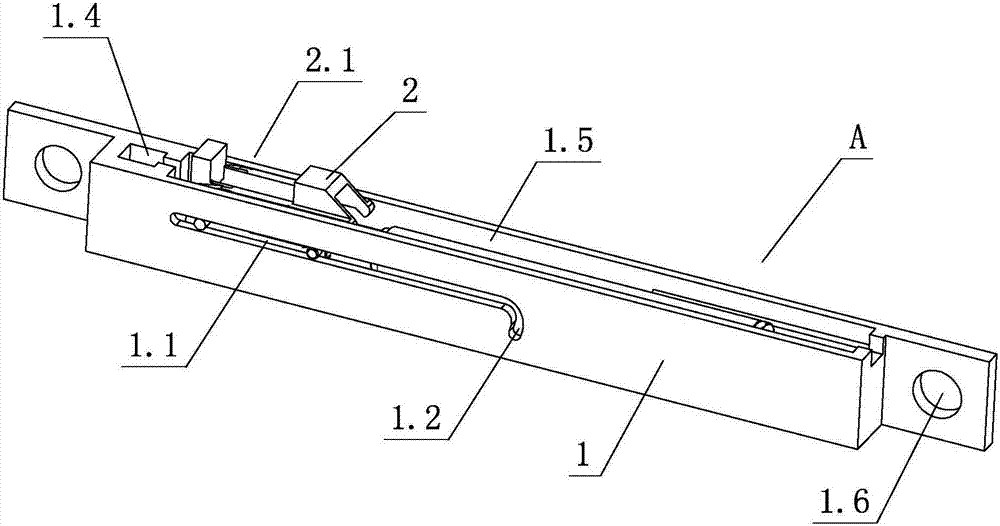

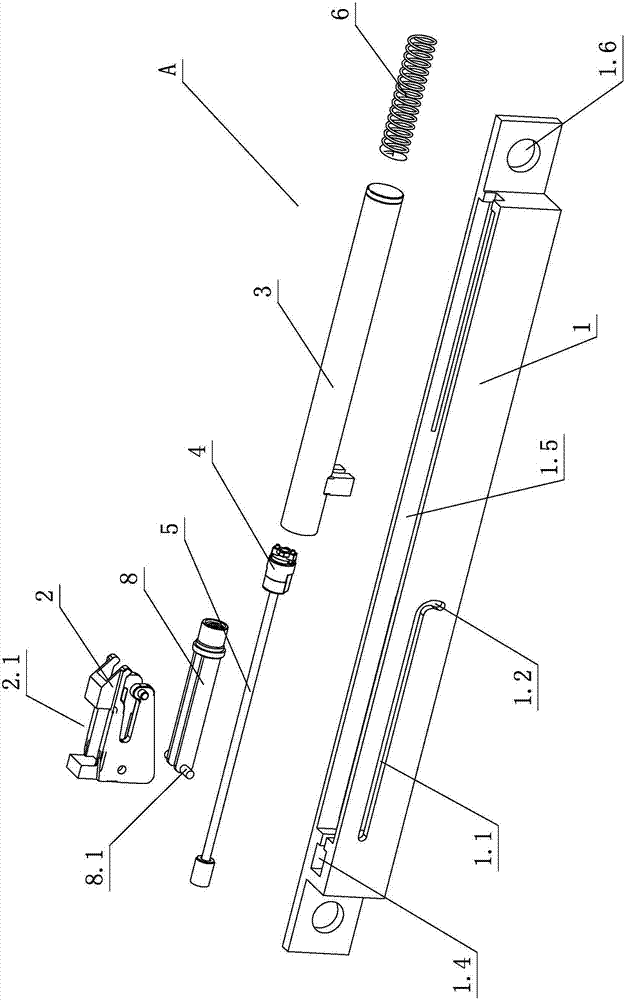

[0027] see Figure 1-Figure 9 , the furniture damping buffer structure includes a damping device A, the damping device A includes a fixed bracket 1, a swing element 2, a damper and an elastic element, and the damper is at least composed of a cylinder 3, a piston 4 and a piston rod 5, and the piston 4 is arranged on In the cylinder body 3, one end of the piston rod 5 extends into the cylinder body 3 and is connected with the piston 4, and the other end extends out of the cylinder body 3 and is fixedly arranged on the fixed bracket 1, and the cylinder body 3 is slidably arranged on the fixed bracket 1 , the fixed bracket 1 is provided with a linear sliding area 1.1 and a curved standby area 1.2, the swing element 2 is slidably arranged on the linear sliding area 1.1 and the curved standby area 1.2, and swings or rotates between the piston rod 5 and the cylinder body 3, elastic One end of the element elastically acts on the swing element 2 or the damper, and the other end elastic...

no. 2 example

[0040] see Figure 10 , this furniture damping buffer structure is different from the first embodiment in that: the moving part is the furniture sliding rail C, and the fixed part is the furniture fixing sliding rail D; the toggle device B is arranged on the furniture moving sliding rail On C, the damping device A is set on the fixed slide rail D of the furniture, or the damping device A is set on the movable slide rail C of the furniture, and the toggle device B is set on the fixed slide rail D of the furniture.

[0041] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com