Filling mining method adopting room-and-pillar method and for underwater extremely-thin ore body

A filling mining and ultra-thin ore technology, which is applied in underground mining, filling, surface mining, etc., can solve the problems of high ore body loss rate and high mining cost, reduce wall cutting costs, improve ore recovery rate, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

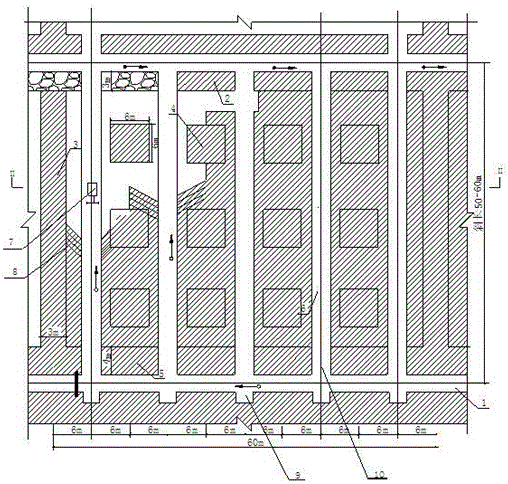

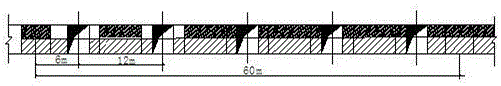

[0026] combined with figure 1 with 2 , the present invention exploits the submerged thickness of the water body below 0.8m, and the gently inclined extremely thin ore body with an inclination angle below 30 degrees comprises the following steps:

[0027] 1) Mining house structure

[0028] Divide the standard ore blocks along the direction of the underground mine layer. The length of the direction is 60m, the vertical height of the middle section is 10m, and the oblique length is 50-60m. The standard ore blocks are divided into 5 mining houses with a span of 12m. Ore pillars, ore pillars include intermediate pillars 3, point pillars 4, top pillars 2 and bottom pillars 5, the middle pillar 3 is 3m in size, point pillar 4 is 6×6m in size, top pillar 2 is 3m, bottom pillar 5 is 4m, and the Column 3 is set between two standard ore blocks, and the area of the ore column accounts for 30.9% of the entire stope area.

[0029] 2) Mining and cutting: on the upper and lower sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com