Overrun clutch

A technology of overrunning clutches and pawls, which is applied in the field of clutches, can solve the problems of small transmission torque, short life of structural parts, and concentration of pawl contact stress, and achieve the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

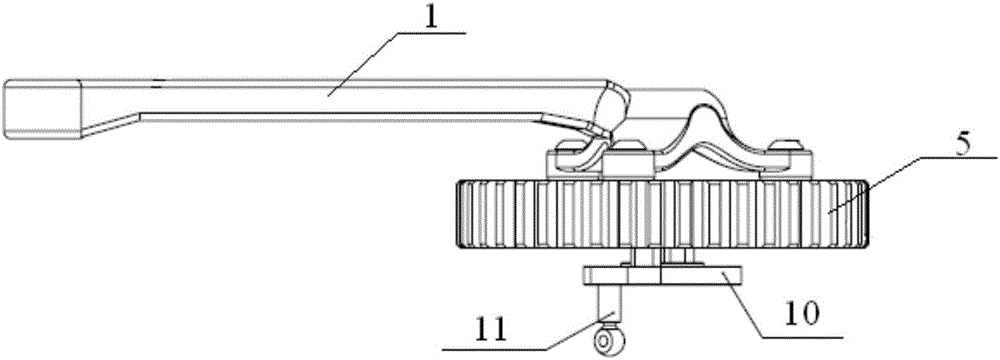

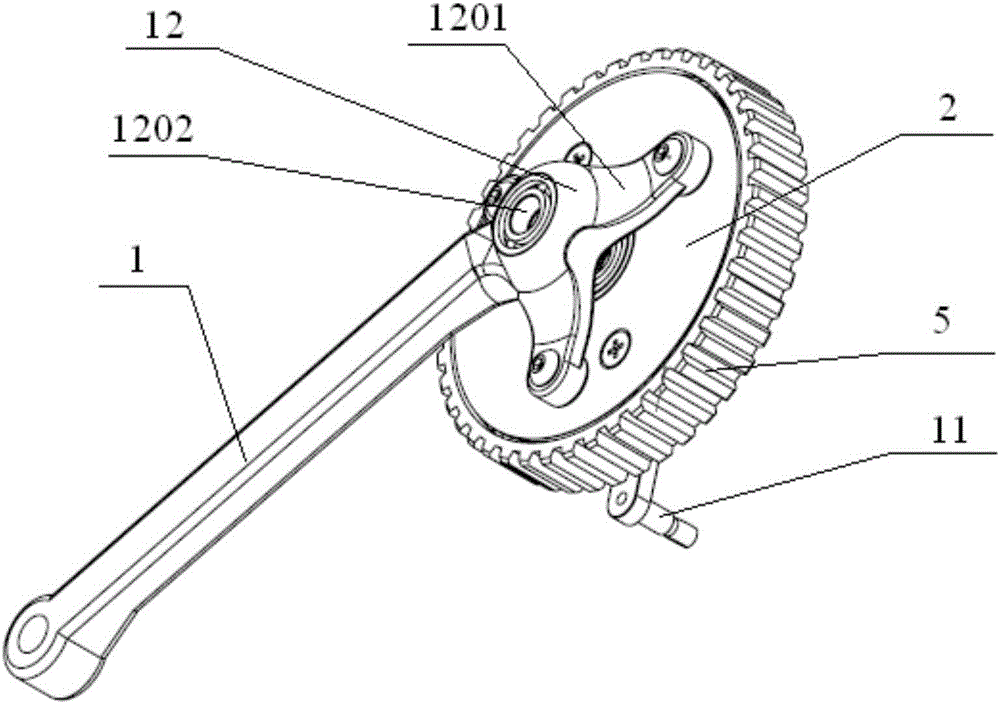

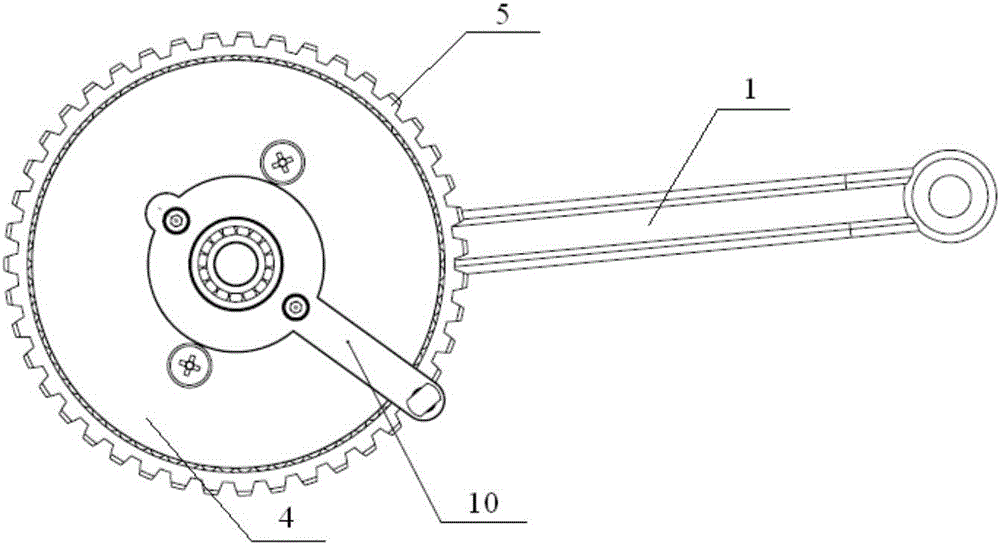

[0050] see Figure 1-14, The invention discloses an overrunning clutch, comprising: an operating rod 1, a first cover plate 2, a second cover plate 4, an intermediate rotating block 3, a rotating ratchet wheel 5 with internal and external teeth, and a pawl 6. Wherein, the first end of the operating rod 1 is used to bear the applied load, the second end of the operating rod 1 is connected with the first cover plate 2, the middle rotating block 3 is connected with one side of the first cover plate 2, and the second cover plate 4 Connected with the other side of the middle rotating block 3, the internal and external tooth rotating ratchet 5 is coaxial with the middle rotating block 3, and the internal and external tooth rotating ratchet 5 is installed between the first cover plate 2 and the second cover plate 4, and the internal and external tooth rotating ratchet There is a first installation track 14 for installing the ball 13 between the outer teeth 502 of the ratchet 5 and th...

Embodiment 2

[0058] In yet another embodiment of the present invention, the structure of the overrunning clutch in this embodiment is similar to that in the first embodiment, and the similarities will not be repeated, and only the differences will be introduced.

[0059] In the embodiment, it is specifically disclosed that a spring 7 is further arranged between the middle rotating block 3 and the ratchet 6 . Wherein, the spring 7 plays the role of tension and compression.

[0060] Further, the present invention discloses that the overrunning clutch also includes a connecting rod 8 and a nested chuck 9 rotatably connected to the connecting rod 8; the nested chuck 9 is rotatably connected to the second cover plate 4; There is a first groove 301; the connecting rod 8 swings in the first groove 301, and the first end of the connecting rod 8 is connected with the nested chuck 9, and the second end of the connecting rod 8 is connected with the pawl 6; the connecting rod 8 is in the Swinging in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com