Quick Repair Method for Water Leakage Deep in Asphalt Concrete Core Wall of Earth-rock Dam

An asphalt concrete and repair method technology, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of uneven technology of construction units, leakage between layers of asphalt concrete core walls, difficulties, etc., to solve the technical problems of rapid repair , reliable remedies, quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

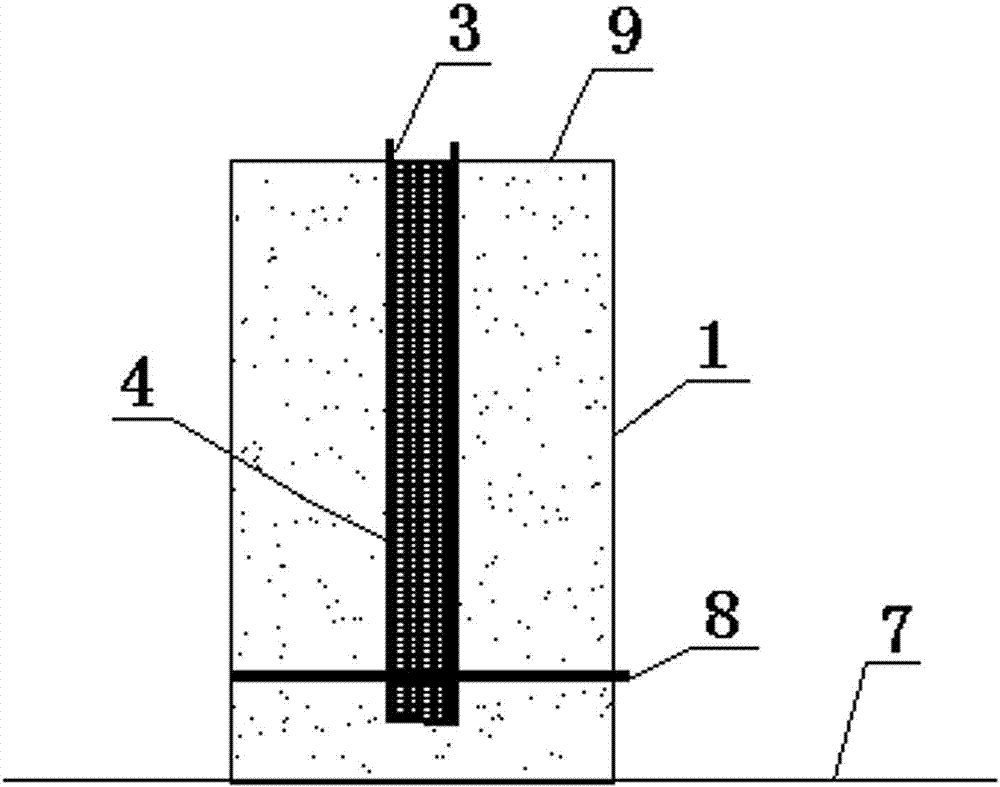

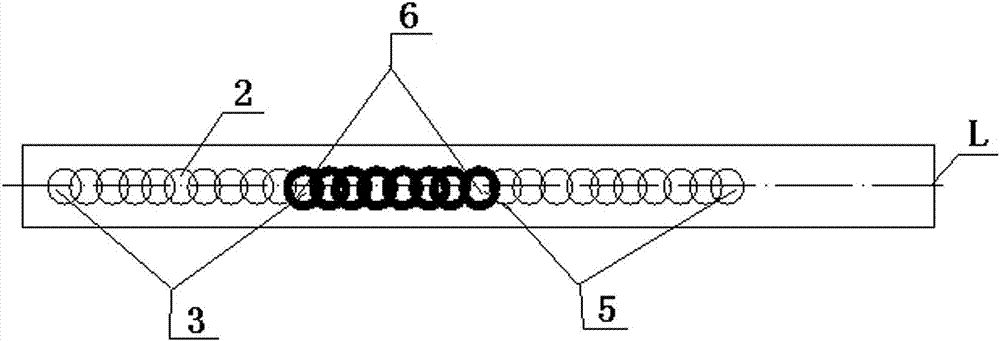

[0013] see figure 1 , figure 2 , the rapid repair method for water leakage deep in the asphalt concrete core wall of an earth-rock dam according to the present invention, the method is to drill a number of holes 2 on the asphalt concrete core wall 1, and the edges of each hole are connected to form the first phase I deep groove along the axis L of the core wall 3. The groove length is 5m. Pour asphalt mortar 4 upwards from the bottom of the groove in the deep groove of the first phase. Drill several holes on the asphalt concrete core wall at a distance of 3.5m from the first phase I deep groove, and the edges of each hole are connected to form a second phase I deep groove 5 with a groove length of 5m along the axis of the asphalt concrete core wall, and pour asphalt mortar . After pouring asphalt mortar in the deep grooves of the first and second phase I for 13 hours, drill several holes on the asphalt concrete core wall between the deep grooves of the first phase I and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com