Reinforcement trolleys suitable for construction in curved sections

A reinforced trolley and trolley technology, which is applied to shaft linings, tunnel linings, underground chambers, etc., can solve the problems of small working surface, low track utilization rate, slow walking speed, etc., to avoid derailment and improve two The effect of secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

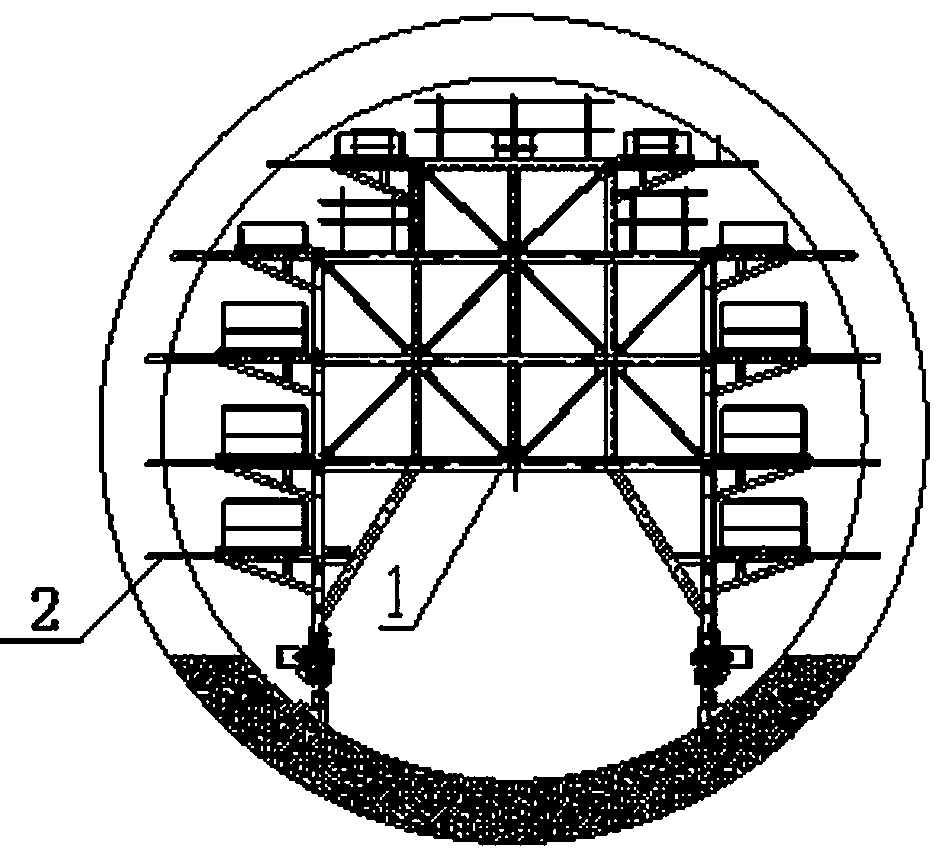

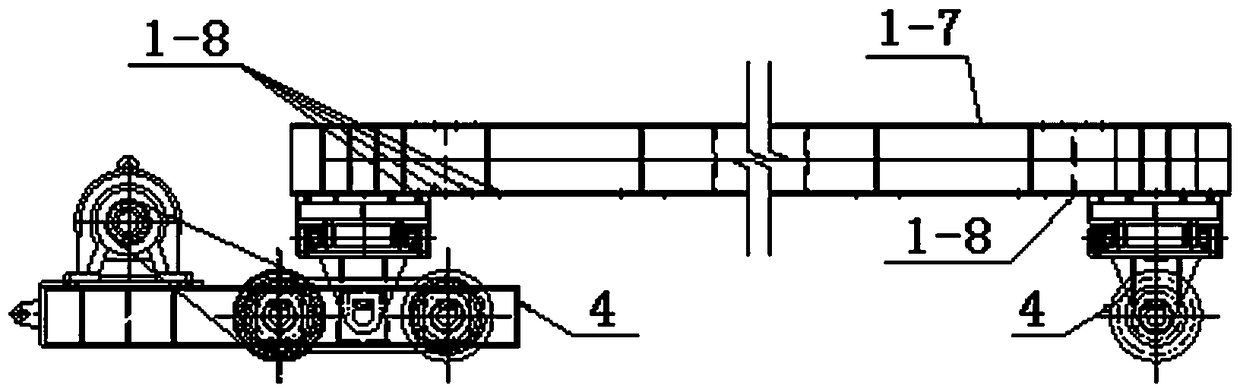

[0021] see figure 1 , figure 2 , this embodiment is applicable to the steel bar trolley for the construction of the turning section, including the steel bar trolley truss 1, the multi-layer side platforms 2 located on both sides of the steel bar trolley truss, the trolley ladder 3, the walking system 4, and the track 5.

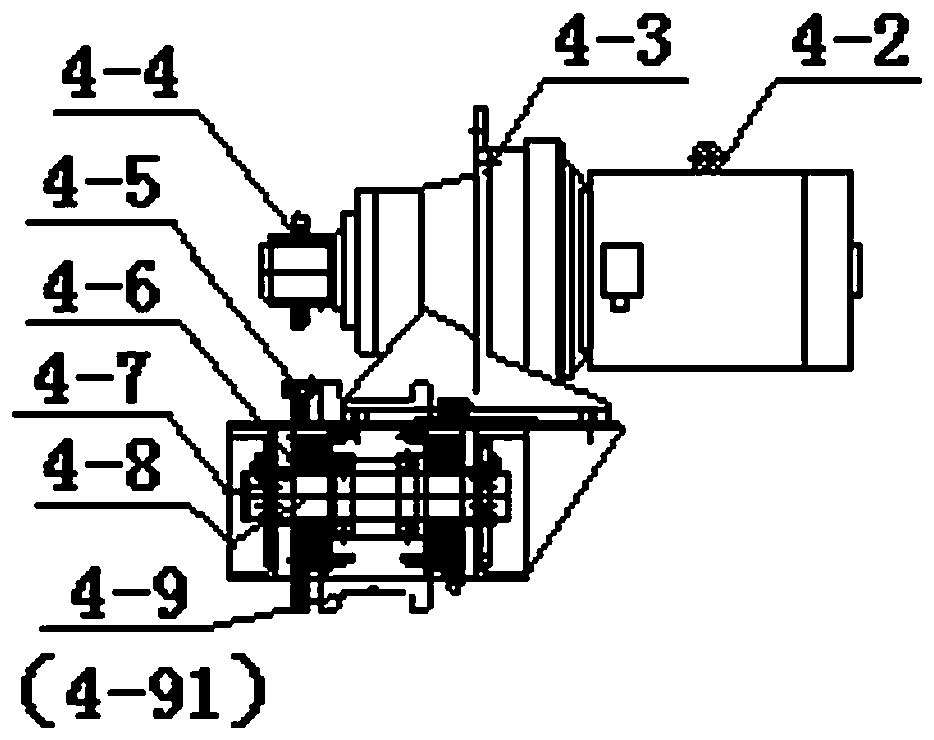

[0022] see Figure 1 to Figure 4 , In the steel trolley truss 1, the vertical pole 1-1 is HW200x200, the beam 1-2 is HW200X200, the horizontal connecting beam 1-3 is 18, the vertical pole 1-4 is 18, and the shear brace 1-5 is 75× 75×5 angle steel, each single piece is connected by M16X60 bolts. There are 8-shaped diagonal braces 1-6 between the bottom beam and the vertical pole, and the material is HW200X200. Bottom longitudinal beams 1-7 are made of double 30 channel steel assembly welding, and there are multiple sets of connecting holes 1-8 on the bottom longitudinal beams. According to the difference in curvature and turning radius, the connecting seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com