Self-locking clamping mechanism of clamp

A clamping mechanism and self-locking technology, used in manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of occupying space and increasing costs, and achieve simple structure, large opening angle, clamping force, stability, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

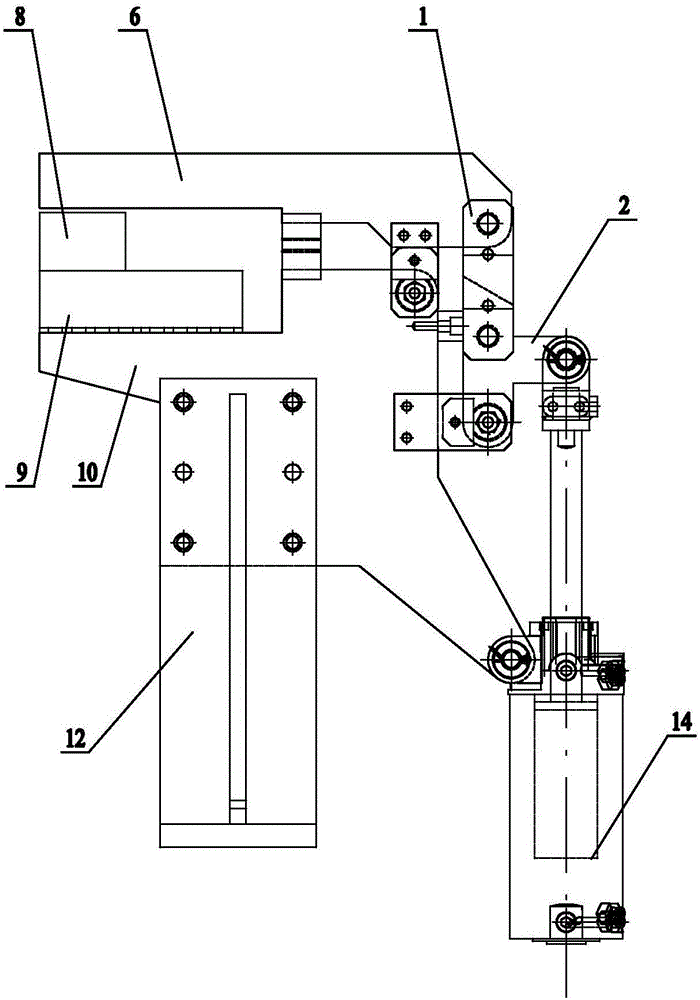

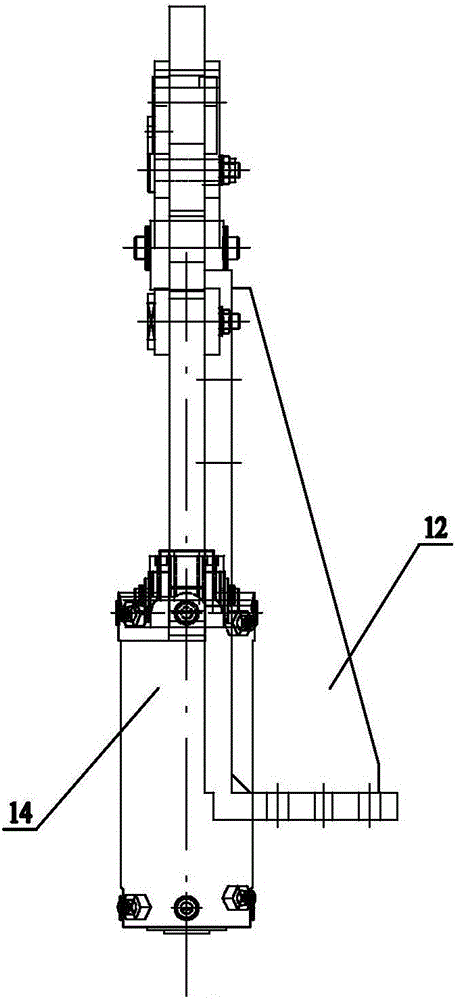

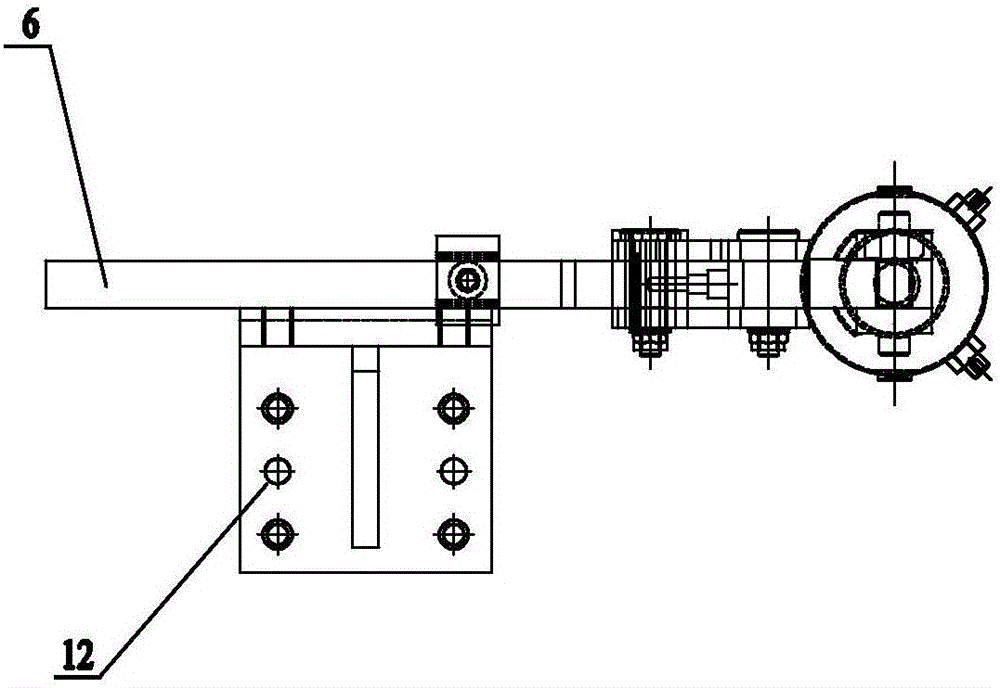

[0015] The clamping mechanism of the self-locking fixture includes a first self-locking block 1, a second self-locking block 2, a limit post 3, a first splint 4, a pressure head 6, a second splint 7, a pressure block 8, and a support block 9 , connecting plate 10, lower limit block 11, base 12 and upper limit block 15, the first self-locking block 1 has a first hinge point and a second hinge point, the second self-locking block 2 has a first hinge point, a second hinge point point and the third hinge point, three hinge points of the second self-locking block 2 form a triangle;

[0016] On the base 12, a connecting plate 10 is fixed, on the connecting plate 10, a second clamping plate 7 is hinged by a pin shaft, on the second clamping plate 7, a pressure head 6 is welded, and on the connecting plate 10, the first clamping plate 4, limiter Position post 3, support block 9 and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com